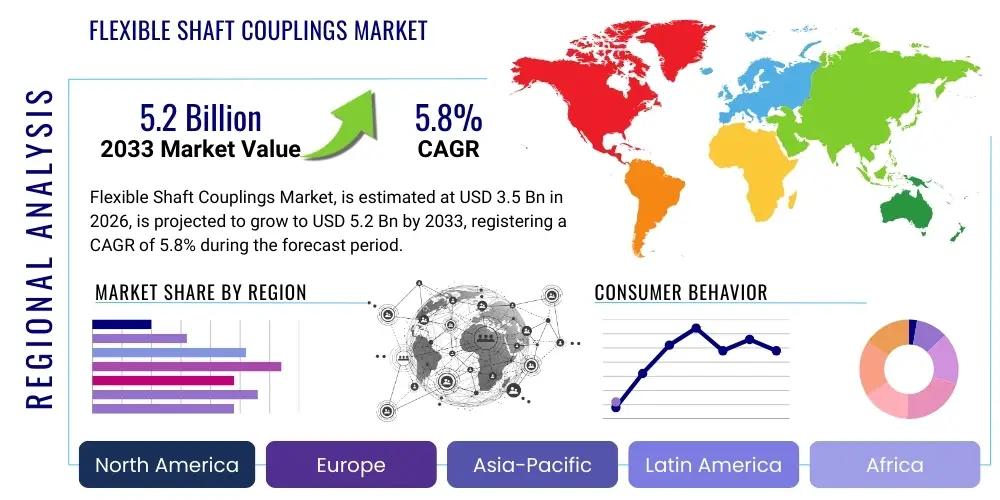

Flexible Shaft Couplings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437352 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Flexible Shaft Couplings Market Size

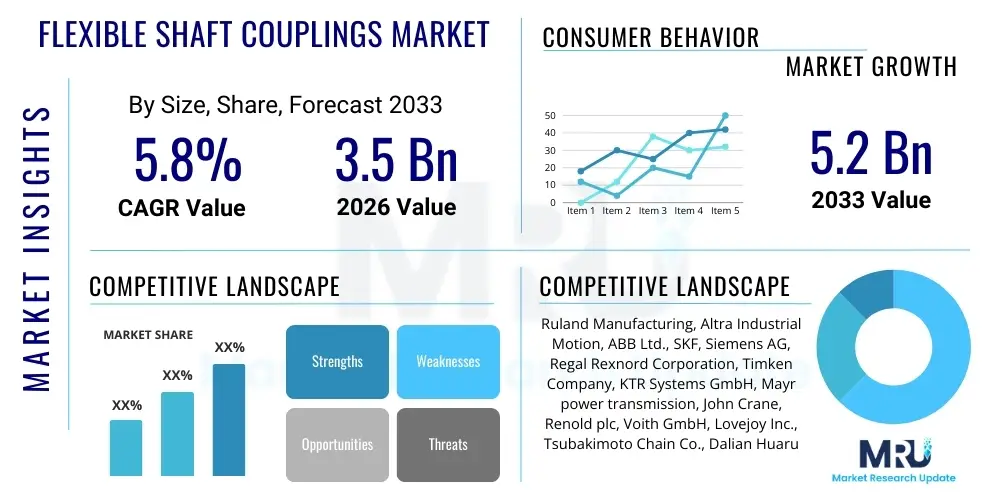

The Flexible Shaft Couplings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $3.5 Billion in 2026 and is projected to reach $5.2 Billion by the end of the forecast period in 2033.

Flexible Shaft Couplings Market introduction

Flexible shaft couplings are mechanical devices used to connect two shafts together for the purpose of transmitting power while accommodating various forms of misalignment, including angular, parallel, and axial offsets. These components are essential in complex mechanical systems because they dampen shock loads and vibration, protecting connected equipment, such as motors, pumps, and gearboxes, from premature wear and failure. The design flexibility of these couplings—ranging from elastomeric jaw couplings that handle high damping to metallic disc and beam couplings optimized for high precision and torque—allows their deployment across a vast spectrum of industrial applications.

The primary applications of flexible shaft couplings span across major industrial sectors, including factory automation, robotics, power generation, oil and gas, and machine tools. Their necessity stems from the practical impossibility of achieving perfect alignment between rotating shafts in real-world operating environments, especially under thermal expansion or dynamic load conditions. Key benefits include extended equipment lifespan, reduced noise levels, improved operational efficiency, and minimized downtime associated with maintenance. The selection of a coupling is critically dependent on the specific application requirements concerning torque capacity, speed, stiffness, and the degree of misalignment anticipated.

Driving factors for market expansion are intrinsically linked to global industrial trends, notably the proliferation of automation technologies, the increasing adoption of robotics in manufacturing processes (Industry 4.0), and the stringent demand for high-precision machinery. Furthermore, the push towards energy efficiency and predictive maintenance systems necessitates couplings capable of reliable performance over extended periods, often leading to the adoption of advanced material couplings and those integrated with sensor technology for condition monitoring. The growing demand for specialized couplings in niche sectors, such as medical devices and aerospace, further contributes to sustained market growth.

Flexible Shaft Couplings Market Executive Summary

The Flexible Shaft Couplings Market is characterized by robust growth driven primarily by the global surge in industrial automation and modernization initiatives across developing economies. Business trends indicate a strong shift towards highly engineered, low-maintenance couplings that offer superior torque density and operational precision, catering specifically to the sophisticated demands of CNC machinery and advanced robotic systems. Furthermore, the market is experiencing consolidation among key players who are focused on expanding their product portfolio through strategic acquisitions and investing heavily in material science R&D to enhance coupling durability and performance in extreme environments, such as high-temperature or corrosive settings.

Regionally, the Asia Pacific (APAC) continues to dominate the market in terms of volume and growth rate, fueled by rapid industrialization, significant investments in infrastructure development, and the establishment of vast manufacturing hubs, particularly in China, India, and Southeast Asian nations. North America and Europe, while mature, exhibit high growth in value due to the strong demand for premium, smart couplings integrated with IoT capabilities used in aerospace, medical technology, and highly regulated manufacturing sectors. The implementation of strict energy efficiency standards in these regions also drives the replacement cycle toward modern, precision-engineered flexible solutions.

Segmentation trends highlight the increasing preference for metallic couplings, such as disc and gear types, in high-torque, high-speed applications requiring zero backlash, particularly within the energy and heavy machinery sectors. Conversely, elastomeric couplings (e.g., jaw and tire couplings) maintain dominance in general industrial pump and motor applications due to their exceptional vibration damping properties and cost-effectiveness. The emerging trend across all segments is customization, where manufacturers leverage advanced manufacturing techniques, including additive manufacturing, to produce application-specific coupling geometries and material combinations tailored for unique operational challenges.

AI Impact Analysis on Flexible Shaft Couplings Market

User queries regarding the impact of Artificial Intelligence (AI) on the Flexible Shaft Couplings Market predominantly revolve around three key themes: predictive maintenance implementation, optimization of coupling design parameters, and the role of AI in quality control during manufacturing. Users are keen to understand how AI algorithms, when applied to sensor data collected from smart couplings (temperature, vibration, torque), can predict coupling failures with high accuracy, thereby shifting maintenance strategies from reactive or scheduled approaches to condition-based monitoring. Concerns often focus on the complexity and cost of retrofitting existing industrial infrastructure with AI-enabled sensor technologies and the standardization of data exchange protocols.

AI's influence extends significantly into the design and manufacturing phases. Generative design techniques powered by AI are enabling engineers to explore thousands of potential coupling geometries that optimize weight, stiffness, and material usage simultaneously, something traditional iterative design processes cannot achieve. This results in lighter, stronger, and more efficient couplings, especially critical for high-performance applications like aerospace where weight reduction is paramount. Furthermore, AI is employed in quality assurance through visual inspection systems, analyzing images or sensor readings during the production line to detect micro-cracks or material inconsistencies faster and more accurately than human inspection.

The overarching expectation is that AI will democratize sophisticated predictive maintenance, allowing small to medium enterprises (SMEs) to leverage high-level operational insights previously only accessible to large organizations. This shift is anticipated to increase the perceived value and adoption rate of premium, smart couplings. However, successful integration relies heavily on the industry establishing common, secure communication frameworks for IoT devices and developing robust, domain-specific AI models trained on large datasets of coupling failure modes across diverse operating conditions.

- AI enhances predictive maintenance by analyzing vibration and thermal data to forecast coupling failure.

- Generative Design algorithms optimize coupling geometry for maximum torque density and minimal material usage.

- AI-driven robotics improve manufacturing precision and quality control checks, reducing defects.

- Optimization of inventory and supply chains through machine learning forecasts coupling demand fluctuations.

- Enables real-time operational diagnostics and immediate alerts for critical misalignment issues.

DRO & Impact Forces Of Flexible Shaft Couplings Market

The Flexible Shaft Couplings Market is shaped by a confluence of influential factors: technological drivers pushing performance boundaries, inherent constraints limiting widespread adoption, and strategic opportunities promising future growth. The primary drivers include the global expansion of factory automation, increasing demand for industrial robots that require highly precise and zero-backlash couplings, and the widespread necessity to retrofit older machinery with efficient components to meet modern operational standards. These factors collectively accelerate the demand for advanced, flexible coupling solutions capable of handling higher speeds and torques while maintaining reliability in dynamic environments. However, the market faces restraints such as the relatively high initial capital investment required for specialized, high-performance couplings (e.g., composite materials or magnetic couplings) and the complexity involved in the precise installation and maintenance of certain types, which necessitates specialized technical expertise.

Significant opportunities arise from the ongoing integration of Internet of Things (IoT) sensors and smart monitoring capabilities directly into couplings, transforming them from passive mechanical components into active data-gathering assets essential for Industry 4.0 environments. Furthermore, the rising need for customized coupling solutions, driven by unique application geometries in sectors like aerospace and custom machinery, presents a strong avenue for market penetration, particularly for manufacturers employing agile manufacturing techniques like 3D printing. The shift towards sustainable manufacturing also opens doors for materials innovation, focusing on lighter, durable, and recyclable coupling components.

The impact forces influencing the market trajectory are primarily technological innovation and regulatory shifts. Technological advancements, particularly in material science (advanced polymers, composites) and manufacturing processes (high-precision machining), continuously push the performance envelope, allowing couplings to operate under more extreme conditions. Concurrently, increasing global regulatory pressure concerning worker safety, energy consumption, and environmental compliance forces end-users to adopt reliable, low-vibration, and efficient couplings, ensuring market momentum towards high-quality products. Geopolitical stability and commodity price volatility, particularly for key raw materials like steel and elastomers, also exert significant, albeit indirect, pressure on manufacturing costs and market pricing strategies.

Segmentation Analysis

The Flexible Shaft Couplings Market is extensively segmented based on type, material, application, and end-use industry, reflecting the diverse operational requirements across the industrial landscape. The segmentation by type is crucial as it dictates the coupling’s functional characteristics, such as torsional stiffness, misalignment compensation capability, and damping properties. Elastomeric couplings, utilizing materials like rubber or polyurethane, are preferred for vibration damping and moderate torque applications, whereas metallic couplings, including disc, diaphragm, and gear types, are selected for high-speed, high-torque, and precision-intensive systems where torsional rigidity is paramount. Understanding these segment dynamics is vital for market players to tailor their product offerings and strategic marketing efforts effectively.

- By Type:

- Elastomeric Couplings (Jaw, Sleeve, Tire, Grid)

- Metallic Couplings (Disc, Diaphragm, Gear, Beam, Bellows)

- By Material:

- Steel and Cast Iron

- Aluminum

- Composites and Plastics

- Elastomers (Rubber, Urethane)

- By Application/End-Use Industry:

- Industrial Machinery (Pumps, Compressors, Mixers)

- Power Generation

- Oil and Gas

- Aerospace and Defense

- Automotive and Transportation

- Robotics and Automation

- Medical Devices

- Machine Tools

- By Torque Capacity:

- Low Torque

- Medium Torque

- High Torque

Value Chain Analysis For Flexible Shaft Couplings Market

The value chain for the Flexible Shaft Couplings Market begins with the rigorous procurement of raw materials, which primarily includes specialized metals (high-grade steel, aluminum alloys) for metallic couplings and engineering polymers/elastomers for damping elements. Upstream analysis reveals that raw material quality and pricing volatility are critical determinants of final product cost and performance, driving manufacturers to establish long-term sourcing contracts and internal material testing capabilities. Following procurement, the manufacturing phase involves complex processes such as precision machining, forging, casting, and advanced molding, emphasizing tight tolerances and surface finishes essential for high-performance couplings, particularly zero-backlash models required in motion control systems.

The midstream stage focuses on assembly, quality assurance, and product testing, where manufacturers increasingly incorporate advanced technologies like computer numerical control (CNC) machining and automated inspection systems to ensure compliance with stringent international standards (e.g., ISO, API). The downstream component encompasses distribution and sales. Distribution channels are typically bifurcated into direct sales to large OEM clients (Original Equipment Manufacturers) in the automation, power, and oil & gas sectors, and indirect sales through a network of specialized industrial distributors, agents, and aftermarket resellers who cater to maintenance, repair, and operations (MRO) demand.

Direct sales channels are favored for highly customized or technically complex coupling solutions where close engineering consultation is required, such as applications in aerospace or large-scale turbomachinery. Indirect channels, relying on distributors with extensive local warehousing and technical support capabilities, are crucial for reaching a fragmented customer base, including small machine shops and general industrial users. The importance of aftermarket support, including replacement parts and maintenance services offered both directly and indirectly, significantly influences customer loyalty and long-term revenue streams, forming a crucial differentiator in the overall market value proposition.

Flexible Shaft Couplings Market Potential Customers

The diverse utility and necessity of flexible shaft couplings across nearly all industrial applications mean that the potential customer base is broad, yet distinct. Primary end-users are large Original Equipment Manufacturers (OEMs) specializing in capital goods, including industrial machinery manufacturers producing pumps, compressors, fans, and blowers, where couplings are integral to the drive system. These customers prioritize reliability, efficiency, and long service life, often leading to bulk procurement contracts for standardized and semi-custom coupling designs. Furthermore, the rapidly expanding robotics and factory automation sector represents a high-value customer segment, demanding highly precise, zero-backlash couplings (like metallic disc and bellows types) for complex motion control systems.

Another significant customer segment includes the energy sector, encompassing power generation facilities (thermal, nuclear, and renewables) and the demanding oil and gas industry. These environments often require couplings designed for extreme operational conditions, involving high speeds, severe temperatures, and corrosive exposure, necessitating specialized materials and robust construction adhering to industry-specific standards such as API 671. The maintenance, Repair, and Operations (MRO) market forms the continuous demand segment, comprising existing industrial plants and infrastructure operators who regularly replace couplings as part of routine maintenance or system upgrades, ensuring a steady, cyclical revenue stream for manufacturers and distributors.

Emerging and niche customers, such as manufacturers of medical devices (requiring miniature, high-precision couplings for surgical robotics and imaging equipment) and aerospace companies (demanding lightweight, high-performance composite couplings), contribute significantly to innovation and higher-margin sales. These specialized customers demand rigorous certification and customization, compelling suppliers to demonstrate superior quality control and engineering support. The shift towards sustainable and predictive maintenance strategies further positions end-users prioritizing smart, sensor-integrated couplings as the key growth demographic for the future.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $3.5 Billion |

| Market Forecast in 2033 | $5.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ruland Manufacturing, Altra Industrial Motion, ABB Ltd., SKF, Siemens AG, Regal Rexnord Corporation, Timken Company, KTR Systems GmbH, Mayr power transmission, John Crane, Renold plc, Voith GmbH, Lovejoy Inc., Tsubakimoto Chain Co., Dalian Huarui Heavy Industry, CENTA Power Transmission, Shanghai KPS Coupling, Cross+Morse, GAM Enterprises, The Carlyle Johnson Machine Company |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flexible Shaft Couplings Market Key Technology Landscape

The technological evolution within the Flexible Shaft Couplings Market is fundamentally driven by the need for increased reliability, higher power density, and reduced maintenance cycles, all while accommodating the demanding speed and precision requirements of modern automated systems. A crucial area of technological advancement lies in material science. Traditional materials like steel and cast iron are being supplemented or replaced by advanced composites (carbon fiber reinforced polymers) and high-performance engineering plastics. These materials offer superior strength-to-weight ratios, crucial for reducing inertial forces in high-speed applications, and inherent resistance to corrosion and chemical exposure, expanding the deployment scope in challenging industrial environments such as chemical processing and offshore oil platforms.

Furthermore, manufacturing technologies are undergoing a significant transformation. The adoption of additive manufacturing (3D printing), particularly selective laser sintering (SLS) and direct metal laser sintering (DMLS), allows for the rapid prototyping and production of complex coupling geometries that are impossible to achieve through traditional subtractive manufacturing. This enables zero-backlash designs with integrated flexures and reduced part count, facilitating rapid customization tailored precisely to specific machine requirements. This capability supports the growing trend of small-batch, high-value manufacturing across sectors like medical equipment and specialized robotics.

The most transformative technological shift is the integration of embedded sensors and IoT connectivity, leading to the rise of "smart couplings." These devices incorporate micro-sensors for real-time monitoring of critical operational parameters such as vibration, temperature, and torque transmission. This data is processed locally or transmitted wirelessly via gateways for cloud-based analysis, enabling predictive maintenance algorithms to determine the optimal time for coupling replacement or alignment correction. This not only prevents catastrophic failures but also maximizes operational uptime, solidifying the role of the coupling as an active, intelligent component within the Industry 4.0 ecosystem.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region in the flexible shaft couplings market, maintaining its leadership position in both production and consumption. The growth is primarily fueled by massive government and private sector investments in infrastructure development, heavy manufacturing expansion (especially automotive and electronics production in China, India, and South Korea), and the aggressive adoption of industrial automation to boost factory output and efficiency. Countries like Vietnam and Indonesia are rapidly emerging as manufacturing hubs, further expanding the regional customer base for both standard and specialized couplings. The demand here is largely volume-driven, focusing initially on cost-effective, durable elastomeric and gear couplings, though the high-precision segment is growing rapidly due to the proliferation of robotics.

- North America: The North American market is characterized by high value and strong demand for advanced, technologically integrated couplings. Growth is concentrated in sophisticated end-use sectors, including aerospace, defense, medical devices, and high-specification oil and gas exploration. Manufacturers in this region prioritize couplings that meet stringent regulatory standards (e.g., API specifications) and feature zero-backlash, high torsional stiffness, and connectivity for predictive maintenance systems. The focus on retrofitting older industrial infrastructure with modern, energy-efficient components also provides sustained growth opportunities, particularly in the machine tools and precision agriculture sectors.

- Europe: Europe represents a mature but technologically forward market, with a strong focus on quality, sustainability, and efficiency (Industry 4.0 compliance). Germany, Italy, and France are the key consumers, driven by their leading positions in automotive manufacturing, machine tools, and specialized industrial machinery. The European market exhibits high demand for precision metallic couplings (disc and bellows) used in motion control and CNC applications. Regulatory frameworks emphasizing energy efficiency and carbon neutrality further compel companies to invest in high-efficiency couplings that minimize energy loss and operational wear, favoring advanced materials and modular designs.

- Latin America (LATAM): The LATAM market, while smaller, offers promising growth avenues, largely dependent on recovery and expansion in the mining, oil & gas, and agricultural sectors, particularly in Brazil and Mexico. The demand is currently focused on robust, standard couplings that can withstand harsh operating conditions and remote maintenance challenges. Investment in modernization and local manufacturing capabilities is gradually increasing, leading to a slow but steady shift toward higher-grade, more reliable coupling solutions to reduce reliance on imported components and improve operational stability.

- Middle East and Africa (MEA): The MEA region is strongly driven by the volatile but significant oil and gas sector and massive construction/infrastructure projects, particularly in the Gulf Cooperation Council (GCC) countries. The demand is heavily skewed towards high-torque, durable couplings designed for pumps, compressors, and specialized process machinery often operating in high-temperature, dusty, or corrosive environments. Investment diversification into manufacturing and logistics centers across key areas like the UAE and Saudi Arabia is expected to broaden the demand base beyond traditional energy applications over the forecast period.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flexible Shaft Couplings Market.- Ruland Manufacturing

- Altra Industrial Motion (part of Regal Rexnord Corporation)

- SKF

- Siemens AG

- Regal Rexnord Corporation

- Timken Company

- KTR Systems GmbH

- Mayr power transmission

- John Crane

- Renold plc

- Voith GmbH

- Lovejoy Inc.

- Tsubakimoto Chain Co.

- Dalian Huarui Heavy Industry

- CENTA Power Transmission

- Shanghai KPS Coupling

- Cross+Morse

- GAM Enterprises

- The Carlyle Johnson Machine Company

- Fenner Drives

Frequently Asked Questions

Analyze common user questions about the Flexible Shaft Couplings market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Flexible Shaft Couplings Market?

Market growth is primarily driven by the exponential expansion of global industrial automation, the proliferation of robotics in manufacturing, and the increasing requirement for precision-engineered components in high-speed machinery across the aerospace and medical sectors. The global push for Industry 4.0 and predictive maintenance further necessitates high-reliability couplings.

How does the choice between elastomeric and metallic couplings affect industrial applications?

Elastomeric couplings, like jaw and tire types, are preferred when vibration damping, shock absorption, and electrical isolation are required, typically in general industrial pumping and mixing applications. Metallic couplings, such as disc and gear types, are chosen for high-torque transmission, high rotational speed, and precision motion control systems where zero backlash and high torsional stiffness are critical, common in CNC machines and turbomachinery.

What role does IoT integration play in the future of flexible shaft couplings?

IoT integration is transformative, enabling "smart couplings" equipped with embedded sensors that monitor vibration, temperature, and torque in real-time. This data facilitates advanced predictive maintenance programs, allowing operators to detect and correct misalignment or wear before failure occurs, significantly improving uptime and reducing operational costs in Industry 4.0 environments.

Which region currently dominates the Flexible Shaft Couplings Market, and why?

The Asia Pacific (APAC) region currently dominates the market due to accelerated industrialization, massive investments in manufacturing infrastructure, high capacity factory output, and widespread adoption of automation technologies, particularly in countries like China, India, and South Korea, driving high volume consumption.

What are the main technical challenges facing manufacturers in the Flexible Shaft Couplings Market?

Key technical challenges include developing couplings that can handle ever-increasing power density requirements while minimizing size and weight; mastering advanced material usage (composites) to improve durability in extreme environments; and ensuring precise, reliable data communication protocols for smart, sensor-integrated coupling solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager