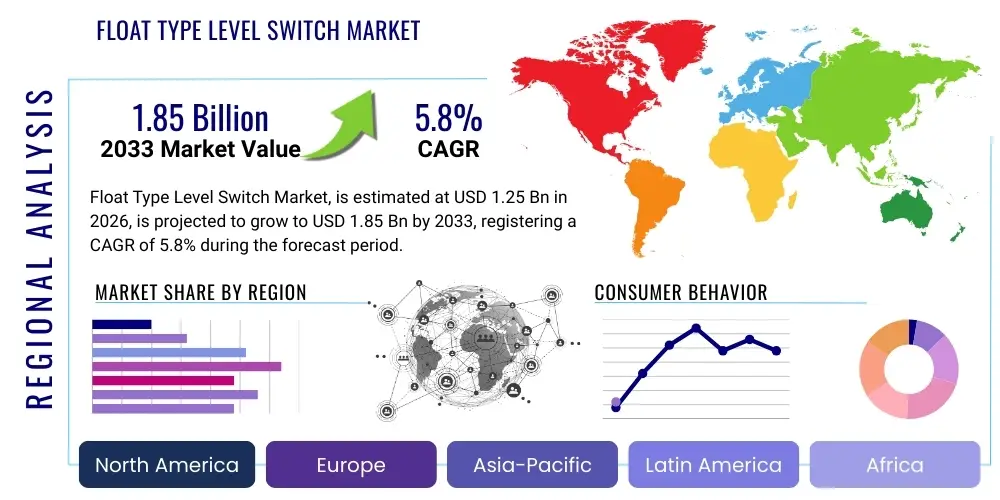

Float Type Level Switch Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438359 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Float Type Level Switch Market Size

The Float Type Level Switch Market is fundamentally driven by the pervasive need for reliable and cost-effective liquid level control across various process industries. These devices, known for their simplicity and robustness, are essential for ensuring operational safety, preventing overflow or dry-run conditions, and managing inventory in tanks and reservoirs globally. The market exhibits steady growth, primarily fueled by the expansion of industrial infrastructure in developing economies, stringent safety regulations mandating automatic liquid level monitoring, and the ongoing modernization of aging facilities in developed regions. While sophisticated alternatives exist, the float switch maintains its competitive edge due to its low maintenance requirements and independence from fluid properties like conductivity or dielectric constant.

The consistent demand from sectors such as water treatment, petrochemicals, and power generation ensures sustained market expansion. Investments in municipal infrastructure projects, particularly in Asia Pacific and the Middle East, necessitate reliable level control solutions for water management systems, boosting the deployment rates of float type switches. Furthermore, continuous product innovation focusing on enhanced material compatibility (e.g., use of specialized plastics and corrosion-resistant alloys) allows these switches to handle aggressive chemicals and high-temperature environments, expanding their scope of application in niche industrial settings. This combination of infrastructural growth and technical refinement underpins the positive market trajectory.

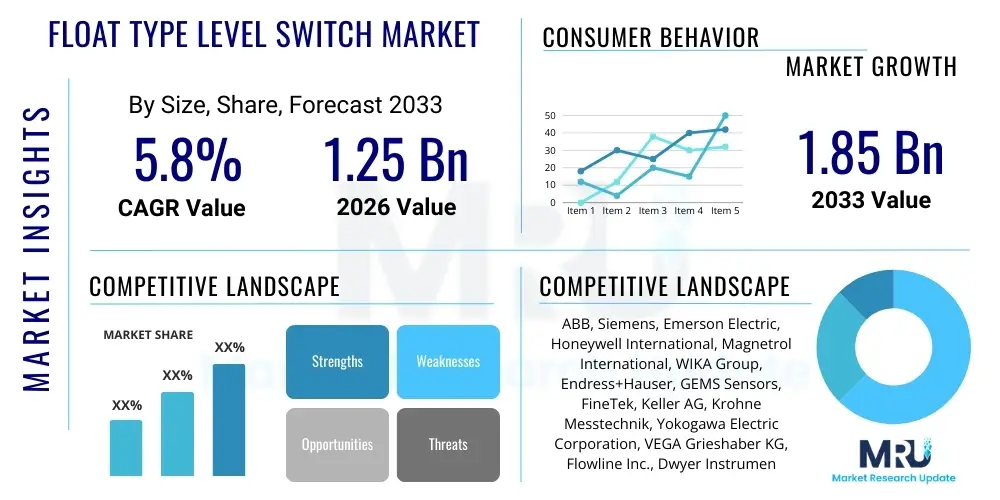

The Float Type Level Switch Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.25 Billion in 2026 and is projected to reach $1.85 Billion by the end of the forecast period in 2033.

Float Type Level Switch Market introduction

The Float Type Level Switch Market encompasses devices utilized to detect the presence or absence of a liquid at a specified level within a tank, vessel, or sump. These switches operate on the principle of buoyancy, where a float mechanism moves with the liquid surface, actuating a reed switch or microswitch assembly when the pre-determined level is reached. The product’s core features are its mechanical simplicity, high reliability, and suitability for point level detection, making it an indispensable tool for automation and safety interlocks in industrial processes.

Major applications of float level switches span across critical industrial domains, including overflow protection in chemical storage tanks, low-level pump control in wastewater stations, high-level alarms in fuel storage facilities, and fluid management in boilers and cooling systems. Their robust construction often allows them to function effectively in harsh environments where electronic sensors might fail. Key benefits include straightforward installation, lack of required external power (in purely mechanical versions), and high repeatability, contributing significantly to process efficiency and preventing catastrophic equipment failure or environmental hazards.

The driving factors behind market expansion include the global increase in capital expenditure on industrial automation, mandatory regulatory compliance requiring fail-safe level monitoring in hazardous fluid management, and the sustained growth of the oil & gas and water treatment industries, which are major end-users. The continuous effort by manufacturers to miniaturize these switches and integrate them with digital output signals further solidifies their relevance in modern control systems.

Float Type Level Switch Market Executive Summary

The Float Type Level Switch Market is characterized by stable growth driven by necessary infrastructure development and increasing industrial automation mandates worldwide. Business trends indicate a strong move toward enhancing material compatibility and achieving higher certifications (such as ATEX/IECEx) to meet the stringent demands of the chemical and petrochemical sectors. Manufacturers are focusing on standardizing product lines for easier integration into existing control architectures, while also exploring opportunities presented by the Industrial Internet of Things (IIoT) by developing switches that provide basic digital communication capabilities, even if the primary sensing mechanism remains mechanical.

Regional trends highlight the Asia Pacific (APAC) region as the dominant growth engine, propelled by rapid industrialization, massive investments in water management infrastructure in countries like China and India, and the proliferation of manufacturing facilities. North America and Europe, while mature markets, emphasize replacement cycles and the adoption of high-performance switches capable of functioning reliably in extreme temperature and pressure conditions, often necessitated by upgrading existing plant safety systems. The Middle East and Africa (MEA) region shows significant promise, linked to ongoing large-scale energy and desalination projects.

Segment trends reveal that the Top Mounted switches dominate revenue share due to their ease of installation and suitability for deep tank applications, offering flexibility in setting multiple alarm points. Furthermore, the segmentation by material, particularly the increasing preference for Stainless Steel and advanced engineering plastics, reflects the industry’s focus on durability and corrosion resistance, particularly within the challenging environments of the pharmaceutical and chemical processing segments. The Water & Wastewater application segment remains the largest volume consumer, demanding cost-effective and reliable solutions for basic pump control and reservoir monitoring.

AI Impact Analysis on Float Type Level Switch Market

User queries regarding AI’s impact on the Float Type Level Switch Market typically revolve around whether simple mechanical sensors will become obsolete, how AI can utilize the binary data provided by float switches, and if AI integration justifies the higher cost of 'smart' level sensing technologies. The core concerns address the potential for AI to optimize system maintenance and predictive failure detection without requiring a complete overhaul of existing mechanical infrastructure. Analysis shows that while the switch itself is inherently mechanical and provides only basic binary data (on/off, high/low), AI primarily impacts the supervisory control and maintenance layers. AI algorithms are crucial for processing data aggregated from numerous such point-level sensors, identifying anomalies, and optimizing pump cycling based on environmental and operational variables, thereby extending the utility and lifespan of the mechanical switches installed.

- AI integration supports predictive maintenance schedules by correlating switch failure signals with operational runtime and environmental stress factors.

- Optimization of pump and valve control logic using AI minimizes mechanical wear on float switches caused by excessive cycling.

- AI-driven anomaly detection identifies potential system failures when multiple float switches in a sequence provide conflicting or unexpected binary signals.

- Data aggregation platforms utilize float switch status inputs alongside continuous level measurements (from other sensors) to build comprehensive digital twins of liquid processing systems.

- Reduced reliance on continuous human monitoring and manual checks, as AI can prioritize maintenance alerts based on float switch status deviations.

DRO & Impact Forces Of Float Type Level Switch Market

The Float Type Level Switch Market is influenced by a dynamic interplay of factors that both accelerate adoption and pose limitations. Key drivers include rigorous governmental safety standards, particularly concerning the handling and storage of flammable or hazardous liquids, which necessitate redundant and proven level detection systems. The overall global thrust towards industrial process optimization, where efficient fluid management is paramount to reducing waste and energy consumption, further spurs demand. However, the market faces constraints primarily due to intensifying competition from advanced non-contact technologies like radar and ultrasonic sensors, which offer continuous measurement and greater accuracy, sometimes preferred in highly technical or high-value applications. Additionally, the mechanical nature of float switches means they are susceptible to fouling, scaling, or viscous fluid buildup, potentially leading to operational failures.

Opportunities for growth are heavily centered on the integration of these traditionally mechanical switches into modern IIoT frameworks. By embedding transmitters or communication modules that digitize the binary signal, manufacturers can offer ‘smart float switches’ that integrate seamlessly with plant control systems (DCS/SCADA), providing diagnostic feedback beyond simple status. Impact forces largely stem from technological substitution pressure, where continuous level sensors encroach upon the point level detection domain, alongside the powerful driver of increased capital spending on new industrial complexes in developing markets, ensuring a robust foundational demand for reliable, cost-effective level control solutions.

Segmentation Analysis

The Float Type Level Switch Market is systematically segmented based on construction type, mounting method, material composition, and end-use application, allowing manufacturers to cater precisely to diverse industrial requirements regarding pressure, temperature, chemical compatibility, and installation complexity. The segmentation by type, specifically top-mounted versus side-mounted, dictates the application scope; top-mounted switches are favored for large tanks and reservoirs requiring internal access, while side-mounted switches are often used for smaller vessels or for external installation via side ports. Material segmentation (e.g., Stainless Steel, PP, PVDF) is critical, as it directly impacts the switch's suitability for handling aggressive or hygienic media, driving price points and regulatory compliance (e.g., FDA approval for food and beverage applications).

- By Type:

- Side Mounted

- Top Mounted

- Submersible

- By Material:

- Stainless Steel (SS 304, SS 316)

- Plastics (Polypropylene (PP), Polyvinylidene Fluoride (PVDF), Polyamide)

- Other Alloys

- By Application:

- Oil & Gas and Petrochemicals

- Water and Wastewater Treatment

- Chemical Processing

- Food & Beverage

- Pharmaceuticals and Biotechnology

- Power Generation

- Marine and Shipbuilding

Value Chain Analysis For Float Type Level Switch Market

The value chain for the Float Type Level Switch Market begins with the upstream sourcing of specialized raw materials, primarily high-grade stainless steel (304/316) for corrosion resistance, and engineering plastics such as Polypropylene (PP) and PVDF for chemical compatibility and lightweight construction. The quality and stable pricing of these materials directly influence the final product cost and durability. Manufacturers engage in high-precision machining and injection molding to produce the float, stem, and housing components, followed by the critical step of assembly and calibration, which involves integrating the magnetic system and reed switch to ensure accurate point-level detection. Rigorous testing for sealing, pressure tolerance, and temperature stability is performed mid-stream to meet necessary industrial certifications.

Downstream analysis focuses heavily on efficient distribution and application support. The distribution channel is bifurcated into direct sales to major Original Equipment Manufacturers (OEMs) and indirect sales through a network of specialized industrial distributors, automation solution providers, and system integrators. System integrators play a vital role, often bundling the level switches with programmable logic controllers (PLCs) and other instrumentation to deliver comprehensive fluid control systems to end-users. Direct channels are typically utilized for large-volume, custom orders from major petrochemical or power generation facilities, where technical consultation and post-sales service are paramount.

Effective value capture at the downstream end is realized through providing customized solutions (multi-point switches, specific flange sizes) and offering robust technical training and support. The reliability of the distribution network, particularly in emerging markets, is a critical factor influencing market penetration. The trend toward digitalization also impacts the value chain, pushing manufacturers to invest in R&D for switches that offer standardized digital communication protocols, enhancing their perceived value within integrated smart factory environments.

Float Type Level Switch Market Potential Customers

Potential customers for Float Type Level Switches are primarily large-scale industrial entities and utility providers that require precise and reliable point-level detection for liquid inventory, safety interlocks, and pump control mechanisms. The end-user segment is highly diversified but centers around industries dealing with bulk fluid handling under varied environmental conditions. The largest volume consumers are municipal and private Water & Wastewater treatment plants, where these switches are essential for controlling pump stations, monitoring reservoir levels, and ensuring overflow prevention in sedimentation tanks and sumps due to their simplicity and low power consumption.

Beyond utilities, the Petrochemical and Oil & Gas sectors represent a high-value customer base. These customers demand switches made from specialized materials (e.g., Monel or exotic stainless steels) capable of withstanding extreme pressure, temperature, and corrosive hydrocarbons, often requiring certified explosion-proof (Ex) housings. In these environments, float switches act as critical safety instruments, providing high-level alarms to prevent catastrophic spills. Similarly, the Chemical Processing industry relies heavily on float switches for batch control and storage monitoring of aggressive acids and bases, necessitating switches made from inert plastics like PTFE or PVDF.

The Food & Beverage and Pharmaceutical industries constitute another key customer segment, demanding switches that comply strictly with hygienic design standards (e.g., 3-A Sanitary Standards) and are easily cleanable, typically utilizing polished stainless steel (316L) to prevent bacterial growth. These end-users utilize float switches for controlling mixing vessel levels, sterilizers, and cleaning-in-place (CIP) systems, valuing the non-contact internal mechanism (reed switch) which minimizes contamination risk. Overall, any industrial operation reliant on automated, fail-safe fluid management represents a prime customer for float type level switch technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.25 Billion |

| Market Forecast in 2033 | $1.85 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB, Siemens, Emerson Electric, Honeywell International, Magnetrol International, WIKA Group, Endress+Hauser, GEMS Sensors, FineTek, Keller AG, Krohne Messtechnik, Yokogawa Electric Corporation, VEGA Grieshaber KG, Flowline Inc., Dwyer Instruments, Xylem Inc., Mobrey (Emerson), ifm electronic, SICK AG, Thermo Fisher Scientific |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Float Type Level Switch Market Key Technology Landscape

The core technology of the float type level switch remains based on magnetic actuation (reed switches) or mechanical actuation (microswitches) driven by buoyancy. However, the technological landscape is evolving primarily in three areas: material science, miniaturization, and digitization of output. Material innovation is crucial, focusing on developing floats and stems from advanced composite materials and specialized alloys that offer superior resistance to highly aggressive chemicals (e.g., high-concentration acids) and handle extreme temperature variations without compromising mechanical integrity. This expansion of material capability allows float switches to be deployed in previously inaccessible applications.

Miniaturization is another key trend, driven by the demand for level sensing in smaller vessels, portable equipment, and complex OEM machinery where space is severely constrained. Smaller, multi-point float switches are being developed that can monitor various levels (high, low, and intermediate) using a single mounting point, simplifying installation and wiring. Furthermore, manufacturers are increasingly incorporating advanced dampening mechanisms or shielded designs to mitigate false readings caused by turbulence or foaming within the liquid, thereby enhancing the operational reliability of the measurement point.

Crucially, the integration of smart electronics marks a significant technological shift. While the sensing is mechanical, modern float switches are often supplied with embedded transmitters or IO-Link capabilities. These transmitters convert the simple open/closed electrical signal into a standardized digital output or analog current (4-20 mA), allowing seamless connection to modern control systems, remote diagnostics, and condition monitoring tools. This digitization transforms the basic mechanical device into a robust component of the smart factory ecosystem, providing not only level status but also potentially temperature compensation and self-diagnostic features.

The focus on high-pressure and high-temperature applications, common in the power and heavy chemical industries, demands continuous refinement of the sealing technology and robust housing designs. Welded metal construction for stems and floats is becoming standard in critical process environments to ensure lifetime integrity and compliance with rigorous safety certifications. This commitment to engineering robustness, combined with smart output capabilities, defines the current technological trajectory.

Regional Highlights

Regional dynamics play a crucial role in shaping the Float Type Level Switch Market, reflecting differences in industrial maturity, regulatory environment, and infrastructure investment priorities. The Asia Pacific (APAC) region stands out as the primary growth driver, benefiting from high levels of investment in manufacturing facilities, chemical plants, and massive government-led water and sanitation projects across countries like China, India, and Southeast Asian nations. The demand here is driven by the need for cost-effective, high-volume level monitoring solutions to support rapid industrial expansion and urbanization.

North America and Europe represent mature markets characterized by replacement demand and the stringent requirement for certified, high-quality switches utilized in critical safety applications (e.g., SIL-rated systems). These regions emphasize advanced features such as hygienic designs for the food and pharma sectors and specialized materials for demanding petrochemical applications. Regulations like the European Union's ATEX directives and similar North American standards ensure continuous demand for certified and tested products. Growth in these regions is less volumetric and more value-driven, focused on technical excellence and integration capabilities.

The Middle East and Africa (MEA) region is experiencing accelerated market activity linked to substantial investments in oil production, gas processing facilities, and large-scale desalination and infrastructure projects. The harsh environmental conditions (high temperatures, corrosive media) necessitate highly durable and corrosion-resistant switches, often favoring stainless steel and exotic alloys. Latin America shows steady, if slower, growth, influenced primarily by commodity extraction industries (mining, agriculture) and local infrastructure modernization, demanding robust, medium-cost solutions.

- Asia Pacific (APAC): Dominates market growth due to rapid industrialization, high infrastructure spending (especially water utilities), and expansion of the chemical manufacturing base in China and India.

- North America: Focuses on high-specification, safety-critical applications; driven by regulatory compliance (EPA) and modernization of aging oil & gas and chemical infrastructure.

- Europe: Characterized by strong demand for hygienic switches (Food & Beverage, Pharma) and adherence to strict safety standards like ATEX for hazardous area operation.

- Middle East & Africa (MEA): Growth spurred by large government investments in desalination plants, petrochemical facilities, and energy infrastructure requiring rugged, high-temperature switches.

- Latin America: Stable demand influenced by investments in natural resource processing (mining, agriculture) and general industrial process automation upgrades.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Float Type Level Switch Market.- ABB

- Siemens

- Emerson Electric Co.

- Honeywell International Inc.

- Magnetrol International, Incorporated

- WIKA Group

- Endress+Hauser Group Services AG

- GEMS Sensors

- FineTek Co., Ltd.

- Keller AG

- Krohne Messtechnik GmbH

- Yokogawa Electric Corporation

- VEGA Grieshaber KG

- Flowline Inc.

- Dwyer Instruments, Inc.

- Xylem Inc.

- Mobrey (Emerson)

- ifm electronic gmbh

- SICK AG

- Thermo Fisher Scientific

Frequently Asked Questions

What is the primary advantage of a float type level switch over other level sensors?

The primary advantage of the float type level switch is its reliability and simplicity, as it operates solely on the physical principle of buoyancy, independent of liquid properties such as conductivity, dielectric constant, or pressure, making it a highly robust and cost-effective solution for point level detection in diverse fluids.

In which industries are float level switches most commonly used for safety critical applications?

Float level switches are most commonly used in safety critical applications within the Oil & Gas, Petrochemicals, and Power Generation industries, where they provide fail-safe high or low-level alarms necessary for regulatory compliance and preventing hazardous overflows or dry-run conditions in storage tanks and boilers.

How do external factors like turbulence or foaming affect the performance of float switches?

Turbulence or excessive foaming can potentially cause 'chattering' or false switching in standard float switches. To mitigate this, manufacturers often employ damping tubes, specific float designs (like large, stabilizing floats), or time-delay relays to ensure the switch only actuates based on sustained level changes, enhancing stability.

Is the Float Type Level Switch Market being impacted by the rise of IIoT technology?

Yes, while float switches are fundamentally mechanical, the market is integrating IIoT by incorporating smart transmitters that digitize the binary signal (on/off) into communication protocols like 4-20 mA or IO-Link, enabling remote monitoring, diagnostics, and seamless integration into modern plant asset management systems.

What materials are essential for float switches used in corrosive chemical processing environments?

For highly corrosive chemical processing environments, essential materials include specialized plastics such as PVDF (Polyvinylidene Fluoride) and PP (Polypropylene) for their high chemical resistance, and high-grade alloys like Stainless Steel 316L or Monel for high-pressure or high-temperature applications where plastics are unsuitable.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager