Food Aluminum Foil Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432254 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Food Aluminum Foil Market Size

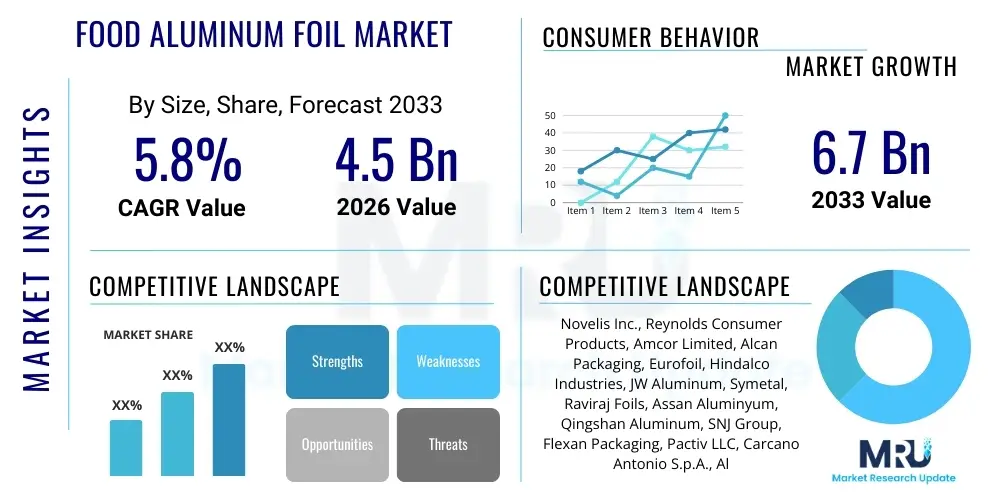

The Food Aluminum Foil Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% (CAGR) between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033.

Food Aluminum Foil Market introduction

The Food Aluminum Foil Market encompasses the manufacturing, distribution, and sale of thin rolled sheets of aluminum utilized predominantly for food preservation, packaging, and preparation applications. Aluminum foil is highly valued in the food sector due to its superior barrier properties against moisture, light, oxygen, and external contaminants, thereby significantly extending the shelf life of perishable goods. This material is essential across various segments, ranging from institutional food service operations and industrial food processing to household cooking and storage.

The primary applications of aluminum foil include wrapping individual food items, manufacturing semi-rigid containers for ready-to-eat meals, and serving as lidding or sealing material for yogurt cups and other dairy products. Key benefits driving its adoption include excellent thermal conductivity for cooking, malleability allowing conformity to various shapes, and inherent recyclability, which appeals to sustainability mandates. The global shift toward convenience foods, coupled with robust growth in the e-commerce sector for food delivery and packaged goods, acts as a pivotal driving factor sustaining market expansion.

Furthermore, the increased complexity of modern supply chains, which requires robust protection against temperature fluctuations and physical damage during transit, has reinforced the reliance on aluminum foil packaging. Innovations focusing on sustainable production, such as lightweighting the foil and developing specialized alloys, are shaping the competitive landscape. The market dynamics are intricately linked to global disposable income levels, urbanization trends, and evolving food safety regulations established by governmental and international bodies.

Food Aluminum Foil Market Executive Summary

The global Food Aluminum Foil Market is characterized by resilient growth driven primarily by escalating demand from the organized retail and food service sectors globally. Business trends indicate a strong emphasis on operational efficiency and the adoption of advanced rolling technologies to produce thinner gauges without compromising barrier integrity, aiming to reduce material costs and enhance sustainability profiles. Major market players are strategically focusing on mergers, acquisitions, and geographical expansion, particularly into high-growth emerging economies in the Asia Pacific region, to solidify their market dominance and access burgeoning consumer bases demanding convenient packaged food solutions.

Regional trends highlight that North America and Europe currently hold significant market shares, supported by mature food processing industries and stringent food safety standards necessitating high-quality barrier packaging. However, the Asia Pacific region is forecast to exhibit the highest Compound Annual Growth Rate (CAGR) due to rapid urbanization, increasing per capita disposable income, and the subsequent expansion of modern retail infrastructure and quick-service restaurants (QSRs). Latin America and the Middle East & Africa are also witnessing accelerated adoption, driven by infrastructure improvements and the proliferation of frozen and prepared food categories.

Segment trends reveal that the Containers and Trays segment dominates the market due to their widespread use in catering and ready-meal packaging, offering convenience and oven-safe properties. Concurrently, the Thin Gauge foil segment (used primarily for wrapping and laminates) is projected to experience robust growth, influenced by consumer preference for flexible packaging solutions. Sustainability remains a central theme across all segments, pushing manufacturers to invest in closed-loop recycling systems and collaborate with regulatory bodies to address end-of-life concerns associated with laminated structures.

AI Impact Analysis on Food Aluminum Foil Market

Common user inquiries concerning the impact of Artificial Intelligence (AI) on the Food Aluminum Foil Market center on optimization, efficiency, and sustainability. Users frequently ask how AI can be leveraged to minimize waste during the rolling and converting processes, improve quality control by detecting microscopic flaws in the foil structure, and optimize supply chain logistics to ensure just-in-time inventory management of raw materials (aluminum ingots). Key themes emerging from these questions involve the potential for predictive maintenance to reduce costly equipment downtime and the implementation of machine learning algorithms to fine-tune alloy compositions for specific barrier performance requirements in food applications.

- AI-driven Predictive Maintenance: Reduces machine downtime in continuous rolling operations, optimizing output and minimizing operational costs.

- Automated Quality Control: High-speed cameras and AI algorithms detect micro-tears or gauge variations in foil production, significantly improving product quality consistency.

- Supply Chain Optimization: Machine learning predicts raw material price fluctuations and optimizes inventory levels of primary aluminum, enhancing cost efficiency.

- Process Parameter Tuning: AI algorithms analyze real-time data from rolling mills to adjust speed, tension, and temperature, achieving maximum throughput and required thickness with fewer defects.

- Enhanced Sustainability Tracking: AI monitors energy consumption during production and tracks recycling stream efficiency, aiding manufacturers in meeting environmental targets.

DRO & Impact Forces Of Food Aluminum Foil Market

The Food Aluminum Foil Market is governed by a dynamic interplay of Drivers (D), Restraints (R), and Opportunities (O), which collectively define the Impact Forces shaping its trajectory. The primary driver is the accelerating demand for packaged and convenience foods globally, particularly due to shifting consumer lifestyles and increasing urbanization. Aluminum foil’s unmatched barrier properties—protecting food from light, moisture, and odors—make it indispensable in this segment. Furthermore, the material’s thermal performance is crucial for frozen meals, catering, and home cooking, reinforcing its market position. The growing awareness and adoption of professional food service packaging standards also fuel sustained growth.

Conversely, the market faces significant restraints, chiefly stemming from environmental pressures concerning single-use plastics and packaging materials. While aluminum is highly recyclable, the collection and processing infrastructure for composite packaging (like foil laminated with paper or plastic) remain challenging in many regions. Volatility in the price of primary aluminum (influenced by global energy costs and trade tariffs) presents a consistent challenge to manufacturers' profit margins. Furthermore, increasing competition from alternative flexible packaging solutions, such as high-barrier films and bio-plastics, seeks to displace aluminum foil in specific applications.

Opportunities for growth are abundant, particularly through technological innovation. Developing bio-based or biodegradable coatings on aluminum foil to improve sealing characteristics and reduce overall material usage offers a significant avenue for differentiation. Expanding recycling infrastructure, especially targeting industrial and food service waste streams, can mitigate environmental concerns. Moreover, strategic market penetration in emerging economies with rapidly modernizing retail sectors offers high potential returns, allowing manufacturers to leverage their core competencies in specialized packaging solutions. These forces collectively dictate capital investment decisions and research prioritization within the industry.

Segmentation Analysis

The Food Aluminum Foil Market is intricately segmented based on material characteristics and application requirements, providing a detailed view of consumer and industrial demands. Segmentation analysis typically involves examining the thickness of the foil (gauge), the specific end-use industry utilizing the product, and the functional application (wrapping, container, or sealing). This granular approach allows manufacturers to tailor production processes and marketing strategies to meet specific sectoral needs, from high-temperature cooking trays in the food service sector to ultra-thin pharmaceutical grade blister packaging.

- Thickness/Gauge:

- Thin Gauge Foil (Below 9 Microns)

- Medium Gauge Foil (9 to 15 Microns)

- Thick Gauge Foil (Above 15 Microns)

- End-Use Industry:

- Food Service (Restaurants, Catering, Institutions)

- Processed Foods (Frozen Meals, Canned Goods)

- Confectionery and Baked Goods

- Dairy and Beverages (Lids and Seals)

- Household/Consumer Use

- Application:

- Wrapping and Flexible Packaging (Pouches, Laminates)

- Semi-Rigid Containers and Trays

- Lids, Seals, and Closures

Value Chain Analysis For Food Aluminum Foil Market

The Value Chain for the Food Aluminum Foil Market begins with upstream analysis, focusing on the sourcing of primary aluminum, which requires intensive energy input for smelting bauxite ore into aluminum ingots. Key upstream activities include securing stable supplies of raw aluminum and managing complex energy contracts. The conversion phase involves continuous casting and cold rolling processes, where ingots are transformed into coils of varying thicknesses. Technological efficiency in the rolling mills is paramount, as minute adjustments determine the final foil quality and gauge consistency required for food contact applications. Major manufacturers often integrate backward into aluminum refining or forging strategic long-term supply agreements to mitigate price volatility.

Midstream operations involve the converting and finishing steps, including annealing, slitting, and potentially laminating the foil with polymers or paper to create composite packaging structures tailored for specific end-users. Quality control is rigorous at this stage, ensuring the absence of pinholes that could compromise barrier performance. Downstream analysis focuses on the distribution channels, which are segmented into direct sales to large food processors and indirect sales through specialized distributors supplying the vast network of food service providers, catering businesses, and retail outlets. Efficient logistics and warehousing are critical to maintain the integrity of the delicate foil rolls and sheets.

The distribution network relies heavily on both direct channels for high-volume industrial clients (like frozen food producers) and indirect channels utilizing wholesalers and specialized packaging distributors to reach the fragmented consumer and small-to-medium enterprise (SME) food service market. The final stage involves the consumer or end-user utilizing the foil for cooking, preservation, or packaging. The value chain is constantly pressured by requirements for greater sustainability, prompting collaboration between material suppliers and converters on improving the recyclability of the final product.

Food Aluminum Foil Market Potential Customers

The customer base for the Food Aluminum Foil Market is highly diversified, spanning major industrial users, commercial entities, and direct consumers. The largest segment of end-users are industrial food processors, including manufacturers of ready-to-eat meals, frozen dinners, and convenience foods, who utilize foil for its heat resistance and strong barrier properties. Catering services, airlines, and institutional kitchens (hospitals, schools) represent another critical segment, relying on semi-rigid foil containers for batch preparation, distribution, and reheating of meals.

The confectionery and specialized food industry segments are major buyers, using aluminum foil for wrapping delicate chocolate products, protecting flavor profiles, and ensuring extended shelf life. Furthermore, pharmaceutical and nutraceutical manufacturers are key indirect customers, as aluminum foil is crucial for blister packaging and strip packs where complete moisture and light barriers are non-negotiable for product integrity. These industries demand foils meeting extremely high purity and compliance standards.

The household segment, composed of individual consumers purchasing rolls of foil through retail channels (supermarkets, hypermarkets, e-commerce), remains a stable revenue stream. This consumer segment uses foil predominantly for household cooking, grilling, roasting, and short-term food storage. Manufacturers continuously adapt product sizes and packaging designs to cater to both the industrial bulk requirements and the specific user-friendliness demanded by the retail consumer market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Novelis Inc., Reynolds Consumer Products, Amcor Limited, Alcan Packaging, Eurofoil, Hindalco Industries, JW Aluminum, Symetal, Raviraj Foils, Assan Aluminyum, Qingshan Aluminum, SNJ Group, Flexan Packaging, Pactiv LLC, Carcano Antonio S.p.A., Alcoa Corporation, Huafon Aluminium, Laminazione Sottile S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Food Aluminum Foil Market Key Technology Landscape

The technological landscape of the Food Aluminum Foil Market is centered on enhancing production efficiency, improving barrier performance, and increasing sustainability. Modern continuous casting and cold rolling technologies are essential, allowing manufacturers to produce large, defect-free coils at extremely thin gauges (sometimes below 6 microns) while maintaining the structural integrity necessary for industrial converting processes. Precision gauge control utilizing sensors and automated feedback loops is a critical technological capability, minimizing material waste and ensuring compliance with strict industry standards regarding thickness uniformity across large batches.

Furthermore, surface treatment and coating technologies are rapidly evolving. Manufacturers are developing specialized lacquers, polymers, and even ceramic coatings applied to the foil surface. These coatings serve dual purposes: enhancing sealing compatibility with other packaging substrates (like plastic trays) and imparting specialized functional properties, such as non-stick surfaces for baking or printable surfaces for branding. The development of high-barrier laminates—where aluminum foil is combined with various plastic films (PET, PE) or paper—is a complex area requiring advanced adhesive chemistry and lamination techniques to create robust, multi-layer structures.

Looking ahead, emerging technologies such as laser scoring are being adopted to create easy-open features and controlled tear lines in laminated foil lids without compromising the barrier before opening. Significant research is also being directed toward developing sustainable alloys that utilize a higher percentage of recycled aluminum scrap (secondary aluminum) without diminishing the purity or performance required for direct food contact. Digitalization, including the use of Industrial Internet of Things (IIoT) sensors, is transforming factory operations, providing real-time data for optimizing energy consumption and production throughput.

Regional Highlights

- Asia Pacific (APAC) Market Dominance: APAC is the fastest-growing region, driven by explosive growth in organized retail, rising consumer expenditure on packaged and convenience foods, and the massive expansion of food processing capabilities in countries like China, India, and Southeast Asian nations. Infrastructure development and high urbanization rates necessitate efficient and safe packaging solutions, leading to increased industrial usage of aluminum foil containers and wrappers.

- North America Market Maturity and Innovation: North America holds a substantial market share, characterized by high adoption rates in the food service sector and household usage. The region is a hub for packaging innovation, focusing on consumer convenience, such as pre-cut foil sheets and heavy-duty specialty foils. Market growth is sustained by the large frozen food industry and stringent FDA regulations demanding reliable food protection barriers.

- Europe Market Focus on Sustainability: Europe represents a mature market with a strong emphasis on sustainability and circular economy principles. While demand is stable across food service and household sectors, the region drives technological advancements in high-recycled content foil and complex laminates designed for improved end-of-life recovery, responding directly to EU directives concerning packaging waste reduction.

- Latin America (LATAM) Market Potential: LATAM is exhibiting moderate growth, spurred by modernization in the retail and food supply chain, particularly in Brazil and Mexico. The increasing penetration of international quick-service restaurant (QSR) chains and the rising demand for shelf-stable packaged goods are key drivers for the adoption of foil packaging and containers.

- Middle East & Africa (MEA) Growth Vectors: The MEA region shows promising growth, particularly in the Gulf Cooperation Council (GCC) countries, supported by expanding tourism, sophisticated catering industries, and significant investment in domestic food production capabilities. High consumption levels in urban centers necessitate robust packaging for food preservation in demanding climate conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Food Aluminum Foil Market.- Novelis Inc.

- Reynolds Consumer Products

- Amcor Limited

- Alcan Packaging (part of Amcor)

- Eurofoil

- Hindalco Industries Limited

- JW Aluminum

- Symetal

- Raviraj Foils Limited

- Assan Aluminyum

- Qingshan Aluminum

- SNJ Group

- Flexan Packaging

- Pactiv LLC

- Carcano Antonio S.p.A.

- Alcoa Corporation

- Huafon Aluminium

- Laminazione Sottile S.p.A.

Frequently Asked Questions

Analyze common user questions about the Food Aluminum Foil market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the current growth of the Food Aluminum Foil Market?

Growth is primarily driven by the increasing global demand for packaged and convenience foods, high adoption rates in the professional food service industry, and the superior barrier properties of aluminum foil against moisture, oxygen, and light, which enhances food preservation and shelf life.

How is the Food Aluminum Foil Market addressing environmental sustainability concerns?

Manufacturers are focusing on lightweighting foil production to reduce material use, increasing the usage of highly recyclable secondary aluminum, and developing innovative coatings and laminates to improve the recyclability of composite packaging structures at the end-of-life stage.

Which geographical region exhibits the fastest growth potential for aluminum foil adoption?

The Asia Pacific (APAC) region, particularly driven by economies like China and India, is projected to experience the fastest growth due to rapid urbanization, expanding middle-class consumer base, and significant modernization of the food processing and retail sectors.

What technological advancements are influencing aluminum foil manufacturing?

Key technological advancements include the adoption of AI and IIoT for enhanced production efficiency, real-time precision gauge control during rolling to minimize defects, and the development of specialized barrier coatings and lamination techniques for high-performance food packaging applications.

What are the main applications of aluminum foil in the food industry?

The main applications include creating semi-rigid containers and trays for ready-to-eat and frozen meals, flexible wrapping and laminates for confectionery and processed foods, and high-barrier lids and seals used extensively in dairy and pharmaceutical packaging.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager