Flatbed Die Cutting Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439418 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Flatbed Die Cutting Machines Market Size

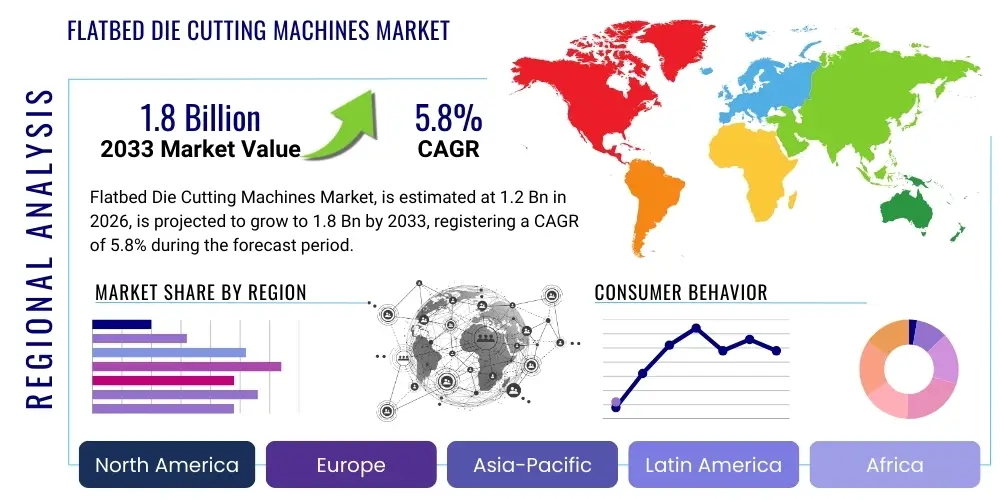

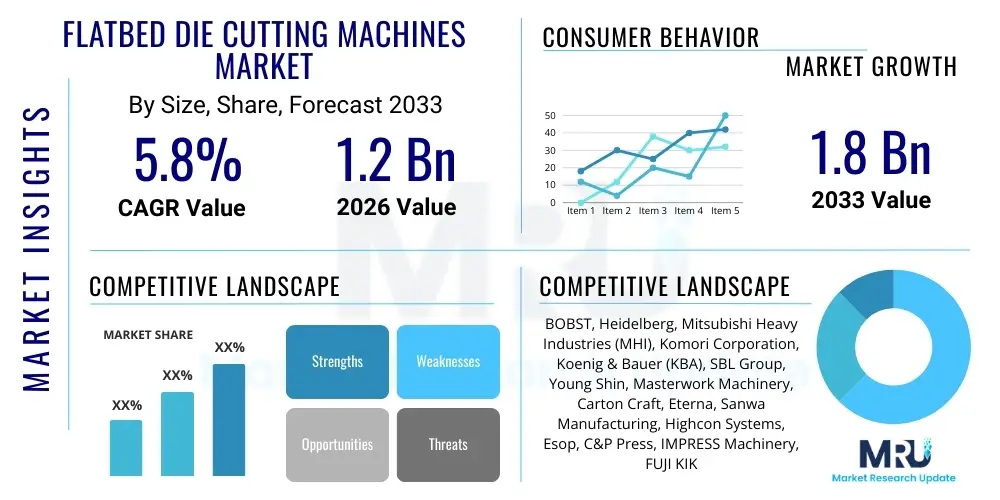

The Flatbed Die Cutting Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.8 Billion by the end of the forecast period in 2033.

Flatbed Die Cutting Machines Market introduction

The Flatbed Die Cutting Machines market constitutes a vital segment within the industrial machinery sector, playing an indispensable role in the precision manufacturing and finishing of diverse materials across a multitude of industries. These sophisticated machines are engineered to perform accurate cutting, creasing, scoring, and perforating operations on various substrates, including paper, paperboard, corrugated board, plastics, textiles, leather, rubber, and even certain composite materials. The fundamental principle involves a flatbed platen that exerts controlled pressure on a custom-designed cutting die, which then precisely cuts or impresses the desired pattern onto the material. This technology is foundational for creating intricate shapes, structural components, and decorative elements that are critical for product functionality and aesthetic appeal. The evolution of flatbed die cutting machines has been marked by continuous innovation, leading to enhanced automation, speed, and versatility, thereby cementing their position as essential assets in modern production lines seeking high-quality and repeatable output.

The major applications of flatbed die cutting machines are extensive and deeply embedded in several high-growth industries. Foremost among these is the packaging sector, where they are indispensable for manufacturing folding cartons, corrugated boxes, blister packs, and specialized protective packaging for consumer goods, food and beverages, pharmaceuticals, and the rapidly expanding e-commerce industry. In the printing industry, these machines are crucial for post-press finishing, enabling the creation of uniquely shaped brochures, labels, business cards, greeting cards, and promotional materials that demand precision and visual appeal. Beyond these traditional applications, flatbed die cutters are increasingly utilized in the automotive sector for interior trim components, gaskets, and insulation, in the electronics industry for precision cutting of insulating films and flexible circuits, and in the textile and footwear industries for pattern cutting of fabrics and leather. The ability to handle both rigid and flexible materials with exceptional accuracy makes them a cornerstone for advanced manufacturing processes.

The benefits derived from employing flatbed die cutting machines are multifaceted and significantly contribute to their widespread adoption. These include unparalleled precision and repeatability, ensuring consistent quality across massive production runs and minimizing material waste through optimized nesting patterns. They offer high production speeds, drastically improving throughput and operational efficiency, thereby reducing lead times. Furthermore, their versatility in handling a broad spectrum of material types and thicknesses, coupled with the ability to execute complex designs, provides manufacturers with significant flexibility in product development and customization. These advantages directly translate into cost-effectiveness through reduced labor requirements, optimized material utilization, and enhanced product quality, ultimately delivering a competitive edge in various markets. Driving factors for market growth encompass the global expansion of packaging consumption, fueled by e-commerce and changing consumer preferences for high-quality, customized products, alongside the ongoing push for automation and efficiency across manufacturing industries worldwide.

Flatbed Die Cutting Machines Market Executive Summary

The Flatbed Die Cutting Machines Market is experiencing dynamic growth, propelled by robust business trends emphasizing automation, precision, and efficiency across diverse industrial applications. A key business trend is the increasing investment in advanced automated flatbed die-cutting solutions by manufacturers seeking to streamline production workflows, reduce labor costs, and meet the escalating demand for high-quality, intricately cut products. The shift towards shorter production runs and personalized packaging, driven by evolving consumer preferences and the proliferation of e-commerce, has further intensified the need for flexible and rapidly reconfigurable die-cutting machinery. Furthermore, industry players are focusing on developing machines capable of handling a wider range of sustainable materials, aligning with global efforts towards eco-friendlier manufacturing practices. This strategic pivot towards technologically advanced and environmentally conscious solutions underscores a market keen on innovation and operational excellence, directly impacting product development cycles and market offerings.

From a regional perspective, the market exhibits varied growth trajectories and demand patterns. Asia Pacific stands out as the largest and most rapidly expanding market, primarily attributed to the region's accelerated industrialization, the booming manufacturing sector in countries such as China, India, and Vietnam, and the exponential growth of e-commerce. Significant investments in infrastructure and factory automation, coupled with rising consumer disposable incomes, are propelling the demand for sophisticated packaging and printed materials. North America and Europe represent mature markets, characterized by a steady demand for technological upgrades, replacement of older machinery, and a strong emphasis on high-precision, automated systems for specialized applications in packaging, automotive, and electronics. These regions are also pioneers in adopting Industry 4.0 concepts, integrating IoT and AI into their die-cutting operations. Meanwhile, Latin America and the Middle East & Africa are emerging as promising markets, driven by developing manufacturing bases, increasing urbanization, and growing consumer markets that are gradually adopting modern industrial processes.

Segmentation trends within the flatbed die cutting machines market further reveal crucial insights. The automatic flatbed die cutting machine segment is projected to dominate, reflecting the industry's unwavering commitment to higher productivity, reduced manual intervention, and enhanced operational safety. In terms of application, the packaging sector, particularly folding carton and corrugated packaging, continues to hold the largest market share, directly benefiting from global consumer goods demand and the e-commerce boom. However, significant growth is also observed in non-traditional applications such as automotive components, electronics, and textiles, indicating market diversification. Regarding materials processed, while paper and paperboard remain foundational, there is an increasing demand for machines capable of efficiently handling plastics, rubber, composites, and specialized films, catering to evolving product requirements. These trends collectively illustrate a market that is not only expanding in volume but also undergoing a profound transformation towards higher technological integration, greater flexibility, and broader application scope to meet complex global manufacturing challenges.

AI Impact Analysis on Flatbed Die Cutting Machines Market

User inquiries concerning the influence of Artificial Intelligence on the Flatbed Die Cutting Machines Market predominantly revolve around themes of operational optimization, predictive capabilities, enhanced customization, and the potential for paradigm shifts in manufacturing efficiency. Common questions explore how AI can elevate the precision and speed of cutting processes, minimize material waste through intelligent nesting algorithms, and reduce machine downtime via predictive maintenance. Users are also keen to understand AI's role in facilitating rapid design changes for short-run production, improving quality control through real-time anomaly detection, and integrating these machines into broader smart factory ecosystems. Underlying these inquiries are expectations of increased productivity, cost savings, and a competitive advantage, alongside concerns about the complexity and cost of AI implementation, the requirement for specialized technical skills, and the impact on traditional operational roles. The collective sentiment points towards AI being a significant catalyst for the next generation of intelligent, autonomous, and highly efficient flatbed die-cutting solutions.

- Predictive Maintenance and Downtime Reduction: AI-driven analytics can continuously monitor machine performance parameters, such as motor vibrations, temperature fluctuations, and pressure readings. By analyzing this real-time data against historical patterns, AI algorithms can accurately predict potential equipment failures before they occur, enabling proactive maintenance scheduling and significantly reducing unscheduled downtime, thereby maximizing operational uptime and overall equipment effectiveness (OEE).

- Optimized Material Utilization and Waste Reduction: Advanced AI algorithms can process complex geometric data of cutting layouts to determine the most efficient nesting patterns on a material sheet or roll. This intelligent optimization minimizes the amount of scrap material generated during the die-cutting process, leading to substantial cost savings, reduced environmental impact, and improved resource efficiency, particularly critical for expensive or specialized materials.

- Enhanced Quality Control and Defect Detection: Integrating AI with high-resolution vision systems allows for real-time inspection of cut materials. AI models can learn to identify subtle imperfections, misalignments, or material flaws that might be missed by human operators or traditional sensors. This proactive defect detection ensures higher product quality, reduces the incidence of rework or scrap, and upholds stringent quality standards across production batches.

- Adaptive Process Control and Precision: AI enables flatbed die cutting machines to dynamically adjust cutting parameters, such as pressure, speed, and blade depth, based on real-time feedback from sensors and the specific properties of the material being processed. This adaptive control ensures consistent cutting precision regardless of variations in material thickness, density, or environmental conditions, leading to superior finish quality and increased operational consistency.

- Streamlined Design-to-Production Workflow: AI can facilitate a more seamless transition from design to manufacturing. By analyzing CAD designs, AI can automatically generate or optimize cutting paths, suggest appropriate dies, and even adapt designs for specific machine capabilities. This reduces setup times, accelerates prototyping, and enables quicker turnaround for customized or short-run jobs, making the production process significantly more agile and responsive to market demands.

- Automated Job Scheduling and Resource Management: AI systems can analyze production schedules, machine availability, material inventory, and order priorities to optimize job sequencing and resource allocation. This leads to more efficient utilization of machine capacity, reduces bottlenecks, and improves overall production planning and execution, contributing to a more responsive and cost-effective manufacturing operation.

- Operator Assistance and Training: AI-powered interfaces can provide operators with intelligent guidance, troubleshooting support, and predictive insights, simplifying complex operations and reducing the learning curve for new personnel. This can enhance operational safety, improve diagnostic capabilities, and facilitate on-the-job training through augmented reality or interactive simulations.

- Energy Efficiency Optimization: AI algorithms can analyze energy consumption patterns of flatbed die cutting machines and suggest or implement optimizations to reduce power usage without compromising performance. This might involve optimizing idle times, adjusting motor speeds, or fine-tuning hydraulic systems, leading to lower operating costs and a reduced carbon footprint.

DRO & Impact Forces Of Flatbed Die Cutting Machines Market

The Flatbed Die Cutting Machines Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, each contributing to the market's trajectory and the overall impact forces at play. A primary driver is the unprecedented growth of the global e-commerce sector, which inherently fuels an escalating demand for diverse, customized, and high-quality packaging solutions. As online retail expands, so does the need for efficiently produced folding cartons, corrugated boxes, and protective inserts, directly boosting the adoption of advanced die-cutting technologies. Concurrently, the increasing global consumption of consumer goods, particularly in emerging economies, necessitates a constant supply of aesthetically appealing and functional packaging, further intensifying market demand. The overarching industry trend towards automation in manufacturing, driven by the desire to enhance productivity, reduce labor costs, and improve precision and safety, also acts as a powerful catalyst for the adoption of automatic flatbed die cutting machines across various sectors. These factors collectively create a robust demand environment for die-cutting solutions that are both efficient and versatile.

Despite these strong drivers, the market faces several notable restraints that can impede its growth. The substantial initial capital investment required for acquiring high-end, automated flatbed die cutting machines can be a significant barrier for small and medium-sized enterprises (SMEs), particularly in developing regions with limited access to financing. Furthermore, the operational complexity of these advanced machines often necessitates a highly skilled workforce for both operation and maintenance, posing challenges related to labor availability and training costs. Economic uncertainties, global supply chain disruptions, and geopolitical instabilities can lead to reduced industrial investments, impacting machinery sales. The emergence of alternative cutting technologies, such as laser cutting, waterjet cutting, and digital cutting tables, though not always direct competitors due to differing material capabilities and throughputs, can exert competitive pressure in specific niche applications, especially for very short runs or highly intricate designs on certain materials. Lastly, growing environmental concerns regarding material waste generated during the die-cutting process, despite optimization efforts, continue to be a challenge requiring ongoing innovation in sustainable practices and material recovery.

Amidst these challenges, numerous opportunities are poised to drive future market expansion and innovation. The escalating demand for short-run, personalized, and on-demand packaging and printing solutions presents a fertile ground for flatbed die cutters, which excel in flexibility, quick changeovers, and cost-effectiveness for varied batch sizes. Furthermore, the expanding array of applications in non-traditional sectors such as medical device manufacturing (for sterile packaging and components), advanced electronics (for flexible circuits and insulation), and specialized automotive components offers new avenues for market penetration and product diversification. The ongoing integration of Industry 4.0 principles, including the Internet of Things (IoT) for real-time monitoring and Artificial Intelligence (AI) for predictive maintenance and process optimization, presents significant opportunities for developing smarter, more autonomous, and interconnected die-cutting machines. Moreover, the rapid industrialization and burgeoning consumer markets in emerging economies represent substantial untapped potential, offering strategic market players avenues for growth through targeted product offerings and localized support. Strategic partnerships, continuous technological innovation in material processing, and the development of energy-efficient and modular machine designs will be critical for capitalizing on these opportunities and shaping the future competitive landscape. The cumulative impact forces thus push the market towards greater automation, precision, and integration, with a strong emphasis on adaptability and sustainability.

Segmentation Analysis

The Flatbed Die Cutting Machines Market is meticulously segmented to provide a granular understanding of its diverse components, allowing for comprehensive analysis of market dynamics, competitive landscapes, and future growth trajectories. This segmentation facilitates a detailed examination of various machine configurations, operational methodologies, specific industry applications, the range of materials processed, and the geographical distribution of demand. Such a structured approach is essential for identifying distinct market niches, understanding the varying needs of different end-users, and enabling manufacturers and suppliers to strategically align their product development and market penetration efforts. The insights derived from this detailed segmentation are pivotal for informed decision-making, investment strategies, and anticipating shifts in consumer and industrial demands across the global market. Each segment and sub-segment reflects unique technological requirements, economic drivers, and operational preferences that collectively define the market's intricate structure.

- By Type:

- Manual Flatbed Die Cutting Machines: These machines require significant human intervention for material feeding, die placement, and finished product retrieval. They are typically characterized by lower capital cost and simpler mechanics, making them suitable for small-scale operations, prototyping, educational purposes, or specialized tasks where high precision over high volume is prioritized. Their robust construction often ensures longevity, and their simplicity allows for easier troubleshooting.

- Semi-Automatic Flatbed Die Cutting Machines: Offering a balance between manual operation and full automation, these machines incorporate automated features such as automatic sheet feeders or delivery systems, but still necessitate manual involvement for specific stages like loading dies or stacking finished goods. They provide improved throughput and consistency compared to manual machines, making them ideal for medium-volume production where cost-efficiency and some level of automation are desired without the full investment in a completely automatic system.

- Automatic Flatbed Die Cutting Machines: Representing the pinnacle of efficiency and precision, these machines are fully integrated systems that automate the entire die-cutting process from material feeding and cutting to waste stripping and finished product stacking. Designed for high-volume production, they offer superior speed, accuracy, and reduced labor costs. They are often equipped with advanced control systems, quick changeover capabilities, and sometimes integrated quality control features, making them indispensable for large-scale packaging and printing operations requiring consistent quality and high throughput.

- By Operation Mode:

- Sheet-to-Sheet: This mode processes individual sheets of material, where each sheet is fed, cut, and then ejected. It is the most common operation mode for flatbed die cutting machines, particularly suitable for rigid and semi-rigid materials like paperboard, corrugated board, and plastic sheets used in packaging, printing, and display materials. This method allows for precise registration and often accommodates thicker materials.

- Roll-to-Roll: In this mode, material is fed from a continuous roll, processed by the die cutter, and then rewound onto another roll or cut into individual pieces. This is highly efficient for flexible materials and applications such as labels, flexible packaging films, and certain textiles. It minimizes waste by optimizing material usage across the continuous web and is ideal for very high-volume production.

- By Application:

- Packaging (Folding Carton, Corrugated Boxes, Blister Packaging): The dominant application segment, encompassing the creation of a vast array of packaging solutions for food & beverages, pharmaceuticals, cosmetics, consumer electronics, and e-commerce. Precision cutting and creasing are critical for the structural integrity and aesthetic appeal of these packaging types.

- Printing (Labels, Brochures, Promotional Materials): Essential for post-press finishing in commercial printing, creating custom shapes, windows, and perforations for labels, business cards, brochures, and other marketing collateral, enhancing visual impact and functionality.

- Gaskets & Industrial Components: Used for precision cutting of materials like rubber, cork, foam, and specialized composites to produce seals, spacers, insulators, and other critical components for automotive, aerospace, and general industrial machinery.

- Textiles & Leather: For pattern cutting in the apparel, footwear, upholstery, and automotive interior industries, enabling efficient and accurate shaping of fabrics, non-wovens, and leather goods.

- Automotive: Specific applications include cutting interior trim, insulation, sound dampening materials, and various functional components with high precision.

- Electronics: Used for cutting insulating films, flexible circuits, electromagnetic shielding, and other precision components for electronic devices.

- Other Applications: Includes specialized uses in medical device manufacturing (e.g., disposable components, sterile packaging), aerospace, construction (e.g., insulation materials), and bespoke creative projects requiring intricate material shaping.

- By End-Use Industry:

- Packaging Industry: The primary consumer, driven by global demand for consumer goods, e-commerce growth, and the need for diverse packaging formats.

- Printing & Publishing Industry: For value-added post-press services, custom print jobs, and specialized finishes.

- Automotive Industry: For manufacturing internal and external vehicle components requiring precise material conversion.

- Electronics Industry: For components, insulators, and flexible circuits in various electronic devices.

- Textile & Apparel Industry: For efficient pattern cutting in garment manufacturing, footwear, and technical textiles.

- Other Manufacturing Industries: Includes sectors like medical, construction, advertising, and general industrial manufacturing that require precision cutting for their specific product lines.

- By Material Processed:

- Paper & Paperboard: The most widely processed material, fundamental for packaging (folding cartons) and printing applications.

- Corrugated Board: For heavy-duty packaging, shipping boxes, and point-of-sale displays, requiring robust cutting and creasing capabilities.

- Plastics: Including PET, PVC, PP, polycarbonate sheets used for blister packaging, clamshells, clear boxes, and various industrial components.

- Rubber: Essential for manufacturing gaskets, seals, and vibration dampeners due to its flexibility and sealing properties.

- Textiles: Fabrics, non-woven materials, technical textiles for apparel, automotive interiors, and industrial filters.

- Foam: For packaging inserts, cushioning, insulation, and protective components, offering shock absorption properties.

- Composites: Advanced materials like fiberglass, carbon fiber prepregs, and other layered materials for specialized industrial and aerospace applications, demanding high cutting force.

- Other Materials: Encompasses a range of specialized materials such as leather, cork, magnetic sheeting, adhesive films, and abrasive papers, catering to niche market demands.

- By Regional Outlook:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Flatbed Die Cutting Machines Market

The value chain of the Flatbed Die Cutting Machines Market is an intricate network encompassing several critical stages, from the procurement of raw materials and sophisticated components to the manufacturing, distribution, and comprehensive aftermarket services provided to end-users. This chain begins with upstream activities, where a diverse array of suppliers provides essential inputs. These include specialized steel for constructing robust machine frames and precision die boards, advanced electronic components for control panels, programmable logic controllers (PLCs), and human-machine interfaces (HMIs). High-performance motors, hydraulic and pneumatic systems, sensors, and cutting blades are also critical inputs, sourced from global specialists in industrial automation and precision engineering. The quality, reliability, and technological sophistication of these upstream components directly dictate the performance, durability, and innovation potential of the final die-cutting machinery. Strong, collaborative relationships with these upstream suppliers are paramount for machine manufacturers to ensure consistent quality, manage costs, and drive technological advancements in their products, ultimately influencing their competitive standing in the global market.

Following the upstream supply, the core manufacturing and assembly phase is where the flatbed die cutting machines are meticulously constructed. Leading machine manufacturers invest significantly in research and development to design innovative models that offer enhanced speed, precision, automation, and material handling capabilities. This stage involves the precise assembly of thousands of components, rigorous quality control checks, and extensive testing to ensure that each machine meets stringent performance standards and safety regulations. Manufacturers often specialize in producing specific types of machines, such as automatic, semi-automatic, or large-format models, catering to different industrial scales and application requirements. After the manufacturing process is complete, the machines move into the distribution phase. This involves both direct and indirect sales channels. Direct channels see manufacturers selling directly to large corporate clients or key accounts, often offering customized solutions, installation, and comprehensive service packages. This direct approach facilitates close client relationships and tailored support, particularly for complex integrations.

Indirect distribution channels, conversely, involve a network of authorized distributors, agents, and resellers who play a crucial role in extending market reach, especially into diverse geographical regions and to small and medium-sized enterprises (SMEs). These intermediaries typically provide localized sales support, technical expertise, installation services, operator training, and essential after-sales support, including spare parts and maintenance. Their ability to offer immediate, local assistance is often a decisive factor for customers. Downstream analysis focuses on the deployment and utilization of these machines by end-users across various industries such as packaging, printing, automotive, electronics, and textiles. The effectiveness of the value chain is ultimately measured by the machine's ability to seamlessly integrate into an end-user's production line, meet specific operational demands, and contribute to overall productivity and product quality. Robust after-sales service, including regular maintenance, technical support, and the provision of consumables and replacement dies, is a critical component of the downstream segment, ensuring continuous machine performance, maximizing uptime, and fostering long-term customer loyalty in a highly competitive market environment. The entire value chain is constantly evolving, driven by technological advancements, market demands, and global economic shifts.

Flatbed Die Cutting Machines Market Potential Customers

The market for Flatbed Die Cutting Machines caters to a broad and diverse spectrum of potential customers, each with unique requirements for precision material conversion and finishing. At the forefront of this customer base is the omnipresent packaging industry. Companies specializing in the production of folding cartons for consumer goods, durable corrugated boxes for shipping and logistics, and intricate blister packaging for pharmaceuticals and electronics represent the largest and most consistent demand segment. These customers rely heavily on flatbed die cutters to achieve the precise shapes, clean creases, and accurate perforations vital for creating functional, protective, and visually appealing packaging that drives brand recognition and ensures product integrity during transit. The relentless growth of e-commerce, which mandates an endless supply of various packaging types, further solidifies this industry as a cornerstone customer for flatbed die cutting machinery, driving demand for both high-volume automatic systems and versatile machines capable of handling customized, short-run jobs efficiently.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BOBST, Heidelberg, Mitsubishi Heavy Industries (MHI), Komori Corporation, Koenig & Bauer (KBA), SBL Group, Young Shin, Masterwork Machinery, Carton Craft, Eterna, Sanwa Manufacturing, Highcon Systems, Esop, C&P Press, IMPRESS Machinery, FUJI KIKAI KOGYO CO., LTD., Shanghai Dragon, Hanjiang, Iijima MFG. CO., LTD., Standard Paper Box Machine Co., Guangdong Huitong, Wenzhou Guangming, Jinan Presstek, Dalian Light Industry Machinery, Brausse Group, Tunkers Maschinenbau GmbH, Cerutti Packaging Equipment S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flatbed Die Cutting Machines Market Key Technology Landscape

The Flatbed Die Cutting Machines Market is profoundly shaped by an evolving and sophisticated technology landscape, continually pushing the boundaries of precision, speed, automation, and material versatility. At the core of this landscape are advancements in mechanical engineering, particularly the integration of high-performance servo motor drives and precision gear systems. These components enable exceptionally accurate control over platen movement, pressure application, and material feeding, ensuring consistent and repeatable cutting, creasing, and stripping operations. The development of robust, vibration-dampening machine frames, often constructed from specialized alloys, further enhances stability and precision, allowing for processing a wide array of materials from delicate films to thick corrugated boards with minimal deviation. Furthermore, sophisticated pressure control systems, capable of minute adjustments, are crucial for adapting to varying material thicknesses and ensuring clean, burr-free cuts, contributing significantly to the overall quality of the finished product. These fundamental mechanical and control technologies form the bedrock upon which modern flatbed die cutters are built, dictating their primary operational characteristics and performance benchmarks.

Looking towards the future, the market is rapidly embracing Industry 4.0 paradigms, with a strong emphasis on IoT (Internet of Things) connectivity, Artificial Intelligence (AI) integration, and enhanced cybersecurity. IoT sensors embedded throughout the machine monitor a myriad of operational parameters, including motor load, temperature, vibration, and material flow, transmitting real-time data for comprehensive performance analysis and predictive maintenance. AI algorithms analyze this data to anticipate potential machine failures, optimize cutting parameters for different materials, and even suggest ideal job sequencing to maximize throughput and energy efficiency. Cloud connectivity enables remote monitoring, diagnostics, and software updates, ensuring machines operate at peak performance globally. Furthermore, advancements in die-making technologies, such as laser-cut dies and flexible dies, contribute to faster production of cutting tools and support more intricate designs. The development of advanced stripping and blanking units, capable of removing waste efficiently and separating individual products, also plays a crucial role. These technological innovations collectively propel the flatbed die cutting machines market towards greater intelligence, autonomy, and adaptability, securing its essential role in the future of precision manufacturing and packaging.

Regional Highlights

- North America: This region represents a mature yet consistently innovative market for flatbed die cutting machines, characterized by a strong emphasis on advanced automation, digital integration, and high-precision machinery. The demand is primarily driven by a robust packaging industry, particularly for consumer goods, processed foods, and the expansive e-commerce sector, which necessitates efficient and high-quality packaging solutions. The region also boasts a significant printing industry and specialized manufacturing sectors (automotive, electronics) that require sophisticated die-cutting capabilities. Investment trends focus on upgrading existing machinery with intelligent features and integrating machines into smart factory ecosystems to enhance productivity and reduce operational costs.

- Europe: As another highly developed market, Europe is a key innovation hub for flatbed die cutting technology, distinguished by stringent quality standards, a strong focus on sustainability, and a demand for high-performance, energy-efficient machines. Countries such as Germany, Italy, and the UK are major contributors, driven by a well-established manufacturing base in packaging, commercial printing, and specialized industrial components. The region's emphasis on reducing environmental footprint also drives the adoption of machines capable of minimizing material waste and processing eco-friendly substrates. Ongoing R&D in automation and digitalization, coupled with a focus on Industry 4.0 principles, maintains Europe's competitive edge.

- Asia Pacific (APAC): The Asia Pacific region stands as the largest and most rapidly expanding market globally for flatbed die cutting machines. This explosive growth is primarily fueled by rapid industrialization, the burgeoning manufacturing sectors in economies like China, India, Japan, and Southeast Asian countries, and the unparalleled expansion of e-commerce. Significant investments in new production capacities, alongside the modernization of existing factories, are propelling the demand for both automatic and semi-automatic machines across the packaging, printing, and electronics industries. The region offers immense growth opportunities due to a large consumer base, increasing disposable incomes, and the continuous shift towards packaged goods, making it a critical market for global manufacturers.

- Latin America: This region is an emerging market for flatbed die cutting machines, exhibiting steady growth influenced by increasing industrialization, urbanization, and rising consumer demand for packaged products. Countries such as Brazil, Mexico, and Argentina are key markets, driven by the expansion of local manufacturing bases and foreign direct investments. While cost-efficiency remains a significant consideration, there is a growing inclination towards adopting more automated and efficient machinery to enhance production capabilities and meet regional demand for improved packaging and printed materials. The market here is characterized by a blend of new installations and upgrades to existing facilities.

- Middle East & Africa (MEA): The MEA region represents a developing market with nascent but rapidly expanding manufacturing and packaging industries. The ongoing efforts towards economic diversification away from oil dependence, coupled with significant investments in infrastructure and industrial development, are creating new opportunities for the adoption of flatbed die cutting machines. Countries like Saudi Arabia, UAE, and South Africa are leading the charge, seeking modern machinery to enhance local production capabilities, particularly in packaging, printing, and construction materials. The demand here is driven by the need to build robust industrial ecosystems and cater to a growing consumer base, with a focus on acquiring reliable and efficient equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flatbed Die Cutting Machines Market.- BOBST

- Heidelberg

- Mitsubishi Heavy Industries (MHI)

- Komori Corporation

- Koenig & Bauer (KBA)

- SBL Group

- Young Shin

- Masterwork Machinery

- Carton Craft

- Eterna

- Sanwa Manufacturing

- Highcon Systems

- Esop

- C&P Press

- IMPRESS Machinery

- FUJI KIKAI KOGYO CO., LTD.

- Shanghai Dragon

- Hanjiang

- Iijima MFG. CO., LTD.

- Standard Paper Box Machine Co.

- Guangdong Huitong

- Wenzhou Guangming

- Jinan Presstek

- Dalian Light Industry Machinery

- Brausse Group

- Tunkers Maschinenbau GmbH

- Cerutti Packaging Equipment S.p.A.

Frequently Asked Questions

What is a flatbed die cutting machine and how does it work?

A flatbed die cutting machine is an industrial apparatus designed for precise cutting, creasing, scoring, and perforating various sheet-fed materials such as paper, cardboard, plastics, and textiles into specific shapes and designs. It operates by utilizing a flatbed platen that applies intense, controlled pressure to a custom-made steel rule die, which contains sharpened blades and creasing lines. This die is pressed against the material, forcing the blades to cut through or into the substrate and the creasing rules to create folds. This mechanical action ensures highly accurate and repeatable results, making it essential for producing intricate components and structured packaging across diverse manufacturing applications with consistent quality and high throughput.

Which industries primarily use flatbed die cutting machines?

Flatbed die cutting machines are indispensable across numerous industries due to their versatility and precision. The packaging industry is the largest consumer, employing them extensively for manufacturing folding cartons, corrugated boxes, and blister packaging for consumer goods, food, and pharmaceuticals. The printing industry heavily relies on them for post-press finishing, creating custom-shaped brochures, labels, and promotional materials. Additionally, they are crucial in the automotive sector for interior trims, gaskets, and insulation; in electronics for cutting insulating films and flexible circuits; and in the textile and footwear industries for precise pattern cutting. Their ability to process diverse materials with high accuracy makes them vital for any sector requiring intricate material conversion.

What are the main advantages of automatic flatbed die cutting machines?

Automatic flatbed die cutting machines offer substantial advantages, particularly for high-volume and high-precision manufacturing. Their primary benefits include superior operational efficiency due to full automation of material feeding, cutting, waste stripping, and finished product stacking, minimizing human intervention. This leads to significantly increased throughput, reduced labor costs, and enhanced production speeds. Furthermore, they deliver exceptional precision and repeatability, ensuring consistent product quality across extensive production runs. Many models integrate advanced control systems and digital workflows, allowing for rapid job changeovers, optimized material usage to reduce waste, and real-time monitoring, ultimately boosting overall equipment effectiveness and delivering a strong return on investment.

How is AI impacting the flatbed die cutting machines market?

Artificial Intelligence is profoundly impacting the flatbed die cutting machines market by introducing a new era of smart manufacturing capabilities. AI-driven predictive maintenance systems analyze machine performance data to forecast potential failures, enabling proactive servicing and dramatically reducing unscheduled downtime. AI algorithms optimize cutting paths and material nesting, leading to significant reductions in material waste and increased resource efficiency. Integrated AI vision systems facilitate real-time quality control, instantly identifying and correcting imperfections. Moreover, AI enhances adaptive process control, allowing machines to dynamically adjust parameters based on material properties, and streamlines design-to-production workflows for customized orders, resulting in higher precision, greater agility, and substantial cost savings across the manufacturing process.

What are the key factors driving the growth of the flatbed die cutting machines market?

Several pivotal factors are driving the robust growth of the flatbed die cutting machines market. The exponential expansion of the global e-commerce sector is a primary catalyst, fueling an immense demand for diverse and customized packaging solutions. Concurrently, the increasing global consumption of consumer goods necessitates a continuous supply of high-quality, aesthetically pleasing packaging, further boosting market demand. The pervasive trend of industrial automation, aimed at enhancing productivity, reducing labor costs, and improving precision across manufacturing sectors, is another significant driver. Furthermore, ongoing technological advancements in machine design, such as increased operational speeds, enhanced material handling, and greater digital integration, coupled with a growing emphasis on sustainable packaging materials, collectively propel market expansion and innovation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager