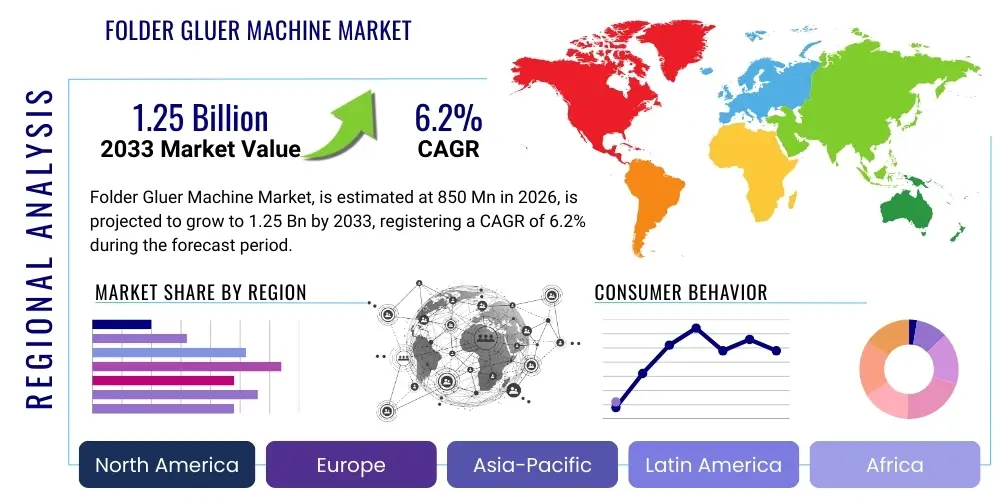

Folder Gluer Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439456 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Folder Gluer Machine Market Size

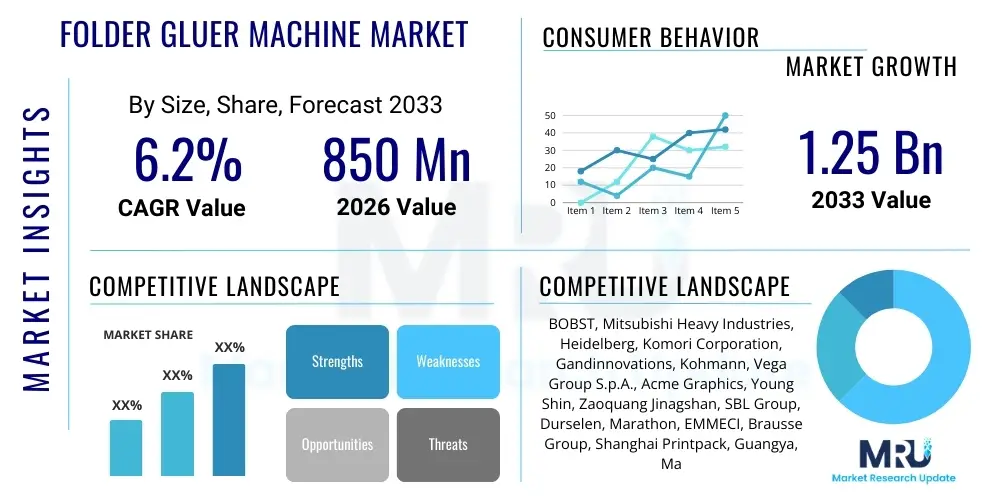

The Folder Gluer Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033. The market is estimated at USD 850 million in 2026 and is projected to reach USD 1.25 billion by the end of the forecast period in 2033.

Folder Gluer Machine Market introduction

The Folder Gluer Machine Market encompasses the global industry involved in the manufacturing, distribution, and utilization of machinery designed to fold and glue various types of packaging materials, primarily paperboard, corrugated board, and plastics, into their final structural forms. These machines are integral to the packaging industry, providing automated solutions for creating boxes, cartons, envelopes, and other folded packaging products. The primary function involves taking pre-cut and creased blanks, folding them precisely along designated lines, and applying adhesive to specific tabs to form a complete, ready-to-fill package.

Folder gluer machines are sophisticated pieces of equipment that can range from semi-automatic to fully automatic, offering varying levels of speed, precision, and versatility. Their product descriptions often highlight features such as modular design, quick changeover capabilities, digital control systems, and compatibility with a wide array of material thicknesses and product specifications. Major applications span across diverse sectors including food and beverage, pharmaceuticals, cosmetics, consumer electronics, and general industrial packaging. The machines are crucial for producing packaging for cereals, medicines, perfumes, mobile phones, and a myriad of other consumer and industrial goods, ensuring product protection and brand presentation.

The benefits of employing folder gluer machines are substantial, primarily revolving around enhanced production efficiency, reduced labor costs, superior product consistency, and improved packaging quality. These machines significantly accelerate the packaging process compared to manual methods, minimizing errors and ensuring uniform product presentation. Key driving factors for market growth include the burgeoning e-commerce sector, which demands high volumes of protective and branded packaging, the increasing adoption of automation in manufacturing processes to optimize operational costs, and the rising global demand for packaged consumer goods due to population growth and urbanization. Moreover, technological advancements focusing on higher speeds, greater accuracy, and eco-friendly adhesive applications are continuously propelling market expansion.

Folder Gluer Machine Market Executive Summary

The Folder Gluer Machine Market is characterized by robust business trends driven by the escalating demand for automated packaging solutions across various industries. A significant trend involves the development of more versatile and modular machines capable of handling a broader range of packaging designs and materials, facilitating quicker changeovers and reducing downtime. Furthermore, there is a pronounced shift towards incorporating smart manufacturing principles, with machines featuring advanced sensors, IoT connectivity, and predictive maintenance capabilities, enhancing operational efficiency and reliability. Sustainability is another critical business trend, as manufacturers focus on developing machines compatible with recyclable and biodegradable packaging materials, as well as optimizing adhesive usage to minimize waste and environmental impact. The competitive landscape is dynamic, with both established global players and innovative regional manufacturers vying for market share through continuous product development and strategic partnerships.

Regionally, the market exhibits diverse growth patterns. Asia Pacific stands out as the fastest-growing region, propelled by rapid industrialization, expanding manufacturing sectors, and increasing consumer disposable incomes, particularly in emerging economies like China and India. This region is witnessing significant investment in new production capacities and the modernization of existing packaging facilities. North America and Europe, while mature markets, continue to demonstrate steady growth, driven by stringent quality standards, a strong emphasis on automation to combat labor shortages, and sustained demand from well-established food, pharmaceutical, and e-commerce industries. Latin America and the Middle East & Africa are also showing promising growth, albeit from a smaller base, attributed to evolving retail landscapes and rising industrial output.

In terms of segmentation, the market is primarily categorized by machine type (automatic, semi-automatic), technology (manual, mechanical, digital), application (corrugated packaging, pharmaceutical packaging, cosmetic packaging, food & beverage packaging), and end-use industry. The automatic folder gluer segment currently dominates the market due to its high efficiency and minimal human intervention, meeting the demands of large-scale production. The food and beverage packaging application segment remains a significant contributor, driven by consistent consumer demand for packaged goods. Emerging segments include specialized machines for e-commerce packaging, which requires robust and customizable solutions, and those catering to sustainable packaging formats. The trend across segments is towards higher levels of integration, automation, and customization to meet specific client requirements and evolving market dynamics.

AI Impact Analysis on Folder Gluer Machine Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the efficiency, precision, and flexibility of folder gluer machines. Key themes often revolve around the potential for AI-driven systems to optimize machine settings autonomously, predict maintenance needs, enhance quality control through real-time defect detection, and streamline complex changeover processes. Concerns include the initial investment costs, the availability of skilled labor to manage AI-integrated machinery, and the data security implications of networked systems. Expectations are high for AI to reduce operational costs, minimize material waste, and significantly improve overall production throughput and consistency, thereby extending the lifespan and profitability of packaging lines.

- AI-powered predictive maintenance reduces downtime by analyzing machine data to anticipate failures, scheduling proactive interventions.

- Real-time quality control systems using AI-driven vision inspection can detect minute defects in folding and gluing, minimizing waste and ensuring product integrity.

- Automated machine parameter optimization through AI algorithms allows for dynamic adjustments to speed, pressure, and adhesive application based on material properties and environmental conditions, enhancing precision.

- AI integration facilitates quicker and more accurate changeovers for different product specifications by recommending optimal settings and guiding operators.

- Enhanced energy efficiency through AI algorithms that monitor and adjust power consumption based on production load, reducing operational costs.

- AI-driven robotics can integrate seamlessly with folder gluer lines for automated feeding, stacking, and palletizing, further streamlining the entire packaging workflow.

- Supply chain optimization via AI for better inventory management of raw materials and spare parts, directly impacting machine uptime and overall plant efficiency.

DRO & Impact Forces Of Folder Gluer Machine Market

The Folder Gluer Machine Market is significantly influenced by a confluence of drivers, restraints, and opportunities, collectively shaping its trajectory and competitive landscape. The primary drivers include the relentless growth of the e-commerce sector globally, which necessitates high-volume, reliable, and often customized packaging solutions to protect goods during transit and enhance brand experience. Concurrently, the increasing automation in manufacturing industries worldwide, aimed at reducing labor costs, improving efficiency, and ensuring consistent product quality, further fuels the demand for advanced folder gluer machines. Moreover, the sustained expansion of the food and beverage, pharmaceutical, and personal care industries, driven by population growth and changing consumer lifestyles, consistently generates demand for various types of folded and glued packaging.

However, the market also faces considerable restraints. The high initial capital investment required for acquiring advanced automatic folder gluer machines can be a significant barrier for small and medium-sized enterprises (SMEs), particularly in developing regions. Additionally, the complexity of operating and maintaining sophisticated machinery necessitates skilled labor, which can be scarce, leading to increased operational costs and potential production bottlenecks. Economic uncertainties and fluctuations in raw material prices, such as paperboard and adhesives, can also impact manufacturing costs for both machine producers and end-users, potentially slowing market adoption. Furthermore, the rapid pace of technological change often leads to concerns about machine obsolescence, requiring continuous investment in upgrades and new models.

Despite these challenges, numerous opportunities exist for market expansion and innovation. The growing emphasis on sustainable packaging solutions presents a lucrative avenue for manufacturers to develop machines compatible with eco-friendly materials like recycled paperboard and biodegradable adhesives. Customization and personalization trends in packaging offer opportunities for versatile machines capable of handling short runs and diverse designs efficiently. The integration of Industry 4.0 technologies, including IoT, AI, and machine learning, into folder gluer machines is creating new possibilities for predictive maintenance, remote diagnostics, and enhanced operational efficiency. Moreover, the untapped potential in emerging markets, characterized by evolving retail infrastructures and increasing industrialization, provides significant growth prospects for both new machine installations and upgrades to existing facilities. Strategic collaborations and mergers among machine manufacturers and technology providers are also presenting opportunities to offer integrated solutions and expand market reach, addressing the evolving needs of the global packaging industry.

Segmentation Analysis

The Folder Gluer Machine Market is comprehensively segmented to provide a granular understanding of its diverse components, allowing for targeted market strategies and detailed analysis. This segmentation typically categorizes the market based on several key parameters, including machine type, level of automation, application area, and the end-use industry. Each segment represents distinct market dynamics, catering to specific operational requirements and production scales within the global packaging landscape. Understanding these segments is crucial for stakeholders to identify growth pockets, assess competitive intensity, and tailor product offerings to meet varied customer needs, ranging from high-volume, fully automatic production lines to flexible, semi-automatic solutions for specialized or smaller batch operations.

- By Type:

- Automatic Folder Gluer Machine

- Semi-Automatic Folder Gluer Machine

- By Technology:

- Cold Glue Technology

- Hot Melt Glue Technology

- Plasma Treatment Technology

- Other Gluing Technologies

- By Application:

- Corrugated Packaging

- Pharmaceutical Packaging

- Cosmetic Packaging

- Food & Beverage Packaging

- Tobacco Packaging

- Electronic Products Packaging

- Other Industrial Packaging

- By End-Use Industry:

- Food & Beverage Industry

- Pharmaceutical Industry

- Cosmetics & Personal Care Industry

- Electronics Industry

- Printing & Packaging Industry

- Automotive Industry

- Textile Industry

- Other Manufacturing Industries

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Folder Gluer Machine Market

The value chain for the Folder Gluer Machine Market is a complex network involving multiple stages, from raw material sourcing to the final end-user application, highlighting the interdependencies and value addition at each step. Upstream analysis focuses on the suppliers of critical components and materials required for machine manufacturing. This includes providers of steel, aluminum, and other metals for machine frames and parts, electronic components for control systems, motors, sensors, conveyors, and various specialized tooling. The quality and availability of these components directly impact the machine's performance, durability, and cost-effectiveness. Relationships with these upstream suppliers are crucial for ensuring a stable supply chain and incorporating advanced technological features into the final product.

The manufacturing stage involves the design, assembly, testing, and quality assurance of the folder gluer machines. Manufacturers invest heavily in research and development to innovate machine capabilities, improve efficiency, and adapt to evolving packaging trends. This stage adds significant value through precision engineering, integration of advanced automation and software, and adherence to international manufacturing standards. Post-manufacturing, the downstream analysis focuses on the distribution channels that connect these sophisticated machines to end-users. Distribution can occur through direct sales channels, where machine manufacturers sell and service their products directly to large clients, often involving extensive pre-sales consultation and after-sales support.

Alternatively, indirect distribution channels involve leveraging a network of distributors, agents, or system integrators. These intermediaries play a vital role in market penetration, particularly in regions where direct presence is challenging. They often provide localized sales, installation, training, and maintenance services, bridging the gap between manufacturers and diverse client bases. The choice of distribution channel depends on factors like market reach, cost-efficiency, and the level of technical support required. Ultimately, the efficiency of the entire value chain, from material procurement to after-sales service, dictates the market competitiveness, customer satisfaction, and overall profitability within the Folder Gluer Machine Market.

Folder Gluer Machine Market Potential Customers

The Folder Gluer Machine Market primarily serves a broad spectrum of end-users and buyers, all seeking efficient and reliable solutions for their packaging requirements. These potential customers span across various industries that rely heavily on automated packaging processes for their products. Large-scale packaging converters form a significant customer base, as they specialize in producing a wide range of cartons, boxes, and specialty packaging for multiple brands and industries. These converters require high-speed, versatile machines capable of handling diverse materials and complex designs to meet fluctuating client demands and maintain competitive pricing.

Another crucial segment of potential customers includes manufacturing companies in the food and beverage industry, pharmaceutical companies, cosmetic and personal care product manufacturers, and consumer electronics producers. These industries necessitate precise, high-quality, and often sterile or tamper-evident packaging to comply with stringent regulatory standards and ensure product safety and brand integrity. For instance, food companies use folder gluers for cereal boxes and frozen food cartons, while pharmaceutical firms use them for medicine boxes and healthcare product packaging. The increasing demand for packaged goods in these sectors directly translates into a sustained demand for folder gluer machines.

Furthermore, the burgeoning e-commerce sector and logistics companies are emerging as significant potential customers. With the exponential growth of online retail, there is an ever-increasing need for robust, cost-effective, and often customized corrugated or paperboard packaging to protect products during shipping. Small and medium-sized enterprises (SMEs) are also growing their interest in folder gluer machines, particularly semi-automatic models, as they seek to enhance their packaging efficiency and product presentation to compete with larger players. Essentially, any enterprise involved in the production, packaging, or distribution of goods that require folded and glued carton or box forms represents a potential customer for folder gluer machine manufacturers, continuously seeking solutions that offer speed, precision, and cost-effectiveness.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 million |

| Market Forecast in 2033 | USD 1.25 billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BOBST, Mitsubishi Heavy Industries, Heidelberg, Komori Corporation, Gandinnovations, Kohmann, Vega Group S.p.A., Acme Graphics, Young Shin, Zaoquang Jinagshan, SBL Group, Durselen, Marathon, EMMECI, Brausse Group, Shanghai Printpack, Guangya, Masterwork Group, Taiwan Prosperity, Wenzhou Zhongke Packaging Machinery |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Folder Gluer Machine Market Key Technology Landscape

The Folder Gluer Machine Market is continuously evolving with significant technological advancements aimed at enhancing speed, precision, versatility, and sustainability. A key aspect of the technology landscape is the widespread adoption of digital control systems, often integrated with Human-Machine Interfaces (HMIs) and touchscreens. These systems allow for intuitive operation, precise parameter adjustments, and real-time monitoring of production processes, greatly simplifying changeovers and improving overall operational efficiency. Servo motor technology is another critical advancement, enabling highly accurate and repeatable movements of machine components, leading to superior folding and gluing quality, especially for complex carton designs and high-speed production lines.

Furthermore, advanced gluing technologies are central to the market's innovation. Cold glue applications remain prevalent, but hot melt systems are gaining traction due to their quick drying times and strong bonds, particularly for certain materials and applications. Beyond traditional adhesives, technologies like plasma treatment are being increasingly used for surface activation of difficult-to-bond materials, improving adhesion strength and reliability. Automated feeding and pre-folding sections, often incorporating vacuum or friction feeders, ensure a smooth and consistent supply of carton blanks, minimizing jams and maximizing throughput. The integration of sophisticated sensors and vision inspection systems is also paramount, providing real-time quality control by detecting misfolds, incorrect glue application, or material defects, thereby reducing waste and ensuring product integrity.

The embrace of Industry 4.0 principles is fundamentally reshaping the technology landscape. This includes the incorporation of Internet of Things (IoT) capabilities, allowing machines to be networked for data collection, remote monitoring, and predictive maintenance. Machine learning algorithms, often powered by AI, are being developed to optimize machine settings autonomously, learn from production data, and even adapt to slight variations in material properties. Robotics and collaborative robots (cobots) are also finding their place in auxiliary tasks such as feeding, stacking, and palletizing, further automating the end-of-line processes. These technological integrations are not only boosting productivity and reducing labor dependency but also enabling greater customization, flexibility, and a more sustainable manufacturing footprint in the folder gluer machine market.

Regional Highlights

- North America: This region demonstrates a mature market driven by high automation adoption rates, significant investments in advanced packaging solutions by food, pharmaceutical, and e-commerce giants, and stringent quality control standards. Key countries like the United States and Canada are characterized by a demand for high-speed, precise machinery capable of handling diverse packaging formats and responding to rapid innovation cycles.

- Europe: Europe is another well-established market, with countries like Germany, Italy, and France at the forefront of packaging machinery manufacturing and adoption. The market here is shaped by a strong focus on energy efficiency, sustainable packaging solutions, and advanced automation, driven by environmental regulations and a skilled labor shortage. Demand is strong from pharmaceutical and luxury goods sectors.

- Asia Pacific (APAC): The APAC region is the fastest-growing market, primarily fueled by rapid industrialization, expanding manufacturing bases in countries like China and India, and increasing consumer disposable income driving demand for packaged goods. This region is witnessing significant investment in new production facilities and a shift towards modern, automated folder gluer machines to meet large-scale production demands and improve competitive positioning.

- Latin America: This region presents emerging growth opportunities, with Brazil and Mexico leading the adoption of folder gluer machines. Market growth is spurred by increasing foreign investment in manufacturing, a developing retail sector, and growing awareness of packaging efficiency benefits. The demand is often for cost-effective, yet reliable, semi-automatic and automatic solutions.

- Middle East & Africa (MEA): The MEA market is gradually expanding, driven by urbanization, diversification of economies away from oil, and investments in infrastructure and manufacturing, particularly in countries like Saudi Arabia, UAE, and South Africa. The region is seeing increased demand for packaged food and consumer goods, leading to greater adoption of packaging machinery, including folder gluers, to enhance local production capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Folder Gluer Machine Market.- BOBST

- Mitsubishi Heavy Industries

- Heidelberg

- Komori Corporation

- Gandinnovations

- Kohmann

- Vega Group S.p.A.

- Acme Graphics

- Young Shin

- Zaoquang Jinagshan

- SBL Group

- Durselen

- Marathon

- EMMECI

- Brausse Group

- Shanghai Printpack

- Guangya

- Masterwork Group

- Taiwan Prosperity

- Wenzhou Zhongke Packaging Machinery

Frequently Asked Questions

What is a folder gluer machine and its primary function in packaging?

A folder gluer machine is an industrial device used in the packaging industry to automate the process of folding and gluing pre-cut and creased carton blanks into their final structural forms, such as boxes, cartons, and envelopes. Its primary function is to enhance production efficiency, ensure consistent product quality, and reduce labor costs by performing precise folding, adhesive application, and pressing operations at high speeds, making packages ready for filling.

Which industries are the primary end-users of folder gluer machines?

The primary end-users of folder gluer machines span across several key industries including food and beverage (for cereal boxes, frozen food cartons), pharmaceuticals (for medicine boxes, healthcare product packaging), cosmetics and personal care, consumer electronics, and general industrial packaging. The e-commerce and logistics sectors are also significant users due to the high demand for robust and efficient shipping packaging.

What are the key drivers propelling the growth of the Folder Gluer Machine Market?

Key drivers include the rapid expansion of the global e-commerce sector demanding high-volume packaging, increasing adoption of automation in manufacturing to optimize efficiency and reduce labor, and the sustained growth of end-use industries like food and beverage, pharmaceuticals, and personal care. Additionally, technological advancements enhancing machine speed, precision, and versatility contribute significantly to market expansion.

How is AI impacting the Folder Gluer Machine Market?

AI is significantly impacting the Folder Gluer Machine Market by enabling advanced functionalities such as predictive maintenance to minimize downtime, real-time quality control through AI-driven vision systems, automated optimization of machine parameters for enhanced precision, and faster, more accurate changeovers. These AI integrations lead to improved efficiency, reduced waste, and higher overall production throughput.

What are the main types of folder gluer machines available in the market?

The main types of folder gluer machines available are automatic folder gluers and semi-automatic folder gluers. Automatic machines offer high-speed, continuous production with minimal human intervention, ideal for large-scale operations. Semi-automatic machines require more manual loading and supervision but provide greater flexibility for shorter runs, specialized products, or for businesses with lower production volumes and budget constraints.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager