Flame Retardant Zinc Borate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433833 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Flame Retardant Zinc Borate Market Size

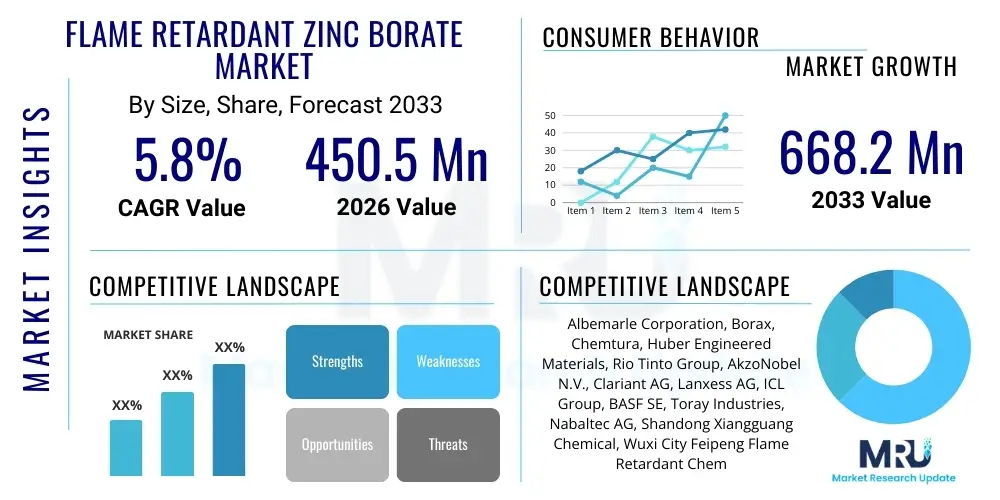

The Flame Retardant Zinc Borate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 668.2 Million by the end of the forecast period in 2033.

Flame Retardant Zinc Borate Market introduction

The Flame Retardant Zinc Borate Market encompasses the global trade and consumption of zinc borate, a crucial inorganic chemical compound utilized primarily as a non-halogenated flame retardant and smoke suppressant additive. Zinc borate (typically denoted as 2ZnO 3B2O3 3.5H2O or anhydrous forms) functions by releasing water vapor upon heating, cooling the combustion zone, and forming a protective char layer that restricts oxygen supply. This dual functionality as a fire retardant synergist—especially when combined with antimony trioxide or alumina trihydrate—enhances its efficacy across various polymeric and cellulosic materials, making it indispensable in modern materials science.

Major applications of zinc borate span across plastics and polymers, specifically in PVC, polyolefins, and nylon formulations used in wire and cable jacketing, pipes, and electrical components. Furthermore, it is heavily employed in specialty coatings, particularly intumescent paints and fire-resistant industrial coatings designed for construction materials and automotive parts. The inherent benefits of zinc borate include low toxicity compared to halogenated alternatives, excellent thermal stability, and effective smoke reduction properties, aligning with stricter global regulatory mandates prioritizing environmental health and safety standards in fire protection.

Driving factors for sustained market growth are predominantly tied to escalating global fire safety regulations, particularly in the construction and transportation sectors. The push towards sustainable and non-toxic flame retardant solutions, mandated by agencies such as the EPA and REACH, strongly favors zinc borate over traditional, sometimes banned, halogenated compounds. Expanding end-use markets, particularly in Asia Pacific’s booming electrical and electronics manufacturing and infrastructure development, further solidify the compound’s essential role in ensuring fire safety compliance while maintaining material integrity and performance.

Flame Retardant Zinc Borate Market Executive Summary

The Flame Retardant Zinc Borate Market is characterized by robust growth driven by stringent international fire safety standards and the widespread transition away from halogenated flame retardants across major industries. Business trends indicate a strong emphasis on product innovation, focusing on ultra-fine particle sizes and novel crystal structures (like anhydrous zinc borate) to improve dispersion, processing efficiency, and performance in high-temperature polymer systems. Strategic partnerships and regional capacity expansions, especially in chemical manufacturing hubs, are common tactics among leading players aiming to secure raw material access and optimize supply chain logistics to meet surging demand from developing economies.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, primarily fueled by massive infrastructure projects, rapid urbanization, and explosive growth in the electrical, electronics, and automotive manufacturing sectors in China, India, and Southeast Asian nations, demanding high volumes of cost-effective fire safety additives. North America and Europe, while mature markets, maintain high demand due to rigorous environmental regulations (REACH, RoHS) that strictly limit traditional additives, thus driving continuous adoption of non-halogenated alternatives like zinc borate for specialized, high-performance applications in aerospace and construction coatings.

Segment trends underscore the dominance of the Plastics and Polymers application segment, particularly in high-voltage wire insulation and exterior building materials, where fire safety compliance is non-negotiable. Furthermore, the specialized coatings segment shows accelerated growth, driven by the increasing use of intumescent and fire-resistant paints required for protecting structural steel and wooden elements in commercial and residential construction projects. The market is also witnessing a demand shift toward higher-purity grades of zinc borate, which offer enhanced synergism and superior thermal performance essential for advanced engineering plastics used in electric vehicle components and renewable energy infrastructure.

AI Impact Analysis on Flame Retardant Zinc Borate Market

User queries regarding AI's impact on the zinc borate market frequently center on three core themes: optimization of manufacturing processes, accelerated material discovery, and predictive supply chain management. Users are concerned about whether AI can help fine-tune the synthesis of zinc borate to achieve narrower particle size distributions and improved morphology, directly influencing its efficacy as a flame retardant synergist. A second major theme is the potential for AI-driven computational chemistry to rapidly screen and design novel, highly efficient flame retardant formulations, potentially reducing reliance on extensive traditional R&D testing. Finally, users seek clarification on how machine learning algorithms can stabilize input costs (boron and zinc raw materials) by providing accurate forecasts and managing inventory across complex global supply chains.

The application of Artificial Intelligence and machine learning in the Flame Retardant Zinc Borate sector is predominantly focused on increasing operational efficiency and accelerating innovation cycles. AI models are being deployed to analyze real-time data from chemical reactors, optimizing parameters such as temperature, pressure, and mixing rates to ensure consistent production of high-purity zinc borate grades, thereby reducing batch variability and waste. This precision manufacturing capability, often referred to as Industry 4.0 integration, allows manufacturers to meet stringent quality specifications demanded by the electronics and aerospace industries, where even minor variations in additive quality can compromise fire safety performance.

Furthermore, AI is instrumental in accelerating material informatics. By analyzing vast databases of existing flame retardant chemistries, polymer matrices, and combustion data, machine learning algorithms can predict the optimal loading levels and synergistic combinations of zinc borate with other additives (e.g., magnesium hydroxide or phosphorus compounds). This capability drastically shortens the development cycle for new fire-safe materials, enabling quicker response to evolving regulatory requirements and specialized end-user needs, such as fire protection systems for battery casings in electric vehicles or lightweight composites in urban air mobility vehicles.

- AI-driven process optimization enhances manufacturing efficiency and reduces energy consumption during zinc borate synthesis.

- Machine Learning accelerates R&D by predicting optimal synergistic formulations, minimizing physical testing and time-to-market.

- Predictive analytics improves supply chain resilience by forecasting raw material demand (boron, zinc) and mitigating geopolitical price volatility.

- Quality control automation using computer vision ensures uniform particle size distribution, critical for additive performance in polymers.

- AI helps customize additive solutions for niche applications, such as high-temperature engineering plastics used in specialized transport sectors.

DRO & Impact Forces Of Flame Retardant Zinc Borate Market

The Flame Retardant Zinc Borate market is powerfully shaped by the synergy between increasing regulatory stringency and the pervasive industry demand for sustainable, high-performance materials. The primary driver is the global legislative shift banning or restricting halogenated flame retardants due to their environmental persistence and toxicity concerns, creating an undeniable market vacuum that non-halogenated alternatives like zinc borate are filling rapidly. This regulatory pressure, particularly emanating from Europe (REACH) and similar initiatives in North America and Asia, compels manufacturers across construction, electronics, and automotive sectors to integrate zinc borate to maintain market access and consumer trust. However, the market faces constraints primarily related to the fluctuating prices and secure sourcing of key raw materials, specifically boron minerals, which are geographically concentrated and subject to geopolitical and mining constraints, impacting overall production costs and market stability.

Opportunities for market expansion are significant, centered around emerging applications in high-growth industries. The rapidly accelerating Electric Vehicle (EV) market presents a major demand opportunity, as zinc borate is crucial for formulating fire-safe battery enclosures, charging station components, and internal wiring systems where thermal runaway mitigation is critical. Furthermore, the massive global investment in 5G infrastructure and advanced data centers demands highly stable and fire-resistant polymer housings and cable jacketing, providing a captive market for high-purity zinc borate grades. Innovation in nanotechnology, leading to zinc borate nanoparticles, also presents an avenue for enhanced performance with lower loading levels, appealing to specialized plastics manufacturers seeking to maintain mechanical integrity while maximizing fire safety features.

The market is influenced by three major impact forces: technological advancements, regulatory evolution, and supply chain dynamics. Technological innovation, specifically the development of synergistic compounds that boost zinc borate’s efficacy, enhances its competitive advantage over other non-halogenated retardants like magnesium hydroxide. Regulatory changes act as an exogenous force, continuously reshaping market requirements; any further tightening of fire standards or expansion of material bans will directly accelerate zinc borate adoption. Finally, the ability of key market players to establish resilient, diversified supply chains for boron and zinc raw materials will determine their capacity to absorb price shocks and consistently meet global demand, profoundly affecting market competitiveness and overall growth trajectory.

Segmentation Analysis

The Flame Retardant Zinc Borate market is segmented extensively based on product grade, specific application areas, and the key end-use industries that consume these additives. This structured approach allows for a precise understanding of demand patterns, pricing mechanisms, and regional consumption variances. The segmentation reveals a dynamic interplay between high-volume, standard-grade demands, primarily from construction and general plastics manufacturing, and the rapidly growing niche for high-purity grades required by specialized sectors like aerospace and high-performance electronics, which necessitates minimal impurities and uniform particle morphology for superior integration into complex polymer matrices.

Analyzing the Application segmentation highlights the dominance of the plastics and polymers sector, reflecting the ubiquitous need for fire safety in consumer goods and infrastructure materials, followed closely by specialized coatings, which rely heavily on zinc borate’s smoke suppression and char promotion capabilities in intumescent systems. The segmentation by End-Use Industry demonstrates the essential nature of fire safety additives in the Construction industry, driven by global building codes, and the accelerating demand from the Electrical & Electronics sector, which must comply with rigorous safety standards for electronic components and cabling to prevent fire incidents, especially in high-density power applications.

Furthermore, understanding the Grade segmentation—ranging from standard hydrated zinc borate (2ZnO 3B2O3 3.5H2O) to anhydrous forms and specialized micro-fine powders—is critical for producers. Standard grades appeal to cost-sensitive bulk users, while high-purity and nano-grades command premium pricing and are targeted towards advanced engineering plastics where material clarity, low loading, and superior processing characteristics are paramount. This segmentation underscores the necessity for manufacturers to diversify their product portfolio to address the varied technical requirements and cost sensitivities across the broad spectrum of industrial consumers utilizing zinc borate for fire safety purposes.

- By Grade:

- High Purity Grade

- Standard Grade

- Anhydrous Zinc Borate

- By Application:

- Plastics & Polymers (PVC, Polyolefins, Nylon, Engineering Plastics)

- Rubber (Conveyor Belts, Hoses)

- Coatings & Paints (Intumescent Coatings, Industrial Finishes)

- Adhesives & Sealants

- Textiles & Fabrics

- By End-Use Industry:

- Construction & Infrastructure (Building Materials, Insulation)

- Electrical & Electronics (Wire & Cable, PCB Laminates)

- Automotive & Transportation (Interior Components, Under-hood Parts)

- Aerospace & Defense

- Consumer Goods (Appliances, Furniture)

Value Chain Analysis For Flame Retardant Zinc Borate Market

The value chain for the Flame Retardant Zinc Borate market commences with the upstream extraction and refinement of key raw materials, primarily zinc oxide and boron minerals (such as colemanite or borax). This initial stage is crucial as the geopolitical concentration of high-quality boron reserves means that control over sourcing and mining operations provides significant competitive leverage and dictates material input costs. Manufacturers then engage in the chemical synthesis of zinc borate, a process involving highly specialized reaction and crystallization techniques to produce the various grades required by the market, with focus areas including particle size control, surface treatment, and ensuring product purity, which ultimately determines the additive’s functional performance.

Mid-stream activities involve processing and formulation, where zinc borate is incorporated into masterbatches, compounds, or liquid dispersions optimized for ease of use in polymer processing equipment. Distribution channels are bifurcated between direct sales for large-volume industrial consumers (e.g., major polymer producers or chemical giants) and indirect sales through specialized chemical distributors and agents, who manage inventory, technical support, and logistical needs for smaller formulators and regional manufacturers. Efficient logistics and robust warehousing are essential due to the bulk nature of the product and the global dispersion of end-use manufacturing sites, especially in emerging Asian markets.

Downstream analysis focuses on the end-use industries, including major compounders in the plastics sector, coatings formulators, and textile manufacturers. These end-users integrate the zinc borate product into their final applications—such as fire-resistant building panels, wire insulation, or intumescent coatings. The success of the downstream integration relies heavily on the technical support provided by the zinc borate producers, ensuring optimal loading levels and compatibility with complex polymer matrices. Furthermore, adherence to country-specific fire safety certifications (e.g., UL, NFPA, European standards) acts as a critical gatekeeper in the downstream part of the value chain, directly linking product quality to market acceptance.

Flame Retardant Zinc Borate Market Potential Customers

Potential customers for Flame Retardant Zinc Borate are widely distributed across several capital-intensive and regulatory-sensitive industries, all sharing the core requirement for enhanced fire safety and smoke suppression without compromising material properties. The primary customer segment comprises large-scale polymer compounders and resin manufacturers, who purchase zinc borate in bulk to formulate fire-resistant compounds used in wire and cable jacketing, PVC pipes, and injection-molded components for consumer electronics and automotive interiors. These customers prioritize high consistency, competitive pricing, and certified compliance with international environmental standards, often requiring technical collaboration to tailor the additive for specific polymer types.

A significant and growing customer base includes manufacturers of specialized coatings and paints, particularly those producing intumescent coatings for the construction industry and protective marine or aerospace finishes. These buyers value zinc borate’s ability to act as a smoke suppressant and char former, crucial for achieving passive fire protection in structural applications. Demand from the construction sector is continuous, driven by mandatory building codes that require non-combustible or self-extinguishing materials in residential and commercial developments globally. Furthermore, the textile industry represents a critical, though smaller, customer segment, utilizing zinc borate in back coatings for fabrics used in furniture, upholstery, and specialized industrial textiles for protective gear.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 668.2 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Albemarle Corporation, Borax, Chemtura, Huber Engineered Materials, Rio Tinto Group, AkzoNobel N.V., Clariant AG, Lanxess AG, ICL Group, BASF SE, Toray Industries, Nabaltec AG, Shandong Xiangguang Chemical, Wuxi City Feipeng Flame Retardant Chemical, Weifang Boron Chemical, Nippon Light Metal Co. Ltd., Henan Hangrui Chemical Co. Ltd., J&H Chemical Co., Xinyang Chemical Co. Ltd., Fuzhou Borax Chemicals. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flame Retardant Zinc Borate Market Key Technology Landscape

The technological landscape in the Flame Retardant Zinc Borate market is rapidly evolving, focusing primarily on refining the morphology and structure of the additive to maximize its functional performance within diverse polymer systems. A crucial area of innovation involves microencapsulation and surface treatment technologies. Microencapsulation helps to prevent the early release of water of hydration during polymer processing at high temperatures, thereby ensuring the full flame retardant potential is preserved until the material reaches its thermal decomposition point during a fire event. Surface modifications, often using silane or other coupling agents, are employed to improve the dispersibility of zinc borate particles within hydrophobic polymer matrices, preventing agglomeration and maintaining the mechanical integrity of the final product.

Another significant technological advancement centers on the production of specialized grades, particularly anhydrous zinc borate and ultra-fine/nano-sized particles. Anhydrous forms are essential for polymers requiring exceptionally high processing temperatures where hydrated forms would prematurely release water and cause bubbling or void formation. Conversely, nano-sized zinc borate particles offer superior surface area for interaction, allowing for reduced loading levels while maintaining or even improving fire safety efficacy and enhancing material transparency, which is vital for specialized coatings and clear plastics applications. These advancements are driven by the need for multi-functional additives that comply with stringent performance specifications in modern engineering plastics.

Furthermore, technology is playing a role in the synthesis process itself, shifting towards continuous, energy-efficient production methods that yield highly uniform crystalline structures. Research in synergistic formulations is also key; companies are developing proprietary blends that combine zinc borate with other non-halogenated compounds, such as expanding graphite, red phosphorus, or alumina trihydrate, to achieve superior synergistic effects—often enabling materials to meet UL94 V-0 ratings with a lower overall additive weight. This technological focus ensures that zinc borate remains a viable, high-performance solution against competing technologies in the increasingly complex field of fire safety engineering.

Regional Highlights

The global demand profile for Flame Retardant Zinc Borate exhibits significant geographical variation, dictated by regional manufacturing concentration, regulatory frameworks, and infrastructure development pace.

- Asia Pacific (APAC): APAC is the dominant and fastest-growing region, driven by massive investments in infrastructure (residential and commercial construction), coupled with the region's status as a global manufacturing hub for electrical and electronic goods. China and India are key contributors, where rapid urbanization necessitates the increased use of fire-resistant building materials and components, leading to high-volume consumption of zinc borate, particularly the standard and cost-effective grades.

- North America: This region represents a mature but highly regulatory-driven market. Demand is strong in the specialized sectors, particularly in high-performance coatings, automotive components, and aerospace, where strict UL and NFPA standards mandate the use of non-halogenated flame retardants. Focus here is increasingly on high-purity and specialized zinc borate grades that meet stringent environmental scrutiny.

- Europe: Driven by the REACH regulation and the strong environmental consciousness of the EU, Europe exhibits a robust shift towards non-halogenated solutions. The market is characterized by high demand from the construction sector (adherence to Eurocodes) and the electrical industry, with significant emphasis on sustainable sourcing and life-cycle analysis of chemical additives, favoring suppliers with transparent and environmentally sound production processes.

- Latin America (LATAM) & Middle East and Africa (MEA): These regions are emerging markets with moderate growth potential. Demand is closely tied to local construction booms, particularly in the GCC countries for large-scale energy and infrastructure projects. Market expansion is expected to accelerate as fire safety regulations mature and international standards are increasingly adopted in key industrial sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flame Retardant Zinc Borate Market.- Albemarle Corporation

- Borax (A member of the Rio Tinto Group)

- Chemtura (Now part of Lanxess AG)

- Huber Engineered Materials

- Rio Tinto Group

- AkzoNobel N.V.

- Clariant AG

- Lanxess AG

- ICL Group

- BASF SE

- Toray Industries

- Nabaltec AG

- Shandong Xiangguang Chemical

- Wuxi City Feipeng Flame Retardant Chemical

- Weifang Boron Chemical

- Nippon Light Metal Co. Ltd.

- Henan Hangrui Chemical Co. Ltd.

- J&H Chemical Co.

- Xinyang Chemical Co. Ltd.

- Fuzhou Borax Chemicals

Frequently Asked Questions

Analyze common user questions about the Flame Retardant Zinc Borate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of zinc borate in fire safety applications?

Zinc borate serves as a synergistic non-halogenated flame retardant and smoke suppressant. Its primary functions are to release water upon heating (cooling the fire), promote the formation of a stable char layer (insulating the underlying material), and significantly reduce the production of dense, toxic smoke compared to many traditional additives.

How do global regulations, such as REACH, impact the demand for zinc borate?

Regulations like REACH in Europe and similar initiatives globally drive strong demand for zinc borate by restricting the use of highly effective but toxic halogenated flame retardants. As industries transition to safer, non-halogenated alternatives, zinc borate, known for its low toxicity profile, becomes a preferred and compliance-friendly additive for plastics, coatings, and textiles.

Which end-use industry is the largest consumer of flame retardant zinc borate?

The Construction and Infrastructure industry is the largest end-use consumer. Zinc borate is extensively used in fire-resistant building materials, insulation, cable jacketing, and intumescent coatings, primarily driven by mandatory international building codes that prioritize passive fire protection in commercial and residential structures.

What are the key technological challenges in manufacturing high-quality zinc borate?

Key challenges include maintaining precise control over particle size distribution and morphology, which is crucial for optimal dispersion and efficacy in polymers. Manufacturers also face the challenge of developing anhydrous grades that can withstand high processing temperatures without premature decomposition, a necessity for specialized engineering plastics.

Is the price of zinc borate stable, or is it affected by raw material volatility?

The price stability of zinc borate is heavily influenced by the volatility of its primary raw material, boron minerals (like borax). Since boron reserves are geographically concentrated, geopolitical factors and mining output fluctuations can significantly impact input costs, leading to price variations in the final zinc borate product.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager