Fluid Rotary Unions Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437504 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Fluid Rotary Unions Market Size

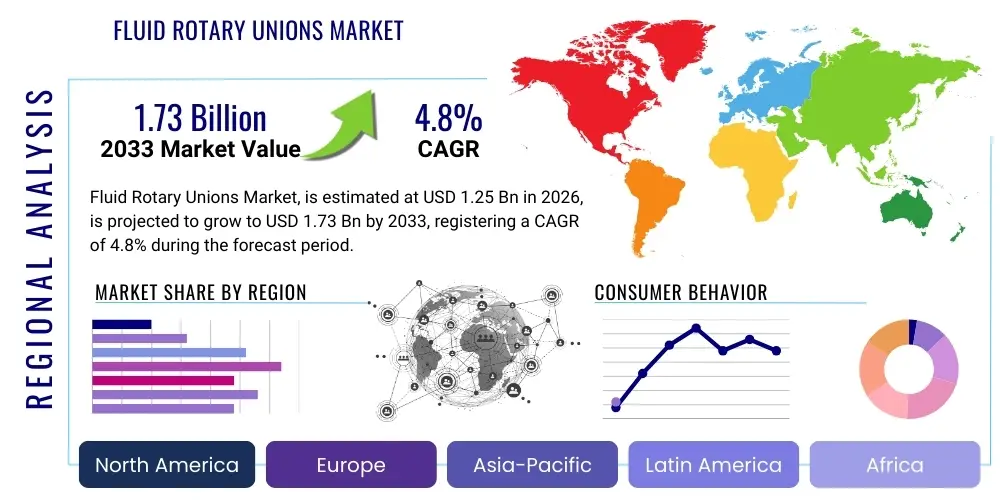

The Fluid Rotary Unions Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at $1.25 Billion in 2026 and is projected to reach $1.73 Billion by the end of the forecast period in 2033.

Fluid Rotary Unions Market introduction

The Fluid Rotary Unions Market encompasses specialized mechanical components engineered to transfer fluids—such as air, hydraulic oil, water, coolant, or chemicals—from a stationary source to a rotating piece of machinery. These essential devices maintain a sealed connection while accommodating high rotational speeds and variable pressures, ensuring uninterrupted fluid delivery vital for cooling, lubrication, or power transmission in continuous industrial processes. The core function of a rotary union is to prevent leaks and contamination, offering reliability and efficiency across demanding operational environments, particularly where energy and media exchange between fixed and moving parts is necessary.

The product, often referred to as rotary joints or swivel joints, is characterized by precision engineering, incorporating highly durable seals (like mechanical seals or labyrinth seals) and robust bearing systems. Major applications span high-speed machining centers, papermaking machines, printing presses, converting equipment, oil and gas drilling platforms, and packaging machinery. Key benefits driving market adoption include significantly enhancing machine uptime, facilitating higher operating speeds, reducing energy consumption through optimized fluid transfer, and extending the lifespan of critical machinery components by providing effective temperature management and lubrication.

Market growth is predominantly driven by the accelerating trend of industrial automation and the increasing demand for high-performance, high-precision machine tools globally. Furthermore, the expansion of the packaging industry, spurred by e-commerce proliferation, and significant investment in the aerospace and defense sectors, where specialized multi-passage unions are critical, further bolster market dynamics. The shift towards energy-efficient manufacturing processes and the need for reliable fluid handling solutions in complex robotic systems are also major contributing factors.

Fluid Rotary Unions Market Executive Summary

The Fluid Rotary Unions Market is currently characterized by strong growth fueled by the convergence of Industry 4.0 initiatives and persistent demand from heavy manufacturing sectors. Business trends indicate a robust focus on miniaturization, multi-media capabilities (combining fluid and electrical transfer), and the integration of smart monitoring features to predict maintenance needs. Key market participants are heavily investing in advanced sealing technologies, particularly ceramic and silicon carbide seals, to withstand increasingly harsh operating conditions involving high temperatures and abrasive media, thus enhancing product longevity and performance metrics. Strategic mergers, acquisitions, and technological partnerships aimed at expanding regional manufacturing footprints and diversifying end-use application portfolios are common strategies among market leaders.

Regionally, Asia Pacific (APAC) stands out as the primary engine of market expansion, primarily due to the rapid industrialization, substantial growth in the manufacturing and automotive sectors in China, India, and Southeast Asia, and escalating investments in machine tool production. North America and Europe maintain significant market shares, characterized by a high demand for premium, customized, and technologically sophisticated rotary unions, particularly within aerospace, specialized machinery, and renewable energy equipment manufacturing. Regulatory standards emphasizing operational safety and energy efficiency in mature economies are further pushing the adoption of high-precision, low-friction rotary union solutions.

Segment trends reveal that hydraulic and coolant rotary unions dominate the market by product type, driven by widespread use in heavy-duty machinery and CNC applications, respectively. The material segment is seeing a preference shift towards specialized stainless steel and carbon steel alloys offering superior corrosion resistance and durability. In terms of end-use, the Machine Tools sector retains the largest market share, requiring continuous innovation in high-speed, high-pressure coolant unions. However, the Robotics and Automation sector is exhibiting the fastest growth trajectory, demanding compact, lightweight, and multi-passage unions capable of handling power, data, and fluid transfer simultaneously within confined spaces, reflecting the broader movement toward integrated system solutions.

AI Impact Analysis on Fluid Rotary Unions Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Fluid Rotary Unions market frequently center on predictive maintenance capabilities, optimization of operational parameters, and the role of AI in quality control and design processes. Users are concerned with how AI can minimize unexpected downtime associated with seal failure, optimize fluid flow rates based on real-time load conditions, and accelerate the development of highly customized rotary union geometries. The key themes revolve around achieving 'zero downtime' through data-driven insights, integrating sensor technology with AI algorithms for health monitoring (vibration, temperature, pressure analytics), and utilizing generative design techniques to improve the efficiency and lifespan of sealing elements and bearings. There is a strong expectation that AI will transition rotary unions from passive components to active, self-monitoring system elements, drastically altering maintenance schedules and operational reliability in high-stakes manufacturing environments.

- AI-Powered Predictive Maintenance: Utilizing machine learning algorithms to analyze real-time sensor data (vibration, temperature) from rotary unions, predicting potential seal or bearing failure hours or days in advance, thereby minimizing unplanned downtime.

- Optimized Fluid Management: AI systems adjusting fluid pressure, temperature, and flow rates dynamically through the rotary union based on the machine's current operational load and material requirements, improving process efficiency and reducing fluid waste.

- Generative Design for Components: Employing AI-driven generative design software to rapidly develop optimized internal geometries and lighter, more resilient housing structures for rotary unions, enhancing performance under extreme conditions.

- Automated Quality Control: Using computer vision and AI for high-throughput inspection of manufactured rotary union components, ensuring micron-level precision and consistency in seals and bearing surfaces.

- Smart Inventory and Logistics: AI improving forecasting accuracy for spare parts (seals, bearings) required for specific types of rotary unions across multiple industrial sites, optimizing inventory holding costs.

DRO & Impact Forces Of Fluid Rotary Unions Market

The dynamics of the Fluid Rotary Unions Market are strongly influenced by the growth in global manufacturing output and the relentless pursuit of automation and efficiency across industries. Key drivers include the proliferation of high-speed CNC machining centers that mandate reliable high-pressure coolant unions, and significant technological advancements in sealing materials that extend product life. Restraints primarily revolve around the high initial cost of complex multi-passage and specialty unions, particularly those designed for extreme environments, and the challenge posed by increasing competition from low-cost regional manufacturers, which affects pricing power in standardized product segments. Opportunities are abundant in the emerging markets of additive manufacturing (3D printing), where rotary unions are crucial for controlling powder application and temperature regulation, and in the renewable energy sector, specifically large-scale wind turbine applications requiring robust pitch control systems.

The impact forces within this market are significant. Technological innovation acts as a major accelerating force, pushing manufacturers to integrate condition monitoring sensors (IoT) directly into the unions, transforming them into smart components ready for Industry 4.0 ecosystems. Supply chain volatility, particularly affecting raw material costs (specialized steel, ceramics), exerts a restraining force, potentially increasing production costs. Furthermore, the mandatory need for precise sealing technology in industries like aerospace and pharmaceuticals imposes extremely high barriers to entry regarding quality and certification, ensuring that established high-precision manufacturers maintain a competitive edge despite pricing pressures. The cyclical nature of capital expenditure in heavy manufacturing also creates a fluctuating impact force on demand.

Segmentation Analysis

The Fluid Rotary Unions market segmentation offers a critical framework for understanding demand heterogeneity across various industrial applications and technical requirements. The market is primarily segmented based on the type of fluid transferred (Hydraulic, Pneumatic, Coolant, Water), the construction material, the number of passages (single or multi), and the specific end-use industry. This structure reflects the necessity for highly customized solutions, as the performance criteria for a rotary union in a high-speed machine tool (requiring extreme thermal stability and high pressure) differ vastly from one used in a low-speed, high-torque application like oil drilling. The segmentation underscores the trend towards specialized, high-precision products that deliver optimal performance in their intended operational niche, moving away from generic, one-size-fits-all solutions, particularly in high-value industrial automation.

- By Type:

- Hydraulic Rotary Unions

- Pneumatic Rotary Unions

- Coolant Rotary Unions (High-Speed & High-Pressure)

- Water and Steam Rotary Unions

- Multi-Media/Hybrid Rotary Unions

- By Number of Passages:

- Single Passage

- Multi-Passage (2-12 passages)

- By Material:

- Stainless Steel

- Carbon Steel

- Aluminum

- Brass and Bronze Alloys

- Specialty Engineered Plastics

- By End-Use Industry:

- Machine Tools (CNC Machining Centers)

- Oil & Gas (Drilling Rigs, Offshore Platforms)

- Packaging and Converting

- Printing and Paper Manufacturing

- Textiles

- Food & Beverage

- Aerospace & Defense

- Robotics and Automation

Value Chain Analysis For Fluid Rotary Unions Market

The value chain for the Fluid Rotary Unions market begins with the upstream segment, focusing heavily on raw material procurement, particularly high-grade specialty steels, advanced ceramics (Silicon Carbide, Tungsten Carbide) for sealing components, and high-performance elastomers. The quality and purity of these raw materials are paramount as they directly influence the rotational speed, pressure handling capability, and overall lifespan of the final product. Key upstream activities include forging, precision casting, and sourcing of specialized bearings and springs. Suppliers maintaining stringent quality control and offering rapid material customization capability hold significant leverage within this segment.

The central manufacturing phase involves highly technical precision machining (CNC turning, grinding), specialized surface treatments (hard coating, plating), and clean-room assembly, especially crucial for high-speed and aerospace applications. Manufacturers differentiate themselves through proprietary sealing technologies, unique bearing designs, and robust R&D focused on minimizing frictional torque and heat generation. Following manufacturing, distribution channels are bifurcated. Direct distribution is common for highly specialized, customized, and large-volume orders, typically involving direct engagement with large OEMs in the machine tool and aerospace sectors. Indirect distribution relies heavily on industrial distributors, authorized resellers, and system integrators who provide local inventory, technical support, and installation services to smaller MRO (Maintenance, Repair, and Overhaul) clients and regional end-users.

The downstream segment encompasses the installation, integration, and long-term maintenance of the rotary unions within complex machinery. End-users require continuous technical support, training, and rapid access to spare parts (seals and bearings). The shift toward condition monitoring has increased the importance of after-sales services and technical diagnostics provided by manufacturers or their authorized partners. Optimization of the distribution network, ensuring global availability of precision components and technical expertise, is vital for maintaining market share and minimizing customer downtime, ultimately linking product quality and supply chain efficiency directly to end-user satisfaction and operational continuity.

Fluid Rotary Unions Market Potential Customers

The primary customers for fluid rotary unions are Original Equipment Manufacturers (OEMs) who integrate these components into their machinery, and large industrial end-users requiring replacement units or specialized retrofits (MRO). The most significant segment remains the Machine Tool industry, including manufacturers of high-performance CNC lathes, milling machines, and grinding equipment, which rely on rotary unions for the consistent, high-pressure delivery of coolants to the spindle and tool interface. Furthermore, the Oil & Gas sector represents a critical customer base, demanding specialized unions for mud and cement transfer on drilling rigs and swivel stacks on offshore platforms, where robustness against abrasive fluids and extreme pressure is non-negotiable.

Another rapidly expanding customer segment includes companies involved in high-throughput converting and packaging machinery, where rotary unions handle air, vacuum, or water for process control. The Food & Beverage and Pharmaceutical industries are also key buyers, requiring stainless steel, hygienic-design rotary unions for clean-in-place (CIP) processes and general media transfer under stringent sanitary regulations. Lastly, the emerging fields of robotics and automation, coupled with the growth of 3D printing equipment manufacturers, seek compact, multi-passage unions capable of managing complex fluid, electrical, and data transfer simultaneously, marking them as high-growth potential customers for advanced, integrated solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.25 Billion |

| Market Forecast in 2033 | $1.73 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kadant Inc., DSTI, Deublin Company, Rotary Systems Inc., Christian Maier GmbH, Moog Inc., Slip Ring, Moflon, GAT, Sealant, Rotoflux, Pera, Talco, Oerlikon Balzers, Dynisco, MAIER, Unique, Fibrox, Aethel, BGB. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fluid Rotary Unions Market Key Technology Landscape

The technological landscape of the Fluid Rotary Unions market is continuously evolving, driven by the need to support higher rotational speeds, extreme pressure differentiation, and corrosive fluid compatibility. A core technological focus is the advancement of sealing technologies. While traditional PTFE seals are common, there is a strong shift toward precision-engineered mechanical seals utilizing highly durable and friction-resistant materials such as Silicon Carbide (SiC) and Tungsten Carbide (WC). These materials offer significantly improved wear resistance, extending service intervals and reducing torque, which is critical for energy efficiency in high-speed applications like CNC spindles. Furthermore, the development of non-contact sealing solutions, such as labyrinth seals and ferrofluidic seals, is gaining traction in ultra-high-speed and contamination-sensitive environments where zero leakage and minimal friction are mandatory requirements.

Another significant technological advancement involves the integration of Smart Rotary Union technology, enabling condition monitoring and predictive maintenance capabilities. This involves embedding miniature sensors—monitoring temperature, vibration, pressure, and leakage—directly into the union housing. These IoT-enabled components transmit real-time data back to a central control system or cloud platform. This technological integration allows end-users to transition from scheduled maintenance to predictive maintenance, optimizing operational expenditure and preventing catastrophic failure. The ability to monitor dynamic operating conditions in real-time is particularly valuable in critical applications within the aerospace and heavy machinery sectors, where downtime costs are prohibitive.

Furthermore, innovation is centered on optimizing internal fluid passages and bearing systems. Multi-passage rotary unions are becoming increasingly complex, integrating pathways for multiple distinct media (e.g., hydraulic oil, high-pressure air, and electrical signals) within a single compact unit. This complexity necessitates advanced CFD (Computational Fluid Dynamics) modeling during the design phase to minimize pressure drop and turbulence, ensuring efficient media transfer. The use of hybrid ceramic bearings in high-speed unions is also increasing, offering superior heat dissipation, lighter weight, and longer life compared to traditional steel bearings, directly addressing the demands imposed by modern, high-throughput manufacturing processes.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market due to massive capital investment in manufacturing, particularly in China, South Korea, Japan, and India. The region's dominance is driven by the booming automotive production, rapid adoption of automation and robotics in consumer electronics manufacturing, and extensive growth in the production of high-performance machine tools. Demand is strong for both standardized, cost-effective unions and specialized high-end coolant unions for precision manufacturing operations.

- North America: North America holds a substantial market share, characterized by high demand for specialized, high-performance rotary unions, particularly in the aerospace and defense industry, where high-pressure, multi-passage fluid handling is essential for aircraft and military equipment. The region is a leader in adopting smart, IoT-enabled unions and advanced sealing materials, driven by stringent quality standards and the high operational cost of downtime in advanced manufacturing.

- Europe: Europe is a mature market focusing on high-quality and sustainable solutions. Germany, Italy, and France are key contributors, driven by a robust presence in the machine tool, printing, and specialized industrial machinery sectors. European manufacturers often prioritize energy efficiency, compliance with environmental regulations (such as minimizing leakage), and superior component longevity, leading to higher adoption rates of premium, low-friction sealing technologies and custom-engineered solutions.

- Latin America (LATAM): The LATAM market, while smaller, is exhibiting steady growth, largely driven by the expansion of the packaging, food processing, and oil and gas sectors, particularly in Brazil and Mexico. Demand is sensitive to capital expenditure cycles and focused on reliable, durable unions suited for challenging environments and often operating under older, refurbished machinery requiring robust, easily maintainable components.

- Middle East and Africa (MEA): Growth in MEA is highly concentrated within the Oil & Gas and petrochemical industries, particularly in the Gulf Cooperation Council (GCC) countries. There is significant demand for heavy-duty, corrosion-resistant rotary unions designed to handle high pressures and temperatures encountered during drilling, exploration, and refining processes, often prioritizing durability and resistance to harsh media and extreme climate conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fluid Rotary Unions Market.- Kadant Inc.

- DSTI

- Deublin Company

- Rotary Systems Inc.

- Christian Maier GmbH

- Moog Inc.

- Slip Ring

- Moflon

- GAT (General Automatic Transfer)

- Sealant

- Rotoflux

- Pera

- Talco

- Oerlikon Balzers

- Dynisco

- MAIER

- Unique

- Fibrox

- Aethel

- BGB

Frequently Asked Questions

Analyze common user questions about the Fluid Rotary Unions market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors primarily drive the demand for high-speed coolant rotary unions?

Demand is primarily driven by the increasing adoption of high-speed Computer Numerical Control (CNC) machine tools. These machines require coolant to be delivered reliably at pressures exceeding 100 bar and rotational speeds up to 20,000 RPM to optimize metal removal rates and extend tool life, mandating specialized high-performance coolant unions.

How does the choice of sealing material impact rotary union performance?

The sealing material is critical for performance and lifespan. Materials like Silicon Carbide (SiC) and Tungsten Carbide (WC) are favored in high-pressure and abrasive applications due to their exceptional hardness and low friction coefficient, significantly reducing wear and maintenance frequency compared to standard graphite or PTFE seals.

What distinguishes a single-passage union from a multi-passage union?

A single-passage rotary union transfers only one medium (fluid or gas) at a time. A multi-passage union, conversely, is designed to transfer two or more distinct media simultaneously, often including power, data, and multiple fluid types, making them essential for complex automation and robotic applications.

Which end-use industry represents the largest market share for fluid rotary unions?

The Machine Tools industry, encompassing CNC machining and specialized grinding equipment manufacturing, holds the largest market share. This sector requires continuous, reliable fluid transfer for cooling, lubrication, and chip flushing in high-throughput environments globally.

What role does IoT integration play in modern rotary union technology?

IoT integration enables modern rotary unions to incorporate embedded sensors for continuous monitoring of key parameters (temperature, vibration). This capability facilitates advanced predictive maintenance strategies, allowing operators to anticipate and prevent component failure before unscheduled machine downtime occurs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager