Folder Gluers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433873 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Folder Gluers Market Size

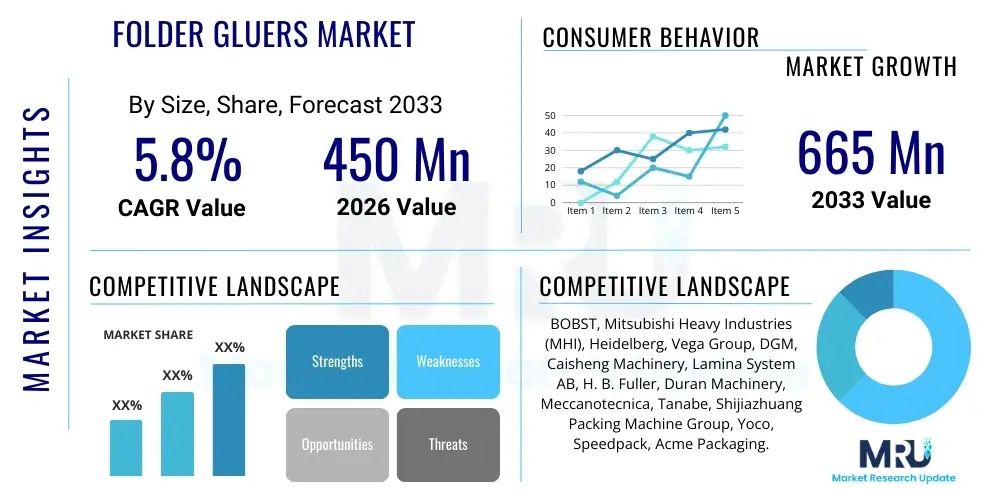

The Folder Gluers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 665 Million by the end of the forecast period in 2033. This consistent growth trajectory is primarily fueled by the accelerating global demand for automated packaging solutions, particularly within the e-commerce sector and the rapidly expanding consumer goods industries. Manufacturers are increasingly prioritizing high-speed, high-precision machinery capable of handling complex carton designs, which necessitates significant investment in advanced folder gluer systems to maintain competitive production efficiencies and quality standards.

Folder Gluers Market introduction

The Folder Gluers Market encompasses the machinery utilized in the final stages of folding carton production, where flat die-cut blanks are folded and glued into their finished three-dimensional forms, such as straight-line, crash-lock, or four/six-corner boxes. These sophisticated machines are pivotal in the packaging industry, ensuring the integrity and aesthetic quality of the final packaging structure. They operate with high precision, utilizing various gluing techniques, including cold glue systems (PVA) and hot melt systems, often integrated with advanced servo drives and control software to manage high throughput rates and quick job changes.

Major applications of folder gluers span critical industrial sectors, including Food & Beverage (F&B), pharmaceuticals, cosmetics, electronics, and general consumer goods. The efficiency and reliability of modern folder gluers directly translate into significant operational benefits for packaging converters, such as reduced labor costs, minimization of material waste, and vastly improved production speeds. Modern systems are increasingly modular, allowing for greater customization and the integration of quality assurance tools like barcode readers and vision inspection systems, thereby enhancing their versatility across diverse packaging formats.

The driving factors underpinning market expansion include the global surge in packaged consumer goods consumption, particularly in densely populated emerging economies, and the structural shift toward automated manufacturing processes (Industry 4.0). Furthermore, the burgeoning e-commerce sector requires robust, high-volume secondary packaging solutions, creating sustained demand for reliable, high-speed folder gluer machinery capable of producing complex and durable packaging structures necessary for logistics and shipment integrity.

Folder Gluers Market Executive Summary

The Folder Gluers Market Executive Summary highlights robust growth driven by irreversible global business trends toward automation and specialized packaging demand. Regionally, the Asia Pacific (APAC) stands out as the primary engine of growth, underpinned by massive manufacturing expansion, rapid urbanization, and increased consumer spending across India, China, and Southeast Asian nations. This regional dominance is coupled with strategic investments in machinery upgrades in established markets like North America and Europe, where the focus is shifting toward sustainable packaging materials and high-efficiency systems capable of handling lightweight and recycled substrates without compromising speed or reliability.

Segment trends reveal a distinct preference for automatic and high-speed folder gluers, particularly those equipped with advanced features such as servo-driven technology and automatic setup capabilities, designed to minimize downtime and maximize productivity in high-volume environments. The crash-lock bottom segment continues to be highly lucrative due to its inherent strength and ease of assembly for end-users, driving specific technological development in machines specializing in complex folds. The pharmaceutical and food & beverage sectors represent the most crucial application segments, demanding stringent quality control integration (e.g., vision inspection systems) within the gluing process, thereby pushing technological innovation toward precision and traceability solutions.

Overall, market dynamics suggest intense competition centered on technological differentiation, particularly concerning digitalization and system integration. Leading manufacturers are focusing R&D efforts on reducing the total cost of ownership (TCO) for end-users by enhancing energy efficiency and reducing the maintenance footprint of the machinery. Strategic market penetration relies heavily on establishing strong, localized service networks and offering modular, future-proof machinery that can adapt to rapidly evolving packaging material specifications and design complexity demands.

AI Impact Analysis on Folder Gluers Market

Users frequently inquire about the direct and transformative role Artificial Intelligence (AI) and machine learning (ML) will play in the operational efficiency and quality assurance of folder gluer systems. Common user questions revolve around predictive maintenance capabilities: "How accurately can AI forecast machinery failure?" and "Will AI reduce material waste significantly?" Additionally, questions concerning integration are prevalent: "How difficult is it to retrofit existing folder gluers with AI-powered vision systems?" and "Does AI lead to faster changeovers for complex jobs?" The overarching theme of user concern centers on achieving higher output quality, minimizing operational variance, and justifying the significant capital investment required for these intelligent systems.

The analysis indicates that AI is fundamentally shifting folder gluer operations from reactive maintenance to proactive, predictive management. Machine learning algorithms, processing continuous data streams from sensors related to machine speed, temperature, vibration, and glue consumption, are now capable of detecting subtle anomalies that precede equipment failure, offering maintenance schedules precisely when required, rather than relying on fixed time intervals. This minimizes unexpected downtime, which is critical in high-throughput packaging environments. Furthermore, AI-powered quality control systems, utilizing high-resolution cameras, can learn to identify defects such as incorrect folds, poor glue adhesion, or misalignments at speeds unattainable by human inspectors or traditional sensors, ensuring near-perfect output quality.

The application of AI extends to optimizing complex manufacturing parameters. AI models can analyze job specifications, material properties (such as board thickness or coating type), and environmental factors (humidity) to automatically adjust machine settings, including belt speeds, pressure points, and glue application volume, ensuring optimal performance from the first carton. This enhanced self-optimization capability drastically reduces setup time for new jobs (a core component of Answer Engine Optimization for high-value machinery inquiries) and significantly lowers the quantity of initial setup waste, thereby directly addressing key customer pain points regarding efficiency and sustainability.

- AI facilitates Predictive Maintenance (PdM) by analyzing vibration and thermal data, forecasting component failure weeks in advance, maximizing uptime.

- Machine Vision Systems leveraging AI ensure 100% quality inspection, detecting minute defects in folding, gluing, and print registration at high production speeds.

- Optimized Production Scheduling uses ML algorithms to sequence jobs based on complexity and resource availability, minimizing changeover time and maximizing overall equipment effectiveness (OEE).

- AI-driven autonomous parameter adjustment calibrates glue application and pressure settings automatically based on real-time material feedback and environmental conditions.

- Enhanced energy consumption tracking and optimization through AI monitors power usage patterns, suggesting operational adjustments for improved sustainability.

DRO & Impact Forces Of Folder Gluers Market

The Folder Gluers Market is governed by dynamic forces where the increasing global requirement for efficient packaging machinery (Driver) clashes with the significant initial capital expenditure (Restraint). The persistent growth of e-commerce, which requires versatile and high-volume corrugated and folding carton packaging, acts as a substantial driver, necessitating investments in faster and more reliable folder gluer systems. Conversely, the complexity of modern machinery requires a highly skilled technical workforce for operation and maintenance, posing a restraint, especially in regions facing labor shortages. However, the move towards sustainable packaging materials (e.g., bio-degradable and recycled substrates) presents a major opportunity for manufacturers to innovate specialized gluing systems and create a competitive advantage, thereby driving new market segments.

The primary impact forces influencing this market relate heavily to technological obsolescence and regulatory alignment. The rapid advancement in automation and Industry 4.0 standards compels end-users to frequently upgrade their existing machinery to remain competitive, creating a continuous replacement cycle. Furthermore, stricter safety regulations and quality mandates in sectors like pharmaceuticals (traceability and validation) place immense pressure on folder gluer manufacturers to integrate precise quality control features, such as advanced serialization and camera verification systems, which significantly elevates the perceived value and functionality of new machines.

The market also experiences external economic impact forces, particularly volatile raw material prices (paperboard, glue) and fluctuating global shipping costs, which influence the final cost of packaging production. While high costs temporarily suppress immediate capital expenditure, the long-term strategic need for automation, driven by the inescapable necessity to reduce operational labor dependency and increase yield per shift, ensures that the underlying growth trajectory of folder gluers remains strong and fundamentally resilient against minor economic headwinds.

Segmentation Analysis

The Folder Gluers Market is strategically segmented based on several critical parameters, including the Type of Folder Gluer (differentiating basic and complex folding capabilities), the Operational Mode (determining the level of automation), the Application (the type of box produced), and the End-use Industry. This stratification allows market participants to tailor machinery designs and features to specific customer needs, ranging from small-scale commercial printers requiring basic straight-line gluer functionality to large, multi-national converters demanding integrated, high-speed, 6-corner folding and gluing systems with integrated quality assurance modules. Analyzing these segments is essential for understanding where technological investment is most concentrated and where untapped market opportunities lie, particularly regarding specialized applications and emerging markets.

- By Type:

- Straight Line Gluers

- Lock Bottom Gluers (Crash Lock, 4/6 Corner)

- Specialty Gluers (e.g., Wallet, CD Sleeves, Custom Designs)

- By Operational Mode:

- Manual

- Semi-Automatic

- Automatic (High-Speed)

- By Application:

- Folding Cartons (Standard, Microflute)

- Corrugated Boxes (Heavy Duty, Shipping Containers)

- Paperboard and Cardboard

- By End-use Industry:

- Food and Beverage (F&B)

- Pharmaceutical and Healthcare

- Cosmetics and Personal Care

- Consumer Electronics

- General Packaging and Logistics

Value Chain Analysis For Folder Gluers Market

The Folder Gluers Market value chain begins with upstream activities, primarily involving the sourcing and processing of precision engineering components. Key upstream inputs include high-tolerance machined parts, advanced servo motors, specialized belts, electrical control systems (PLCs, HMIs), and sophisticated gluing systems (hot melt applicators, cold glue pumps). Manufacturers rely heavily on specialized suppliers for these technical components, making strategic sourcing and quality control of these inputs paramount to the final machine's reliability and speed. The competitive advantage at this stage often rests on proprietary software development and the integration of third-party vision inspection technology.

The central manufacturing stage involves the assembly, calibration, and rigorous testing of the folder gluer machinery, where optimization for speed, versatility, and ease of setup is critical. Following manufacturing, the distribution channel plays a vital role. Direct distribution is common for high-value, custom-built automatic lines, allowing manufacturers to maintain close client relationships and offer immediate, dedicated after-sales support and installation services. Indirect distribution, leveraging specialized distributors and agents, is frequently used for standardized models or penetration into geographically remote or emerging markets, capitalizing on local knowledge and established sales networks.

The downstream segment involves the end-users—packaging converters, integrated box manufacturers, and commercial printers—who utilize the folder gluers to produce finished cartons for various industries. The final value delivered is characterized by the machine's efficiency (output per hour), precision (quality of folding/gluing), and versatility (ability to handle different substrates and box styles). Continuous technical support, preventative maintenance contracts, and the timely provision of spare parts are essential downstream activities that maintain machine OEE and customer satisfaction, solidifying the long-term value derived from the initial capital investment.

Folder Gluers Market Potential Customers

The primary potential customers and key buyers of folder gluer machinery are large-scale packaging converters and integrated corrugated box manufacturers who require high-volume, automated finishing solutions. These entities, often serving multiple demanding sectors simultaneously, necessitate robust machinery that offers high throughput, minimal setup time, and superior reliability. The decision-making process for these customers is driven primarily by Total Cost of Ownership (TCO), machine versatility (handling multiple box types and materials), and the integration capabilities with other upstream and downstream packaging equipment, such as die-cutters and packing lines.

A second significant customer base exists within specialized packaging segments, particularly the pharmaceutical and premium cosmetics industries. These end-users demand folder gluers equipped with advanced features like 100% carton inspection, serialization, and tamper-evident gluing systems to meet stringent regulatory compliance and brand protection standards. Their purchasing decisions are heavily weighted by precision, validation capabilities, and the machine's ability to minimize human error in critical applications. Furthermore, mid-sized commercial printers expanding into complex folding carton production also represent a growing customer segment, typically targeting highly versatile, medium-speed machines offering rapid return on investment (ROI).

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 665 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BOBST, Mitsubishi Heavy Industries (MHI), Heidelberg, Vega Group, DGM, Caisheng Machinery, Lamina System AB, H. B. Fuller, Duran Machinery, Meccanotecnica, Tanabe, Shijiazhuang Packing Machine Group, Yoco, Speedpack, Acme Packaging. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Folder Gluers Market Key Technology Landscape

The technological landscape of the Folder Gluers Market is dominated by advancements aimed at increasing speed, enhancing operational versatility, and integrating digital control. Central to modern folder gluer design is the widespread adoption of advanced Servo Technology, replacing traditional mechanical drives. Servo motors provide independent, precise control over different sections of the machine (e.g., feeder, alignment, folding, pressing), allowing for instantaneous adjustments and higher speeds. This technological shift is crucial for handling complex box structures and managing quick changeovers with minimal mechanical intervention, substantially boosting OEE. Furthermore, the development of highly reliable and versatile gluing systems, including proprietary Hot Melt systems that offer superior bond strength and fast drying times, continues to drive market performance, especially for challenging substrates like laminated or UV-coated boards.

Another major technological pillar is the integration of Industry 4.0 concepts, particularly through advanced Human-Machine Interfaces (HMIs) and connectivity tools. Modern folder gluers feature intuitive, large-format touch screens that facilitate automated setup based on stored job recipes, significantly reducing the reliance on operator skill for initial calibration. This connectivity allows for machine-to-machine communication, providing real-time production data that feeds into manufacturing execution systems (MES), enabling advanced analytics on performance, downtime causes, and glue consumption rates. Such digitalization is mandatory for large converters operating multiple gluer lines, seeking centralized management and performance benchmarking.

Moreover, quality assurance technologies have evolved from simple sensor checks to sophisticated, integrated Vision Inspection Systems. These systems, often leveraging high-speed linear cameras and advanced processing software (sometimes AI-enhanced), scan every single carton for defects such as misaligned folds, glue application errors, color shifts, and non-compliance with serialization codes. This 100% inspection capability is non-negotiable in regulated industries like pharmaceuticals, where defect rates must be near zero. Technological progress in this area is characterized by higher scan speeds and greater resolution, ensuring quality without sacrificing the machine’s maximum throughput capacity, thereby optimizing the balance between speed and quality—a critical factor for competitive differentiation.

Regional Highlights

The global Folder Gluers market exhibits distinct regional dynamics reflecting varying levels of industrialization, labor costs, and regulatory environments.

- Asia Pacific (APAC): APAC is projected to maintain the highest growth rate and market share throughout the forecast period. This dominance is attributed to rapid industrialization, massive expansion of the domestic manufacturing and export sectors, and the resultant soaring demand for high-volume packaging machinery, particularly in China and India. The regional emphasis is on acquiring high-speed, fully automatic machines to address low labor costs and rising production volumes.

- North America: This region is characterized by high operational costs and a strong push toward automation. Market demand focuses on premium, highly automated folder gluers incorporating advanced servo technology, remote diagnostics, and Industry 4.0 compliance. The stringent quality requirements in pharmaceutical and food packaging drive investments in integrated vision inspection and traceability systems.

- Europe: Europe is a mature market driven primarily by replacement cycles and technological upgrades, with a strong emphasis on sustainability and energy efficiency. European converters prioritize machines capable of handling recycled, lightweight, and fiber-based substrates effectively, aligning with EU environmental regulations and the circular economy mandate. Innovation focuses on reducing waste and improving machine modularity.

- Latin America (LATAM): The LATAM market, while smaller, offers significant growth potential, driven by urbanization and the expanding middle class, which boosts local consumer goods production. Investment trends here favor reliable, mid-range automatic and semi-automatic machines offering a balance between initial cost and performance, with Brazil and Mexico leading the regional demand.

- Middle East and Africa (MEA): Growth in MEA is patchy but strong in regional hubs like the UAE and Saudi Arabia, fuelled by diversification efforts and investment in local food processing and logistics infrastructure. The market seeks versatile folder gluers capable of operating reliably in challenging climatic conditions, supported by strong local service agreements.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Folder Gluers Market.- BOBST

- Mitsubishi Heavy Industries (MHI)

- Heidelberg

- Vega Group

- DGM

- Caisheng Machinery

- Lamina System AB

- H. B. Fuller

- Duran Machinery

- Meccanotecnica

- Tanabe

- Shijiazhuang Packing Machine Group

- Yoco

- Speedpack

- Acme Packaging

- Sinaiko

- Kama GmbH

- Wenzhou Ruian Guangfa

- Wenhong Precision Machinery

- Jinglu Group

Frequently Asked Questions

Analyze common user questions about the Folder Gluers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What types of box styles can modern folder gluers produce efficiently?

Modern folder gluers are highly versatile, capable of producing straight-line cartons, crash-lock bottom boxes (automatic locking), 4-corner boxes, 6-corner boxes, specialty wallets, and often custom designs like CD sleeves or confectionery packaging, depending on the machine’s configuration and modularity.

How does servo technology improve the performance of folder gluer machines?

Servo technology offers precise, independent control over various machine sections, enabling higher operational speeds, superior alignment accuracy, and significantly faster job changeovers through digital parameter adjustments, directly translating to improved OEE and reduced labor requirements.

What is the primary factor driving demand for high-speed automatic folder gluers?

The exponential growth of the global e-commerce industry, which demands massive volumes of standardized and specialized secondary packaging solutions in short turnaround times, is the primary factor necessitating high-speed, fully automatic folder gluer investments worldwide.

What is the role of AI and vision systems in modern folder gluer operations?

AI-powered vision systems perform 100% quality inspection at production speeds, detecting defects in folding, gluing, and registration. AI also facilitates predictive maintenance by analyzing machine sensor data, proactively preventing unexpected downtime and minimizing waste.

Which region dominates the Folder Gluers Market and why is its growth rate highest?

The Asia Pacific (APAC) region dominates the Folder Gluers Market due to robust manufacturing output, increasing consumer demand, rapid urbanization, and continuous industrial investment in packaging automation across key economies like China, India, and Southeast Asia.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager