Floating Stairs Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436717 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Floating Stairs Market Size

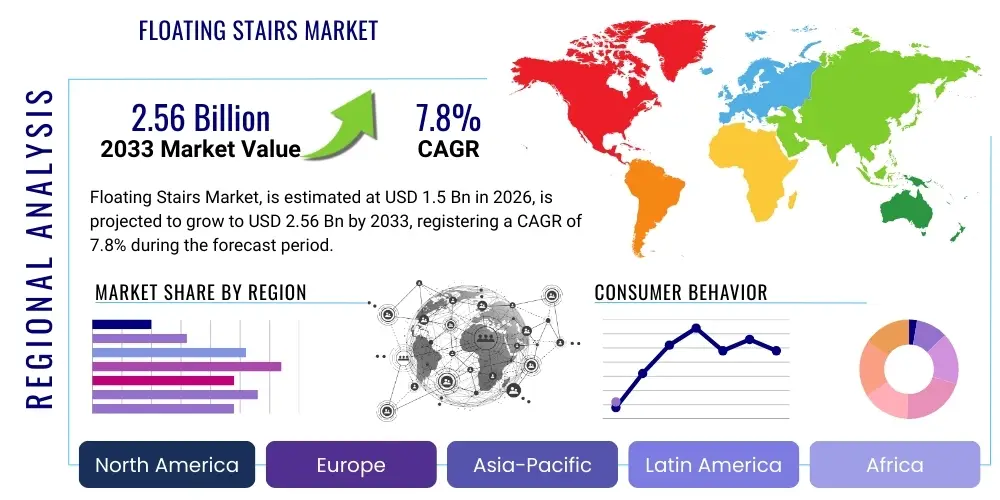

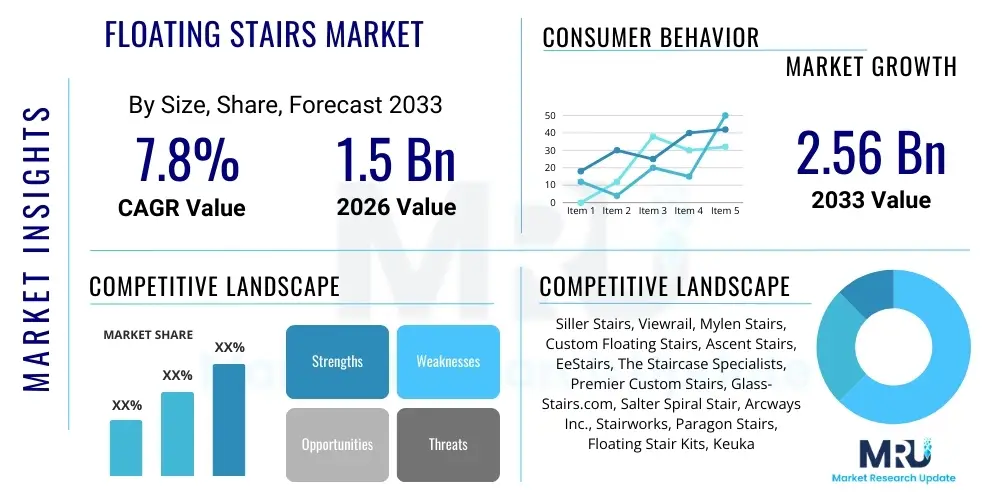

The Floating Stairs Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.56 Billion by the end of the forecast period in 2033.

Floating Stairs Market introduction

The Floating Stairs Market encompasses the design, manufacture, and installation of staircases characterized by their structural independence from visible supports beneath the treads, creating an aesthetic of floating or cantilevered steps. These architectural elements, also known as cantilever stairs or open-riser stairs, are predominantly utilized in high-end residential and premium commercial constructions where modern design, spatial efficiency, and visual minimalism are paramount. Floating stairs serve as a central focal point, combining functional utility with sculptural artistry, thereby significantly enhancing the perceived value and luxury appeal of the property. The primary market drivers include the global surge in modern and minimalist interior design trends, coupled with advancements in structural engineering that allow for safer and more visually striking installations using materials such as tempered glass, high-grade metals (steel, aluminum), and exotic hardwoods.

Product descriptions typically emphasize the hidden structural components—often utilizing a robust steel spine or cantilevered brackets anchored deeply into a load-bearing wall—which are concealed within the wall or floor assembly. Major applications span luxury homes, boutique hotels, modern office spaces, architectural firms, and high-end retail environments. These stairs offer unparalleled light transmission and open sightlines, contributing to a more airy and spacious environment, a critical benefit in contemporary urban construction where maximizing visual space is essential. Furthermore, customization is a core offering in this market, with bespoke solutions tailored to specific architectural dimensions, material palettes, and load requirements, distinguishing the offerings from standard, prefabricated staircase systems.

The benefits derived from adopting floating stairs are numerous, extending beyond mere aesthetics. They offer superior spatial integration, reducing the visual mass traditionally associated with conventional stairwells. Driving factors sustaining market growth include the increasing discretionary income of homeowners seeking unique architectural features, the continuous innovation in materials science—particularly concerning high-strength, lightweight alloys—and favorable regulatory frameworks in developed regions that permit sophisticated, engineered structural installations. Additionally, the growing influence of social media and design platforms showcasing aspirational architecture further fuels consumer demand for these distinctive structural features in modern construction projects globally.

Floating Stairs Market Executive Summary

The Floating Stairs Market is positioned for robust expansion, driven primarily by evolving architectural preferences emphasizing open-concept designs, minimalist aesthetics, and the integration of structural elements as artistic focal points. Business trends indicate a shift towards highly personalized, made-to-order fabrication processes, necessitating close collaboration between specialized manufacturers, architects, and structural engineers. Key market players are investing heavily in innovative anchoring technologies, such as advanced tension rod systems and invisible stringers, to enhance installation efficiency and structural integrity while maximizing the floating effect. Furthermore, sustainability is becoming a key differentiator, with increased demand for responsibly sourced wood, recycled metals, and low-impact production techniques, particularly in the European and North American markets.

Regionally, North America remains the largest revenue generator, spurred by a strong housing market for luxury custom builds and extensive commercial refurbishment activities prioritizing cutting-edge design. However, the Asia Pacific (APAC) region, led by rapidly developing economies like China and India, is projected to exhibit the fastest Compound Annual Growth Rate (CAGR). This acceleration is attributed to massive urbanization, the burgeoning luxury real estate sector, and the increasing adoption of Western architectural styles in premium commercial complexes and high-rise residential towers. European markets continue to demonstrate steady, mature growth, focusing intensively on high-quality craftsmanship, design innovation, and adherence to stringent building codes, particularly favoring sleek material combinations like glass and steel.

Segment trends highlight the dominance of the residential application sector, though the commercial segment, particularly hospitality and corporate headquarters, is rapidly gaining share due to the desire for distinctive branding and impressive entrance spaces. In terms of material, metal stairs, specifically those using powder-coated or brushed stainless steel, hold the largest market share due to their exceptional durability and ability to support cantilevered designs with minimal visual structure. The Cantilevered type segment, representing the purest form of the floating aesthetic with no visible support underneath each tread, commands premium pricing and is expected to witness the highest growth rate, reflecting the market's continuous pursuit of ultra-modern architectural solutions.

AI Impact Analysis on Floating Stairs Market

User queries regarding the intersection of AI and the Floating Stairs Market primarily revolve around optimizing structural design, enhancing manufacturing precision, and improving installation logistics. Common concerns include how AI can ensure compliance with complex local building codes for bespoke cantilever systems, whether generative design can minimize material waste while maintaining load-bearing capacity, and the potential for robotic assistance in the highly specialized installation process. Users are also keen to understand how AI-driven predictive analytics can forecast demand for specific materials (e.g., exotic hardwoods vs. high-strength composites) and manage complex supply chains for custom projects. The expectation is that AI will move floating stairs from a manual, high-risk engineering process to a standardized, automated, and error-proof fabrication cycle, making these luxury features more accessible and safer to implement across diverse construction projects.

The application of Artificial Intelligence is poised to revolutionize several critical stages within the Floating Stairs market value chain. In the design phase, AI-powered generative design tools can rapidly iterate through thousands of structurally sound design options, optimizing the geometry of the concealed stringer or mounting plate to achieve maximum structural efficiency with minimum material usage, adhering precisely to specified aesthetic parameters and local seismic or load-bearing regulations. Furthermore, AI algorithms are vital for performing complex Finite Element Analysis (FEA) simulations in minutes, analyzing stress distribution and deflection under various load scenarios—a task previously requiring extensive manual engineering hours—thereby accelerating the prototyping and approval process for customized installations significantly.

In the manufacturing and installation realms, AI impacts production through predictive maintenance schedules for specialized CNC machinery used to cut and finish materials like thick glass or structural steel, ensuring near-zero downtime for high-value custom orders. Furthermore, computer vision systems, integrated with robotics, can enhance quality control by performing non-destructive testing and ensuring millimeter-perfect alignment of anchoring points, which is crucial for the safety and aesthetics of floating treads. AI also optimizes supply chain logistics, predicting lead times for specialized materials and managing just-in-time inventory for projects, mitigating delays inherent in bespoke luxury construction, ultimately improving project profitability and client satisfaction.

- AI-driven Generative Design: Optimization of cantilevered structures for minimal material use and maximum load stability.

- Predictive Engineering: Rapid Finite Element Analysis (FEA) simulations to ensure structural compliance with complex building codes.

- Automated Quality Control: Computer vision systems verifying precision machining and alignment of hidden stringer connections.

- Supply Chain Optimization: Algorithms forecasting material demand (e.g., custom wood or steel components) and managing complex logistics.

- Robotic Pre-Assembly: Use of robotics for high-precision welding and anchoring component fabrication, reducing human error.

DRO & Impact Forces Of Floating Stairs Market

The Floating Stairs Market is influenced by a confluence of accelerating drivers (D), significant restraints (R), and compelling opportunities (O), which collectively define the impact forces shaping its trajectory. The primary driver is the pervasive trend toward contemporary, minimalist architecture globally, where floating stairs serve as essential design anchors. Restraints principally revolve around the high initial cost of materials and specialized engineering required for safe installation, which limits adoption in mid-range construction projects. Opportunities are emerging through advancements in composite materials and modular design techniques that promise to reduce costs and simplify the installation process, broadening the market appeal. The combined impact of these forces suggests a sustained growth trajectory, particularly as technological innovations mitigate traditional installation complexities.

Driving forces center on the aesthetic appeal and spatial advantages offered by floating stairs. Architects and interior designers increasingly specify these structures to maximize light flow, create open environments, and introduce sculptural elements into interior spaces. Furthermore, rising global disposable incomes, particularly in rapidly urbanizing regions, enable greater investment in luxury architectural features. Technological advancements in anchoring systems, such as proprietary wall-mounted brackets and sophisticated internal stringers, have improved the structural reliability and safety perceptions of floating stairs, addressing previous concerns among consumers and regulatory bodies. The continued success of high-density urban living also boosts demand, as floating designs are excellent solutions for making smaller spaces feel larger and more open.

Conversely, significant restraints impede faster market penetration. The complexity of engineering and installation requires highly specialized labor, substantially increasing the overall project cost compared to conventional stairs. Strict and often varying international building codes regarding cantilevered structures and load requirements necessitate intensive, customized structural analysis for almost every installation, adding time and expense. Moreover, concerns regarding long-term maintenance, vibration, and perceived safety risk, especially in high-traffic commercial environments or homes with young children, remain persistent challenges that manufacturers must proactively address through transparent engineering data and enhanced safety features like invisible railing options. Opportunities, however, lie in modular prefabrication techniques, which standardize components while allowing for customization, potentially lowering manufacturing costs and installation time, alongside the integration of smart technologies like integrated LED lighting and motion sensors to enhance safety and aesthetic appeal.

- Drivers: Global adoption of minimalist interior design, high demand for custom architectural features, technological advancements in hidden structural supports, and increased investment in luxury residential construction.

- Restraints: High installation and engineering complexity, significant initial cost compared to conventional stairs, strict and diverse regional building codes for cantilevered structures, and safety perceptions regarding open risers.

- Opportunities: Development of modular and standardized floating stair kits, integration of advanced composite materials for lighter yet stronger treads, expansion into the high-end renovation and commercial office sector, and leverage of digital tools for design customization.

- Impact Forces: High (Positive impact expected due to increasing aesthetic demand outweighing cost barriers as engineering solutions become more standardized and efficient).

Segmentation Analysis

The Floating Stairs Market is comprehensively segmented based on Type, Material, and Application, providing a detailed understanding of consumer preferences and regional adoption patterns. Segmentation allows manufacturers and suppliers to tailor their product offerings and marketing strategies to specific end-user needs, whether prioritizing structural minimalism (Cantilevered type) or cost-effectiveness (Single Stringer). The analysis confirms the luxury residential sector remains the primary consumer base, yet rapid growth is anticipated in the commercial sector, where visual impact and modern design are crucial for brand presentation. Understanding these segments is key to maximizing market penetration and capitalizing on emerging design trends across different construction verticals.

In terms of materials, the market reflects a continuous balance between traditional luxury (hardwood) and modern engineering (steel and glass). Steel and metal stringers and treads dominate the market share due to their inherent strength and versatility in supporting the floating structure while minimizing the visual footprint. Glass treads, though premium and requiring specialized care, are increasingly popular for creating maximal transparency and light flow, especially in high-end retail and corporate lobbies. The functional segmentation by type—Cantilevered, Single Stringer, and Double Stringer—shows that while Cantilevered systems are aesthetically preferred for the true 'floating' effect, stringer systems offer greater structural stability and simplified adherence to certain building codes, often serving as a compromise between aesthetics and regulatory compliance in larger installations.

The application segmentation clearly delineates the high-value customization required for residential projects versus the high-volume, durability-focused requirements of commercial applications. Residential use demands intricate, personalized design tailored to individual homeowner tastes, whereas commercial projects emphasize fire resistance, high load capacity, and long-term durability to withstand heavy foot traffic. The growth in renovations and retrofitting of existing buildings, utilizing floating stair technology to modernize interiors, also represents a growing sub-segment, necessitating flexible, adaptable installation solutions that can be integrated into pre-existing structural frameworks without extensive demolition. This nuanced segmentation drives innovation towards both highly bespoke fabrication and standardized component systems.

- By Type:

- Single Stringer Floating Stairs

- Double Stringer Floating Stairs

- Cantilevered Floating Stairs

- By Material:

- Wood (Hardwoods, Engineered Wood)

- Metal (Stainless Steel, Carbon Steel, Aluminum)

- Glass (Tempered, Laminated)

- Concrete and Composites

- By Application:

- Residential (Custom Homes, Luxury Apartments)

- Commercial (Hotels, Corporate Offices, Retail Spaces)

- Industrial (Select Architectural Applications)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Floating Stairs Market

The value chain for the Floating Stairs Market is inherently complex due to the custom nature of the product, starting with the specialized procurement of high-quality materials such as structural steel, tempered glass, and premium hardwoods. The upstream activities involve raw material sourcing, which demands strict adherence to architectural specifications and certifications for load-bearing components. This phase is critical as the structural integrity of a floating staircase depends entirely on the quality and precision of the foundational elements. Key upstream partnerships include specialized steel fabricators capable of precision welding and machining for the hidden stringers, and high-end timber mills providing exotic, dimensionally stable woods suitable for high-wear treads. Efficiency in upstream logistics is paramount, as delays in custom component manufacturing directly impact project timelines.

Midstream activities encompass design, engineering, and manufacturing. This is the most value-intensive stage, involving close collaboration between structural engineers (to validate safety and compliance), designers (to achieve the desired aesthetic), and specialized manufacturing workshops. Advanced CNC cutting, welding, and finishing processes ensure the precise fit required for the seamless, 'floating' look. Manufacturers often utilize proprietary techniques for anchoring and mounting systems. The downstream aspect involves logistics, site preparation, and highly specialized installation. Installation requires certified, experienced teams capable of integrating the staircase structure directly into the building's load-bearing elements (walls or floors) while concealing all supports, often demanding close coordination with other trades like drywallers and flooring contractors.

The distribution channel is predominantly direct or project-specific indirect. Direct distribution involves manufacturers dealing straight with architects, designers, or high-net-worth individual clients for bespoke residential projects, offering complete design-build and installation services. Indirect channels involve partnerships with general contractors, luxury home builders, or specialized interior fit-out companies who integrate the floating stairs into a broader construction package. Given the high cost and complexity, mass-market retail channels are rarely utilized, though pre-engineered 'kits' are sold through select specialty building material distributors. Successful delivery relies heavily on clear communication, digital modeling (BIM), and exceptional project management to ensure the final product meets the stringent quality and safety standards expected in the luxury construction segment.

Floating Stairs Market Potential Customers

The core end-users and buyers of floating stairs primarily comprise entities involved in the development and refurbishment of high-value, aesthetically driven properties. The largest segment is the luxury residential market, including high-net-worth individuals building custom homes, developers of exclusive multi-family residential towers, and specialized interior designers managing high-end renovation projects. These customers prioritize unique architectural statements, superior material quality, and the efficient use of space, viewing the staircase as a central design feature that elevates the home's overall value and modern aesthetic. They demand extensive customization, precise engineering documentation, and seamless, integrated installation services tailored to complex structural requirements.

The second major group consists of commercial end-users, predominantly within the hospitality and corporate sectors. Boutique hotels, luxury resorts, and high-profile corporate headquarters purchase floating stairs to create striking, memorable entrance lobbies or communication points between floors. For these buyers, the stairs serve a dual purpose: functional circulation and powerful brand articulation, reflecting innovation and prestige. Commercial buyers typically require materials that are durable, fire-resistant, and capable of handling heavy, continuous traffic, often opting for robust steel or concrete structural elements combined with non-slip treated treads and integrated safety features that meet commercial building codes.

A growing customer segment includes architectural firms and general contractors specializing in modern, high-design construction. These professionals often act as intermediaries, specifying and procuring floating stair systems on behalf of their clients. They prioritize manufacturers who offer extensive engineering support, Building Information Modeling (BIM) compatibility, reliable project logistics, and warranties that cover both the structure and the installation process. Their purchasing decisions are heavily influenced by the manufacturer's reputation for innovation, adherence to deadlines, and proven track record in integrating complex structural components into diverse building types, thus ensuring a seamless project execution from concept to completion.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.56 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siller Stairs, Viewrail, Mylen Stairs, Custom Floating Stairs, Ascent Stairs, EeStairs, The Staircase Specialists, Premier Custom Stairs, Glass-Stairs.com, Salter Spiral Stair, Arcways Inc., Stairworks, Paragon Stairs, Floating Stair Kits, Keuka Studios |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Floating Stairs Market Key Technology Landscape

The technological landscape of the Floating Stairs Market is characterized by innovations focused on achieving structural invisibility, enhancing safety, and improving installation efficiency. A foundational technology involves proprietary cantilever systems, which use heavy-gauge steel plates or structural beams embedded deep into load-bearing walls. Recent advancements include sophisticated mounting brackets that distribute load forces more effectively across the wall structure, often utilizing chemical anchors and precise welding techniques verified by ultrasound or magnetic particle testing. Furthermore, the use of advanced structural analysis software, often integrating Building Information Modeling (BIM) methodologies, allows engineers to simulate real-world stress and strain on complex geometries before fabrication, minimizing structural risks and ensuring regulatory compliance in highly customized designs.

Material science innovation is another critical area. Manufacturers are increasingly utilizing high-strength, lightweight alloys, such as aerospace-grade aluminum and specialized stainless steel, to minimize the overall mass of the hidden stringer while maximizing support. In tread construction, the market is seeing increased adoption of laminated and tempered glass treated with anti-slip coatings, and high-performance composite woods that offer superior dimensional stability and fire ratings compared to traditional lumber. These material breakthroughs allow for longer cantilevers and thinner tread profiles, further amplifying the illusion of floating. Additionally, surface treatment technologies, such as advanced powder coatings and specialized metal finishes, provide enhanced durability and corrosion resistance, essential for maintaining the aesthetic integrity over the lifetime of the structure.

Digital fabrication technologies, notably advanced Computer Numerical Control (CNC) machining and robotic welding, are central to the production phase, guaranteeing the millimeter-level precision required for bespoke floating stair components. Since any misalignment can compromise both the aesthetic and structural safety, these technologies are indispensable. Moreover, the integration of smart features, such as recessed LED lighting systems integrated beneath the treads or within the hidden stringer channel, utilizing low-voltage, energy-efficient technology and motion sensors, not only enhances safety during use but also emphasizes the architectural form of the staircase. These integrated lighting solutions are often controlled via smart home systems, reflecting the high-tech demands of the luxury construction sector.

Regional Highlights

Regional dynamics play a crucial role in shaping the Floating Stairs Market, influenced by local architectural traditions, disposable income levels, and stringency of building codes. North America, encompassing the United States and Canada, currently holds the largest market share. This dominance is attributed to a robust market for custom luxury housing, widespread adoption of modern interior aesthetics, and a high concentration of specialized architectural firms willing to specify and implement complex cantilevered designs. Demand in this region is also characterized by a preference for metal and wood combinations, focusing on durability and compliance with stringent structural load requirements prevalent in states like California and Florida. Significant investment in commercial high-rise construction also continues to drive demand for visually impactful corporate staircases.

Europe represents a mature yet highly quality-conscious market, focusing heavily on bespoke craftsmanship and design innovation, particularly in countries like Germany, Italy, and the UK. European consumers often prioritize sustainable materials and exceptionally high-end finishes, favoring the integration of glass and sophisticated steelwork that aligns with minimalist Scandinavian or industrial design aesthetics. Strict European Union building directives require manufacturers to focus intently on structural certification (e.g., CE marking) and fire resistance, driving innovation towards safer, highly engineered components. The renovation market is particularly strong here, where floating stairs are used extensively to modernize historic or compact urban properties.

The Asia Pacific (APAC) region is forecasted to be the fastest-growing market, primarily fueled by rapid urbanization, massive infrastructure development, and the burgeoning wealth of consumers in China, India, and Southeast Asia. The increasing Westernization of high-end residential and commercial architecture, coupled with a preference for novel, status-symbol architectural features, is driving adoption. While local manufacturing capacity is growing, many high-end projects still rely on imported specialized components or turnkey installation services from established European and North American manufacturers. In this region, safety standards are rapidly catching up, increasing the requirement for well-documented engineering and installation protocols, especially in seismically active areas.

- North America: Market leader driven by luxury residential construction, large commercial projects, and a strong preference for modern aesthetics. Key focus on steel and custom-engineered installations.

- Europe: Mature market characterized by high standards of craftsmanship, sustainability mandates, and stringent safety certifications. Strong demand in the luxury renovation segment.

- Asia Pacific (APAC): Fastest growing region due to rapid urbanization, rising affluence, and increasing adoption of contemporary architectural styles in major cities. Emphasis on large-scale commercial and high-end residential towers.

- Latin America (LATAM): Emerging market showing growth in upscale residential projects and tourist infrastructure (boutique hotels), albeit constrained by economic volatility and complex import processes.

- Middle East and Africa (MEA): High demand concentrated in Gulf Cooperation Council (GCC) countries, driven by mega-projects, ultra-luxury residential developments, and reliance on international architectural standards. Preference for opulent materials such as glass and polished metals.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Floating Stairs Market.- Siller Stairs

- Viewrail

- Mylen Stairs

- Custom Floating Stairs

- Ascent Stairs

- EeStairs

- The Staircase Specialists

- Premier Custom Stairs

- Glass-Stairs.com

- Salter Spiral Stair

- Arcways Inc.

- Stairworks

- Paragon Stairs

- Floating Stair Kits

- Keuka Studios

- Lapeyre Stair

- Active Metal

- Design 500

- Stairway Manufacturers Association (SMA)

- Spiral Stairs of America

Frequently Asked Questions

Analyze common user questions about the Floating Stairs market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary structural differences between cantilevered and stringer-based floating stairs?

Cantilevered floating stairs achieve the purest "floating" look by having each tread anchored individually and deeply into a load-bearing wall, concealing the support entirely. Stringer-based floating stairs rely on a single, hidden steel beam (stringer) running beneath the treads or within the wall, providing continuous support and often simplifying engineering and installation, although they may not appear quite as structurally independent as true cantilevers.

How much more expensive are floating stairs compared to traditional closed-riser staircases?

Floating stairs are significantly more expensive, typically ranging from 50% to 300% higher than traditional stairs. The higher cost is driven by several factors: the use of specialized high-strength materials, the required extensive structural engineering analysis for customization, and the need for highly specialized, meticulous on-site installation by certified technicians to ensure the structural integrity and aesthetic alignment of the hidden supports.

Are floating stairs safe, and do they comply with standard building codes?

Yes, when properly designed and installed by qualified professionals, floating stairs are structurally sound and comply with applicable building codes. Compliance necessitates rigorous structural calculations (often using Finite Element Analysis) to meet local load-bearing and seismic requirements. Key safety considerations often focus on required railings, particularly in commercial or high-traffic settings, and ensuring treads meet required anti-slip standards.

What materials are most commonly used for floating stair treads and supports?

The most common materials for treads are high-grade hardwoods (like oak or walnut) and tempered glass, selected for their aesthetic appeal. Supports rely heavily on high-strength metals, specifically carbon steel or stainless steel, engineered into robust, hidden stringers or cantilevered mounting plates. Composites are emerging as a strong material option due to their durability and lighter weight, offering a balance between strength and aesthetic requirements.

What is the typical lifespan and maintenance requirement for a floating staircase?

A high-quality, properly engineered and installed floating staircase has a structural lifespan comparable to the building itself, often exceeding 50 years. Maintenance is generally minimal, focused primarily on cleaning the treads and checking the stability of the railings and anchoring points annually. Wood treads may require periodic refinishing, while metal and glass components usually only require routine cleaning to maintain their appearance.

The Floating Stairs Market's trajectory is deeply intertwined with evolving consumer demands for highly personalized and sophisticated architectural elements. As modern design continues to prioritize open spaces and structural minimalism, the floating staircase transitions from a mere functional necessity to a centerpiece of interior design. This necessitates continuous innovation not only in materials and engineering but also in the manufacturing processes, particularly through the integration of digital fabrication and AI-driven design tools. The shift towards bespoke production means that manufacturers must excel in project management, seamlessly integrating design, engineering compliance, manufacturing precision, and complex on-site installation. The high barrier to entry—due to the technical specialization required—ensures that market competition focuses primarily on quality, engineering reliability, and aesthetic uniqueness, rather than simply on cost.

Geographically, while established Western markets provide stability and revenue anchors, the explosive growth anticipated in the APAC region promises lucrative expansion opportunities for companies able to adapt their products and certification processes to diverse regulatory environments and emerging consumer tastes. The future success of market participants hinges on their ability to standardize the technically complex elements—such as anchoring and load distribution systems—while simultaneously offering maximum customization in aesthetic finishes and tread materials. Furthermore, addressing the perceived safety risks associated with open-riser and cantilevered designs through transparent engineering data and robust, yet visually unobtrusive, safety solutions (like minimalist glass balustrades) will be crucial for broader market acceptance, particularly in the rapidly growing commercial application segment.

The convergence of luxury construction trends and advancements in structural technology ensures that floating stairs remain a premium product category. The increasing sophistication of Building Information Modeling (BIM) tools is simplifying the integration of these complex structures into overall building design, reducing potential conflicts and improving collaboration among architects, engineers, and builders. This technological streamlining is expected to gradually mitigate some of the traditional cost and time restraints, making floating stair solutions viable for a slightly wider range of high-end construction projects beyond exclusively bespoke luxury homes. Investments in sustainable material sourcing and circular design principles will further future-proof market offerings, aligning with global green building standards and appealing to environmentally conscious architects and developers.

The specialized nature of the Floating Stairs Market means that supply chain resilience is a constant concern. Manufacturers often rely on a select group of highly specialized suppliers for custom-machined steel and unique glass elements. Any disruption in this upstream supply chain, particularly for internationally sourced exotic materials, can severely impact project timelines and profitability. Therefore, leading market players are focusing on establishing dual-sourcing strategies and increasing vertical integration of the manufacturing process where feasible, to gain better control over quality and delivery schedules. The market's high value-per-unit ratio justifies significant investment in research and development aimed at creating proprietary, patentable structural systems that offer a competitive advantage in both ease of installation and structural performance, cementing the product's position as a symbol of architectural excellence and modern engineering capability.

Looking ahead, the market is poised to see further blurring of lines between residential and commercial applications, driven by corporate environments that seek to emulate the high-design, personalized feel of luxury homes. This trend will necessitate the development of products that meet commercial safety standards (fire ratings, load capacity) while retaining the elegant, minimalist aesthetic typical of residential floating stairs. Educational efforts directed at architects, designers, and local building code officials are also critical for sustained growth, ensuring that the unique structural requirements and safety features of floating stairs are well understood, facilitating smoother approval processes and reducing potential regulatory friction in new construction and renovation projects globally. This proactive engagement will help maintain the market's positive growth trajectory towards the projected USD 2.56 Billion valuation by 2033.

Technological advancement is not limited to structural integrity; aesthetic innovations are also pushing the boundaries of design. For instance, manufacturers are experimenting with magnetic levitation technology, although nascent, potentially paving the way for truly support-free steps in the very long term. More immediately relevant are innovations in smart glass technology, allowing treads to change opacity or display integrated graphics, adding an interactive element to the staircase design. These highly specialized features underscore the market's positioning within the ultra-luxury segment. The engineering precision required for these integrations demands advanced digital twin capabilities, where every component is modeled and tested virtually before physical fabrication, minimizing waste and ensuring first-time installation success, which is paramount given the high cost of rework in custom architectural projects.

Furthermore, the competitive landscape is evolving, moving beyond simply manufacturing and supply toward offering comprehensive, end-to-end design consultation and project management services. Leading companies are increasingly employing in-house teams of licensed structural engineers and BIM specialists to work directly with client architects, ensuring the floating stair design is flawlessly integrated into the primary structure from the earliest conceptual stages. This approach reduces risk for the client and reinforces the manufacturer's reputation as a reliable, high-expertise partner. This specialization in consultation and integration serves as a key barrier to entry for smaller or less technologically equipped competitors, solidifying the market leadership of established firms known for handling complex, high-stakes architectural contracts with precision and structural guarantees.

Regional variations in design sensibility significantly influence material choices. In the Nordic countries, for example, the preference leans heavily toward minimalist steel structures combined with light-colored, certified sustainable wood, maximizing light and integrating seamlessly into clean, white interiors. Conversely, in parts of the Middle East, there is higher demand for lavish materials such as polished exotic stone or elaborate decorative metalwork incorporated into the tread design, reflecting a taste for maximalist luxury even within a modern structural context. Market players must maintain flexible production facilities capable of handling these diverse material inputs and intricate fabrication specifications. The ability to source, certify, and flawlessly integrate premium materials—whether rare hardwoods or highly specialized glass panels—is a crucial differentiator in winning high-value, international contracts within the floating stairs market.

Finally, the growing awareness of embodied carbon and material sustainability is expected to push the market toward lighter, more durable, and recyclable materials. Research into advanced composite materials that can mimic the appearance and feel of traditional wood or stone while offering superior performance characteristics and lower environmental impact during production is gaining traction. Manufacturers who successfully certify their products under globally recognized sustainability standards (such as LEED or BREEAM) will gain a significant competitive edge, particularly when targeting large-scale commercial and governmental architectural projects that often mandate green building compliance. The future of the Floating Stairs Market will be defined not just by invisible support systems, but by visibly responsible and advanced manufacturing practices.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager