Floating Bollards Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433412 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Floating Bollards Market Size

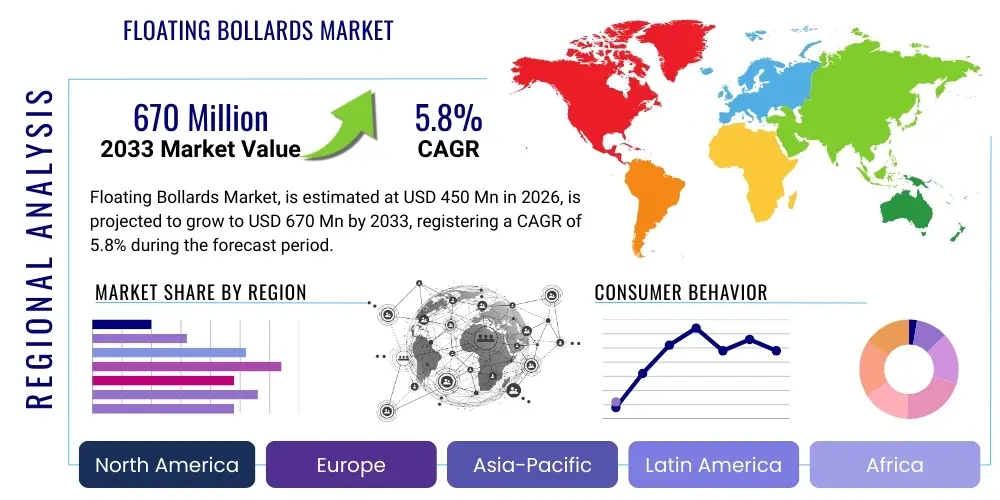

The Floating Bollards Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. This robust growth trajectory is underpinned by increasing global investment in modernizing maritime infrastructure, particularly in developing coastal economies facing rising sea levels and fluctuating tide patterns. The necessity for reliable mooring solutions that adapt dynamically to environmental conditions is a primary driver of market expansion across diverse marine applications.

The market is estimated at USD 450 Million in 2026, reflecting the initial penetration of these advanced mooring systems in high-traffic ports and high-end marinas. Floating bollards offer significant advantages over fixed structures by reducing stress on vessels and infrastructure, thereby enhancing operational safety and longevity. This initial market valuation is heavily influenced by high-cost, specialized installations required for large commercial vessels.

The market is projected to reach USD 670 Million by the end of the forecast period in 2033. This substantial increase is attributed to technological advancements, standardization of product designs, and the growing adoption of composite materials which reduce manufacturing costs and installation complexity. Furthermore, regulatory mandates concerning port safety and efficiency are expected to accelerate the replacement cycle of traditional fixed bollards with dynamic floating counterparts globally.

Floating Bollards Market introduction

The Floating Bollards Market encompasses specialized mooring equipment designed to secure vessels in marine environments where water levels fluctuate significantly due to tides or changing operational needs. Unlike conventional fixed bollards, floating bollards maintain a consistent, optimal point of contact with the vessel's mooring lines regardless of the water level, ensuring secure docking and reducing wear and tear on both the vessel and the harbor infrastructure. These systems are crucial components in modern, adaptive maritime facilities, ranging from busy commercial ports to exclusive recreational marinas and specialized naval bases.

The core product description includes highly engineered structures typically mounted on floating pontoons, docks, or other buoyant platforms. They are manufactured using robust, corrosion-resistant materials such as high-grade steel, marine-grade aluminum, or advanced fiber-reinforced polymers (composites), ensuring longevity in harsh saltwater environments. Major applications span commercial shipping terminals, cruise ship docking areas, specialized industrial waterways, and private yacht harbors. Their primary benefits include enhanced safety, reduced operational downtime during tide changes, superior load distribution, and increased flexibility in accommodating diverse vessel types and sizes within the same facility.

Key driving factors accelerating market adoption include the urgent global need for climate-resilient infrastructure capable of managing extreme weather events and sea-level rise. Furthermore, increasing global trade volume necessitates higher port efficiency and faster turnaround times, which floating bollards facilitate by simplifying the mooring process. Strict international maritime safety regulations, coupled with ongoing modernization initiatives across major global ports, cement the necessity and attractiveness of these advanced mooring solutions, pushing the market towards sustained expansion throughout the forecast period.

Floating Bollards Market Executive Summary

The Floating Bollards Market is characterized by robust growth driven primarily by technological convergence and shifting regulatory landscapes favoring resilient infrastructure. Key business trends include the consolidation of specialized marine engineering firms and an increasing focus on developing smart, sensor-equipped bollards capable of real-time monitoring of mooring line tension and environmental conditions. Manufacturers are prioritizing lightweight, high-strength composite materials to improve durability and reduce installation costs, making these previously niche products more accessible for mid-sized marinas and public infrastructure projects. Strategic partnerships between hardware manufacturers and port management software providers are crucial for optimizing integrated port operations, marking a definitive trend toward system integration rather than standalone product sales.

Regionally, Asia Pacific is anticipated to be the fastest-growing market, propelled by massive government investments in coastal infrastructure development, particularly in China, India, and Southeast Asian nations addressing severe congestion in major shipping hubs. North America and Europe maintain leading market shares, primarily driven by the replacement of aging infrastructure and the high demand from premium recreational boating sectors and stringent environmental compliance requirements. Latin America and the Middle East & Africa are emerging markets, with growth concentrated around energy export terminals and planned luxury coastal developments that demand state-of-the-art marine security and efficiency.

Segment trends highlight the dominance of hydraulic and automated operation systems due to their precision and ease of use in managing large vessels. In terms of material, high-grade steel continues to hold a significant volume share due to its established strength profile, though aluminum and composite segments are witnessing rapid growth, capitalizing on their corrosion resistance and reduced maintenance needs. Application analysis shows that commercial ports and harbors remain the largest revenue generators, while the residential docks and private marina segment demonstrate the highest growth potential, reflecting increasing private investment in waterfront properties globally.

AI Impact Analysis on Floating Bollards Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Floating Bollards Market center around the automation potential, predictive maintenance capabilities, and integration with broader smart port systems. Users frequently ask how AI can optimize mooring line tension in dynamic weather conditions, if machine learning algorithms can predict infrastructure failure before it occurs, and how AI-driven data analysis can improve port security and traffic flow management involving floating structures. The key themes revolve around achieving 'autonomous mooring'—where the bollard system itself utilizes real-time data from environmental sensors (tides, winds, currents) and vessel specifications to autonomously adjust or advise on optimal mooring parameters. User expectations are high regarding enhanced safety, reduced labor dependency, and achieving quantifiable gains in operational efficiency through intelligent data processing inherent in AI platforms, moving beyond simple sensor-based systems to truly predictive and adaptive infrastructure.

- AI facilitates predictive maintenance by analyzing strain gauge data, usage patterns, and environmental exposure history to forecast component lifespan and scheduled necessary repairs, significantly reducing unexpected downtime.

- Implementation of deep learning models enables real-time dynamic load optimization, allowing floating bollards to automatically adjust tension settings based on live wave and wind conditions, minimizing stress on both the vessel and the infrastructure.

- AI systems integrate floating bollard data with broader Smart Port systems, optimizing vessel scheduling, berth allocation, and reducing congestion by providing accurate time estimates for securing and releasing vessels.

- Machine vision algorithms combined with sensor data enhance security protocols by detecting unauthorized mooring attempts, unusual loading patterns, or potential security breaches near the floating infrastructure.

- AI-driven simulation tools assist in the optimal design and placement of floating bollards within new or existing marine facilities, ensuring maximum efficiency and safety compliance tailored to specific geographic and hydrographic conditions.

DRO & Impact Forces Of Floating Bollards Market

The dynamics of the Floating Bollards Market are shaped by a complex interplay of Drivers (D), Restraints (R), Opportunities (O), and potent Impact Forces. Key drivers include the overwhelming global demand for climate-resilient and adaptable maritime infrastructure necessary to manage escalating sea-level variability and extreme weather patterns. Concurrently, operational demands for faster vessel turnaround times in highly congested commercial ports push operators towards dynamic, efficient mooring solutions, further propelling market adoption. Restraints primarily involve the substantial initial capital investment required for deploying high-specification floating systems, which can deter smaller port operators or regional marinas with limited budgets. Additionally, the need for specialized engineering expertise during installation and maintenance acts as a significant barrier to entry in certain emerging markets.

Opportunities are vast, centering around the integration of advanced digitalization—such as the Internet of Things (IoT) sensors and Artificial Intelligence (AI)—to create 'Smart Bollard' systems capable of predictive monitoring and autonomous operation. The development of advanced, low-cost composite materials presents a significant opportunity to democratize the technology, making it affordable for residential and smaller private dock applications, expanding the addressable market beyond traditional commercial ports. Furthermore, market expansion into inland waterways and rivers, where water levels are highly unpredictable due to seasonality and dam management, represents an untapped potential segment for floating bollard technology.

The primary impact forces include stringent governmental regulations concerning maritime safety and environmental sustainability, mandating the use of safer and more robust mooring equipment. Technological advancement, particularly in materials science and hydraulics, is a continuous force reducing costs and improving performance characteristics, driving down the total cost of ownership over time. The economic impact of global trade growth acts as a macro force, directly correlating the demand for efficient port infrastructure with overall economic activity. Lastly, the ecological force of climate change necessitates investment in adaptive infrastructure, making floating bollards a mandatory upgrade rather than a discretionary purchase in vulnerable coastal areas worldwide.

- Drivers: Global rise in sea levels and frequency of extreme weather events; increasing volume of international maritime trade necessitating faster, safer vessel mooring; modernization and upgrade cycles of existing, aging port infrastructure; and growing demand from the luxury and high-end recreational boating sector for high-quality docking solutions.

- Restraints: High initial investment costs compared to traditional fixed bollards; complexity associated with installation, requiring specialized marine engineering knowledge; lack of standardization across different hydraulic and monitoring systems creating integration challenges; and potential maintenance issues related to moving parts submerged in corrosive environments.

- Opportunities: Integration of IoT and sensor technology for Smart Mooring systems; penetration into emerging markets in Africa and Latin America undergoing port development; utilization of advanced composite materials to reduce weight and manufacturing costs; and expansion into inland waterway applications and temporary or modular docking solutions.

- Impact Forces: Climate change adaptation requirements (Ecological); stringent international maritime organization (IMO) safety standards (Regulatory); globalization and economic stability (Economic); and rapid advances in smart sensing and hydraulic technologies (Technological).

Segmentation Analysis

The Floating Bollards Market is systematically segmented based on Material Type, Operational Mechanism, and Application Area to provide a granular understanding of market dynamics and targeted investment opportunities. The segmentation reflects the diverse technical requirements imposed by varying maritime environments and vessel sizes. Material choices directly influence durability, corrosion resistance, and cost, with high-strength materials dominating commercial sectors and lighter composites gaining traction in leisure segments. Operational mechanisms delineate the level of automation and control offered, affecting overall port efficiency and safety protocols.

Analysis by segment reveals distinct market maturity levels. The traditional steel bollard segment, while mature, maintains stability through its proven reliability in heavy-duty commercial applications. Conversely, the automatic/hydraulic operation segment is experiencing exponential growth, driven by ports seeking minimal human intervention and maximum precision during mooring operations for very large container ships and tankers. The application segment underscores the criticality of this equipment in core maritime infrastructure, with commercial ports serving as the cornerstone of revenue generation, while the military and naval segment represents a niche but highly demanding market focused purely on security and resilience.

Understanding these segment characteristics is vital for stakeholders, allowing them to tailor product development and market entry strategies. For instance, companies targeting the Asia Pacific region should focus on cost-effective, high-volume segments (e.g., steel and manual operation for standard docks), whereas companies aiming for North American or European markets should prioritize technological sophistication, offering integrated IoT and composite material solutions for premium marinas and large-scale industrial berths. This structured view of the market ensures resource allocation aligns with high-potential growth pockets.

- By Material Type:

- High-Grade Steel Bollards (Dominant in heavy-duty applications)

- Marine-Grade Aluminum Bollards (Preferred for lightweight, corrosion-resistant structures)

- Fiber-Reinforced Plastic/Composite Bollards (Growing segment for recreational and low-load environments)

- By Operational Mechanism:

- Manual Floating Bollards (Traditional, low-cost solutions)

- Automatic/Hydraulic Floating Bollards (High precision, used in high-traffic commercial ports)

- Semi-Automatic/Sensor-Assisted Bollards (Bridging the gap between manual and full automation)

- By Application:

- Commercial Ports and Harbors (Largest revenue segment, focus on large cargo and tanker vessels)

- Marinas and Recreational Docks (Focus on aesthetic and low maintenance)

- Naval Bases and Military Installations (Emphasis on security and rapid deployment)

- Industrial and Specialized Waterways (e.g., Oil and Gas Terminals, Offshore structures)

Value Chain Analysis For Floating Bollards Market

The value chain for the Floating Bollards Market commences with the upstream activities centered on raw material procurement and highly specialized component manufacturing. Upstream suppliers are responsible for providing high-quality, certified marine-grade steel alloys, aluminum extrusions, advanced composites, and precision hydraulic/electronic components necessary for automated systems. Quality control and material certification are paramount at this stage due to the high-stress, corrosive environment in which the final product operates. Key players often maintain long-term partnerships with certified metal foundries and specialized component makers to ensure material traceability and reliability, significantly influencing the total manufacturing cost and overall product lifespan.

Midstream activities involve the design, engineering, and manufacturing process of the floating bollard unit itself. This stage requires sophisticated marine engineering expertise to design buoyant structures and mooring interfaces that can withstand immense dynamic loads and adapt seamlessly to environmental changes. Manufacturers focus on lean production processes, integrating welding, coating (e.g., galvanization or specialized marine paints), assembly, and rigorous load testing. Distribution channels, forming part of the downstream process, rely heavily on direct sales to large port authorities, specialized engineering procurement and construction (EPC) firms, and authorized marine equipment distributors. Given the customized nature of large installations, the direct sales approach often dominates the commercial segment.

The downstream sector concludes with installation, commissioning, maintenance, and after-sales services, which are critical elements influencing customer satisfaction and repeat business. Installation typically requires specialized maritime construction teams. Post-installation support is crucial, particularly for hydraulic and sensor-equipped bollards, demanding regular inspections and specialized servicing. Direct distribution is common for large commercial contracts, where the manufacturer provides end-to-end service. Indirect channels, such as regional marine supply houses and engineering consultants, handle sales to smaller marinas and residential customers, providing localized support and maintenance expertise across different geographic regions.

Floating Bollards Market Potential Customers

Potential customers for Floating Bollards represent a broad spectrum of the maritime and coastal development industry, all unified by the critical need for secure, adaptable, and efficient vessel mooring solutions. The largest segment of end-users is governmental and quasi-governmental bodies that manage major international commercial ports and national harbors. These entities require robust, often automated, high-capacity floating bollards capable of handling the largest container ships, bulk carriers, and oil tankers, with purchasing decisions driven primarily by safety regulations, throughput efficiency targets, and long-term infrastructure resilience against climate change impacts.

Another significant customer base comprises the private sector entities involved in specialized maritime operations, including global logistics and shipping companies that invest in their dedicated terminals, operators of specialized terminals (e.g., LNG, crude oil, or specific mineral export facilities), and major cruise line corporations that develop or operate dedicated cruise ship berths. For these private operators, the purchase motivation is centered on reducing operational risk, maximizing asset utilization (faster mooring/unmooring), and ensuring the protection of high-value vessels and cargo, making the premium cost of floating bollards justified by the reduction in operational losses.

The third major group includes developers and operators of marinas, yacht clubs, and high-end residential waterfront properties. While the load requirements are lower than commercial ports, these buyers prioritize durability, aesthetics, user-friendliness (especially semi-automatic features), and minimal environmental disturbance. Military and naval agencies also constitute a highly specialized, though smaller, customer segment, demanding customized, highly resilient floating systems for secure docking of naval fleets, where specifications emphasize rapid mooring capabilities and enhanced physical security features against potential threats.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 670 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mampaey Offshore Industries B.V., Trelleborg AB, Shibata Industrial Co. Ltd., Cavotec SA, SFT, Anchor Marine, TDK Solutions, Viking Marine Products, Profloat, Marinetek Group Oy, Bellingham Marine, Structurmarine, Intermarine LLC, Poseidon Marine, JFC Marine. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Floating Bollards Market Key Technology Landscape

The technological landscape of the Floating Bollards Market is rapidly evolving, moving from purely mechanical devices to sophisticated, interconnected systems. Central to this evolution is the integration of high-precision hydraulic power units (HPUs) that enable the automatic adjustment of the bollard's position relative to the floating structure, ensuring optimal load angle and tension. These HPUs are increasingly being paired with PLC (Programmable Logic Controller) systems and specialized software interfaces, allowing port operators to monitor and control multiple bollard units simultaneously from a centralized control room, greatly enhancing operational safety and efficiency during challenging weather or tide conditions.

The second major technological thrust involves the deployment of Internet of Things (IoT) devices and advanced sensor technology. Modern floating bollards are frequently equipped with load cells and strain gauges that measure mooring line tension in real-time, feeding critical data back into port management systems. This data not only informs operational decisions but also powers predictive maintenance algorithms, alerting maintenance crews to potential hardware stress or fatigue before failure occurs. Furthermore, GPS and acoustic positioning systems are being utilized to accurately track the movement of the floating infrastructure itself, ensuring compliance with strict safety margins and preventing potential conflicts within crowded berthing areas.

Material science innovation constitutes the third critical area. While high-strength steel remains standard for maximum capacity, there is a distinct technological shift towards utilizing advanced composite materials (such as carbon fiber reinforced polymers) and specialized corrosion-resistant coatings. These materials offer a superior strength-to-weight ratio, are highly resistant to the severe corrosive effects of saltwater, and significantly reduce the structural load on the underlying floating pontoons. This material technology allows for lighter, more durable, and lower-maintenance bollard solutions, extending the product lifespan and reducing the total cost of ownership for end-users, especially in niche markets like luxury yachting and remote industrial sites.

Regional Highlights

Regional variations in the adoption and growth rates of the Floating Bollards Market are significant, reflecting differences in economic development, infrastructure age, and vulnerability to climate change.

- Asia Pacific (APAC): APAC is projected to exhibit the highest CAGR during the forecast period. The growth is fueled by massive infrastructure investment programs, particularly China's Belt and Road Initiative and India's Sagarmala Project, which necessitate the rapid expansion and modernization of coastal and inland ports. Rapid industrialization and high exposure to monsoons and tropical cyclones make resilient floating infrastructure essential. The market demand in APAC is characterized by a high volume of new installations in developing ports, often prioritizing durable steel solutions over high-cost automation.

- North America: North America holds a substantial market share, driven primarily by the replacement of aging infrastructure and high regulatory standards for safety and environmental protection. Demand is robust across both the commercial shipping lanes on the East and West Coasts and the affluent recreational boating sector, especially in Florida and the Pacific Northwest. The market here favors technologically advanced, high-end automated systems integrated with sophisticated digital port management platforms.

- Europe: Europe is a mature but highly innovative market. Key drivers include stringent EU mandates on port security (ISPS Code compliance) and operational efficiency (T-TESS). Western European ports, such as Rotterdam, Antwerp, and Hamburg, are early adopters of smart bollard technology, focusing on fully hydraulic and sensor-equipped systems. The region shows a growing preference for sustainable and composite materials in marina and yacht club applications.

- Latin America: This region is an emerging market with growth concentrated around energy export terminals (oil and gas) and agricultural bulk shipping ports in Brazil, Mexico, and Chile. Market growth is heavily influenced by foreign investment in infrastructure and the necessity to handle high commodity throughput. Adoption is often project-specific, requiring customized heavy-duty solutions.

- Middle East and Africa (MEA): Growth in MEA is driven by strategic initiatives such as developing major hubs in the UAE (Jebel Ali) and Saudi Arabia (NEOM project), demanding world-class, state-of-the-art port facilities. The market is defined by high-value, large-scale projects, often utilizing the most advanced automatic bollard systems to manage immense vessel traffic in strategic shipping lanes.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Floating Bollards Market. These companies are pivotal in driving innovation, setting industry standards, and influencing global market penetration through technology and strategic partnerships.- Mampaey Offshore Industries B.V.

- Trelleborg AB

- Shibata Industrial Co. Ltd.

- Cavotec SA

- SFT (Shandong Fendou Technology)

- Anchor Marine

- TDK Solutions

- Viking Marine Products

- Profloat

- Marinetek Group Oy

- Bellingham Marine

- Structurmarine

- Intermarine LLC

- Poseidon Marine

- JFC Marine

- Stop-Flex Inc.

- Dolphin Mooring Systems

- FenderTec B.V.

- Qingdao Weflo Rubber & Plastic Mfg. Co., Ltd.

- Marine Tech Sp. z o.o.

Frequently Asked Questions

Analyze common user questions about the Floating Bollards market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of floating bollards over fixed bollards?

The primary advantage is their dynamic adaptability to fluctuating water levels. Floating bollards maintain an optimal, constant height and angle relative to the moored vessel regardless of tides or water fluctuation, minimizing stress on the mooring lines and infrastructure, thereby ensuring maximum safety and operational efficiency.

How does the integration of IoT affect the performance of modern floating bollards?

IoT integration enhances performance by enabling real-time monitoring of critical parameters such as mooring line tension, load distribution, and environmental conditions (wind, waves). This data allows for predictive maintenance, remote diagnostics, and automated, dynamic adjustments, significantly reducing operational risks and downtime.

Which material type is most suitable for high-capacity commercial port applications?

High-grade marine-certified steel is typically the most suitable material for high-capacity commercial port applications due to its superior tensile strength and proven reliability in handling extreme loads imposed by large container ships and tankers. Specialized coatings are applied to mitigate corrosion risks inherent in saltwater environments.

What are the key factors driving the market growth in the Asia Pacific region?

Market growth in the Asia Pacific region is predominantly driven by extensive government investments in maritime infrastructure modernization, rapid expansion of commercial shipping hubs to handle increasing global trade volumes, and the urgent need for climate-resilient solutions due to high regional vulnerability to coastal hazards and sea-level rise.

Are floating bollards suitable for use in inland waterways and rivers?

Yes, floating bollards are highly suitable for inland waterways, rivers, and lock systems where water levels frequently change due to seasonal flooding, drought, or dam operation. Their ability to compensate for vertical shifts makes them crucial for secure and reliable mooring in these dynamic freshwater environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager