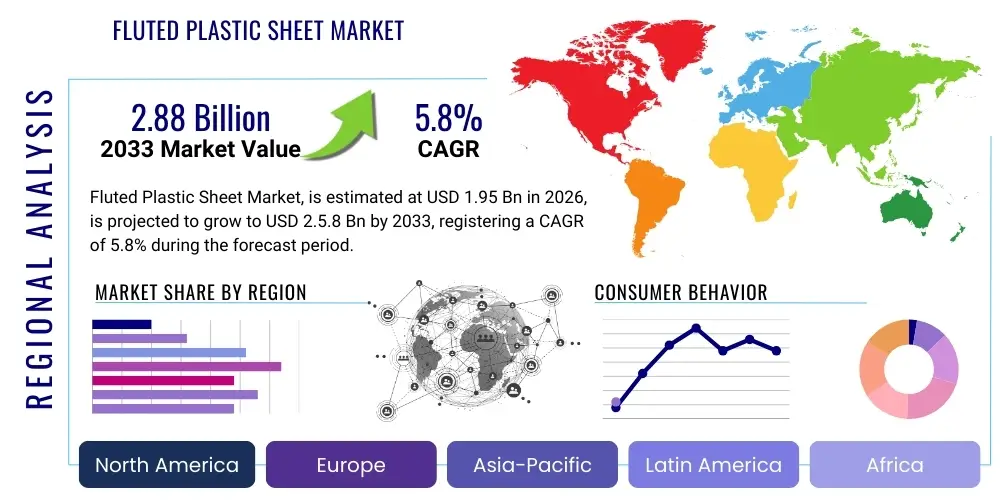

Fluted Plastic Sheet Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438262 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Fluted Plastic Sheet Market Size

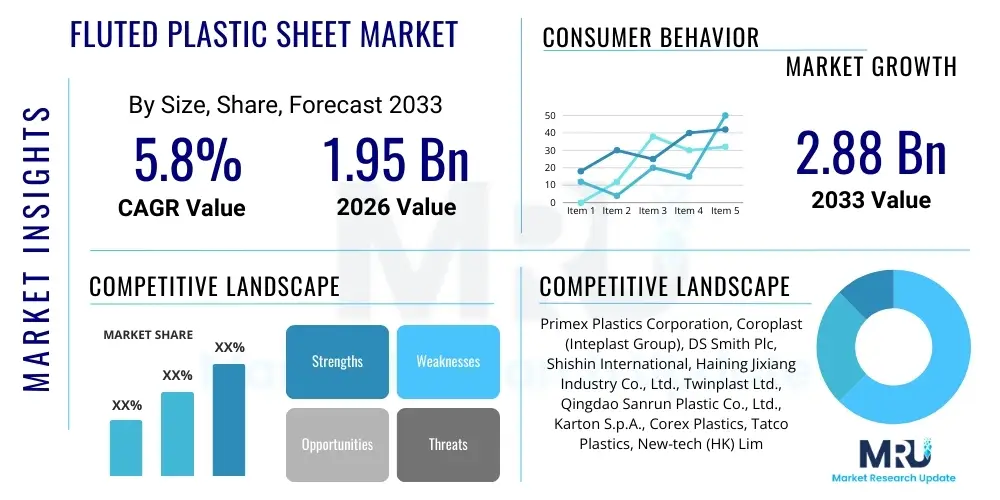

The Fluted Plastic Sheet Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.95 Billion in 2026 and is projected to reach USD 2.88 Billion by the end of the forecast period in 2033.

Fluted Plastic Sheet Market introduction

Fluted plastic sheets, often referred to by brand names such as Coroplast or Correx, are extruded twin-wall polypropylene or polyethylene products characterized by their lightweight, high-strength, and weather-resistant properties. These sheets consist of two outer flat layers separated by vertical ribs or flutes, creating internal air channels that provide excellent cushioning and rigidity. Their versatility makes them an indispensable material across numerous industries, serving as a superior alternative to traditional materials like cardboard, wood, and rigid PVC in many applications where moisture resistance and durability are paramount.

The primary applications of fluted plastic sheets span across protective packaging, large format signage, and construction materials. In packaging, they are crucial for returnable transit packaging, sleeve packs, and protective layers for delicate goods due to their high load-bearing capacity and reusability, aligning strongly with modern circular economy initiatives. For the signage industry, their smooth surface and ability to be easily cut and printed upon make them ideal for temporary or outdoor advertising, election signage, and point-of-sale displays. Their inherent resistance to water, chemicals, and temperature fluctuations further enhances their utility in harsh industrial and outdoor environments.

Market growth is predominantly driven by the exponential expansion of the e-commerce sector, which necessitates robust, lightweight, and efficient packaging solutions that can withstand complex logistics chains. Additionally, the growing global focus on sustainable practices fuels demand, as fluted plastic sheets, particularly those made from polypropylene, are fully recyclable and offer extended lifecycles compared to disposable cardboard packaging. Manufacturers are continually investing in high-speed extrusion technologies and material science innovations to enhance sheet printability and introduce sustainable bio-based or recycled content variations, ensuring the material remains competitive and relevant across emerging industrial needs.

Fluted Plastic Sheet Market Executive Summary

The Fluted Plastic Sheet Market is positioned for robust expansion, primarily fueled by significant infrastructural investments in emerging economies and the pervasive need for durable, customizable packaging across global supply chains. Packaging remains the dominant application segment, driven by industries requiring sterile, reusable, or heavy-duty containers, such as automotive, pharmaceuticals, and logistics. Key business trends indicate a strong focus on automation in the manufacturing process, allowing producers to achieve higher output rates and tighter quality control, thus addressing the rising volume demand from major retail and industrial clients who rely on just-in-time inventory management.

Regional dynamics highlight the Asia Pacific (APAC) region as the epicenter of future growth, owing to rapid industrialization, burgeoning construction activity, and the region's status as a global manufacturing hub, particularly for electronics and automotive components which require intricate protective packaging. Conversely, North America and Europe, while mature, are focusing heavily on premiumization and high-end applications like specialized outdoor advertising and advanced material handling systems. These developed markets are characterized by stringent environmental regulations, prompting manufacturers to prioritize closed-loop recycling systems and introduce products with documented recycled content to maintain market access and comply with Extended Producer Responsibility (EPR) schemes.

Segment trends emphasize the increasing demand for sheets in the 4mm to 8mm thickness range, striking an optimal balance between cost-effectiveness, rigidity, and weight for packaging and medium-term signage. Furthermore, the market is witnessing material shifts toward higher-grade polypropylene formulations that offer improved impact resistance and enhanced thermal stability. Successful market players are those establishing integrated supply chains, spanning resin procurement to localized distribution networks, thereby mitigating the impacts of volatile raw material prices and offering rapid customization services to diverse end-user industries, cementing their competitive advantage in this evolving landscape.

AI Impact Analysis on Fluted Plastic Sheet Market

User inquiries regarding AI's impact on the Fluted Plastic Sheet Market frequently center on operational efficiency, predictive supply chain management, and material optimization. Users are keen to understand how AI-driven tools can reduce manufacturing waste, optimize the extrusion process for varying sheet specifications, and forecast raw material demand volatility (specifically polypropylene resin prices). Furthermore, there is significant interest in how AI can automate the design process for custom packaging solutions, reducing lead times for complex, fitted corrugated plastic containers required by electronics and automotive sectors. The overarching theme is leveraging AI to achieve higher operational efficiency and enhanced customization capabilities while navigating cost pressures and sustainability goals.

- AI-driven predictive maintenance optimizes extrusion machinery, minimizing downtime and reducing manufacturing defects in sheet consistency.

- Demand forecasting models, powered by machine learning, improve inventory management of polypropylene resins, buffering manufacturers against sudden price fluctuations and ensuring stable production schedules.

- Automated quality control systems use computer vision to detect subtle imperfections or inconsistent fluting patterns in real-time, significantly reducing non-conforming product waste.

- AI algorithms optimize logistics and route planning for large-volume deliveries of fluted sheets to distant distribution centers, cutting transportation costs and carbon emissions.

- Generative design tools utilize AI to rapidly prototype custom fluted sheet packaging inserts (e.g., dunnage) that maximize product protection while minimizing material usage.

DRO & Impact Forces Of Fluted Plastic Sheet Market

The Fluted Plastic Sheet Market is influenced by a powerful combination of drivers, restraints, and opportunities that shape its trajectory and competitive intensity. The primary driving forces include the sustained expansion of the e-commerce sector, which requires millions of protective, lightweight shipping containers and customized void fillers, and the growing demand for reusable packaging (Returnable Transit Packaging – RTP) within automotive and food processing logistics, which inherently favors the durability of fluted plastic over single-use alternatives. These drivers ensure a consistent, high-volume requirement for the product across global industrial bases.

Conversely, the market faces significant restraints, chiefly the inherent volatility in the pricing of crude oil derivatives, which directly impacts the cost of polypropylene and polyethylene resins—the key raw materials. This price instability challenges manufacturers' profitability and complicates long-term contract pricing. Furthermore, the rise of stringent environmental legislation, particularly in Europe, imposing taxes on non-recycled plastic packaging, pressures manufacturers to accelerate investments in high-quality recycling infrastructure and verifiable closed-loop systems, adding capital expenditure burden.

Opportunities for expansion are centered around product innovation and geographical penetration. The development of advanced, specialized fluted plastic sheets with features like anti-static protection (critical for electronics) or fire retardancy (essential for construction and public signage) opens high-margin application niches. Geographically, untapped potential remains high in developing regions of Africa and parts of Latin America, where rapid urbanization and nascent industrial sectors are initiating the transition from traditional wood and cardboard materials to modern, weather-resistant plastic alternatives. Impact forces, therefore, lean heavily towards balancing cost-efficiency with increasingly demanding sustainability metrics.

Segmentation Analysis

The Fluted Plastic Sheet Market is comprehensively segmented based on material type, thickness, application, and end-use industry, providing clarity into diverse consumer needs and technological requirements across the value chain. Polypropylene (PP) dominates the market share due to its superior chemical resistance, flexibility, and suitability for high-frequency printing and reuse applications, making it the material of choice for the packaging and signage sectors. Segmentation by thickness is crucial, as ultra-thin sheets (2mm–3mm) are often used for temporary signage and lightweight disposable packaging, while thicker variants (8mm and above) are reserved for heavy-duty applications such as construction formwork protection and robust industrial container manufacturing, reflecting a clear price-to-performance gradient across product categories.

- By Material Type:

- Polypropylene (PP)

- Polyethylene (PE)

- Recycled and Bio-based Polymers

- By Thickness:

- 2mm – 5mm

- 6mm – 10mm

- Above 10mm

- By Application:

- Packaging and Storage (Boxes, Sleeves, Totes, Dunnage)

- Signage and Display (Promotional Signs, Point-of-Sale)

- Construction and Building (Floor Protection, Formwork, Waterproofing)

- Agriculture (Seedling Trays, Tree Guards)

- Others (Automotive components, White Goods Backing)

- By End-Use Industry:

- Logistics and E-commerce

- Automotive

- Electronics

- Building and Infrastructure

- Consumer Goods

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Fluted Plastic Sheet Market

The value chain for the fluted plastic sheet market begins upstream with the procurement of essential petrochemical feedstocks, primarily propylene and ethylene monomers, which are then polymerized into polypropylene (PP) and polyethylene (PE) resins. The stability and availability of these polymer resins are critical, as they constitute the largest variable cost for manufacturers. Key upstream participants include major chemical companies and resin producers who exert significant pricing power due to the specialized nature and global commodity status of these polymers. Ensuring stable, high-quality resin supply, especially sustainable or recycled variants, is a continuous challenge for midstream sheet extruders.

The midstream segment involves the core manufacturing process, where polymer resins are extruded into flat sheets and then processed using specialized machinery to create the characteristic fluted structure. Manufacturers focus heavily on optimizing extrusion technology to achieve high output speed, consistent thickness, and superior surface quality for printing. After extrusion, secondary processes like die-cutting, printing (often using UV digital printing for high-resolution graphics), and welding transform the raw sheets into final products such as custom packaging boxes or signs. The competitive advantage at this stage hinges on technological efficiency and the ability to offer customized finishing services.

The downstream segment includes distribution and ultimate end-use. Fluted plastic sheets reach end-users through both direct sales (for large industrial buyers like automotive manufacturers who require custom Returnable Transit Packaging) and indirect distribution channels (through industrial distributors, sign supply wholesalers, and specialized packaging converters). Indirect channels provide market reach and inventory management for smaller businesses. The integration of digital platforms and rapid fulfillment capabilities is increasingly vital in the downstream market, particularly for serving the decentralized and time-sensitive needs of the e-commerce and temporary signage sectors. Successful downstream operations require deep engagement with converters who finalize the product specifications for niche applications.

Fluted Plastic Sheet Market Potential Customers

The core customer base for fluted plastic sheets is highly diversified, spanning multiple robust industrial sectors that prioritize material durability, hygiene, and reusability. The logistics and e-commerce sector represents a monumental growth area, relying heavily on fluted sheets for lightweight yet sturdy custom totes, divider trays, and long-lasting storage containers that are essential for automated warehousing systems and complex supply chain loops. These customers value the material's extended lifespan over cardboard, reducing replacement costs and operational friction in high-throughput environments.

Another major segment is the advertising and visual communications industry. Customers in this area, including marketing agencies, retail chains, and political organizations, utilize fluted sheets extensively for large format, temporary, and outdoor signage. The material's weather resistance and excellent print surface make it the standard choice for election signs, promotional sandwich boards, and retail aisle displays. For these customers, rapid turnaround, cutting precision, and vibrant ink adhesion are the most critical purchase criteria, often leading them to suppliers with advanced UV digital printing capabilities.

Furthermore, specialized industrial customers, particularly in the automotive and pharmaceutical sectors, are critical buyers. Automotive manufacturers use fluted plastic sheets almost exclusively for custom dunnage and component protection within their manufacturing lines and transport loops, ensuring zero-damage delivery of sensitive parts. The pharmaceutical industry requires sterile, easily washable, and durable secondary packaging for transit and cleanroom operations. These end-users demand high technical specifications, including antistatic properties or specialized flame ratings, making them high-value, albeit volume-sensitive, clients for premium sheet manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.95 Billion |

| Market Forecast in 2033 | USD 2.88 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Primex Plastics Corporation, Coroplast (Inteplast Group), DS Smith Plc, Shishin International, Haining Jixiang Industry Co., Ltd., Twinplast Ltd., Qingdao Sanrun Plastic Co., Ltd., Karton S.p.A., Corex Plastics, Tatco Plastics, New-tech (HK) Limited, Shanghai D&R Plastic Sheets Co., Ltd., Matra Plast Inc., Sangean International, Northern Corrugated Plastics |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fluted Plastic Sheet Market Key Technology Landscape

The manufacturing of fluted plastic sheets is heavily reliant on sophisticated polymer extrusion technology, which is the foundational process dictating product quality and cost-efficiency. Recent technological advancements focus on multi-layer co-extrusion systems, allowing manufacturers to embed specialized properties within the sheet structure, such as UV inhibitors for enhanced outdoor durability or conductive layers for anti-static applications critical for the electronics industry. High-speed, wide-format extrusion lines are becoming standard, enabling increased production capacity and reduced energy consumption per unit area, optimizing operational costs in the face of rising global energy prices. Continuous investment in precision tooling minimizes thickness variation, crucial for maintaining structural integrity and consistent performance across large batches.

Beyond core manufacturing, the key technology landscape is defined by advanced finishing and conversion techniques. Digital printing technology, specifically UV-curable inkjet printing, has revolutionized the signage segment. This technology allows for direct printing onto the fluted plastic surface with high resolution, rapid curing, and exceptional resistance to fading and abrasion, enabling rapid customization and shorter run lengths which cater to the fast-paced advertising market. Complementary technologies include sophisticated computer numerical control (CNC) cutting and routing systems, which ensure precise custom shapes and complex packaging designs (dunnage and inserts) can be produced efficiently without costly manual intervention or specialized molds.

Furthermore, technology related to material handling and recycling is gaining prominence. As sustainability pressures intensify, manufacturers are implementing technologies for incorporating recycled content back into the sheets, often requiring advanced filtration and compounding equipment to handle impurities without compromising the structural or visual quality of the final product. Future technological developments are anticipated in developing bio-based or biodegradable polymers that can be processed using existing fluted sheet extrusion lines, representing a significant opportunity for sustainable innovation within the material landscape, aiming to meet future regulatory mandates and consumer preferences for eco-friendly materials.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven by its status as a global manufacturing hub, particularly in China, India, and Southeast Asian nations. The massive infrastructure and construction boom, coupled with the rapid growth of domestic e-commerce markets, drives substantial demand for protective packaging and construction barriers. Government initiatives promoting industrial output and logistics efficiency further solidify the region's dominance, making it the primary target for capacity expansion by global players.

- North America: This region holds a significant market share, largely characterized by high adoption rates in the signage and heavy-duty industrial packaging sectors. North American market maturity translates into higher demand for specialized products, such as anti-static sheets for high-tech manufacturing and complex, reusable component trays for the demanding automotive industry. Innovation here is focused on efficiency in automated material handling systems and advanced digital printing applications.

- Europe: The European market is defined by stringent environmental regulations and a strong emphasis on the circular economy. This region leads in the adoption of recycled content and closed-loop systems for fluted plastic sheets, driving market demand toward premium, certified sustainable products. The application spectrum is balanced between logistics (RTP) and construction safety, demanding high-quality, durable sheets that comply with rigorous EU standards for material safety and waste management.

- Latin America (LATAM): Growth in LATAM is accelerating due to urbanization and increasing investment in retail infrastructure and manufacturing capabilities, particularly in Brazil and Mexico. The market is transitioning from traditional packaging materials, favoring the cost-effective and moisture-resistant properties of fluted plastic sheets for local agriculture and temporary building protections. Cost efficiency and accessibility remain key purchasing drivers in this region.

- Middle East and Africa (MEA): This region is characterized by steady growth fueled by large-scale construction projects and diversification away from oil economies, notably in the UAE and Saudi Arabia. Fluted plastic sheets find strong utility in signage for new commercial developments and protective layers in harsh desert environments where resistance to high temperatures and dust is essential. Strategic investments in local manufacturing capacity are emerging to serve regional demand effectively.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fluted Plastic Sheet Market.- Primex Plastics Corporation

- Coroplast (Inteplast Group)

- DS Smith Plc

- Shishin International

- Haining Jixiang Industry Co., Ltd.

- Twinplast Ltd.

- Qingdao Sanrun Plastic Co., Ltd.

- Karton S.p.A.

- Corex Plastics

- Tatco Plastics

- New-tech (HK) Limited

- Shanghai D&R Plastic Sheets Co., Ltd.

- Matra Plast Inc.

- Sangean International

- Northern Corrugated Plastics

- Linyi Sanbao Plastics Co., Ltd.

- Crown Polycarbonate

- Polyflute Sheet Co., Ltd.

- Wenzhou Huajiang Plastic Co., Ltd.

- BGP Manufacturing Ltd.

Frequently Asked Questions

Analyze common user questions about the Fluted Plastic Sheet market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary material used to manufacture fluted plastic sheets?

The majority of fluted plastic sheets are manufactured from polypropylene (PP) resin, favored for its excellent chemical resistance, high stiffness-to-weight ratio, durability, and complete recyclability, making it suitable for demanding applications like Returnable Transit Packaging (RTP).

Which application segment drives the highest demand in the fluted plastic sheet market?

The Packaging and Storage application segment, including reusable totes, custom dunnage, and protective layer pads, accounts for the highest volume demand, driven primarily by the global logistics needs of the e-commerce and automotive industries.

How does the fluted plastic sheet market address growing sustainability concerns?

The market addresses sustainability by focusing on high recyclability, implementing closed-loop systems to reuse industrial waste, and increasing the integration of post-consumer recycled (PCR) content into new sheets, thereby extending the material lifecycle compared to single-use alternatives.

What is the main driver for market growth in the Asia Pacific region?

Rapid industrialization, expansive growth in the manufacturing sector (especially electronics and automotive component production), and significant infrastructure development are the main drivers propelling the market growth for fluted plastic sheets in the Asia Pacific (APAC) region.

Are there specialized types of fluted plastic sheets for the electronics industry?

Yes, specialized fluted plastic sheets with anti-static or conductive properties are crucial for the electronics industry. These materials prevent electrostatic discharge (ESD) damage during the transport and storage of sensitive electronic components, ensuring product integrity throughout the supply chain.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager