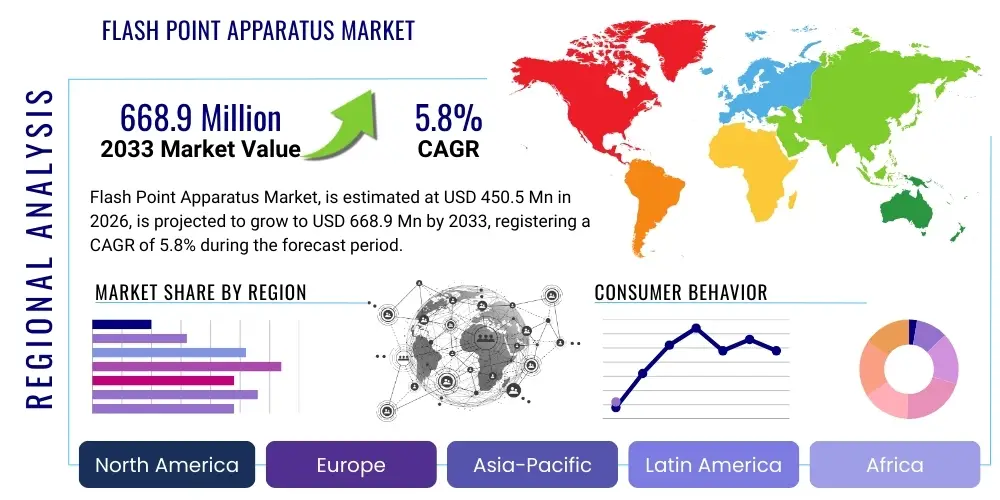

Flash Point Apparatus Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439133 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Flash Point Apparatus Market Size

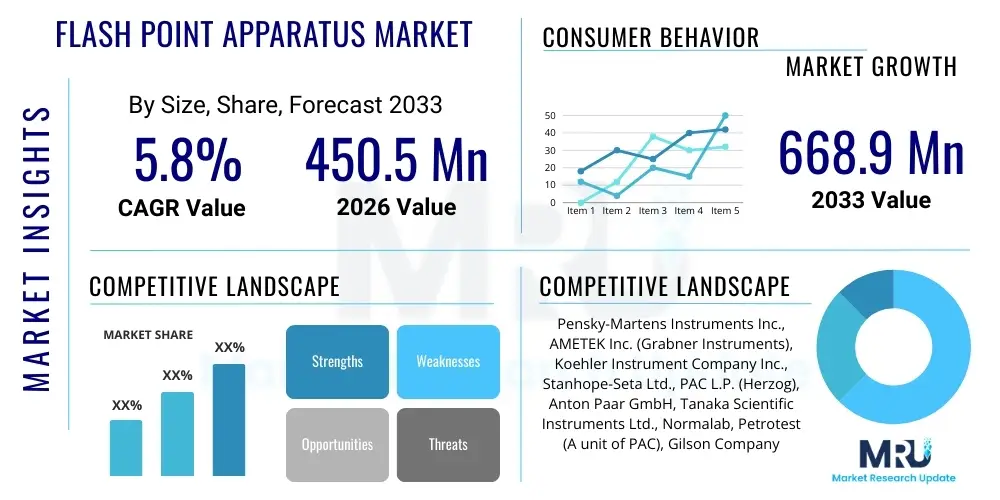

The Flash Point Apparatus Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 668.9 Million by the end of the forecast period in 2033.

Flash Point Apparatus Market introduction

The Flash Point Apparatus Market encompasses the instruments and systems utilized for determining the lowest temperature at which a volatile material, such as petroleum products, solvents, and chemicals, ignites in the presence of an ignition source under standardized test conditions. This critical safety parameter, known as the flash point, is essential for classifying materials for storage, transportation, and regulatory compliance, particularly within highly regulated industries like petrochemicals, aviation, and pharmaceuticals. The core function of these devices is to ensure operational safety and product quality assurance by adhering to international standards established by organizations such as ASTM, ISO, and IP. Market expansion is fundamentally driven by increasing global focus on industrial safety standards, stringent environmental regulations regarding hazardous material handling, and the continuous need for quality control in fuel and lubricant production chains.

Flash point apparatuses are broadly categorized into closed-cup testers (such as Pensky-Martens and Abel) and open-cup testers (such as Cleveland Open Cup). Closed-cup methods are generally used for materials that flash at ambient temperatures or have specific handling requirements, offering better precision and safety by limiting vapor dissipation. Open-cup methods, conversely, are frequently employed for higher flash point materials and bitumen. The adoption of automated flash point testers is a significant trend, replacing traditional manual systems, leading to enhanced accuracy, reduced operator error, and improved laboratory efficiency. These automated systems often feature integrated cooling and heating functionalities, touch-screen interfaces, and built-in diagnostic capabilities, making them indispensable tools for modern analytical laboratories engaged in quality assurance and research and development activities.

Major applications of flash point apparatus include testing jet fuels, diesel, kerosene, lubricating oils, and various solvents and chemicals to prevent fire hazards. Benefits derived from using accurate apparatus include compliance with international safety mandates, optimization of product formulations, reduction in product liability risks, and streamlining of global trade operations involving hazardous goods. Key driving factors propelling the market forward include the rapid expansion of the oil and gas infrastructure in emerging economies, continuous modernization requirements within existing refineries, and the growing demand for biofuels and sustainable energy sources which necessitate precise characterization testing.

Flash Point Apparatus Market Executive Summary

The Flash Point Apparatus Market is undergoing robust expansion, primarily fueled by strict regulatory frameworks concerning flammable liquids across vital sectors like petrochemicals and transportation. Business trends indicate a strong shift towards highly automated, miniaturized, and integrated testing solutions that offer superior precision and reduced sample consumption. Key industry players are focusing on developing multi-functional instruments capable of performing various physical property tests alongside flash point determination, thus maximizing laboratory throughput and efficiency. Supply chain resilience, digitalization of testing records, and remote calibration services are emerging as critical competitive advantages in this technologically evolving market landscape.

Regionally, Asia Pacific (APAC) dominates the market share and is projected to exhibit the fastest growth, largely due to rapid industrialization, burgeoning demand for refined petroleum products, and massive investments in infrastructure development, particularly in China and India. North America and Europe maintain significant market presence, characterized by high adoption rates of advanced, closed-cup automated systems driven by stringent environmental and safety compliance mandates. Growth in the Middle East & Africa (MEA) is intrinsically linked to expansions in crude oil refining and petrochemical manufacturing capacities, mandating continuous investment in advanced testing equipment to ensure quality exports and operational safety standards.

Segmentation analysis reveals that the automated segment holds the majority share owing to the demand for high-throughput testing in industrial environments, offering reliable data integrity and minimal variance compared to manual methods. Based on the end-user industry, the Petroleum & Lubricants sector remains the largest consumer, given the necessity of characterizing every batch of fuel and oil produced. Furthermore, the closed-cup apparatus type segment is witnessing higher penetration due to its utility in testing both low and high flash point liquids under conditions that better simulate real-world storage and handling environments, thereby reinforcing safety protocols across the entire product lifecycle.

AI Impact Analysis on Flash Point Apparatus Market

User inquiries regarding AI's influence in the Flash Point Apparatus Market frequently center on the potential for predictive maintenance of testing equipment, enhancement of data quality and interpretation, and the eventual automation of quality control decision-making processes. Users are concerned about whether AI models can accurately predict flash points based on material composition or historical production data, potentially reducing the need for physical testing frequency while maintaining regulatory compliance. Key themes highlight expectations for AI integration in optimizing test parameters, detecting anomalies or errors during automated testing cycles, and providing instantaneous, comparative analysis against global regulatory benchmarks. While the apparatus itself remains a physical necessity for regulatory approval, AI is expected to revolutionize data handling, operational efficiency, and long-term asset management within testing laboratories.

- AI-driven Predictive Maintenance: Utilizing sensor data from apparatus to forecast equipment failure, minimizing downtime and calibration inconsistencies.

- Enhanced Data Analytics: AI algorithms analyze vast datasets generated by automated testers, identifying subtle trends and correlations between material composition and flash point deviation.

- Quality Control Optimization: Machine learning models assist in setting optimal testing conditions (heating rate, stir speed) specific to complex or non-standard sample matrices.

- Automated Regulatory Compliance Checking: AI integrates testing results directly with global standards (ASTM, ISO), providing instant pass/fail assessments and documentation generation.

- Virtual Flash Point Prediction: Employing AI/ML to predict the flash point of blends or novel chemical formulations prior to synthesis, accelerating R&D processes.

- Error Detection and Validation: Algorithms monitor test cycle performance in real-time to flag operator or equipment malfunctions, ensuring data reliability.

DRO & Impact Forces Of Flash Point Apparatus Market

The Flash Point Apparatus Market dynamics are driven by mandatory regulatory compliance and the increasing global output of volatile chemicals and petroleum derivatives. However, the market faces constraints related to high initial investment costs for advanced automated systems and the necessity for specialized, high-frequency calibration procedures. Opportunities are prominent in developing miniaturized, portable devices for field testing and integrating advanced spectroscopic techniques for real-time analysis. The impact forces acting on this market include intensifying governmental safety legislation, technological advancements in sensor technology, and sustained growth in the petrochemical industry, making accurate flash point determination a non-negotiable step in the value chain.

Drivers include the expanding global refining capacity, particularly in Asian economies, which necessitates corresponding growth in quality control infrastructure. Furthermore, regulatory bodies worldwide, such as the Department of Transportation (DOT) and the International Maritime Organization (IMO), continually update safety classifications, compelling industries to adopt the latest, most precise testing methodologies. The proliferation of complex chemical products, including specialized solvents, paints, and biofuels, each requiring precise flash point certification, further strengthens market demand. The push for automation in laboratories seeking to reduce operational expenditures (OPEX) and improve data integrity is a major technological impetus.

Restraints primarily involve the substantial capital expenditure required to transition from manual, legacy apparatus to modern, highly accurate automated systems, which can be prohibitive for smaller research laboratories or industrial facilities. Additionally, the inherent complexity and need for continuous expert training in operating and maintaining sophisticated analytical instruments pose a logistical challenge, particularly in developing regions. Counterfeit or non-compliant testing equipment entering the market also represents a constraint, potentially leading to inaccurate results, compromising safety, and eroding trust in standardized testing procedures. Moreover, the cyclical nature of the oil and gas industry can introduce periodic volatility in capital investment spending, indirectly impacting the procurement of new apparatus.

Opportunities are vast in the development of modular flash point testing systems that can be customized for diverse sample types, including highly viscous materials or corrosive chemicals. The burgeoning field of field testing and remote monitoring presents a significant growth avenue, allowing for immediate safety checks on site, reducing delays in logistics and operations. Furthermore, integrating the apparatus with Laboratory Information Management Systems (LIMS) and cloud-based data storage offers opportunities for creating smarter, interconnected laboratories that leverage big data for trend analysis and quality assurance improvement. Research into non-contact or micro-volume testing methods also offers potential breakthroughs in efficiency and safety.

Segmentation Analysis

The Flash Point Apparatus Market is meticulously segmented across dimensions including product type, methodology, degree of automation, and end-user application, reflecting the diverse regulatory and operational requirements across industries. Understanding these segments is crucial for manufacturers to tailor product development and for end-users to select the most appropriate instrument that aligns with their specific testing protocols and regulatory mandates. The core differentiation often lies between automated and manual systems, driven by throughput requirements and the criticality of minimizing human error in safety-critical measurements. The choice of methodology, predominantly closed-cup versus open-cup, is dictated by the chemical characteristics of the sample being tested and the specific regulatory standard required for classification.

Further granularity exists within the application segment, highlighting the specialized needs of sectors like petrochemicals (high-volume fuel testing), aerospace (jet fuel safety), and the chemical industry (solvent and paint formulation). Geographic segmentation also plays a pivotal role, where compliance with regional standards (e.g., European EN standards vs. US ASTM standards) necessitates specific instrument configurations and certification. The increasing adoption of portable apparatus represents a distinct segmentation trend, catering to organizations requiring flexibility and immediate results outside of a fixed laboratory environment, such as transportation companies or field inspection services.

The growth trajectory within these segments is highly varied; while the manual segment maintains a baseline presence for educational and low-volume R&D purposes, the automated closed-cup segment is anticipated to drive the market's value growth due to its superior efficiency, reliability, and ease of integration into modern lab automation frameworks. Manufacturers are strategically positioning themselves by offering scalable solutions, ranging from entry-level semi-automatic models suitable for small laboratories to fully automated, networked, high-throughput systems designed for major refineries and bulk chemical producers.

- By Product Type:

- Pensky-Martens Closed Cup Tester

- Abel Closed Cup Tester

- Tag Closed Cup Tester

- Cleveland Open Cup Tester (COC)

- Other Specialized Testers (e.g., Small Scale Closed Cup Testers)

- By Operation Mode:

- Automated Flash Point Apparatus

- Manual Flash Point Apparatus

- Semi-Automated Flash Point Apparatus

- By End-User:

- Petroleum & Lubricants Industry

- Chemical & Petrochemical Industry

- Pharmaceutical Industry

- Transportation and Logistics

- Academic & Research Institutions

- Government and Regulatory Bodies

- By Testing Methodology:

- Closed-Cup Method

- Open-Cup Method

Value Chain Analysis For Flash Point Apparatus Market

The value chain for the Flash Point Apparatus Market begins with the upstream suppliers of precision components, specialized electronics, heating/cooling elements, and high-quality construction materials (e.g., stainless steel, robust polymers). Upstream analysis reveals that reliance on sophisticated sensor technology and microcontroller units requires strong partnerships with specialized electronics manufacturers. Manufacturers of flash point apparatus focus on precision engineering, software development for automation, rigorous quality control, and adherence to international testing standards (e.g., calibrating temperature probes precisely). The complexity and specialized nature of the finished product mean that integration and assembly form a significant portion of the value addition.

The distribution channel is multifaceted, relying heavily on specialized analytical instrument distributors and regional sales representatives who possess technical expertise in laboratory safety and standardization protocols. Direct sales strategies are often employed by major global manufacturers for high-volume customers (e.g., large refineries), offering customized installation, application training, and long-term service contracts. Indirect channels utilize third-party distributors who manage regional inventory, customer relationship management, and local regulatory certifications. The after-sales service, including calibration, maintenance, and supply of certified reference materials, is a critical component of the value chain, ensuring the apparatus maintains accuracy over its operational lifespan.

Downstream analysis focuses on the integration of these apparatus into the end-users’ workflow, primarily quality control laboratories (QC labs), R&D departments, and regulatory inspection agencies. The value derived downstream is the certification and classification of materials, which directly impacts safety, regulatory compliance, and marketability. Efficiency and reliability of the apparatus are paramount, as testing bottlenecks can significantly disrupt production schedules in high-throughput industries like petrochemicals. Feedback from downstream users regarding ease of use, data reporting features, and compliance with evolving regulatory requirements continually informs upstream product improvements and technological updates.

Flash Point Apparatus Market Potential Customers

The primary consumers and end-users of Flash Point Apparatus are entities that manufacture, transport, store, or regulate flammable and combustible liquids, spanning a broad spectrum of industrial and governmental organizations. The most significant customer base resides in the oil refining and petrochemical sector, where flash point determination is mandatory for almost every product, from crude oil fractions to finished fuels, solvents, and specialized lubricants. These entities require high-throughput, automated testing solutions that can seamlessly integrate into their large-scale process control systems to maintain continuous quality assurance and safety standards during production.

Secondary but crucial customer segments include the coatings, adhesives, and paint industries, which utilize various solvents and must characterize the flammability of both raw materials and final products for labeling and handling safety data sheets (SDS). The transportation and logistics sector, particularly those involved in maritime shipping and rail transport of hazardous materials, also represent significant buyers, often requiring portable or field-testing apparatus to verify cargo classifications prior to shipment. Furthermore, governmental bodies, including customs agencies, environmental protection agencies, and fire safety departments, purchase and utilize these devices for regulatory enforcement and verification of commercial compliance.

Research and academic institutions represent a steady, niche customer base, utilizing flash point testers for material science research, chemical synthesis studies, and vocational training programs related to industrial safety and chemical engineering. The growing shift towards renewable fuels, such as biodiesel and ethanol blends, has created a specialized customer group among biofuel producers and testing labs, as these products require frequent and precise flash point monitoring due to their complex and variable chemical compositions. Therefore, potential customers span industrial giants demanding fully automated systems to smaller, specialized QA/QC laboratories focused on niche product certification.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 668.9 Million |

| Growth Rate | CAGR 5.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Pensky-Martens Instruments Inc., AMETEK Inc. (Grabner Instruments), Koehler Instrument Company Inc., Stanhope-Seta Ltd., PAC L.P. (Herzog), Anton Paar GmbH, Tanaka Scientific Instruments Ltd., Normalab, Petrotest (A unit of PAC), Gilson Company Inc., Eralytics GmbH, Lawler Manufacturing Co. Inc., SCI (Shanghai) Co. Ltd., Humboldt Mfg. Co., Shanghai Keke Scientific Instruments Co. Ltd., TIME-CALIBRATION Laboratories Inc., Spectro Scientific, Scinco Instruments Co., Labthink Instruments Co. Ltd., Sigma-Aldrich (Merck KGaA) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flash Point Apparatus Market Key Technology Landscape

The technological landscape of the Flash Point Apparatus Market is primarily defined by the evolution from manual, glass-based apparatus to sophisticated, microprocessor-controlled automated systems designed for minimal operator intervention and maximum precision. Automated apparatus utilizes highly precise temperature sensors (e.g., Platinum Resistance Thermometers, PRTs) and advanced heating/cooling elements capable of maintaining the highly controlled temperature ramp rates mandated by international testing standards (e.g., ASTM D93, D56, D92). The integration of robust microcontrollers allows for automated execution of complex test protocols, precise timing of the ignition source introduction, and immediate recording of the flash point, significantly reducing variability and enhancing repeatability.

A key technological development is the implementation of advanced detection mechanisms. Modern apparatus often employs photo-optical or ionization sensors to detect the presence of the brief flash, which is far more reliable and objective than manual visual observation. Furthermore, technological advancements include self-diagnostic capabilities and automated calibration checks, which ensure the instrument's readiness and compliance before each test run. The trend towards miniaturization is also prominent, with small-scale closed-cup testers (e.g., utilizing methods like ASTM D3828) gaining traction for testing small, expensive, or highly hazardous samples, offering safety advantages and reduced waste generation.

Connectivity and data management represent another crucial technology frontier. Latest generation flash point testers are equipped with Ethernet and USB interfaces, facilitating seamless integration with Laboratory Information Management Systems (LIMS). This connectivity supports digital data transfer, centralized archiving, and comprehensive audit trails, essential for regulatory traceability. Furthermore, some high-end models incorporate Peltier cooling technology, eliminating the need for external cooling baths or circulation units, thus simplifying laboratory setup and improving temperature control stability, particularly for testing low flash point materials in diverse environmental conditions. The ongoing technological migration is focused squarely on efficiency, safety, and verifiable data integrity.

Regional Highlights

Regional dynamics in the Flash Point Apparatus Market are heavily influenced by industrial infrastructure, regulatory stringency, and consumption patterns of petroleum and chemical products. Asia Pacific (APAC) stands out as the highest growth region, driven by massive industrial expansion, particularly in China, India, and Southeast Asian nations. The region's increasing energy demand necessitates continuous expansion and modernization of refining capacity and chemical manufacturing plants, creating a consistent need for high-throughput automated testing instruments to meet export quality standards and rapidly evolving local safety regulations. Governments in this region are prioritizing safety standards in manufacturing and logistics, thereby mandating the purchase of compliant apparatus.

North America and Europe constitute mature markets characterized by high penetration of automated and high-precision apparatus. Growth in these regions is primarily spurred by replacement cycles, regulatory updates demanding higher accuracy (e.g., in aviation fuel testing), and the shift toward environmentally friendly biofuels which require specific testing protocols. European standards (CEN) and US standards (ASTM) are globally influential, driving technology adoption. Furthermore, the robust presence of major petrochemical companies and analytical instrument manufacturers in these regions ensures continuous innovation and rapid deployment of the latest technological solutions, including integrated AI and LIMS connectivity.

The Middle East and Africa (MEA) market growth is intrinsically tied to the region's dominant role in global oil and gas production and export. Significant investments in downstream activities, aimed at increasing refining capabilities and diversifying petrochemical output, are key drivers. The demand here is centered on highly robust, industrial-grade automated testers capable of handling crude oil and various refined products under often challenging climatic conditions. Latin America exhibits steady growth, primarily led by Brazil and Mexico, due to local energy sector investments and the need for standardized quality control in their developing industrial base and expanding fuel distribution networks.

- Asia Pacific (APAC): Highest CAGR; driven by rapid industrialization, expansion of refining facilities, and increasing implementation of mandatory safety standards in countries like China and India.

- North America: Mature market; focused on technological replacement, stringent aviation fuel safety regulations, and high adoption rates of automated Pensky-Martens testers.

- Europe: Regulatory-driven market; demand is high for compliance with EU safety directives (e.g., REACH), strong presence in specialized chemical testing, and focus on energy transition fuels.

- Middle East & Africa (MEA): Growth linked to oil and gas export quality assurance and increasing domestic downstream processing capacity; demand for durable, industrial-scale equipment.

- Latin America: Steady demand fueled by infrastructure development, investment in biofuel production, and modernization of state-owned energy facilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flash Point Apparatus Market.- AMETEK Inc. (Grabner Instruments)

- Koehler Instrument Company Inc.

- Anton Paar GmbH

- PAC L.P. (Herzog, Petrotest)

- Stanhope-Seta Ltd.

- Tanaka Scientific Instruments Ltd.

- Normalab

- Eralytics GmbH

- Lawler Manufacturing Co. Inc.

- Humboldt Mfg. Co.

- Penske-Martens Instruments Inc.

- SCI (Shanghai) Co. Ltd.

- Gilson Company Inc.

- Spectro Scientific

- Scinco Instruments Co.

- Labthink Instruments Co. Ltd.

- Metrohm AG

- Thermo Fisher Scientific Inc.

- Siemens AG (Testing Equipment Division)

- Test Kit Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Flash Point Apparatus market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between open-cup and closed-cup flash point apparatus?

The primary difference lies in the testing environment and application. Closed-cup methods (e.g., Pensky-Martens) test in a closed vessel, simulating storage conditions and preventing vapor dissipation, generally providing a lower, more conservative flash point value critical for safety classification of fuels and solvents. Open-cup methods (e.g., Cleveland Open Cup) test in an open vessel, allowing vapor to escape, and are typically used for high flash point materials, lubricants, and bitumen, adhering to standards like ASTM D92.

Why is automation becoming essential in the Flash Point Apparatus Market?

Automation is essential because it eliminates operator bias, significantly improves repeatability and reproducibility of results, and enhances laboratory throughput by reducing test time and minimizing errors. Automated systems manage precise heating rates, ignition timing, and data reporting according to international standards (AEO focus: precision, compliance, throughput).

Which industry segment drives the highest demand for flash point testing equipment?

The Petroleum and Lubricants industry segment generates the highest demand. Flash point determination is a mandatory quality control step for every batch of crude oil, jet fuel, diesel, gasoline, and lubricating oil produced globally, ensuring product safety, performance, and compliance with transportation and safety regulations (AEO focus: petrochemicals, mandatory QC, safety).

What major regulatory standards govern the use and calibration of flash point testers?

The market is governed by internationally recognized standards primarily set by ASTM International (e.g., ASTM D93, D56, D92, D3828) and the International Organization for Standardization (ISO, e.g., ISO 2719, ISO 3679). Compliance with these standards is critical for apparatus manufacturers and end-users to ensure global trade and regulatory acceptance of material classifications (AEO focus: ASTM, ISO, regulatory compliance, global trade).

How is the integration of LIMS impacting the efficiency of modern flash point testing laboratories?

LIMS integration significantly boosts laboratory efficiency by automating data capture directly from the apparatus, eliminating manual data entry errors, facilitating centralized data storage and retrieval, and enabling immediate generation of regulatory compliant reports and audit trails. This digital integration supports the industry trend towards paperless and smart laboratory operations (AEO focus: data integrity, LIMS, paperless operations, audit trails).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager