Fluted Polypropylene Sheets Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436192 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Fluted Polypropylene Sheets Market Size

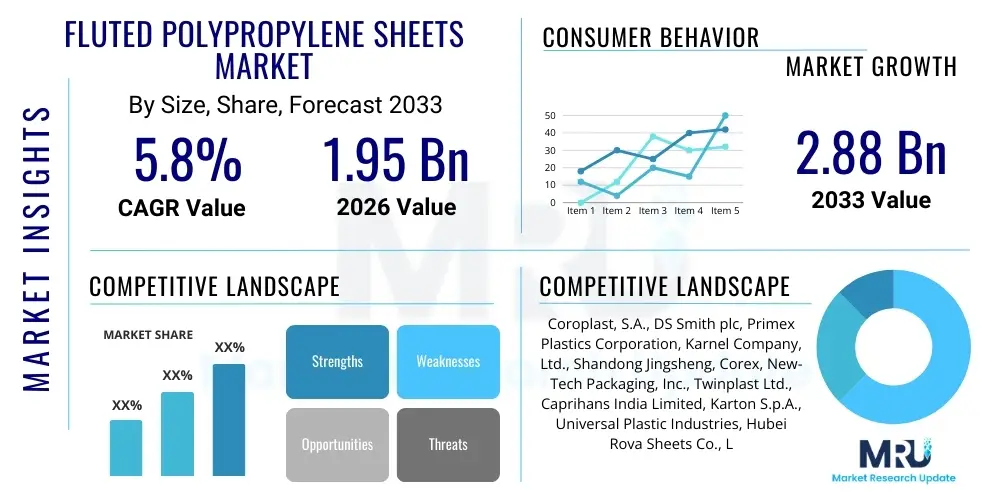

The Fluted Polypropylene Sheets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.95 Billion in 2026 and is projected to reach $2.88 Billion by the end of the forecast period in 2033.

Fluted Polypropylene Sheets Market introduction

The Fluted Polypropylene (PP) Sheets Market encompasses the production and distribution of extruded sheets characterized by a corrugated internal structure, which provides lightweight rigidity, excellent impact resistance, and water-proofing properties. Often referred to commercially as Coroplast, Corflute, or Twin-Wall Plastic Sheets, these products are manufactured primarily through extrusion processes involving high-quality polypropylene resins. The twin-wall architecture maximizes strength while minimizing material use, making them highly economical and versatile across numerous industries. These sheets are also chemically resistant, non-toxic, and easily recyclable, positioning them as a sustainable alternative to traditional materials like corrugated cardboard and certain rigid plastics in various applications.

Major applications of Fluted Polypropylene sheets span across protective packaging, visual communication (signage and display), construction, and agriculture. In the packaging sector, they are widely utilized for reusable transit boxes, automotive component containers, and food processing trays due to their hygienic and durable nature. For the signage industry, the sheets' smooth surface, printability, and weather resistance make them the preferred substrate for promotional signs, political campaign boards, and point-of-sale displays. Their inherent benefits—including superior durability compared to cardboard, resistance to moisture and chemicals, and extremely low weight—drive their increasing adoption across global supply chains that prioritize logistics efficiency and sustainability.

Driving factors for market growth are strongly linked to the expansion of global e-commerce, which requires vast amounts of durable and customized protective packaging solutions. Furthermore, increasing infrastructure development, particularly in Asia Pacific, boosts demand for temporary partitioning and concrete formwork applications in construction. The shift toward sustainable materials, coupled with technological advancements in digital printing that allow for high-resolution graphics on these sheets, further solidifies the market's trajectory. These sheets offer a favorable balance of cost, performance, and environmental footprint, sustaining their critical role in modern industrial and retail environments.

Fluted Polypropylene Sheets Market Executive Summary

The Fluted Polypropylene Sheets market exhibits robust growth driven by escalating demand from the packaging and signage sectors, which are capitalizing on the material's durability, lightweight characteristics, and moisture resistance. Key business trends indicate a strong focus on enhancing sustainability metrics, with manufacturers investing in production technologies that allow for higher recycled content integration and the development of specialized grades suitable for advanced applications like automotive dunnage and high-end reusable containers. Pricing strategies are becoming increasingly complex, balancing the volatility of crude oil and polypropylene monomer costs with the market's imperative for cost-effective packaging solutions, leading to increased vertical integration among major players to secure raw material supply.

Regional trends highlight the Asia Pacific (APAC) as the dominant and fastest-growing region, fueled by massive manufacturing output, urbanization, and burgeoning retail and construction activity, particularly in China and India. North America and Europe maintain significant market shares, characterized by high adoption rates in sophisticated display marketing and reusable industrial logistics systems, often adhering to strict environmental regulations that favor durable plastic packaging over single-use alternatives. Segment trends show that the Packaging application segment, particularly customized and foldable boxes, remains the largest revenue generator, while the Signage and Display segment continues its rapid expansion, leveraging improvements in digital printing technologies for enhanced visual appeal and faster turnaround times.

Overall, the market is moderately fragmented, with intense competition driving innovation in terms of sheet thickness customization, surface treatments (e.g., anti-static or UV stabilization), and the creation of fire-retardant versions for specialized construction or electrical applications. The shift towards AEO and GEO optimized content in marketing and sales of industrial materials is influencing how manufacturers engage with B2B customers, necessitating detailed specification sheets and performance data readily available online. Success in this market is increasingly dependent on the ability to offer highly customized solutions that meet specific end-user performance requirements while adhering to global sustainability mandates.

AI Impact Analysis on Fluted Polypropylene Sheets Market

User queries regarding the impact of Artificial Intelligence (AI) on the Fluted Polypropylene Sheets market predominantly revolve around operational efficiency, customized product design, and optimizing the complex logistics inherent in large-scale sheet distribution. Key themes include how AI can be leveraged to predict raw material price fluctuations (polypropylene resin), improve production yield through predictive maintenance on extrusion lines, and enhance quality control systems to detect subtle flaws in the fluted structure immediately. Furthermore, users are keenly interested in AI’s role in accelerating the design phase for bespoke packaging and signage, allowing for rapid prototyping, precise material usage estimation based on load-bearing requirements, and dynamically optimized sheet cutting patterns to minimize waste, directly addressing sustainability and cost concerns in a highly competitive manufacturing environment.

- AI-driven Predictive Maintenance: Optimizes extrusion machinery uptime by predicting potential failures, reducing unplanned stoppages, and maintaining consistent sheet quality.

- Supply Chain Optimization: Uses machine learning algorithms for real-time demand forecasting and inventory management, minimizing stockouts and reducing storage costs for both raw materials and finished goods.

- Enhanced Quality Control (QC): AI vision systems rapidly scan sheets post-extrusion to identify structural defects, thickness inconsistencies, or color variations far more efficiently than human inspection.

- Customization and Design Automation: AI assists in generating optimized structural designs for complex packaging (e.g., multi-fold boxes, specialized dunnage) based on specific load and size parameters, drastically shortening the time-to-market for custom orders.

- Waste Reduction: Machine learning optimizes cutting and stacking patterns (nesting algorithms) to maximize material utilization from large sheets, significantly lowering manufacturing waste and improving sustainability metrics.

- Sustainable Sourcing Prediction: AI models analyze global commodity markets and geopolitical factors to predict fluctuations in polypropylene resin prices, aiding strategic purchasing and inventory hedging.

DRO & Impact Forces Of Fluted Polypropylene Sheets Market

The dynamics of the Fluted Polypropylene Sheets market are shaped by a powerful confluence of drivers necessitating durable packaging and display solutions, offset by inherent restraints related to material costs and disposal complexity, yet underpinned by significant opportunities in green technology and new application penetration. The primary driver is the pervasive growth of the e-commerce sector globally, which necessitates lightweight, robust, and often reusable packaging for secure product transit. Furthermore, governmental and corporate sustainability mandates are increasingly favoring polypropylene over single-use cardboard, provided recycling infrastructure is adequate. However, restraints include the direct linkage of polypropylene prices to crude oil markets, creating significant operational cost volatility for manufacturers, alongside challenges related to the public perception and large-scale post-consumer collection and recycling processes necessary for these specific plastic products.

Impact forces currently influencing the market include the substitution threat from emerging bio-plastics and advanced fiber-based materials, which, while currently higher in cost, are aggressively marketed as superior sustainable alternatives. Buyer power is generally high, especially in large-volume packaging contracts, forcing manufacturers to continuously improve efficiency and compress margins. Supplier power remains moderate but volatile, given the reliance on a limited number of petrochemical giants for resin supply. Technological intensity is high, driven by the need for advanced printing, precise coating applications, and efficient, high-speed extrusion lines to maintain competitiveness and meet stringent performance specifications demanded by automotive and pharmaceutical end-users.

Opportunities for expansion are concentrated in leveraging digital fabrication techniques to offer highly specialized, short-run customization, catering to niche industrial and marketing campaigns. Furthermore, there is a substantial untapped potential in the agricultural sector, particularly for crop protection, seedling containers, and temporary field storage solutions, where the material’s waterproof and durable nature provides significant advantages over traditional wooden or cardboard alternatives. Successful companies will capitalize on these opportunities by developing proprietary, high-performance formulations and establishing robust closed-loop recycling programs with their major industrial clients.

Segmentation Analysis

The Fluted Polypropylene Sheets market is systematically segmented based on product characteristics such as thickness, primary application areas, and the end-use industries that predominantly utilize the material. Thickness segmentation is crucial as it dictates the mechanical strength and application suitability, ranging from thin, lightweight sheets suitable for temporary signage to thick, robust sheets required for heavy-duty industrial dunnage and construction applications. Application segmentation provides insights into the primary revenue streams, emphasizing the dominance of packaging solutions driven by e-commerce logistics and the high-volume demand from the dynamic signage and display industry which requires excellent print quality and weather resistance. The end-use industry analysis highlights the diverse penetration of this material across industrial manufacturing, retail supply chains, and specialized agricultural needs.

Understanding these segments is essential for strategic planning, allowing manufacturers to tailor product development and marketing efforts towards high-growth areas. For example, the industrial end-use segment demands products with enhanced anti-static properties and chemical resistance, whereas the retail segment focuses more on aesthetics, ease of handling, and cost-effectiveness for promotional displays. The continuous refinement of manufacturing processes allows for tailored products, such as UV-stabilized sheets for prolonged outdoor use or fire-retardant grades required in specific building codes. This detailed segmentation aids stakeholders in accurately forecasting demand, optimizing supply chains, and differentiating their offerings in a highly competitive global market.

- By Thickness:

- 2 mm to 5 mm (Lightweight Signage, Temporary Protection)

- 6 mm to 10 mm (Standard Packaging, POS Displays, Construction Forms)

- Above 10 mm (Heavy-Duty Dunnage, Structural Components, Large Format Signage)

- By Application:

- Packaging (Reusable Boxes, Totes, Separation Pads, Protective Dunnage)

- Signage and Display (Promotional Boards, Point-of-Sale, Real Estate Signs)

- Construction (Temporary Floor Protection, Concrete Formwork, Partitioning)

- Automotive (Component Protection, Assembly Line Totes)

- Agriculture (Seedling Trays, Tree Guards, Bins)

- By End-Use Industry:

- Industrial and Manufacturing (Logistics, Component Handling)

- Retail and E-commerce (Display, Transit Packaging)

- Building and Construction (Site Management, Material Protection)

- Graphics and Advertising (Marketing Campaigns)

Value Chain Analysis For Fluted Polypropylene Sheets Market

The value chain for the Fluted Polypropylene Sheets market begins with the upstream procurement of raw materials, primarily polypropylene (PP) resin, which is derived from petrochemical processes. Since PP resin quality and price volatility significantly impact the final product cost, strong relationships with major polymer suppliers are critical. This upstream stage also includes the sourcing of necessary additives, such as colorants, UV stabilizers, and anti-static agents, which enhance the sheets’ performance for specialized applications. Efficiency in the upstream segment dictates production margins and directly affects the final pricing strategy offered to downstream customers.

The middle segment involves the core manufacturing process—extrusion. Manufacturers utilize twin-screw extruders to melt the resin and form the characteristic twin-wall structure. This stage includes cutting, sealing, and optional treatments like corona treatment for improved print adhesion. Effective process management, minimizing scrap, and maximizing machine throughput are key competitive differentiators here. Downstream activities involve converting the bulk sheets into final products (e.g., die-cutting for boxes, printing for signage) and managing complex distribution channels, which include direct sales to large industrial users and indirect sales through distributors, specialized packaging companies, and sign makers.

Distribution channels are multifaceted: Direct channels are typically employed for major B2B contracts, serving automotive or large logistics companies that require customized, long-term supply agreements. Indirect channels leverage regional distributors and specialized wholesalers to reach smaller end-users, retailers, and local construction firms. The efficiency of the distribution network, particularly the ability to handle large, bulky items cost-effectively, is a major factor in maintaining market penetration and customer satisfaction. The seamless flow from PP resin sourcing to final product delivery through optimized logistics is paramount to profitability.

Fluted Polypropylene Sheets Market Potential Customers

The primary potential customers and end-users of Fluted Polypropylene Sheets are large-scale industrial consumers and businesses requiring durable, weather-resistant materials for packaging, protection, or display. Leading buyers include major multinational automotive manufacturers who utilize the sheets for reusable dunnage and internal component separation during transit, minimizing damage and waste across their complex supply chains. Furthermore, high-volume e-commerce and logistics companies are significant purchasers, requiring customizable, lightweight totes and boxes for automated handling systems and last-mile delivery protection. The inherent resistance of PP sheets to moisture and chemicals makes them indispensable for these logistics operations.

Beyond the industrial sector, the retail and quick-service restaurant (QSR) industries are major consumers in the signage application segment, demanding vibrant, weather-proof, and easily installable promotional materials and menu boards. In the construction industry, general contractors and specialty trade companies purchase these sheets extensively for temporary floor, wall, and window protection during build-outs, as well as for cost-effective concrete form liners. Lastly, the agricultural sector, including commercial nurseries and large farming operations, represents a growing customer base, utilizing the sheets for seed propagation trays, protective plant barriers, and seasonal produce containers due to the material's longevity and hygiene.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.95 Billion |

| Market Forecast in 2033 | $2.88 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Coroplast, S.A., DS Smith plc, Primex Plastics Corporation, Karnel Company, Ltd., Shandong Jingsheng, Corex, New-Tech Packaging, Inc., Twinplast Ltd., Caprihans India Limited, Karton S.p.A., Universal Plastic Industries, Hubei Rova Sheets Co., Ltd., Polyfoam Corporation, Qingdao Dazheng Group, Tah Sheng Plastic, Northern Corrugated Plastic, Protopak, Inteplast Group, Summit Plastics Inc., K. K. Nag Pvt. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fluted Polypropylene Sheets Market Key Technology Landscape

The manufacturing technology for Fluted Polypropylene Sheets is centered around highly efficient and specialized extrusion systems, predominantly utilizing high-output single-screw or twin-screw extruders combined with advanced flat die heads. Key technological advancements focus on improving the structural integrity and uniformity of the internal fluting, ensuring consistent rigidity and weight distribution across the sheet surface, which is vital for load-bearing packaging applications. Modern extrusion lines incorporate sophisticated temperature and pressure controls to handle a wider range of recycled polypropylene content without compromising mechanical properties, directly supporting sustainability goals. Furthermore, in-line corona treatment equipment is standard, enhancing the surface energy of the sheets for superior adhesion of UV inks and adhesives, which is essential for high-quality digital and screen printing used in the signage sector.

Post-extrusion technology is equally critical, encompassing advanced converting processes such as computerized numerical control (CNC) cutting, automated die-cutting, and ultrasonic welding. CNC cutting systems utilize precise laser or blade technology guided by optimizing software to minimize material waste during the creation of complex packaging components or large-format displays, optimizing material yield significantly. The adoption of high-speed digital printing presses, specifically optimized for polypropylene substrates, allows for mass customization, shorter production lead times, and superior color fidelity compared to traditional methods. These technological improvements collectively enable manufacturers to offer highly personalized products efficiently and maintain a competitive edge based on speed and quality.

Beyond primary production, material technology is evolving rapidly, focusing on specialty additives. Researchers are developing new formulations incorporating advanced UV stabilizers to prolong outdoor lifespan (critical for agricultural and exterior signage), anti-static compounds for protecting sensitive electronic components within packaging, and fire-retardant chemistries to meet strict building and safety regulations. The integration of Industry 4.0 principles, including sensor technology on the production line and AI-driven process optimization, further characterizes the technological landscape, ensuring that production remains agile, cost-effective, and responsive to fluctuating market demand for specialized, high-performance Fluted Polypropylene Sheets.

Regional Highlights

The global Fluted Polypropylene Sheets market demonstrates distinct regional dynamics heavily influenced by local manufacturing bases, logistics infrastructure, and regulatory environments concerning plastic usage.

- North America (USA, Canada, Mexico): Characterized by high penetration in the automotive and sophisticated retail signage sectors. The focus here is on high-quality, reusable packaging systems (dunnage) and specialized construction applications. Market growth is stable, driven by sustained e-commerce expansion and high demand for political and real estate signage.

- Europe (Germany, UK, France, Italy): Driven by strict environmental regulations promoting durable, reusable packaging over single-use alternatives. Europe shows high demand for specialized sheets with recycled content and fire-retardant features for construction projects, focusing on closed-loop recycling programs initiated by major corporations.

- Asia Pacific (APAC) (China, India, Japan, South Korea): The largest and fastest-growing regional market globally. Growth is fueled by massive urbanization, burgeoning manufacturing and exports, and exponential growth in the local e-commerce markets. China serves as the dominant manufacturing hub, providing low-cost sheets globally, while India and Southeast Asia present enormous opportunities in construction and agricultural applications.

- Latin America (Brazil, Argentina): Market growth is moderate but accelerating, supported by expanding retail infrastructure and increasing investment in logistics and supply chain modernization, requiring more efficient packaging solutions for domestic and international trade.

- Middle East and Africa (MEA) (GCC Countries, South Africa): Growth is primarily linked to large-scale infrastructure and construction projects (e.g., in the UAE and Saudi Arabia) and the need for durable, climate-resistant signage and temporary protective materials suitable for harsh desert environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fluted Polypropylene Sheets Market.- Coroplast, S.A.

- DS Smith plc

- Primex Plastics Corporation

- Karnel Company, Ltd.

- Shandong Jingsheng

- Corex

- New-Tech Packaging, Inc.

- Twinplast Ltd.

- Caprihans India Limited

- Karton S.p.A.

- Universal Plastic Industries

- Hubei Rova Sheets Co., Ltd.

- Polyfoam Corporation

- Qingdao Dazheng Group

- Tah Sheng Plastic

- Northern Corrugated Plastic

- Protopak

- Inteplast Group

- Summit Plastics Inc.

- K. K. Nag Pvt. Ltd.

Frequently Asked Questions

Analyze common user questions about the Fluted Polypropylene Sheets market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary driver for the Fluted Polypropylene Sheets Market growth?

The primary driver is the rapid global expansion of the e-commerce sector, necessitating lightweight, durable, and reusable protective packaging solutions for secure transit and logistics efficiency.

Are Fluted Polypropylene Sheets truly recyclable, and how does this affect sustainability?

Yes, Fluted PP sheets are generally 100% recyclable, provided they are properly collected and processed. This recyclability and their potential for repeated reuse position them as a more sustainable alternative to single-use materials, particularly in closed-loop industrial systems.

Which application segment holds the largest share in the Fluted Polypropylene Sheets Market?

The Packaging application segment, including reusable totes, custom boxes, and protective dunnage for industrial components (especially automotive), consistently holds the largest market share due to high volume industrial demand.

How does the volatility of raw material prices impact the profitability of manufacturers?

The profitability is directly linked to the price volatility of polypropylene (PP) resin, a petroleum derivative. Manufacturers often employ hedging strategies or focus on highly customized, value-added products to mitigate risks associated with fluctuating upstream costs.

What key technological advancements are shaping the production of these sheets?

Key advancements include high-speed extrusion lines for utilizing recycled content, AI-driven process control for quality assurance, and advanced CNC cutting and digital printing technologies that enable high-precision customization and reduced material waste.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Fluted Polypropylene Sheets Market Size Report By Type (General Type, Functional Type), By Application (Package Box, Cushion Plate, Printing Plate & Billboard, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Fluted Polypropylene Sheets Market Statistics 2025 Analysis By Application (Package Box, Cushion Plate, Printing Plate & Billboard), By Type (General Type, Functional Type), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager