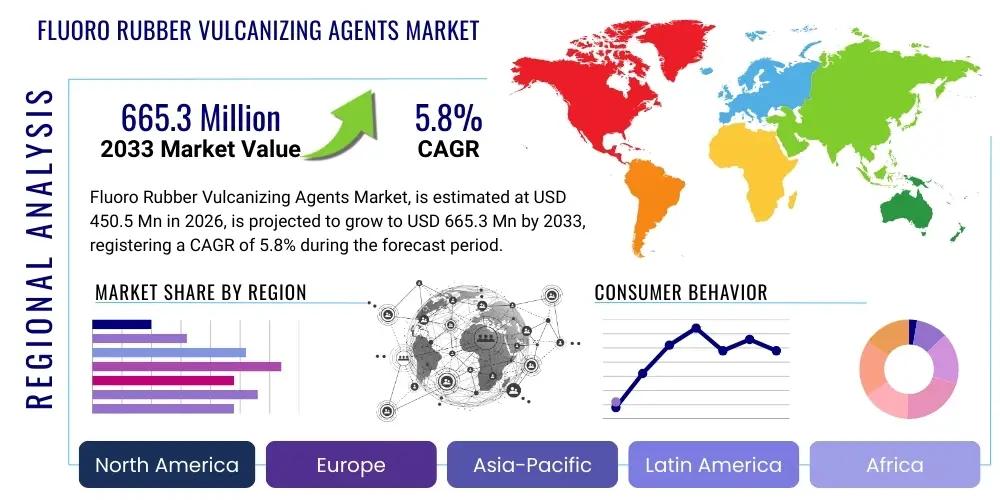

Fluoro Rubber Vulcanizing Agents Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438505 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Fluoro Rubber Vulcanizing Agents Market Size

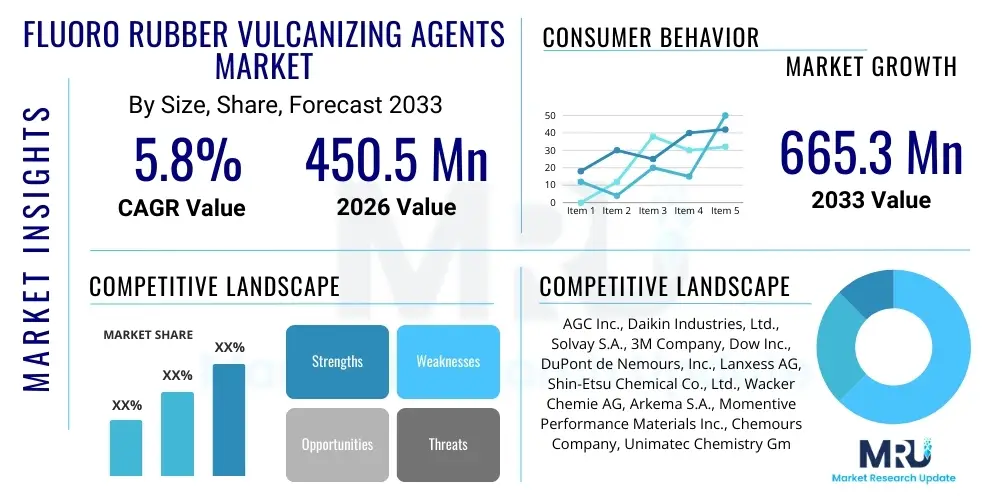

The Fluoro Rubber Vulcanizing Agents Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 665.3 Million by the end of the forecast period in 2033. This consistent growth trajectory is primarily driven by the escalating demand for high-performance elastomers in critical industrial applications, particularly within the automotive, aerospace, and chemical processing sectors, where extreme temperature and chemical resistance are non-negotiable requirements.

Fluoro Rubber Vulcanizing Agents Market introduction

The Fluoro Rubber Vulcanizing Agents Market encompasses specialized chemical compounds essential for curing and cross-linking raw fluoroelastomers (FKM/FFKM) into stable, high-performance rubbers. These agents, which primarily include polyol, peroxide, and amine systems, facilitate the formation of robust molecular networks, granting the finished rubber superior resistance to heat, aggressive chemicals, oils, and fuels. Fluoroelastomers are critical materials used in environments where standard rubbers fail, such as in high-temperature engine seals, chemical processing gaskets, and oilfield equipment.

Major applications driving market expansion include sealing components in internal combustion engines and electric vehicle battery systems, hydraulic seals in aerospace applications, and O-rings and diaphragms utilized in stringent chemical manufacturing processes. The inherent benefits of using these vulcanizing agents are the enhanced mechanical properties, prolonged service life, and superior compression set resistance of the final rubber products, which significantly reduce maintenance costs and improve operational safety in high-stress environments. Driving factors include stringent environmental regulations necessitating leakage prevention, the rapid expansion of electric vehicle manufacturing requiring robust sealing solutions, and continuous technological advancements in aerospace and defense sectors demanding extremely reliable materials.

The market is characterized by high barriers to entry due to the specialized chemical synthesis and strict performance standards required by end-users. Manufacturers must comply with global standards for safety and reliability, especially those dictated by the automotive and aerospace industries. Product innovation focuses on developing more efficient, faster-curing, and safer vulcanizing agents that improve the processing efficiency of fluoroelastomers while maintaining or enhancing the final material properties, pushing the overall market value higher through technological differentiation.

Fluoro Rubber Vulcanizing Agents Market Executive Summary

The Fluoro Rubber Vulcanizing Agents Market is poised for significant expansion, fueled by robust business trends emphasizing material longevity and operational safety across multiple industries. Key business trends include the shift towards polyol-based vulcanizing systems due to their excellent scorch safety and fast cure rates, coupled with increasing investments in R&D aimed at developing fluorine-free or low-fluorine alternatives to address emerging sustainability concerns. The increasing complexity of modern machinery necessitates elastomers that can withstand increasingly aggressive operating conditions, thereby maintaining high demand for FKM-based components and their associated vulcanizing agents. Consolidation among major chemical suppliers and strategic partnerships with primary fluoroelastomer manufacturers are defining competitive dynamics.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, driven by massive expansions in automotive manufacturing, particularly in China and India, and surging investment in chemical processing and electronics industries. North America and Europe maintain strong market shares, characterized by high-value applications in aerospace and sophisticated industrial machinery, coupled with strict regulatory frameworks that mandate the use of high-performance seals. Segment trends reveal that the Polyol-based segment dominates the market by type due to its versatility and widespread acceptance in general FKM curing. Application-wise, the Automotive sector remains the largest consumer, although the Oil & Gas and Chemical Processing sectors show above-average growth rates due to increasing demand for seals resistant to aggressive solvents and high-pressure steam environments.

In summary, the market exhibits high resilience and steady growth, underpinned by the indispensable nature of high-performance elastomers in modern industrial infrastructure. Strategic focus areas for market participants include capacity expansion in APAC, optimization of supply chains for key raw materials (e.g., Bisphenol AF), and continuous innovation in vulcanization technology to meet evolving performance specifications. The integration of advanced diagnostics in manufacturing processes is also a rising trend, ensuring consistent quality and optimizing batch processing times for specialized vulcanizing agent formulations.

AI Impact Analysis on Fluoro Rubber Vulcanizing Agents Market

Common user questions regarding AI's impact on the Fluoro Rubber Vulcanizing Agents Market typically center on optimization, material discovery, and supply chain predictability. Users frequently ask: "How can AI accelerate the discovery of new, more efficient vulcanizing agents?" "Will AI-driven process control reduce manufacturing defects and improve product consistency?" and "Can machine learning predict raw material price volatility affecting vulcanizing agent costs?" The analysis reveals a collective expectation that AI will primarily serve as a powerful tool for enhancing R&D efficiency, optimizing complex chemical formulations, and ensuring higher quality control in the often intricate curing processes of fluoroelastomers. Key concerns revolve around the initial investment required for digitalization and the need for highly specialized data scientists familiar with polymer chemistry.

- AI-driven Predictive Maintenance: Utilizing sensor data from curing equipment to predict optimal vulcanization cycles, reducing energy consumption, and minimizing material waste due to under/over-curing.

- Formulation Optimization: Employing machine learning algorithms to screen thousands of potential compound combinations (vulcanizing agents, accelerators, stabilizers) rapidly, identifying optimal formulations for specific application requirements (e.g., enhanced acid resistance or lower compression set).

- Supply Chain Resilience: Using AI to analyze global geopolitical and commodity data to forecast supply disruptions or price fluctuations in key precursors, such as fluoropolymers and specialty amines, allowing manufacturers to optimize procurement strategies.

- Quality Control Enhancement: Implementing computer vision and AI analytics in manufacturing lines to detect microscopic defects or inconsistencies in vulcanizing agent batches, ensuring extremely high purity and reliability.

- Accelerated R&D: Simulating chemical reactions and cross-linking kinetics using AI models, dramatically reducing the time and cost associated with traditional physical experimentation for developing novel, high-temperature vulcanizing systems.

DRO & Impact Forces Of Fluoro Rubber Vulcanizing Agents Market

The Fluoro Rubber Vulcanizing Agents Market dynamics are shaped by a strong interplay of growth drivers (D), significant restraints (R), and compelling opportunities (O), all mediated by powerful impact forces. The primary drivers include the relentless global push toward high-performance materials in extreme environments, particularly in automotive engine seals and high-pressure oilfield equipment, demanding reliable FKM components. Opportunities stem from the rapid proliferation of Electric Vehicles (EVs) and hybrid vehicles, which require specialized, thermally stable seals for battery packs and power electronics, creating new, high-value application niches for advanced vulcanizing systems. However, the market faces constraints such as the high cost of raw fluorinated materials, strict regulatory scrutiny concerning fluorinated compounds (PFAS restrictions), and the technical complexity involved in achieving consistent vulcanization quality, requiring precise control over temperature and time.

The impact forces influencing this market are multifaceted, encompassing technological advancements, regulatory pressures, and raw material availability. Technological evolution dictates the formulation complexity; for instance, the continuous demand for FFKM substitutes drives innovation in specialized polyol and peroxide systems capable of handling ultra-high-performance elastomers. Regulatory forces, particularly environmental mandates in Europe and North America related to chemical safety and waste disposal, directly affect manufacturing practices and product composition, potentially constraining certain less environmentally friendly amine-based curing systems. Furthermore, the volatility in crude oil prices indirectly impacts the costs of many chemical precursors, applying pressure on the profit margins of vulcanizing agent suppliers. These forces necessitate continuous adaptation and strategic sourcing by market participants to maintain competitive advantage.

Segmentation Analysis

The Fluoro Rubber Vulcanizing Agents Market is comprehensively segmented based on the chemical Type of the agent, the specific Application industry, and the Geographical region. This segmentation provides crucial insights into market penetration and growth potential across various dimensions. Understanding these segments is vital for businesses aiming to optimize their product portfolios and geographical strategies, focusing on high-growth areas such as specialized peroxide cures for automotive parts or polyol systems tailored for critical aerospace seals. The market structure reflects the highly specialized nature of fluoroelastomer processing, where the choice of vulcanizing agent is intrinsically linked to the required end-product performance characteristics and manufacturing efficiency.

- By Type:

- Polyol-based Vulcanizing Agents

- Peroxide-based Vulcanizing Agents

- Amine-based Vulcanizing Agents

- Other Specialty Systems (e.g., Sulfur systems for hybrid compounds)

- By Application:

- Automotive (Seals, O-rings, Gaskets, Hoses)

- Aerospace & Defense (Hydraulic Systems, Fuel Systems)

- Chemical Processing & Industrial Machinery (Valves, Diaphragms)

- Oil & Gas (Downhole Tools, Packers, Blowout Preventers)

- Semiconductor & Electronics (High-purity seals)

- Pharmaceutical & Medical

- By Grade:

- Standard Grade

- High-Purity Grade

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Fluoro Rubber Vulcanizing Agents Market

The value chain for the Fluoro Rubber Vulcanizing Agents Market begins with the upstream sourcing of highly specialized chemical raw materials, including fluorinated precursors, specific polyols (like Bisphenol AF or V-compounds), organic peroxides, and specialty amines. These precursors often require complex and energy-intensive synthesis processes, typically involving niche chemical manufacturers. Upstream complexity and raw material price volatility significantly influence the final cost structure of the vulcanizing agents. Consolidation and long-term contracts in this initial phase are crucial for maintaining stable production costs and consistent supply quality, given the strict purity requirements of the downstream elastomer manufacturers.

The midstream involves the synthesis and formulation of the vulcanizing agent compounds, often proprietary blends designed to optimize cure rates, scorch safety, and ultimate physical properties of the FKM. Manufacturers of vulcanizing agents operate highly specialized chemical plants, adhering to rigorous quality standards, such as ISO certifications, demanded by the aerospace and automotive industries. Distribution channels are predominantly indirect, utilizing specialized chemical distributors who possess expertise in handling and transporting these performance chemicals to global fluoroelastomer compounders and fabricators. Direct distribution is typically reserved for large-volume customers or strategic accounts requiring highly customized formulations and technical support, ensuring tight integration between the agent producer and the compounder.

The downstream segment is dominated by fluoroelastomer compounders and finished component manufacturers (e.g., seals, O-rings, gaskets). These end-users incorporate the vulcanizing agents into raw FKM polymers and then mold and cure the final components. The performance of the vulcanizing agent directly impacts the quality and reliability of the finished product, which is then sold to diverse sectors like automotive OEMs, aircraft manufacturers, and chemical plant operators. The feedback loop from the end-users regarding component performance is critical, driving continuous innovation in agent formulations to meet escalating thermal, chemical, and mechanical requirements.

Fluoro Rubber Vulcanizing Agents Market Potential Customers

Potential customers for Fluoro Rubber Vulcanizing Agents are primarily organizations involved in the compounding, fabrication, and use of high-performance fluoroelastomer components. The largest cohort of buyers are the fluoroelastomer compounders and rubber processors who purchase the vulcanizing agents in bulk to cross-link raw FKM polymers into commercial rubber sheets, profiles, and pre-forms. These processors then supply molded components to various industries. Specific end-user/buyers include Tier 1 and Tier 2 suppliers in the automotive industry requiring high-temperature seals for turbochargers, fuel injectors, and powertrain systems, increasingly focusing on battery seals for electric vehicles due to thermal management needs.

Another significant customer base comprises manufacturers in the aerospace and defense sectors, including airframe and engine OEMs, who demand extremely reliable hydraulic and fuel system seals that meet stringent military and civil aviation specifications (e.g., AMS standards). Furthermore, companies operating within the chemical processing, pharmaceuticals, and semiconductor industries are critical buyers. These sectors require ultra-high-purity seals, diaphragms, and O-rings resistant to aggressive media like strong acids, solvents, and plasma etching gases, driving demand for specialized, often high-purity grade, vulcanizing agents that do not introduce extractable contaminants into the finished elastomer product.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 665.3 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AGC Inc., Daikin Industries, Ltd., Solvay S.A., 3M Company, Dow Inc., DuPont de Nemours, Inc., Lanxess AG, Shin-Etsu Chemical Co., Ltd., Wacker Chemie AG, Arkema S.A., Momentive Performance Materials Inc., Chemours Company, Unimatec Chemistry GmbH, Gujarat Fluorochemicals Limited (GFL), Halocarbon Products Corporation, Central Glass Co., Ltd., Dalian Richon ChemCo., Ltd., Shandong Huayi Group, Jiangsu Meilan Chemical Co., Ltd., Shanghai 3F New Materials Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fluoro Rubber Vulcanizing Agents Market Key Technology Landscape

The technology landscape in the Fluoro Rubber Vulcanizing Agents Market is centered around optimizing the cross-linking mechanisms for improved cure kinetics, thermal stability, and mechanical performance. The three dominant technologies are the polyol cure system (utilizing polyhydroxy compounds like Bisphenol AF), the peroxide cure system (utilizing organic peroxides and co-agents such as triallylisocyanurate, or TAIC), and the amine cure system (used primarily for specific co-polymer grades). Recent innovations focus heavily on enhancing the efficiency of polyol cure systems by modifying the accelerator components, such as quaternary phosphonium salts, to achieve faster cures without compromising scorch time, a critical parameter in high-speed molding operations. Furthermore, the development of specialty peroxide cure systems is expanding to handle high-fluorine content elastomers and FFKM, where traditional polyol cures are less effective, pushing the boundaries of temperature resistance.

A major technological focus is the development of ultra-clean and low-extractable vulcanizing agents, particularly essential for high-purity applications in the semiconductor and pharmaceutical industries. This involves rigorous purification techniques and the synthesis of specialized, low-volatility co-agents that minimize the leaching of residues during the component's operational life. Another emerging area is the integration of nanotechnology, where certain nanoparticles are being investigated as supplementary cross-linking promoters or reinforcing fillers that can interact synergistically with the vulcanizing agent to improve modulus and tear strength of the final elastomer, offering a route to superior material performance under dynamic loads.

The manufacturing process itself is undergoing technological refinement, including continuous process chemistry techniques replacing traditional batch processing. This shift aims to ensure higher uniformity and consistency in the vulcanizing agent composition, which is paramount for predictable elastomer performance. Furthermore, advanced analytical techniques like Differential Scanning Calorimetry (DSC) and Rheometry are increasingly integrated into the R&D and quality assurance stages to precisely map the curing profile and optimize the cross-link density, ensuring that the resulting fluoroelastomer meets the increasingly demanding specifications set by critical end-use sectors like aerospace and deep-sea oil extraction.

Regional Highlights

The Fluoro Rubber Vulcanizing Agents Market exhibits distinct geographical drivers reflecting global manufacturing shifts and regulatory environments. Asia Pacific (APAC) currently holds the dominant market share and is projected to demonstrate the highest CAGR during the forecast period. This growth is underpinned by the region's massive manufacturing base, particularly in China, South Korea, and Japan, which are home to large-scale automotive, electronics, and chemical industries. The rapid expansion of electric vehicle production in China is a key catalyst, driving the need for specialized, thermally stable seals requiring advanced vulcanizing agents. Furthermore, increasing investment in industrial infrastructure and machinery across Southeast Asia boosts demand for high-durability seals and gaskets.

North America and Europe represent mature markets characterized by high-value, high-performance applications. North America’s demand is concentrated in the aerospace & defense sectors, along with the stringent requirements of the oil & gas (O&G) industry for deep-sea drilling and high-pressure well environments. The European market is strongly influenced by strict environmental and safety regulations, pushing manufacturers toward optimized, sustainable, and high-purity vulcanizing systems compliant with REACH and specific material restrictions (e.g., concerning PFOA/PFOS derivatives). Innovation often originates in these regions due to intense R&D activities driven by major chemical corporations and stringent regulatory pressure to improve material longevity and process safety.

The Latin America (LATAM) and Middle East & Africa (MEA) regions, while smaller, are showing promising growth driven primarily by the expansion of petrochemical operations (MEA) and increased automotive production capacity (LATAM, particularly Brazil and Mexico). The demand profile in MEA is highly specialized, focused on vulcanizing agents for elastomers used in aggressive, high-temperature oil and gas extraction equipment. Market penetration strategies in these emerging regions often rely on establishing strong distribution partnerships and offering technical support tailored to the specific climatic and operational challenges prevalent in these geographies.

- Asia Pacific (APAC): Dominates the market, fueled by massive automotive (especially EV) and electronics manufacturing expansion; highest consumption growth for standard and high-purity grades.

- North America: Strong demand concentrated in aerospace, defense, and high-specification oil & gas sectors; focus on extreme temperature resistance and reliability.

- Europe: Characterized by stringent environmental regulations (REACH compliance) driving innovation in sustainable vulcanizing agent formulations; mature market for industrial and automotive sealing applications.

- Middle East & Africa (MEA): Growth driven by investment in upstream and downstream petrochemical processing, requiring highly resilient seals for aggressive media and high heat.

- Latin America (LATAM): Steady growth linked to regional automotive production and expanding industrial machinery base; focused on cost-effective yet reliable solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fluoro Rubber Vulcanizing Agents Market.- AGC Inc.

- Daikin Industries, Ltd.

- Solvay S.A.

- 3M Company

- Dow Inc.

- DuPont de Nemours, Inc.

- Lanxess AG

- Shin-Etsu Chemical Co., Ltd.

- Wacker Chemie AG

- Arkema S.A.

- Momentive Performance Materials Inc.

- Chemours Company

- Unimatec Chemistry GmbH

- Gujarat Fluorochemicals Limited (GFL)

- Halocarbon Products Corporation

- Central Glass Co., Ltd.

- Dalian Richon ChemCo., Ltd.

- Shandong Huayi Group

- Jiangsu Meilan Chemical Co., Ltd.

- Shanghai 3F New Materials Co., Ltd.

- Sartomer (Arkema Group)

Frequently Asked Questions

Analyze common user questions about the Fluoro Rubber Vulcanizing Agents market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary types of vulcanizing agents used for fluoro rubber (FKM)?

The primary types are Polyol-based (most common for general FKM), Peroxide-based (used for specific FKM grades and improved chemical resistance), and Amine-based systems (used for older co-polymer grades and specialized applications).

How does the growth of Electric Vehicles (EVs) impact the demand for fluoro rubber vulcanizing agents?

EV growth drives high demand because battery packs and power electronics require robust, thermally stable fluoroelastomer seals to manage extreme temperatures and prevent leakage, necessitating reliable and high-purity vulcanizing agents.

Which geographical region dominates the consumption of fluoro rubber vulcanizing agents?

Asia Pacific (APAC), led by major manufacturing countries like China, dominates the consumption market due to substantial expansion in the automotive, electronics, and general industrial sectors requiring high-performance seals.

What is the main difference between polyol-based and peroxide-based vulcanization?

Polyol vulcanization typically offers good processability and excellent compression set resistance, ideal for standard FKM. Peroxide vulcanization provides superior chemical resistance and thermal stability, often used for more aggressive media or higher fluorine content elastomers.

Are there regulatory concerns affecting the market for fluoro rubber vulcanizing agents?

Yes, global regulations, particularly in Europe (REACH), impose restrictions on the use of certain fluorinated chemicals (PFAS, including some precursors and co-agents), pressuring manufacturers to develop compliant, low-fluorine, or non-fluorinated alternatives.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager