Flash Dryers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436188 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Flash Dryers Market Size

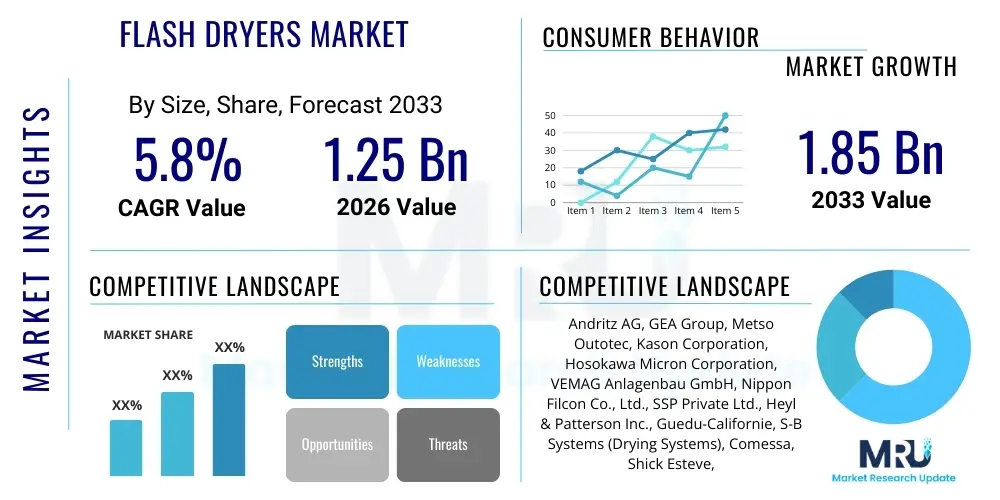

The Flash Dryers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.85 Billion by the end of the forecast period in 2033.

Flash Dryers Market introduction

The Flash Dryers Market encompasses specialized industrial equipment designed for the rapid and continuous drying of heat-sensitive, cohesive, or non-cohesive pastes, slurries, and filter cakes, transforming them into fine, free-flowing powders. These systems utilize a high-velocity stream of heated gas, typically air or inert gas, to instantaneously evaporate moisture from dispersed particles, minimizing residence time and preventing product degradation. Flash dryers are crucial in industries demanding stringent control over particle size, moisture content, and product morphology, offering high thermal efficiency and compactness compared to traditional drying technologies.

The core mechanism involves mixing the wet feed material with the drying medium in a specialized chamber, where the intense heat transfer facilitates almost immediate drying. Major applications span the chemical processing industry, where they handle pigments, inorganic salts, and fine chemicals; the pharmaceutical sector for Active Pharmaceutical Ingredients (APIs) and excipients; and the food and feed industry for starches, proteins, and specialty ingredients. The versatility of flash dryers allows them to be customized for various feed characteristics, including sticky or fibrous materials, making them indispensable in modern manufacturing where throughput and quality are paramount considerations.

Key benefits driving market adoption include enhanced energy efficiency through optimized heat recovery systems, reduced labor requirements due to continuous operation, and superior product quality resulting from precise temperature control and ultra-short drying times. Furthermore, the compact footprint of flash dryer systems makes them suitable for facilities with limited space. Market growth is principally driven by the global expansion of the specialty chemical and pharmaceutical manufacturing sectors, coupled with increasing regulatory pressure on industries to minimize residual solvents and achieve higher purity standards in end products.

Flash Dryers Market Executive Summary

The Flash Dryers Market is experiencing robust growth fueled by surging demand across the Asia Pacific region, specifically driven by large-scale investments in chemical and mining processing capabilities in China and India. Business trends indicate a strong industry focus on integrating advanced automation and sensor technology into drying systems to achieve predictive maintenance and real-time moisture control, thereby maximizing operational uptime and energy savings. Furthermore, manufacturers are increasingly offering hybrid systems, combining flash drying with other methods like fluidization or milling, to cater to complex or highly specialized material processing requirements that standard flash drying alone cannot efficiently handle.

Regionally, North America and Europe maintain a leading position in terms of technological innovation, focusing on energy recovery and closed-loop inert gas drying systems crucial for handling volatile organic compounds (VOCs) prevalent in the pharmaceutical and fine chemical industries. However, the highest volume growth is projected to originate from emerging economies, where rapid industrialization and the establishment of new manufacturing facilities necessitate efficient drying solutions for bulk materials. Regulatory mandates concerning environmental emissions and product quality assurance, particularly in the food and pharmaceutical sectors, are enforcing the adoption of sophisticated, validated flash drying systems globally.

Segmentation trends highlight the increasing dominance of the Spin Flash Dryer segment due to its superior efficiency in handling highly viscous or paste-like materials, making it a favorite in the pigment and polymer industries. Conversely, demand for Ring Flash Dryers remains strong in mineral processing where fine particle size distribution is critical. Application-wise, the Chemical segment retains the largest market share, though the Pharmaceutical segment is projected to exhibit the highest CAGR, propelled by stringent drying requirements for sensitive APIs and increasing global drug manufacturing capacity.

AI Impact Analysis on Flash Dryers Market

Common user inquiries regarding AI's impact on flash dryers often revolve around predictive maintenance schedules, optimizing energy consumption, and achieving superior final product consistency despite feedstock variations. Users frequently question how AI algorithms can model the complex heat and mass transfer dynamics within the drying chamber in real-time and adjust parameters faster than traditional PID controllers. Key themes center on the potential for AI to dramatically reduce system downtime, fine-tune blower speed and inlet temperature based on real-time moisture data, and automatically detect and mitigate potential scaling or fouling issues within the dryer column before they impact production quality. Concerns also include the high initial cost of sensor implementation and the need for specialized expertise to develop and maintain these complex predictive models.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is beginning to revolutionize the operational efficiency of industrial flash drying systems. AI algorithms can process vast amounts of data collected from temperature sensors, flow meters, moisture analyzers, and vibration monitors to build high-fidelity digital twins of the drying process. This capability allows manufacturers to shift from reactive or scheduled maintenance to highly accurate predictive maintenance, anticipating equipment failures, such as fan imbalance or motor wear, weeks in advance. This proactive approach significantly enhances system reliability, minimizes unplanned shutdowns, and maximizes the overall equipment effectiveness (OEE) of drying assets.

Beyond maintenance, AI plays a pivotal role in process optimization. ML models are trained on historical performance data linked to varying feed characteristics (e.g., moisture content, particle size, viscosity) and environmental conditions. When deployed, these models can dynamically adjust operational setpoints—such as gas flow rate, dispersion speed, and classification rotor speed—to maintain optimal thermal efficiency and ensure uniform product quality, even under fluctuating operating conditions. This intelligent control minimizes energy waste by preventing overheating and ensures that the final product meets stringent quality specifications without manual operator intervention, thus optimizing resource utilization and reducing the market's environmental footprint.

- AI enables predictive maintenance schedules, forecasting component failure based on vibration and temperature anomalies.

- Machine Learning algorithms optimize energy consumption by dynamically adjusting inlet temperature and gas velocity based on real-time feed moisture content.

- Enhanced process control through AI minimizes product variation and ensures uniform particle size distribution, critical for pharmaceutical applications.

- Automated fault detection and diagnostics reduce downtime by identifying process instability, such as early signs of product scaling or blockage.

- Digital twins powered by AI simulate various operational scenarios, aiding operators in training and complex process troubleshooting.

DRO & Impact Forces Of Flash Dryers Market

The Flash Dryers Market is primarily driven by the escalating demand for fine powder processing in high-growth industries like pharmaceuticals, specialty chemicals, and advanced battery materials, where flash drying is the preferred method due to its speed and efficiency. Regulatory mandates for higher purity standards and the need for precision drying of sensitive materials further compel investment in these specialized systems. However, the market is constrained by the significant initial capital expenditure required for installing these complex, large-scale systems and the operational challenges associated with handling abrasive or highly sticky feed materials, which can lead to frequent fouling and require specialized cleaning protocols. Opportunities emerge from the increasing adoption of flash drying in emerging bio-fuel and circular economy applications, utilizing waste streams and biomass, alongside technological advancements focused on heat recovery and integration with renewable energy sources.

Drivers include the rapid global capacity expansion within the chemical and pharmaceutical manufacturing sectors, particularly in Asia Pacific, necessitating high-throughput drying solutions. Furthermore, the inherent energy efficiency of flash dryers compared to conventional dryers, especially when handling high moisture content feedstocks, aligns with global sustainability initiatives and cost reduction goals. The necessity to precisely control the final product attributes, such as bulk density, morphology, and residual solvent levels, in high-value products like specialty polymers and pharmaceutical intermediates, cements flash drying as a critical processing step. The transition towards continuous manufacturing processes also favors flash dryers over batch alternatives, contributing significantly to market momentum.

Impact forces acting on the market equilibrium include the high competition from alternative drying technologies, such as spray dryers and vacuum dryers, particularly in small-to-medium-scale operations. The price sensitivity of commodity chemical manufacturers often dictates a preference for less capital-intensive equipment. Technological advancements, however, act as a positive force, with continuous improvements in impeller design, gas dispersion techniques, and classification systems mitigating fouling issues and expanding the range of materials that can be efficiently processed. Regulatory forces, particularly concerning ATEX standards for explosive dust environments, require advanced system designs (e.g., inert gas loops), increasing complexity and cost but simultaneously driving market maturity and specialization.

Segmentation Analysis

The Flash Dryers Market segmentation provides a granular view of product usage based on technology type, material characteristics, and specific industrial applications. Key segments analyzed include the type of flash dryer mechanism employed (Spin, Ring, or Fluidized Bed variants), which dictates suitability for different material consistencies and particle size requirements. The application segmentation delineates end-user industries such as chemicals, pharmaceuticals, food & feed, and mineral processing, reflecting the diverse material handling needs and regulatory environments associated with each sector. Geographical segmentation underscores the regional adoption rates, influenced by industrialization patterns, local regulatory stringency, and capacity investments in major manufacturing hubs globally.

The technological sophistication inherent in each segment allows manufacturers to target niche requirements. For instance, Spin Flash Dryers are optimized for high-viscosity materials requiring mechanical dispersion, offering a robust solution for dyes and pigments. Conversely, Fluidized Bed Flash Dryers are often preferred when handling granular materials that require extended, gentle exposure to the drying medium. Understanding these technological nuances is crucial for market participants looking to tailor their offerings to specific operational demands and efficiency expectations of various end-user industries.

Further analysis of the application segments reveals distinct growth drivers. The Pharmaceutical segment demands stringent material compatibility and validation protocols, driving demand for stainless steel (SS 316L) and highly automated, contained systems. In contrast, the Mineral and Chemical segments prioritize large-scale throughput and energy efficiency, often requiring robust designs capable of handling abrasive or corrosive feedstocks. This divergence in requirements necessitates specialized design approaches, impacting pricing, maintenance profiles, and overall market dynamics within each application category.

- By Type:

- Spin Flash Dryers

- Ring Flash Dryers

- Fluidized Bed Flash Dryers (Integrated Flash Drying)

- By Application:

- Chemical Processing (e.g., Pigments, Polymers, Fertilizers)

- Pharmaceutical & Biotechnology (e.g., APIs, Excipients)

- Food & Feed Industry (e.g., Starches, Proteins, By-products)

- Mineral Processing (e.g., Clays, Mineral Concentrates)

- Others (e.g., Environmental/Sludge Treatment, Biofuels)

- By Operating Mode:

- Batch Drying Systems

- Continuous Drying Systems

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Flash Dryers Market

The value chain for the Flash Dryers Market begins with upstream activities focused on the procurement of high-grade specialized components, including high-efficiency heating elements, sophisticated air handling systems (blowers and fans), precision temperature and moisture sensors, and corrosion-resistant materials (stainless steel alloys). Manufacturers heavily rely on specialized suppliers for these components, ensuring compliance with industrial standards like ASME and regulatory standards for food and pharma (FDA/GMP). Expertise in metallurgical engineering and fluid dynamics is critical at this stage to design durable and effective dispersion mechanisms and classification rotors capable of handling diverse feedstock characteristics.

Midstream activities involve the core manufacturing process, encompassing the engineering design, fabrication, assembly, and rigorous factory acceptance testing (FAT) of the complete drying system. This stage is characterized by high levels of customization, as each flash dryer system is often tailored to the specific thermal and mass transfer properties of the customer's material. Downstream distribution primarily involves direct sales through specialized engineering teams, given the technical complexity and high investment cost of the equipment. Distribution channels are supported by robust after-sales service, including installation, commissioning, process optimization, and long-term maintenance contracts, which constitute a significant revenue stream.

Direct channels, involving direct engagement between the dryer manufacturer and the end-user (e.g., a pharmaceutical company or large chemical plant), are predominant for large-scale, customized projects, ensuring clear communication regarding technical specifications and regulatory compliance. Indirect channels, such as authorized distributors or system integrators, are sometimes utilized in regional markets or for standard, smaller units. Potential customers, including EPC firms (Engineering, Procurement, and Construction) acting on behalf of the end-user, often influence procurement decisions. The value chain is heavily impacted by global supply chain stability for high-quality steel and automation components, alongside the availability of skilled labor for highly specialized fabrication and installation.

Flash Dryers Market Potential Customers

The primary customers for flash dryer systems are large-scale industrial processors requiring continuous, high-volume drying of materials that are either highly sensitive to heat or necessitate a fine, consistent powder output. The chemical manufacturing sector, encompassing producers of organic and inorganic chemicals, specialized polymers, and fertilizers, represents a foundational customer base due to the sheer volume of materials requiring solvent removal and precise moisture control. These customers prioritize reliability, energy efficiency, and systems designed for hazardous environments, often requiring inert gas recirculation capabilities.

Another critical customer segment is the pharmaceutical and biotechnology industry, where flash dryers are indispensable for drying Active Pharmaceutical Ingredients (APIs) and excipients. These end-users demand equipment that adheres strictly to Good Manufacturing Practices (GMP) and regulatory standards, including full material traceability, validated cleaning procedures (CIP/SIP capability), and construction from high-grade stainless steel (e.g., SS 316L). The trend toward continuous pharmaceutical manufacturing further cements flash dryer adoption in this high-value sector, where product quality variance is intolerable.

Furthermore, the mineral processing and metallurgical sectors are significant purchasers, utilizing flash dryers for materials like mineral concentrates, metallic salts, and specialty clays, often characterized by abrasive properties. In recent years, the food and feed industry, particularly manufacturers of instant food products, starches, and feed additives, has increased adoption due to the ability of flash dryers to minimize thermal degradation, thereby preserving nutritional value and functional properties. Emerging markets in battery technology, focusing on drying cathode and anode materials, are rapidly becoming pivotal potential customers due to the strict low-moisture requirements for lithium-ion battery production.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.85 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Andritz AG, GEA Group, Metso Outotec, Kason Corporation, Hosokawa Micron Corporation, VEMAG Anlagenbau GmbH, Nippon Filcon Co., Ltd., SSP Private Ltd., Heyl & Patterson Inc., Guedu-Californie, S-B Systems (Drying Systems), Comessa, Shick Esteve, The Witte Company, Inc., Hebei Meiru Machinery Equipment Co., Ltd., Shandong Tianli Drying Equipment Co., Ltd., J. K. System Pvt. Ltd., Flsmidth, Testori S.p.A., Dedert Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flash Dryers Market Key Technology Landscape

The key technology landscape of the Flash Dryers Market is defined by continuous innovation focused on optimizing energy utilization, improving dispersion efficiency, and broadening the range of materials that can be processed. Modern flash dryers incorporate sophisticated classification systems, such as internal or external air classifiers, which ensure that only material dried to the target moisture content and size is discharged, while oversized or damp particles are efficiently recycled back into the drying zone. This closed-loop classification is critical for achieving tight particle size distributions, particularly necessary in high-value fine chemical and pharmaceutical applications where homogeneity is mandatory. Furthermore, advancements in feed conditioning systems, including specialized mixers and dispersion units, are essential for breaking down highly viscous pastes or filter cakes into discrete particles before entering the drying column, preventing agglomeration and promoting instantaneous drying.

Energy efficiency represents a significant area of technological focus, driven by rising energy costs and environmental regulations. Current flash dryer designs increasingly feature advanced heat recovery systems, often employing exhaust air heat exchangers to preheat the incoming drying air or utilize the recovered heat for auxiliary processes. Furthermore, the adoption of closed-loop inert gas drying systems is a growing trend, necessitated when handling materials containing flammable solvents or when oxidizing the product must be avoided. These systems utilize nitrogen or superheated steam as the drying medium, enabling solvent recovery and ensuring compliance with stringent safety and emission standards (e.g., ATEX directives), albeit at a higher capital cost.

Digitalization and automation technologies are rapidly transforming the operational landscape. Integration of high-fidelity sensors (infrared moisture sensors, mass flow meters) allows for precise, real-time monitoring of key process variables. The use of advanced control systems, including model predictive control (MPC) and robust PLC/DCS interfaces, enables operators to stabilize the drying process against external disturbances and optimize throughput automatically. These technological integrations move flash dryers towards becoming smart, autonomous units capable of self-diagnosing issues and adapting drying parameters dynamically, thereby enhancing reliability and reducing reliance on operator intuition.

Regional Highlights

- Asia Pacific (APAC) Market Dominance: APAC is the fastest-growing and largest market for flash dryers, primarily driven by massive government and private sector investment in the chemical, mining, and bulk pharmaceutical industries across China, India, and Southeast Asia. The region's industrial expansion, coupled with the necessity to process large volumes of mineral concentrates (e.g., zinc, copper) and fertilizers efficiently, creates sustained demand for high-capacity flash drying equipment. Local manufacturing competition is intense, focusing on optimizing cost-effectiveness while gradually incorporating advanced European and North American automation standards.

- North America Market Maturity and Innovation: North America represents a mature but high-value market, characterized by stringent regulatory environments, particularly within the pharmaceutical and food sectors. Market growth here is primarily driven by replacement cycles, modernization of existing facilities, and the adoption of advanced, closed-loop inert gas systems for handling specialized chemicals and solvent-based processes. High labor costs necessitate fully automated systems with minimal operator intervention and robust remote diagnostic capabilities.

- Europe Market Focus on Sustainability and Safety: European markets are defined by strict environmental and safety regulations (REACH, ATEX), favoring manufacturers that offer highly energy-efficient designs and advanced safety features, such as explosion-proof construction and solvent recovery mechanisms. The region exhibits strong demand for customized, niche applications, including specialty polymers and advanced materials. Germany, Italy, and Scandinavia are key hubs for manufacturing excellence and technological adoption in high-specification drying technology.

- Latin America (LATAM) and MEA Growth Potential: LATAM, especially Brazil and Mexico, shows consistent demand fueled by growth in the food processing (e.g., coffee, starch) and mineral extraction industries. The Middle East and Africa (MEA) region’s market is tied largely to investment in fertilizer production, petrochemicals, and mineral processing, particularly in nations with abundant mineral resources. These regions are characterized by a focus on robust, low-maintenance equipment capable of handling challenging feedstocks and often operating under extreme ambient conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flash Dryers Market.- Andritz AG

- GEA Group

- Metso Outotec

- Hosokawa Micron Corporation

- Kason Corporation

- VEMAG Anlagenbau GmbH

- Nippon Filcon Co., Ltd.

- SSP Private Ltd.

- Heyl & Patterson Inc.

- Guedu-Californie

- S-B Systems (Drying Systems)

- Comessa

- Shick Esteve

- The Witte Company, Inc.

- Hebei Meiru Machinery Equipment Co., Ltd.

- Shandong Tianli Drying Equipment Co., Ltd.

- J. K. System Pvt. Ltd.

- Flsmidth

- Testori S.p.A.

- Dedert Corporation

Frequently Asked Questions

Analyze common user questions about the Flash Dryers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary operational difference between a Spin Flash Dryer and a Ring Flash Dryer?

The primary operational difference lies in particle handling and classification. Spin Flash Dryers utilize mechanical agitation and dispersion in the drying chamber, making them ideal for cohesive or paste-like feedstocks. Ring Flash Dryers incorporate an air classifier ring, providing greater control over particle residence time and allowing for more precise control over the final product’s particle size distribution, often favored for crystalline or mineral products.

Which industrial sector drives the highest volume demand for Flash Dryers globally?

The Chemical Processing segment consistently drives the highest volume demand for flash dryers globally. This is attributed to the necessity of efficiently drying large volumes of inorganic chemicals, pigments, and polymer intermediates, where rapid moisture removal is critical for quality and high throughput manufacturing.

What are the key advantages of using a Flash Dryer for heat-sensitive pharmaceutical products?

Flash dryers minimize thermal degradation of heat-sensitive pharmaceuticals because the product's exposure to high temperatures is extremely brief (often measured in seconds). This ultra-short residence time ensures rapid moisture removal while preserving the integrity, chemical composition, and efficacy of Active Pharmaceutical Ingredients (APIs).

How does AI technology enhance the energy efficiency of Flash Drying systems?

AI technology enhances energy efficiency by utilizing Machine Learning models to analyze real-time input variables (feed moisture, ambient temperature, gas flow). Based on this analysis, the system dynamically adjusts the inlet temperature and airflow velocity to use the minimum amount of thermal energy required to achieve the target residual moisture content, thereby preventing unnecessary overheating and optimizing fuel consumption.

What is the main constraint preventing wider adoption of Flash Dryers in smaller processing facilities?

The main constraint is the high initial capital investment required for purchasing, installing, and commissioning a highly specialized Flash Drying system. Additionally, their operational complexity and the need for specialized engineering expertise for maintenance often make them less feasible for smaller-scale operations compared to simpler, less expensive alternatives like tray dryers or conventional fluidized beds.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager