Flat Safety Mirror Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434690 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Flat Safety Mirror Market Size

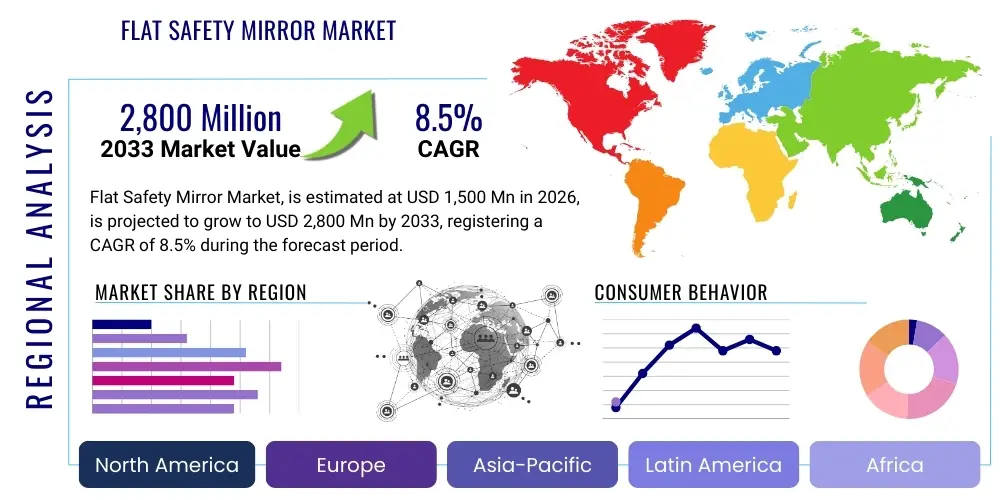

The Flat Safety Mirror Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 1.5 billion in 2026 and is projected to reach USD 2.8 billion by the end of the forecast period in 2033. This substantial expansion is primarily driven by increasing construction activities globally, especially in emerging economies, coupled with stricter governmental regulations mandating the use of safety glass and mirrors in commercial and public infrastructure to enhance occupant safety and security. The shift towards aesthetic yet highly functional building materials further accelerates market valuation.

Flat Safety Mirror Market introduction

The Flat Safety Mirror Market encompasses specially manufactured mirrored glass products designed to minimize the risk of injury in the event of breakage. These mirrors utilize various safety enhancement technologies, primarily involving lamination, tempering, or the application of protective safety film (backing) that holds the broken fragments together, preventing fragmentation into sharp shards. Key product types include Laminated Safety Mirrors, which bond two glass sheets around a polymer interlayer (like PVB), and Safety Backed Mirrors, which have an adhesive film applied to the rear surface.

Major applications of flat safety mirrors span across architectural and construction sectors, particularly for wall cladding, bathroom installations, and gymnasium mirrors where high impact resistance is required. They are also crucial in the automotive industry for specific interior components and increasingly utilized in retail displays, furniture manufacturing, and public transportation infrastructure. The inherent benefits, such as enhanced durability, superior reflective quality, and, most importantly, compliance with stringent international safety standards (e.g., ANSI Z97.1, EN 12600), make them indispensable compared to traditional mirrored glass.

Driving factors for this market include the global focus on preventative safety measures in design and architecture, rapid urbanization leading to increased high-rise commercial and residential construction, and technological advancements improving the manufacturing efficiency and aesthetic properties of safety mirrors. Furthermore, growing consumer awareness regarding product safety and the integration of mirror technology into smart home systems are creating significant demand pathways, ensuring consistent market progression over the forecast horizon.

Flat Safety Mirror Market Executive Summary

The Flat Safety Mirror Market is poised for robust expansion, reflecting strong business trends centered around sustainability, advanced material science, and regulatory compliance. Geographically, Asia Pacific remains the dominant and fastest-growing region, fueled by massive infrastructure investments and residential construction booms in countries like China and India. Western markets (North America and Europe) demonstrate stable demand, driven primarily by renovation cycles, stringent building codes, and the adoption of premium, high-specification laminated mirrors for high-end architectural projects. Business models are evolving towards specialized fabrication services and integration with digital components, focusing heavily on B2B distribution channels serving large construction firms and furniture manufacturers.

Segmentation trends indicate a strong preference for Laminated Safety Mirrors, particularly in applications requiring maximum safety and structural integrity, such as storefronts and public spaces. However, Safety Backed Mirrors maintain significant volume dominance in cost-sensitive residential and furniture applications due to their ease of installation and relatively lower production costs. The commercial end-user segment, including offices, hospitals, and fitness centers, is expected to exhibit the highest CAGR, driven by refurbishment projects prioritizing safety upgrades. Furthermore, the market is experiencing consolidation among Tier 1 manufacturers who are leveraging vertical integration to control the supply chain from raw glass production to final mirror processing, enhancing quality control and optimizing costs.

Key strategic shifts among market players involve significant investment in automated coating technologies (such as sputter coating for superior reflection and durability) and sustainable manufacturing practices, minimizing the use of hazardous materials like copper and lead in the silvering process. This dual focus on operational efficiency and environmental responsibility is crucial for maintaining competitive advantage and navigating increasingly complex global environmental regulations. The core market challenge remains the volatile pricing of raw materials, specifically soda ash and silver nitrate, which necessitates strong supply chain management and hedging strategies among leading producers to ensure stable pricing and margin protection.

AI Impact Analysis on Flat Safety Mirror Market

Common user questions regarding AI’s impact on the Flat Safety Mirror Market frequently revolve around manufacturing optimization, quality control enhancement, and the potential integration of AI into the mirrors themselves (i.e., smart mirror functionality). Users often inquire whether AI can reduce production defects, predict equipment failures (predictive maintenance), and streamline complex customization orders efficiently. The key consensus is that while AI does not directly alter the chemical composition of the mirror, it fundamentally transforms the fabrication and application ecosystem. AI’s primary influence lies in improving operational efficiency, personalizing end-user experiences through integrated smart mirror technology, and significantly enhancing quality assurance processes during the cutting, edging, and coating stages, leading to higher throughput and reduced waste.

- AI-Powered Predictive Maintenance: Utilizing machine learning algorithms to analyze real-time sensor data from cutting tables, coating lines, and tempering furnaces, predicting potential mechanical failures before they occur, thereby minimizing costly downtime and ensuring continuous, high-quality production runs.

- Enhanced Quality Control (QC): Implementing AI-driven vision systems (computer vision) for high-speed, automated inspection of mirror surfaces, identifying minute defects, scratches, or coating irregularities far faster and more accurately than human operators, standardizing product quality across batches.

- Optimized Inventory and Supply Chain Management: Using AI to forecast demand variability across different application segments (e.g., automotive vs. construction) and optimizing raw material procurement (glass sheets, silver, backing films) to minimize holding costs and mitigate supply chain risks.

- Smart Mirror Functionality: AI integration enables flat safety mirrors to transition into interactive display systems, utilizing embedded sensors, facial recognition, and data processing capabilities for health monitoring, virtual try-ons in retail, and personalized information delivery in residential settings.

- Design and Customization Automation: AI tools assist architects and designers by rapidly generating optimal mirror cutting patterns from large glass sheets, minimizing material waste (nesting optimization) and accelerating the turnaround time for highly complex, custom-shaped safety mirror orders.

DRO & Impact Forces Of Flat Safety Mirror Market

The Flat Safety Mirror Market is dynamically influenced by a synergistic combination of drivers, restraints, and opportunities, collectively shaped by powerful impact forces rooted in regulatory compliance and technological evolution. Key drivers include stringent safety regulations worldwide, particularly in the European Union and North America, mandating the use of laminated or safety-backed glass in areas prone to human impact. Concurrently, rapid globalization of the construction industry necessitates adherence to common safety benchmarks, thereby expanding the mandatory installation base for these products. Another powerful driver is the aesthetic appeal and superior reflective properties of modern safety mirrors, which are increasingly replacing traditional materials in high-end architectural designs, coupled with the burgeoning market for integrated smart mirror technology.

Restraints primarily involve the high initial production cost associated with laminated and tempered safety mirrors compared to standard float glass mirrors. This cost differential can sometimes deter adoption in price-sensitive markets or low-budget construction projects. Furthermore, the market is susceptible to volatility in the price of key raw materials, especially silver, copper, and specialized polymers used in lamination films (PVB, SGP), which directly impacts manufacturer margins and final product pricing. Technical constraints related to the weight and installation complexity of thicker safety glass components also pose minor hurdles, requiring specialized fitting and handling procedures in certain construction environments.

Opportunities abound in leveraging sustainable manufacturing processes, such as developing lead-free and copper-free safety mirrors (eco-friendly backing), aligning with global green building initiatives. The expansion of niche applications, including marine construction, aerospace interiors, and high-security installations, offers premium market segments for specialized, high-performance safety mirrors. The most significant long-term opportunity lies in the convergence of mirror technology with IoT and AI, transforming the static product into an interactive digital interface (Smart Safety Mirrors). Impact forces governing the market include stringent regulatory regimes, accelerated technological diffusion, and evolving consumer preference towards premium, high-safety architectural components.

Segmentation Analysis

The Flat Safety Mirror market is analyzed based on product type, application, and end-user, revealing distinct consumption patterns and growth dynamics across various sub-segments. Product segmentation distinguishes between the manufacturing techniques used to achieve safety, primarily focusing on Laminated Safety Mirrors, which offer superior shatter protection by preventing fragments from scattering; Safety Backed Mirrors, which utilize a protective film applied to the rear surface; and Tempered Safety Mirrors, which undergo thermal treatment to increase strength and ensure that upon breakage, the glass crumbles into small, relatively harmless granular pieces. The choice of product is heavily dictated by the specific application's required safety standard and budget constraints, with laminated types commanding premium pricing.

Application segmentation highlights the critical role of these mirrors across diverse industries. The Architectural & Construction segment represents the largest market share, driven by mandatory safety standards for building exteriors, interiors, and public access areas. The Automotive segment utilizes safety mirrors for internal components, focusing on minimizing driver injury during accidents. The Retail & Display and Furniture segments rely on safety-backed mirrors for aesthetically pleasing yet compliant products, while the Industrial segment demands highly durable and chemically resistant safety mirrors for specialized environments. Geographical market dynamics often influence the predominant safety mirror type utilized, with developed economies showing a higher propensity for laminated solutions.

- By Product Type:

- Laminated Safety Mirrors (Premium Segment, High Structural Integrity)

- Safety Backed Mirrors (Volume Segment, Cost-Effective)

- Tempered Safety Mirrors (High Strength, Granular Breakage)

- By Application:

- Architectural & Construction (Residential, Commercial, Institutional)

- Automotive (Interior Components, Specialty Vehicles)

- Retail & Display (Showcases, Fitting Rooms)

- Furniture (Wardrobes, Cabinets)

- Industrial and Specialty Applications

- By End-User:

- Residential (Home Renovation, Interior Design)

- Commercial (Offices, Hotels, Fitness Centers)

- Institutional (Schools, Hospitals, Government Buildings)

Value Chain Analysis For Flat Safety Mirror Market

The value chain for the Flat Safety Mirror Market begins with upstream activities involving the extraction and processing of raw materials. These primarily include silica sand, soda ash, limestone, and cullet (recycled glass) for float glass production, alongside specialized chemicals like silver nitrate and copper compounds for the silvering process, and polymeric resins (PVB, EVA) for lamination films. Upstream analysis highlights that the market is heavily reliant on the operational efficiency and pricing strategies of large float glass manufacturers, who often control the initial quality and cost basis of the mirror substrate. Volatility in energy prices also significantly impacts upstream costs, as float glass manufacturing is highly energy-intensive.

Midstream processing involves critical steps such as precision cutting, edging, cleaning, silvering (applying reflective coating), and the final safety enhancement process (lamination, tempering, or safety backing). This stage adds the highest value and is characterized by technological competition, with manufacturers investing heavily in automated, high-precision machinery to ensure uniformity and compliance with safety standards. Distribution channels—the downstream aspect—are predominantly B2B. Direct sales often target large original equipment manufacturers (OEMs) in the automotive and high-volume furniture sectors, alongside large-scale construction firms requiring custom-sized mirrors.

Indirect distribution relies on a network of specialized glass fabricators, distributors, wholesalers, and retail chains (for smaller, standardized products). The increasing complexity of architectural projects means that specifying high-performance safety mirrors often involves collaborations between manufacturers and specialized architectural glass distributors. Effective supply chain integration, minimizing breakage during transit, and ensuring timely delivery of custom orders are critical success factors in the downstream segment, emphasizing efficient logistics and robust warehousing capabilities to serve the highly diverse end-user base effectively.

Flat Safety Mirror Market Potential Customers

Potential customers for the Flat Safety Mirror Market are highly diversified, primarily comprising entities and businesses engaged in construction, interior fit-outs, transportation, and consumer goods manufacturing, all requiring products that meet defined safety and aesthetic specifications. Architectural firms and construction contractors represent the single largest customer base, purchasing substantial volumes for new commercial buildings, high-rise residential towers, and public infrastructure projects like airports and subway systems, where mandated safety compliance dictates material choice. These customers prioritize bulk capacity, certified safety standards, and reliable supply chains for large-scale installations.

Another major category includes Original Equipment Manufacturers (OEMs) in the furniture and fixture industry. These companies integrate safety-backed mirrors into cabinets, wardrobes, and modular kitchen units to meet consumer safety expectations, focusing on cost-efficiency and consistent supply for mass production. Similarly, the automotive industry requires specialized safety mirrors that are resistant to vibration and impact for use in vehicle interiors. Institutional buyers—including governmental bodies, healthcare providers, and educational facilities—are crucial customers, purchasing certified safety mirrors for environments where minimizing occupant injury is non-negotiable, often driven by strict public procurement guidelines.

Finally, specialized retail sectors, such as fitness centers, dance studios, and high-end retail boutiques, represent growing niche customers. For instance, gyms require large, high-definition, impact-resistant safety mirrors that can withstand frequent cleaning and occasional accidental impacts. These customers often prioritize clarity, size customization, and installation expertise. Manufacturers must tailor their product offerings, whether laminated for maximum public safety or safety-backed for interior furnishing, to these varied end-user requirements, utilizing specialized sales teams for each vertical market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1,500 Million |

| Market Forecast in 2033 | $2,800 Million |

| Growth Rate | CAGR 8.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AGC Inc., Saint-Gobain S.A., Guardian Industries (Koch Industries), Nippon Sheet Glass Co., Ltd. (NSG Group), Euroglas GmbH, Taiwan Glass Industry Corporation, Asahi India Glass Limited (AIS), CSG Holding Co., Ltd., Fuyao Glass Industry Group Co., Ltd., Schott AG, Verrerie de Saint Just, Mirrorcle Technologies, Inc., Vitro Architectural Glass, Pilkington (NSG Group), Gentex Corporation, Magna International, Murata Manufacturing Co., Ltd., Corning Incorporated, Sisecam Group, Kibing Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flat Safety Mirror Market Key Technology Landscape

The technological landscape of the Flat Safety Mirror Market is defined by continuous innovation aimed at improving safety performance, durability, environmental sustainability, and integrating smart functionalities. Core technologies involve advanced chemical processes, specifically the "silvering" process, where manufacturers are increasingly adopting copper-free and lead-free formulas (Eco-friendly mirrors) to comply with environmental mandates like REACH and RoHS. This not only makes the mirrors more sustainable but often enhances resistance to corrosion and moisture degradation, significantly extending their lifespan, especially in high-humidity environments like bathrooms and spas.

In terms of safety features, the most advanced technology is the use of high-performance polymer interlayers, such as SentryGlas Plus (SGP), in laminated mirrors. SGP offers exceptional post-breakage strength and stiffness compared to standard Polyvinyl Butyral (PVB), making these mirrors ideal for structural applications or areas prone to high wind loads or blast threats. Furthermore, the application of specialized safety backing films (CAT I and CAT II) continues to be refined, offering superior adhesion and tear resistance, ensuring that even thin glass safety mirrors retain fragments effectively upon impact, meeting stringent consumer product safety standards.

A burgeoning technological frontier involves the integration of microelectronics into the flat safety mirror substrate, giving rise to smart mirrors. This requires utilizing specialized conductive coatings (often transparent Indium Tin Oxide - ITO) and seamless embedding of touch sensors, LED lighting, and display panels without compromising the mirror's reflective quality or safety backing. Manufacturers are focusing on thin-film processing and advanced etching techniques to create functional, interactive surfaces that maintain the aesthetic characteristics and safety requirements expected of a premium flat safety mirror, thus merging traditional manufacturing with cutting-edge IoT capabilities.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand and supply equilibrium of the Flat Safety Mirror Market, influenced by regional economic growth, regulatory frameworks, and cultural preferences in architecture and design.

- Asia Pacific (APAC): Dominates the global market both in terms of volume and growth rate. This is primarily due to rapid population expansion, massive governmental spending on infrastructure development (especially transportation and public housing), and aggressive urbanization across India, China, and Southeast Asian nations. APAC manufacturers benefit from lower operating costs, enabling them to be major global exporters of basic safety-backed mirrors.

- North America: Characterized by high demand for premium, high-specification products, particularly laminated safety mirrors for high-end residential, institutional, and commercial applications. The market is driven by strict enforcement of building codes (e.g., impact safety standards in gyms and public entryways) and a strong consumer willingness to adopt smart mirror technology, pushing innovation in the digital integration sector.

- Europe: Exhibits mature and stable growth, strongly influenced by environmental regulations (e.g., copper-free mandates) and energy efficiency standards in construction. Western Europe focuses on renovation and refurbishment of existing building stock, leading to steady demand for customized, high-quality safety glass solutions that comply with EN standards. Germany, the UK, and France are key consumers, prioritizing sustainability and longevity.

- Latin America (LATAM): Growth is moderate, tied closely to fluctuating macroeconomic conditions and investment in construction projects in Brazil and Mexico. The market primarily utilizes cost-effective safety-backed mirrors, though demand for laminated products is rising in high-traffic commercial zones.

- Middle East and Africa (MEA): Emerging as a high-potential market, driven by large-scale commercial real estate and hospitality projects, particularly in the UAE and Saudi Arabia. These regions demand aesthetically superior safety mirrors for luxurious hotel and retail complexes, focusing on large format, customized architectural glass solutions often imported from European or Asian suppliers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flat Safety Mirror Market.- AGC Inc.

- Saint-Gobain S.A.

- Guardian Industries (Koch Industries)

- Nippon Sheet Glass Co., Ltd. (NSG Group)

- Euroglas GmbH

- Taiwan Glass Industry Corporation

- Asahi India Glass Limited (AIS)

- CSG Holding Co., Ltd.

- Fuyao Glass Industry Group Co., Ltd.

- Schott AG

- Verrerie de Saint Just

- Mirrorcle Technologies, Inc.

- Vitro Architectural Glass

- Pilkington (NSG Group)

- Gentex Corporation

- Magna International

- Murata Manufacturing Co., Ltd.

- Corning Incorporated

- Sisecam Group

- Kibing Group

Frequently Asked Questions

Analyze common user questions about the Flat Safety Mirror market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between laminated and safety-backed flat mirrors?

Laminated safety mirrors use a polymer interlayer (e.g., PVB) bonding two glass sheets, offering superior structural integrity, preventing fragments from separating, and providing enhanced security. Safety-backed mirrors rely on an adhesive film applied to the rear surface, which primarily holds shattered glass pieces against the backing, often used in less structural applications like furniture.

Which regions are driving the highest growth in the Flat Safety Mirror Market?

Asia Pacific (APAC), particularly China and India, is the leading region in terms of both volume and growth rate, fueled by rapid urbanization, significant government investment in infrastructure, and continuous growth in the residential and commercial construction sectors.

How do stringent building safety regulations impact the demand for flat safety mirrors?

Strict building codes, especially in North America and Europe, mandate the use of safety-compliant glass (such as laminated or tempered products) in high-traffic, potentially hazardous areas like public entryways, balconies, and gymnasium walls, thus acting as a primary driver for mandatory market adoption.

What role does technology play in the manufacturing of eco-friendly flat safety mirrors?

Manufacturers are employing advanced chemical deposition processes to produce copper-free and lead-free safety mirrors. This shift aligns with global sustainability initiatives and environmental regulations (like RoHS), improving the mirror’s resistance to corrosion and reducing the environmental footprint during disposal.

Are smart mirrors considered part of the Flat Safety Mirror Market?

Yes, smart mirrors are a high-value, growing sub-segment. They integrate microelectronics and IoT technology (using conductive coatings and embedded sensors) into safety-compliant flat mirror substrates, transforming them into interactive displays while maintaining mandatory safety performance standards.

The global Flat Safety Mirror Market is experiencing significant transformation, driven by a non-negotiable requirement for enhanced safety across all building environments and coupled with the aesthetic demands of modern architecture. The trend towards sustainable production methods and the incorporation of digital technologies into previously static products are shaping the competitive landscape. Key industry leaders are strategically investing in advanced lamination technologies and expanding production capacity in high-growth regions, especially within Asia Pacific, to capitalize on the increasing construction volume and regulatory mandates. The core challenge of maintaining cost stability amidst fluctuating raw material prices is continuously addressed through supply chain optimization and increased operational automation.

Future growth trajectories are heavily reliant on the adoption rate of smart mirror solutions, which offer manufacturers substantial margins and differentiation opportunities beyond basic safety functionality. As building codes worldwide continue to evolve towards higher safety standards, particularly concerning human impact and natural disaster resilience, the demand for certified, high-performance laminated and tempered safety mirrors will only intensify. This regulatory pressure, combined with consumer preference for durable and aesthetically pleasing products, ensures a sustained positive outlook for the market over the 2026-2033 forecast period, cementing the Flat Safety Mirror as a cornerstone component in modern safe construction practices globally.

The integration of safety mirrors into automotive applications, particularly in advanced driver-assistance systems (ADAS) and sophisticated interior designs, also represents a notable area of specialized growth. These applications require mirrors with specific optical clarity and resilience, often incorporating specialized coatings for anti-fog or self-cleaning properties, further diversifying the technological requirements within the market. Manufacturers who successfully balance high safety certification requirements with customized technological solutions for distinct vertical markets are best positioned to capture market share and navigate the evolving technological and regulatory environment effectively.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager