Food Deaeration Systems Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433768 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Food Deaeration Systems Market Size

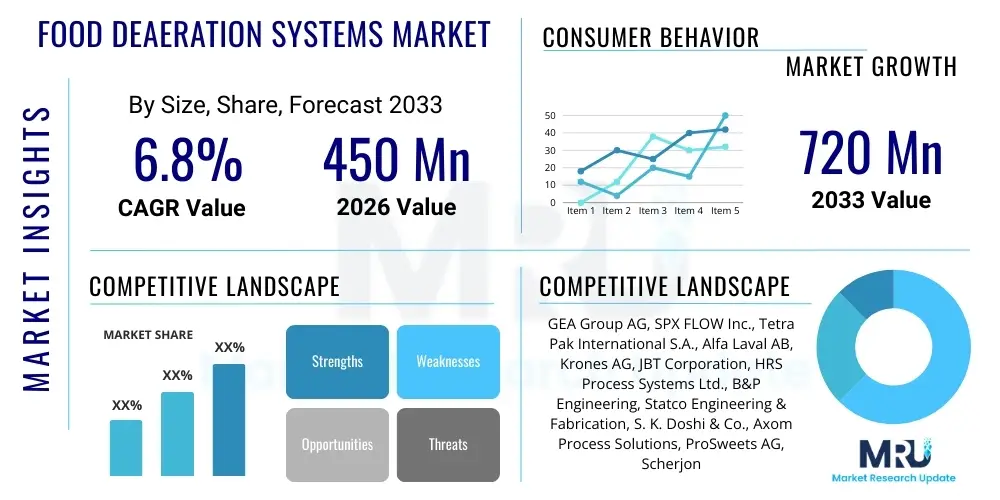

The Food Deaeration Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 720 Million by the end of the forecast period in 2033.

Food Deaeration Systems Market introduction

The Food Deaeration Systems Market encompasses specialized industrial equipment designed to remove dissolved gases, primarily oxygen and carbon dioxide, from liquid food and beverage products before processing or packaging. This critical processing step significantly enhances product quality, extends shelf life, and maintains flavor integrity, preventing oxidative degradation, color changes, and vitamin loss. Food deaeration systems are essential in industries dealing with sensitive liquid or semi-liquid products, including fruit juices, dairy products, sauces, purees, and alcoholic and non-alcoholic beverages. The primary objective is to minimize residual oxygen to less than 1 part per million (ppm), which is crucial for maximizing preservation without relying heavily on artificial additives.

These systems typically utilize technologies such as vacuum deaeration, thermal deaeration, or membrane separation, chosen based on the product viscosity, temperature sensitivity, and required throughput. Vacuum deaerators are the most widely adopted due to their versatility and effectiveness in handling various liquid streams under low-pressure conditions. The increasing global consumer preference for minimally processed foods with natural ingredients drives the demand for deaeration, as manufacturers seek non-chemical methods to ensure microbial stability and sensory attributes over time. Furthermore, the mandatory requirements for aseptic and ultra-high-temperature (UHT) processing, particularly in the dairy and juice sectors, mandate effective upstream deaeration to prevent component damage and foam formation.

The core benefit of deploying advanced food deaeration equipment lies in improving operational efficiency alongside product quality. By removing gases, these systems reduce foaming during filling processes, leading to faster throughput, minimizing product waste, and ensuring precise filling levels. Key driving factors accelerating market expansion include stringent global food safety and quality regulations, the proliferation of sophisticated packaging solutions (like barrier packaging), and continuous technological innovations leading to compact, highly efficient, and energy-saving deaeration units. The shift toward plant-based beverages and functional drinks, which are often highly susceptible to oxidation, further solidifies the market's growth trajectory.

Food Deaeration Systems Market Executive Summary

The Food Deaeration Systems Market exhibits robust growth driven primarily by escalating global demand for high-quality, long-shelf-life liquid foods and beverages, especially those positioned as natural or clean label. Business trends indicate a strong focus on automation and integration, with manufacturers developing systems capable of seamless integration into existing UHT and pasteurization lines, prioritizing low-energy consumption and reduced water usage. The market is characterized by intense competition among European and North American machinery manufacturers specializing in high-capacity, sophisticated vacuum and thermal deaeration solutions, while Asian Pacific players focus on cost-effective, medium-capacity machinery suitable for rapid industrial expansion.

Regional trends highlight the Asia Pacific (APAC) region as the fastest-growing market, propelled by massive urbanization, rising disposable incomes, and the consequent surge in demand for packaged dairy, juices, and ready-to-drink (RTD) beverages. North America and Europe, however, maintain market dominance in terms of value, owing to their early adoption of advanced aseptic processing technologies and stringent quality control standards, requiring state-of-the-art deaeration equipment. Investment patterns in these mature markets are shifting toward retrofitting existing infrastructure with smart, IoT-enabled deaeration units that offer real-time monitoring and predictive maintenance capabilities.

Segment trends reveal that vacuum deaeration technology holds the largest market share due to its wide applicability across diverse product matrices and superior oxygen removal efficiency at lower operating temperatures, preserving heat-sensitive nutrients. The beverage application segment, encompassing juices, soft drinks, and specialty drinks, remains the predominant end-user segment, although the dairy processing sector is demonstrating significant parallel growth, particularly for milk and cream processing where stability and flavor retention are critical. The demand for customized modular systems that can adapt to varying production requirements and future product diversification is a critical ongoing trend influencing purchasing decisions across all segments.

AI Impact Analysis on Food Deaeration Systems Market

User queries regarding the intersection of Artificial Intelligence (AI) and Food Deaeration Systems primarily focus on optimizing process parameters, achieving real-time quality assurance, and minimizing energy expenditure. Key themes center around whether AI can autonomously adjust vacuum levels or temperature profiles based on immediate product flow and dissolved oxygen measurements, thereby maximizing efficiency and consistency. Users are concerned about implementing AI models for predictive maintenance to reduce costly downtime associated with system fouling or pump failure. Furthermore, there is significant interest in how machine learning can analyze vast datasets of batch performance to determine optimal deaeration setpoints for new or complex food matrices, ensuring superior quality while achieving sustainability goals.

- AI-Powered Real-time Quality Control: AI algorithms analyze continuous sensor data (e.g., dissolved oxygen levels, temperature, flow rate) to instantly identify deviations and auto-correct deaeration settings, ensuring consistent product quality with minimal human intervention.

- Predictive Maintenance: Machine learning models monitor vibrational signatures, energy consumption fluctuations, and component wear, accurately predicting equipment failure before it occurs, thereby reducing unplanned downtime and maintenance costs.

- Optimized Energy Consumption: AI dynamically manages vacuum pump cycles and heating elements based on actual processing load, leading to significant reduction in electricity and steam usage compared to static operational protocols.

- Enhanced Recipe Management: AI systems learn from thousands of production runs, recommending the optimal deaeration parameters (vacuum, temperature, hold time) for new product formulations, particularly complex mixtures like high-fiber or plant-based milks.

- Process Integration and Synchronization: AI facilitates the synchronization of the deaeration stage with upstream pasteurization and downstream filling processes, ensuring seamless product transfer and minimizing the risk of re-oxygenation or processing bottlenecks.

DRO & Impact Forces Of Food Deaeration Systems Market

The market is significantly shaped by a confluence of driving forces, structural restraints, and emerging opportunities, collectively defining the competitive landscape and growth trajectory. The predominant driver is the uncompromising global regulatory environment requiring high food safety standards and the corresponding push for extended product shelf life without chemical preservatives. Opportunities primarily revolve around technological advancements in membrane deaeration and the untapped potential of emerging economies adopting advanced processing technologies. Restraints are concentrated on the substantial capital expenditure required for high-end systems and the technical challenges associated with maintaining optimal performance across diverse food viscosities and solids content.

The key impact forces driving adoption include consumer health consciousness, which fuels demand for beverages and foods that retain maximum nutritional value and natural flavor profiles, achievable only through meticulous oxygen removal. Additionally, the proliferation of global supply chains necessitates longer transit times, demanding superior product stability facilitated by effective deaeration. Conversely, the high energy consumption of traditional thermal deaeration systems and the expertise required for complex system maintenance act as dampening forces, particularly for small and medium-sized enterprises (SMEs) in developing regions. These constraints push manufacturers toward developing more modular, energy-efficient, and easy-to-clean (CIP-compatible) designs.

Market growth is highly sensitive to the penetration rate of aseptic processing and UHT technology globally, as deaeration is an indispensable precursor step in these high-level preservation methods. The opportunity space is broadening with the increased commercialization of precision deaeration systems tailored for sensitive and premium products like craft beer, specialized infant formula, and delicate pharmaceutical-grade food supplements. Addressing the high initial investment through flexible financing models and demonstrating clear Return on Investment (ROI) benefits related to waste reduction and quality improvement are crucial levers for market participants to mitigate the restrictive forces.

Segmentation Analysis

The Food Deaeration Systems Market is fundamentally segmented based on the type of technology employed, the specific end-user application, and the geographic region. This segmentation provides a granular view of market dynamics, revealing where specific technological innovations are gaining traction and which food sectors are driving the largest investment. Technology segmentation is pivotal, as the choice of deaeration method directly impacts product quality, operational costs, and energy efficiency. Vacuum deaeration systems currently dominate the market due to their broad applicability and efficacy across a wide range of liquids, from low-viscosity juices to medium-viscosity sauces.

Application-wise, the market is characterized by the distinct processing requirements of the beverage, dairy, and processed food industries. The beverage sector, encompassing water, carbonated soft drinks, and fruit juices, represents the largest revenue generator, necessitated by the need to prevent oxidation and ensure color stability over extended shelf lives. The dairy segment shows accelerated growth, driven by the expanding consumption of UHT milk and cream in Asia and the Middle East, where long ambient storage life is a priority. Processed foods, including soups, purees, and viscous condiments, require robust systems capable of handling higher solids content without compromising deaeration efficiency.

Geographically, market segmentation underscores regional variances in food processing standards and consumer habits. Established markets like North America and Europe prioritize high-automation, large-capacity systems, often seeking customized solutions for niche products. In contrast, the rapidly industrializing markets of Asia Pacific (APAC) and Latin America focus on scalable, robust machinery suitable for high-volume, standardized production runs, particularly driven by urbanization and the corresponding shift from unpackaged to packaged food consumption patterns.

- By Technology:

- Vacuum Deaeration Systems

- Thermal Deaeration Systems

- Membrane Deaeration Systems

- Combined/Hybrid Systems

- By Application:

- Beverages (Juices, Soft Drinks, Alcoholic Beverages, Water)

- Dairy Products (Milk, Cream, Yogurt Mixes)

- Processed Foods (Sauces, Purees, Soups, Ketchup)

- Others (Infant Formula, Pharmaceutical Foods)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Food Deaeration Systems Market

The value chain for the Food Deaeration Systems Market begins with upstream suppliers providing critical raw materials and components, predominantly specialized stainless steel alloys, high-precision pumps, vacuum equipment, and advanced sensors necessary for system construction. These suppliers must adhere to strict sanitary and food-grade standards, impacting the overall cost and quality of the final machinery. Manufacturers then engage in the core activity of design, engineering, and assembly, where innovation in fluid dynamics, thermal efficiency, and hygiene design adds substantial value. Competition at this stage is focused on customization, energy footprint reduction, and meeting specific regulatory requirements such as FDA and CE standards.

The midstream of the value chain involves the distribution and sales channels, which are typically segmented into direct sales by large Original Equipment Manufacturers (OEMs) and indirect sales through specialized industrial machinery distributors or system integrators. Direct sales are preferred for high-value, complex, or customized large-scale projects, allowing for closer client relationships and better after-sales technical support. Indirect channels, relying on distributors, are critical for penetrating geographically dispersed markets and serving smaller food processing clients, often offering bundled solutions that include other ancillary processing equipment.

Downstream activities focus on installation, commissioning, training, and the indispensable segment of after-market services, including spare parts, maintenance contracts, and system upgrades. The profitability of deaeration system suppliers is increasingly reliant on these recurring service revenues, given the capital-intensive nature and long operational lifespan of the equipment. End-users—food and beverage manufacturers—seek systems that ensure minimal downtime and maximum operational lifespan, making comprehensive service agreements a non-negotiable component of the final purchase decision, thus completing the value flow from specialized component production to assured operational support.

Food Deaeration Systems Market Potential Customers

The primary customers for Food Deaeration Systems are large-scale industrial food and beverage manufacturers that operate high-volume liquid processing lines, where product integrity and consistency are paramount. These include multinational beverage corporations focusing on bottled water, fruit juices, and carbonated soft drinks, where oxygen removal is necessary to prevent microbial growth, maintain carbonation stability, and inhibit flavor degradation. Dairy processors, particularly those involved in UHT and extended shelf life (ESL) milk, condensed milk, and cream production, constitute another major end-user group, requiring deaeration to ensure thermal efficiency and prevent protein denaturation during heating processes.

Beyond the core beverage and dairy sectors, potential customers include manufacturers of culinary products such as high-acid sauces, tomato purees, viscous soups, and dressings, where deaeration helps standardize density, prevent separation, and improve pumpability. Furthermore, specialized segments like infant formula producers and manufacturers of nutritional supplements are increasingly vital customers, demanding the highest level of deaeration performance and sanitation standards, often requiring membrane-based or specialized vacuum systems for maximum nutrient preservation. The growth in plant-based milk alternatives (almond, soy, oat), which are highly sensitive to oxidation, has opened a new, rapidly expanding customer base seeking highly precise deaeration solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 720 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GEA Group AG, SPX FLOW Inc., Tetra Pak International S.A., Alfa Laval AB, Krones AG, JBT Corporation, HRS Process Systems Ltd., B&P Engineering, Statco Engineering & Fabrication, S. K. Doshi & Co., Axom Process Solutions, ProSweets AG, Scherjon Equipment, Igeho S.r.l., Seital Srl, Sanitech Industries, Pentair plc, Paul Mueller Company, APV (part of SPX FLOW), Ametek. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Food Deaeration Systems Market Key Technology Landscape

The technological landscape of the Food Deaeration Systems Market is dominated by the maturity and continuous refinement of vacuum deaeration, alongside the rising prominence of membrane separation. Vacuum deaeration operates on the principle of reducing pressure within a chamber, causing dissolved gases to flash off and be efficiently drawn out by a vacuum pump. Modern vacuum systems are now highly engineered with optimized spray nozzles and packed columns to maximize the surface area exposure of the liquid, achieving ultra-low oxygen levels essential for high-quality aseptic filling. Ongoing R&D focuses on creating multi-stage vacuum systems that can handle both non-condensable gases and high vapor loads efficiently, especially important for products with high volatility.

Thermal deaeration, often integrated with pasteurization or UHT processes, utilizes heat to reduce gas solubility before stripping the gases under vacuum. While effective for stable products like water or some dairy applications, this method is less suitable for heat-sensitive beverages. The key trend here is toward Hybrid Systems, which combine mild pre-heating with vacuum or membrane technologies, balancing energy efficiency with delicate handling of nutritional components. These hybrid units offer flexibility, allowing processors to rapidly switch between different product requirements while maintaining strict hygienic design standards, such as full Clean-in-Place (CIP) capability to prevent cross-contamination.

Membrane deaeration represents the cutting edge of the technology landscape, utilizing semi-permeable membranes (typically hollow fiber contactors) that allow dissolved gases to pass through while retaining the liquid product. This method is exceptionally gentle, operating at ambient or low temperatures, making it ideal for highly sensitive products like craft beer, delicate flavorings, or vitamin-enriched beverages, minimizing heat damage and preserving delicate aromas. Though currently having a smaller market share due to higher initial system cost, membrane technology is rapidly expanding, driven by the increasing consumer demand for products with minimal thermal processing and the potential for chemical-free oxygen removal at unmatched precision levels.

Regional Highlights

- North America: This region is characterized by high adoption rates of advanced, highly automated deaeration systems, driven by stringent FDA regulations concerning product safety and quality. The market here is mature, focusing heavily on continuous improvement in operational efficiency, integration of IoT for real-time monitoring, and customization for specialized liquid foods, particularly in the rapidly expanding functional beverage and plant-based dairy sectors. Manufacturers invest heavily in systems that support reduced water and energy footprints, positioning sustainability as a key competitive differentiator. The U.S. and Canada lead in terms of technological sophistication and per capita consumption of packaged, long-shelf-life products.

- Europe: Europe is the epicenter of technological innovation in food processing, housing major global machinery OEMs. The market is defined by an emphasis on hygienic design (EHEDG standards), energy efficiency, and modular system configurations. Demand is strong across the dairy, brewery (where deaeration ensures consistent beer quality and prevents oxidation), and juice sectors. Western European countries like Germany, Italy, and the Netherlands drive innovation, particularly in integrating deaeration into complex aseptic lines and focusing on specialized applications using membrane technology for premium products and flavor preservation.

- Asia Pacific (APAC): APAC is the fastest-growing market globally, propelled by rapidly increasing middle-class populations, significant urbanization, and infrastructural development in food processing capabilities in countries like China, India, and Southeast Asia. The demand is massive for high-volume, cost-effective deaeration solutions to support the burgeoning packaged juice, UHT milk, and soft drink industries. While initial investments often favor standard vacuum deaeration units, the shift toward higher quality standards and international trade requirements is gradually increasing the demand for advanced, automated systems, suggesting significant future growth potential for premium equipment suppliers.

- Latin America (LATAM): Growth in LATAM is tied to the expansion of regional and international food processing companies aiming to cater to the growing demand for convenience and packaged goods, especially juices and dairy products. Brazil and Mexico are key markets showing steady adoption of deaeration systems, driven by improved infrastructure and the need to extend shelf life for distribution across geographically challenging terrains. Price sensitivity remains a factor, favoring robust, low-maintenance systems that offer a strong balance between capital cost and operational reliability.

- Middle East & Africa (MEA): This region shows significant potential, particularly in the Middle East, driven by increased local food processing capacity to reduce import dependency and rapid growth in the HORECA sector. High temperatures necessitate superior preservation techniques, making effective deaeration crucial for dairy and beverage stability. Investments are channeled towards establishing modern UHT and aseptic processing plants, which inherently require high-efficiency deaeration systems, often imported from established European and North American suppliers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Food Deaeration Systems Market.- GEA Group AG

- SPX FLOW Inc.

- Tetra Pak International S.A.

- Alfa Laval AB

- Krones AG

- JBT Corporation

- HRS Process Systems Ltd.

- B&P Engineering

- Statco Engineering & Fabrication

- S. K. Doshi & Co.

- Axom Process Solutions

- ProSweets AG

- Scherjon Equipment

- Igeho S.r.l.

- Seital Srl

- Sanitech Industries

- Pentair plc

- Paul Mueller Company

- APV (part of SPX FLOW)

- Ametek

- ANDRITZ AG

- Barry-Wehmiller Group, Inc.

- Feldmeier Equipment, Inc.

- Separation Systems, Inc.

Frequently Asked Questions

Analyze common user questions about the Food Deaeration Systems market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of implementing a food deaeration system in liquid processing?

The primary benefits include significantly extending the product shelf life by inhibiting oxidative degradation, preserving natural flavors, colors, and vitamins, improving product stability, and increasing operational efficiency by reducing foaming during the filling process. Effective deaeration is mandatory for aseptic and UHT processing quality assurance.

How does vacuum deaeration technology compare to membrane deaeration in terms of application?

Vacuum deaeration is widely used for high-volume, general liquid food and beverage applications (juices, milk) due to its cost-effectiveness and robustness. Membrane deaeration, conversely, is preferred for highly sensitive, low-temperature processing (e.g., craft beer, delicate flavors) as it offers extremely precise oxygen removal without thermal stress, though at a higher initial capital investment.

Which end-user application segment dominates the market for deaeration systems globally?

The Beverage segment, including fruit juices, soft drinks, and bottled water, holds the largest market share. This dominance is driven by the necessity of oxygen removal to prevent spoilage, maintain clear appearance, and ensure packaging stability across long distribution chains, especially for products with extended shelf life claims.

What is the estimated Compound Annual Growth Rate (CAGR) for the Food Deaeration Systems Market between 2026 and 2033?

The Food Deaeration Systems Market is projected to grow at a CAGR of 6.8% during the forecast period (2026–2033). This growth is primarily fueled by rising global demand for packaged, high-quality liquid foods and continued expansion in aseptic processing infrastructure, particularly in the Asia Pacific region.

What role does AI play in modern food deaeration system operation and efficiency?

AI is increasingly utilized to optimize efficiency through predictive maintenance, real-time process control, and dynamic parameter adjustment. AI systems analyze continuous sensor data (e.g., dissolved oxygen) to autonomously fine-tune vacuum levels and temperatures, ensuring consistent quality while significantly minimizing energy consumption and operational waste.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager