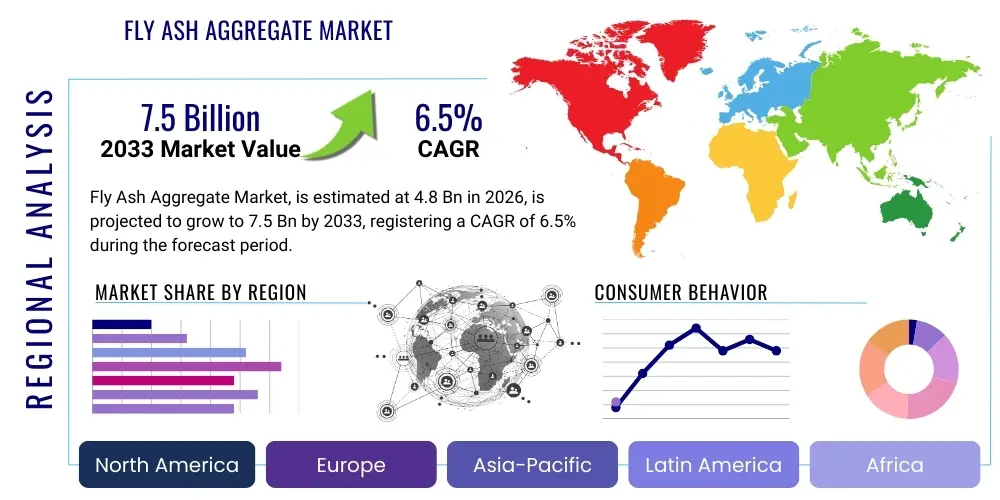

Fly Ash Aggregate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439351 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Fly Ash Aggregate Market Size

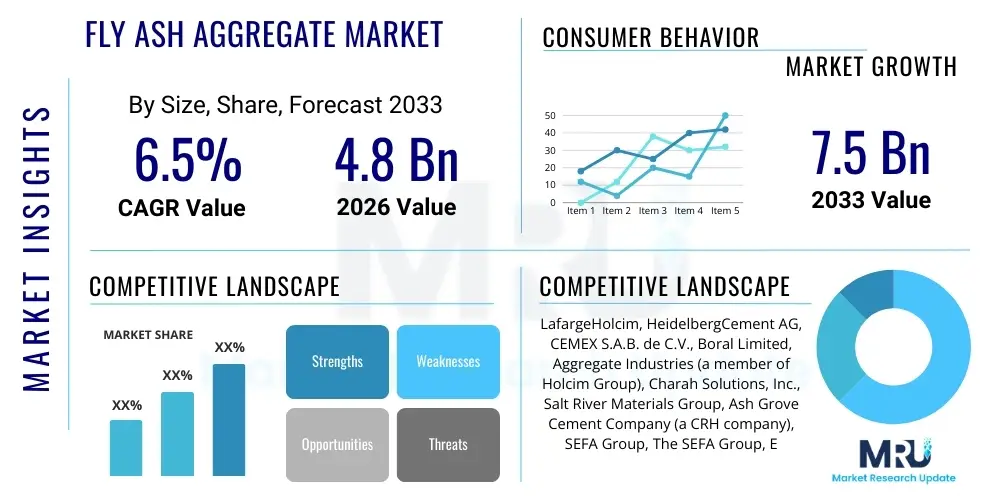

The Fly Ash Aggregate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.5 Billion by the end of the forecast period in 2033. This growth trajectory is significantly influenced by the increasing global emphasis on sustainable construction practices, coupled with a growing awareness of the environmental benefits and economic advantages associated with utilizing industrial by-products like fly ash.

Fly Ash Aggregate Market introduction

The Fly Ash Aggregate market encompasses the production, distribution, and utilization of lightweight aggregates derived from fly ash, a by-product of coal combustion in thermal power plants. These aggregates serve as a sustainable alternative to natural aggregates, which are becoming increasingly scarce and environmentally impactful to extract. The primary product involves processing raw fly ash into spherical, porous, and lightweight particles through various methods such as sintering, cold bonding, or pelletization, making them suitable for construction applications where reduced weight and enhanced performance are desired. This innovation addresses critical industry needs by repurposing a waste material into a valuable construction input.

Major applications for fly ash aggregates include their incorporation into lightweight concrete, road construction and embankments, structural fill, and various precast concrete products. Their use contributes to lower material density, improved thermal insulation properties, and enhanced workability in concrete mixes, reducing overall structural weight and construction costs. Furthermore, these aggregates play a crucial role in mitigating the environmental footprint of the construction industry by diverting vast quantities of fly ash from landfills, thus conserving natural resources and reducing greenhouse gas emissions associated with traditional aggregate production.

The market is primarily driven by several key factors: the escalating demand for sustainable building materials spurred by environmental regulations and corporate sustainability goals, the inherent cost-effectiveness of utilizing recycled materials compared to virgin resources, and the technical advantages offered by fly ash aggregates, such as improved durability and lighter structures. Increasing infrastructure development across emerging economies further propels market expansion, as governments and private entities seek efficient and eco-friendly solutions for large-scale construction projects. The growing adoption of green building certifications also plays a significant role in fostering demand for such innovative materials.

Fly Ash Aggregate Market Executive Summary

The Fly Ash Aggregate Market is experiencing robust growth, driven by an accelerating global shift towards sustainable construction practices and a heightened awareness of environmental resource management. Business trends indicate a strong emphasis on research and development, leading to advanced processing technologies that enhance the quality and applicability of fly ash aggregates. Manufacturers are increasingly focusing on strategic partnerships and collaborations with construction companies and infrastructure developers to integrate these materials into mainstream projects. Furthermore, market participants are investing in vertical integration to control the supply chain from fly ash sourcing to aggregate production, ensuring consistent quality and availability.

Regional trends highlight significant growth in Asia Pacific, particularly in countries like China and India, where rapid urbanization and massive infrastructure projects are underway. These regions benefit from abundant fly ash availability due to numerous thermal power plants and strong governmental support for waste utilization. North America and Europe also demonstrate steady growth, largely propelled by stringent environmental regulations, advanced green building standards, and a mature construction industry keen on adopting innovative, eco-friendly alternatives. Latin America, the Middle East, and Africa are emerging as promising markets, driven by new construction initiatives and a burgeoning awareness of sustainable development benefits.

Segment-wise, the market sees robust demand across various applications, with road construction and concrete production being dominant. The Class F fly ash aggregate segment holds a larger share due to its pozzolanic properties, making it highly suitable for high-performance concrete. However, Class C fly ash aggregate, known for its self-cementing properties, is also gaining traction in specific applications. The end-use industry analysis reveals significant uptake in the infrastructure and commercial sectors, reflecting the scale and material requirements of such projects. The market's overall trajectory is positive, supported by continuous innovation and a global commitment to sustainable development.

AI Impact Analysis on Fly Ash Aggregate Market

Common user questions regarding AI's impact on the Fly Ash Aggregate Market often revolve around efficiency improvements, quality control, and supply chain optimization. Users are keen to understand how AI can streamline the sorting and processing of raw fly ash, given its variable composition, to produce consistent, high-quality aggregates. There is also significant interest in AI's potential to predict market demand, optimize logistics for fly ash collection and aggregate distribution, and enhance the overall sustainability footprint of the industry. Concerns frequently surface regarding the initial investment required for AI integration and the potential need for a skilled workforce to manage these advanced systems.

Users expect AI to revolutionize quality assurance by leveraging machine learning algorithms to analyze material properties in real-time, ensuring aggregates meet stringent construction standards. They anticipate AI-driven predictive analytics to forecast demand patterns more accurately, thereby reducing waste and optimizing production schedules. Furthermore, the role of AI in intelligent automation of manufacturing processes, from sintering to cold bonding, is a key area of interest, promising increased throughput and reduced operational costs. The integration of AI with IoT sensors for continuous monitoring of equipment and processes is also a frequently discussed expectation, aimed at minimizing downtime and maximizing efficiency.

Overall, the predominant themes are efficiency, precision, and sustainability, with users seeking tangible ways AI can solve existing challenges related to material variability, logistical complexities, and the need for higher productivity in the fly ash aggregate sector. The discussions reflect a strong belief in AI's transformative power to make the industry more responsive, cost-effective, and environmentally friendly, despite acknowledging the implementation hurdles.

- AI-powered systems can optimize the sorting and classification of raw fly ash based on its chemical and physical properties, ensuring a more consistent input material for aggregate production.

- Machine learning algorithms can predict the optimal processing parameters (e.g., temperature, binder content) to achieve desired aggregate characteristics, enhancing product quality and reducing energy consumption.

- AI-driven predictive maintenance for manufacturing equipment minimizes downtime and operational costs by forecasting potential failures before they occur.

- Logistics and supply chain management benefit from AI by optimizing routes for fly ash collection and aggregate delivery, reducing transportation costs and carbon emissions.

- Real-time quality control using AI and computer vision can detect and rectify defects in manufactured aggregates, ensuring compliance with industry standards and reducing material waste.

- Demand forecasting models powered by AI can help manufacturers adjust production levels more accurately, preventing overproduction or shortages.

- AI can analyze environmental data to optimize the sustainability footprint of fly ash aggregate production, tracking energy use, emissions, and waste generation.

DRO & Impact Forces Of Fly Ash Aggregate Market

The Fly Ash Aggregate market is significantly influenced by a confluence of drivers, restraints, opportunities, and external impact forces that shape its growth trajectory and competitive landscape. A primary driver is the accelerating demand for sustainable construction materials globally, fueled by stringent environmental regulations and a growing societal preference for eco-friendly building solutions. Governments and regulatory bodies are increasingly mandating the use of recycled content in construction, pushing industries towards innovative materials like fly ash aggregates. The economic advantage of using a waste product that reduces landfill burden while offering competitive performance characteristics also serves as a strong impetus for market expansion. This cost-effectiveness, coupled with superior technical properties in certain applications, provides a compelling reason for adoption.

Despite the strong drivers, several restraints pose challenges to the market's full potential. The inherent variability in the chemical and physical composition of fly ash from different sources can lead to inconsistencies in aggregate quality, which may hinder widespread adoption without robust processing and quality control measures. Limited awareness among architects, engineers, and construction professionals regarding the benefits and proper application of fly ash aggregates also acts as a significant barrier. Furthermore, the established dominance and ingrained preference for traditional aggregates, coupled with their often lower upfront costs and well-understood performance, present stiff competition. Transportation costs for fly ash from power plants to aggregate production facilities, and then to construction sites, can also impact pricing competitiveness.

Opportunities for growth are abundant, particularly in the realm of technological innovation. Advancements in processing techniques, such as improved sintering, cold bonding, and pelletization methods, can mitigate issues related to fly ash variability and enhance aggregate performance. The expansion into emerging economies, characterized by rapid urbanization and infrastructure development, offers vast untapped markets. Developing new and niche applications beyond conventional concrete and road construction, such as specialized geotechnical fills or lightweight structural components, also presents significant growth avenues. Moreover, enhanced collaboration between power utilities, aggregate producers, and construction companies can streamline the supply chain and accelerate market penetration.

Segmentation Analysis

The Fly Ash Aggregate Market is comprehensively segmented to provide a detailed understanding of its various facets, enabling targeted strategies and accurate market forecasting. These segmentations typically include analyses by type of fly ash aggregate, application in construction, and the end-use industry leveraging these materials. Each segment plays a crucial role in defining market dynamics, highlighting areas of high growth, and identifying niche opportunities. Understanding these divisions helps stakeholders, from manufacturers to investors, pinpoint where demand is strongest and how different product formulations or applications are performing across diverse geographical landscapes. This granular view is essential for strategic planning and product development, ensuring that offerings align with specific market needs and regulatory environments.

The segmentation by type distinguishes between Class C and Class F fly ash aggregates, reflecting the different chemical compositions and performance characteristics derived from the coal source. Class F fly ash, typically produced from bituminous or anthracite coal, is rich in silica and alumina and possesses pozzolanic properties, making it ideal for high-strength concrete. Class C fly ash, usually from lignite or sub-bituminous coal, contains significant calcium and exhibits self-cementing properties, valuable for structural fills and certain concrete applications. Analyzing these types separately illuminates their specific market demands and processing requirements. The application segment covers a broad spectrum, from large-scale infrastructure projects to specialized building components, illustrating the versatility of fly ash aggregates. Each application presents unique material specifications and performance expectations, driving innovation in aggregate properties and production techniques.

Further segmentation by end-use industry provides insights into the primary sectors driving demand, such as residential, commercial, industrial, and infrastructure construction. The infrastructure sector, including roads, bridges, and public utilities, often represents the largest consumer due to the sheer volume of materials required for large-scale projects and the increasing emphasis on sustainable practices in public works. Residential and commercial construction segments also show consistent growth, particularly with the rising adoption of green building standards. This detailed segmentation allows market players to tailor their marketing efforts, product development, and distribution channels to effectively serve distinct customer needs within each category, optimizing market penetration and competitive advantage.

- By Type

- Class C Fly Ash Aggregate

- Class F Fly Ash Aggregate

- By Application

- Road Construction

- Concrete Production

- Embankments and Fill

- Mining Applications

- Lightweight Concrete Blocks and Panels

- Geotechnical Fills

- Others (e.g., masonry units, architectural concrete)

- By End-Use Industry

- Residential

- Commercial

- Industrial

- Infrastructure (Roads, Bridges, Public Utilities)

Value Chain Analysis For Fly Ash Aggregate Market

The value chain for the Fly Ash Aggregate Market begins with the upstream processes centered on the sourcing and collection of raw fly ash from thermal power plants. This initial stage involves intricate logistics, including transportation of fly ash, often requiring specialized handling and storage to maintain quality. Key players in this segment are power generation companies and sometimes specialized waste management firms that facilitate the collection and initial processing of fly ash. Upstream analysis also considers the variability in fly ash quality depending on the coal source and combustion conditions, which directly impacts the subsequent aggregate production processes and the final product's performance characteristics. Efficient and consistent sourcing is paramount for cost-effective aggregate manufacturing.

Moving downstream, the value chain encompasses the sophisticated processes of transforming raw fly ash into usable aggregates. This involves several critical steps such as screening, drying, mixing with binders, pelletization, sintering, or cold bonding, depending on the desired aggregate properties. Manufacturers in this segment leverage various technologies to produce lightweight, durable, and structurally sound aggregates that meet specific industry standards. The innovation in this stage is crucial for differentiating products and catering to diverse application requirements. Further downstream are the distribution channels that connect these manufactured aggregates to the end-users. This includes a mix of direct sales to large construction companies and infrastructure projects, as well as indirect channels through distributors, building material suppliers, and specialized contractors who serve a wider array of smaller projects.

Distribution channels are critical for market penetration and reach. Direct channels are often preferred for large-volume orders and projects where specific technical support or customized solutions are required. This allows for direct communication and tailored delivery schedules, fostering strong client relationships. Indirect channels, involving wholesalers and retailers, provide broader market access, particularly to smaller contractors and regional construction firms. These channels benefit from established logistics networks and local market knowledge. The efficiency of both direct and indirect distribution significantly impacts the market's ability to deliver products timely and cost-effectively, ultimately influencing adoption rates and competitive positioning within the construction industry. Effective management of this entire value chain, from source to end-user, is essential for profitability and market growth.

Fly Ash Aggregate Market Potential Customers

The potential customers for the Fly Ash Aggregate Market are diverse, primarily comprising entities within the construction and infrastructure development sectors. These include large-scale civil engineering firms specializing in road construction, bridge building, and public infrastructure projects, who are continuously seeking sustainable and cost-effective alternatives to conventional aggregates. Their demand is driven by government mandates for green construction, performance specifications that benefit from lightweight materials, and the sheer volume of material required for their projects. These customers often require consistent quality and large supply volumes, making direct relationships with aggregate manufacturers crucial for long-term partnerships and project success.

Beyond large infrastructure players, the market also targets concrete manufacturers who produce ready-mix concrete, precast concrete products, and concrete blocks. These manufacturers leverage fly ash aggregates to create lightweight concrete that offers improved thermal insulation, reduced dead load on structures, and enhanced workability. Their interest stems from the desire to offer innovative products that meet evolving building codes and consumer demand for energy-efficient and sustainable structures. The benefits of using fly ash aggregates in concrete production, such as reduced material costs and improved environmental credentials, make them attractive to this segment, driving innovation in concrete mix designs and product development.

Furthermore, potential customers include contractors involved in commercial and residential building construction, particularly those focused on green building certifications and sustainable architectural designs. These end-users appreciate the environmental benefits of utilizing recycled materials and the structural advantages of lightweight aggregates. Mining companies also represent a niche customer segment, using fly ash aggregates for backfilling and ground stabilization applications. The diverse range of potential customers highlights the versatility of fly ash aggregates and their critical role in transforming various facets of the construction and allied industries towards more sustainable and efficient practices, with consistent product quality and reliable supply being key purchasing factors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.5 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | LafargeHolcim, HeidelbergCement AG, CEMEX S.A.B. de C.V., Boral Limited, Aggregate Industries (a member of Holcim Group), Charah Solutions, Inc., Salt River Materials Group, Ash Grove Cement Company (a CRH company), SEFA Group, The SEFA Group, Ecocem, CRH plc, Summit Materials, Inc., Argos USA LLC, GCP Applied Technologies Inc., Votorantim Cimentos, UltraTech Cement Ltd., Reliance Infrastructure Ltd., JFE Engineering Corporation, China National Building Material Group Co., Ltd. (CNBM) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fly Ash Aggregate Market Key Technology Landscape

The technology landscape for the Fly Ash Aggregate Market is continuously evolving, driven by the need for enhanced product quality, cost efficiency, and environmental sustainability in processing industrial by-products. One of the primary technological approaches involves the sintering process, where raw fly ash is mixed with binders and fired at high temperatures to produce lightweight, ceramic-like aggregates. Advancements in sintering technologies focus on optimizing furnace designs, energy efficiency, and emission control, ensuring a uniform aggregate product with desired strength and porosity. The development of advanced pelletization techniques, often combined with sintering, allows for precise control over aggregate size and shape, catering to specific application requirements and improving material consistency.

Another significant area in the technological landscape is cold bonding, a lower-energy process that involves mixing fly ash with chemical binders and water, followed by curing at ambient or slightly elevated temperatures. This method circumvents the high energy consumption associated with sintering, offering a more environmentally friendly and cost-effective production route. Innovations in cold bonding technologies concentrate on developing novel, eco-friendly binders, enhancing reaction efficiency, and accelerating the curing process to achieve comparable mechanical properties to sintered aggregates. Research is also focused on utilizing various waste streams as binders, further improving the overall sustainability of the aggregate production.

Beyond the core manufacturing processes, a range of supporting technologies is vital for the market. These include sophisticated material characterization techniques, such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and various chemical analysis methods, used to assess the quality and composition of incoming fly ash and outgoing aggregates. Automation and process control systems, often integrated with IoT sensors and AI algorithms, are becoming crucial for real-time monitoring, quality assurance, and optimizing production parameters. Furthermore, advancements in dust collection systems and emission control technologies at manufacturing plants are essential for complying with environmental regulations and promoting cleaner production processes, reinforcing the market's commitment to sustainability.

Regional Highlights

- North America: The market in North America is characterized by stringent environmental regulations promoting the use of recycled materials and a mature construction industry. Countries like the United States and Canada are witnessing significant adoption, particularly in lightweight concrete and road construction projects. Investments in sustainable infrastructure development and the push for green building certifications are key drivers.

- Europe: Europe exhibits robust growth, primarily driven by a strong emphasis on circular economy principles and extensive research and development in sustainable construction materials. Germany, the UK, and Scandinavian countries are leading the adoption, leveraging advanced processing technologies and governmental incentives for fly ash utilization to reduce landfill waste and carbon footprint in construction.

- Asia Pacific (APAC): APAC is the fastest-growing region due fueled by rapid urbanization, massive infrastructure development, and abundant availability of fly ash from numerous thermal power plants in countries like China and India. Government initiatives promoting industrial waste utilization and the sheer scale of construction projects are significant market accelerators, with an increasing focus on cost-effective and sustainable solutions.

- Latin America: This region is experiencing emerging growth, driven by increasing construction activities and a growing awareness of sustainable building practices. Countries such as Brazil and Mexico are witnessing gradual adoption, supported by the need for cost-efficient materials in developing infrastructure and residential projects, though challenges in consistent fly ash supply and quality remain.

- Middle East and Africa (MEA): The MEA region presents considerable growth opportunities, particularly with ambitious mega-projects and diversification efforts away from oil economies, which include substantial investments in construction and infrastructure. Countries like UAE and Saudi Arabia are exploring fly ash aggregates to meet their sustainability goals and reduce reliance on traditional raw materials for large-scale urban development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fly Ash Aggregate Market.- LafargeHolcim

- HeidelbergCement AG

- CEMEX S.A.B. de C.V.

- Boral Limited

- Aggregate Industries (a member of Holcim Group)

- Charah Solutions, Inc.

- Salt River Materials Group

- Ash Grove Cement Company (a CRH company)

- SEFA Group

- The SEFA Group

- Ecocem

- CRH plc

- Summit Materials, Inc.

- Argos USA LLC

- GCP Applied Technologies Inc.

- Votorantim Cimentos

- UltraTech Cement Ltd.

- Reliance Infrastructure Ltd.

- JFE Engineering Corporation

- China National Building Material Group Co., Ltd. (CNBM)

Frequently Asked Questions

Analyze common user questions about the Fly Ash Aggregate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using fly ash aggregates in construction?

Fly ash aggregates offer several key benefits, including reduced material weight, which lowers structural loads and transportation costs, improved thermal insulation properties for energy efficiency, and enhanced durability in concrete. Environmentally, they divert industrial waste from landfills, conserving natural resources and reducing the carbon footprint of construction.

How do Class C and Class F fly ash aggregates differ?

Class F fly ash aggregates are typically high in silica and alumina, exhibiting pozzolanic properties, making them ideal for long-term strength development in concrete. Class C fly ash aggregates contain higher calcium content, providing self-cementing properties, which can accelerate early strength gain and are suitable for diverse applications like structural fills.

Are fly ash aggregates as durable as traditional natural aggregates?

Yes, when properly processed and utilized, fly ash aggregates can demonstrate comparable or even superior durability to natural aggregates in many applications. Their consistent spherical shape and controlled porosity can lead to improved workability and reduced shrinkage in concrete, contributing to long-term structural integrity.

What are the main challenges hindering the widespread adoption of fly ash aggregates?

Key challenges include the variability in raw fly ash quality from different sources, which necessitates rigorous processing; a lack of widespread awareness and education among construction professionals; competition from established traditional aggregate markets; and the logistics and transportation costs associated with sourcing and distributing the material.

Which regions are leading in the production and consumption of fly ash aggregates?

Asia Pacific, particularly countries like China and India, leads in both production and consumption due to abundant fly ash availability and rapid infrastructure development. North America and Europe also show significant adoption, driven by stringent environmental regulations and a strong focus on sustainable construction practices.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager