Food Grade Acetylated Distarach Adipate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432161 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Food Grade Acetylated Distarach Adipate Market Size

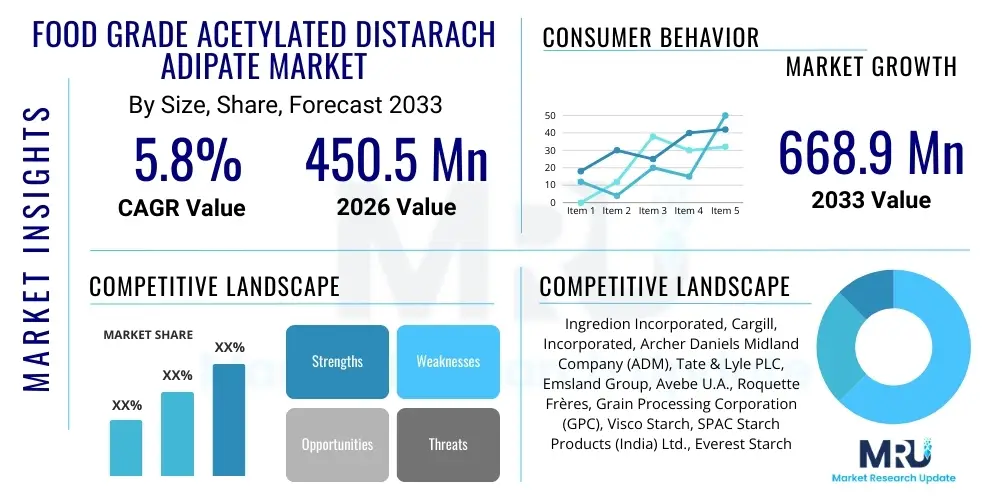

The Food Grade Acetylated Distarach Adipate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 668.9 Million by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by the escalating global demand for convenience foods that require high stability, especially under challenging processing conditions such as freezing, thawing, and high-heat sterilization. Acetylated Distarach Adipate (E1422) is critical for maintaining textural integrity and preventing syneresis in products exposed to these stresses, thereby ensuring extended shelf life and consistent consumer quality.

Food Grade Acetylated Distarach Adipate Market introduction

The Food Grade Acetylated Distarach Adipate Market encompasses the production and utilization of a chemically modified food starch, designated as E1422 under European numbering, derived primarily from natural sources like corn, tapioca, or potato. This specific modification involves two key processes: esterification with acetic anhydride and cross-linking with adipic acid, which results in a highly stable starch granule resistant to heat, shear, acid, and mechanical agitation during industrial food processing. The product functions primarily as an effective thickening, stabilizing, and texture-modifying agent, making it indispensable across a vast array of food applications, particularly those requiring superior freeze-thaw stability such as frozen desserts, ready meals, and canned goods. The intrinsic benefits of E1422, including its ability to improve mouthfeel, control viscosity consistency, and extend product viability, are pivotal drivers for its widespread adoption among global food manufacturers seeking enhanced product performance and optimized production yields.

Major applications for Food Grade Acetylated Distarach Adipate span the entire processed food sector, prominently featuring in bakery fillings, fruit preparations, sauces, salad dressings, and infant foods, where maintaining a stable emulsion or suspension is paramount. The primary driving factor for market expansion is the global shift toward urbanization and dual-income households, which fuels the demand for convenient, ready-to-eat, and frozen food solutions that require robust stability properties. Furthermore, the increasing complexity of modern food formulations, often involving combinations of fats, proteins, and varying pH levels, necessitates the use of high-performance stabilizers like E1422 to ensure product consistency and prevent phase separation during distribution and storage. The market dynamics are also influenced by continuous innovation in starch sourcing and processing techniques aimed at creating tailor-made starches for specific end-user requirements, particularly those focusing on clean-label alternatives, though E1422 itself is generally categorized as a modified starch.

Food Grade Acetylated Distarach Adipate Market Executive Summary

The Food Grade Acetylated Distarach Adipate market exhibits strong business trends characterized by consolidation among major starch producers and intense focus on supply chain resilience, necessitated by fluctuating agricultural commodity prices. Regional trends indicate that Asia Pacific (APAC) is emerging as the fastest-growing market, driven by rapid expansion in the regional processed food and beverage industries, coupled with rising consumer affluence enabling greater uptake of packaged goods requiring stabilization. Conversely, North America and Europe remain mature markets, focusing on premiumization, enhanced functionality, and navigating increasingly stringent food additive regulations, which often prompts manufacturers to seek starches with exceptional performance profiles to justify their inclusion. The market is strategically moving towards diversification of raw material sources, including greater utilization of tapioca and potato starches, which are perceived as offering superior textural benefits and addressing consumer concerns regarding major allergens or specific sourcing preferences, balancing operational efficiency with consumer acceptance.

Segment trends highlight the dominance of the Application segment, particularly within the Bakery & Confectionery sector, where E1422 is crucial for stabilizing fruit fillings and pie glazes against oven heat and subsequent cooling, preventing structural collapse and moisture migration. Within the Function segment, the Stabilizer category commands the largest share, reflecting the primary industrial use of E1422 in preventing syneresis (water separation) and ensuring long-term product uniformity in refrigerated and frozen environments. Geographically, the market’s growth is bifurcated: established Western markets prioritize high-quality, customized ingredients for demanding applications like low-fat dairy alternatives and specialized sauces, while emerging economies focus on volume and cost-effectiveness in mass-market convenience foods. Key players are aggressively investing in backward integration, securing long-term raw material contracts, and expanding their processing capacity in key geographical regions, aiming to optimize logistics and minimize the impact of trade volatility and localized supply chain disruptions, ensuring a continuous supply of highly functional starch derivatives.

AI Impact Analysis on Food Grade Acetylated Distarach Adipate Market

User inquiries regarding the impact of Artificial Intelligence on the Acetylated Distarach Adipate market often center on three key areas: how AI can enhance the consistency and quality control of the starch modification process, its role in optimizing complex supply chains dealing with volatile agricultural inputs, and the potential of machine learning to accelerate the development of new, high-performance starch derivatives. Consumers and industry stakeholders are keen to understand if AI can lead to "smarter" starches that offer superior performance while perhaps reducing the need for high levels of chemical modification, aligning with clean-label trends. The analysis suggests that while AI does not directly influence the chemical reaction itself, its application in predictive modeling, process optimization, and sensor-driven quality monitoring promises substantial improvements in efficiency, consistency, and traceability throughout the entire E1422 value chain, ultimately driving down operational costs and enhancing product reliability for end-users.

AI’s influence is primarily infrastructural and analytical, enabling manufacturers to move beyond traditional batch processing quality checks towards real-time, in-line monitoring of the acetylation and cross-linking stages. This granular data analysis ensures that the degree of substitution and cross-linking is precisely controlled, leading to highly consistent functional properties (viscosity, stability). Furthermore, AI algorithms are being deployed to forecast demand for specific starch types based on seasonal food consumption patterns and macroeconomic indicators, allowing manufacturers to optimize production schedules and inventory levels, mitigating risks associated with ingredient obsolescence or shortages. The overall industry expectation is that AI integration will transform quality assurance from a reactive measure to a predictive system, thereby minimizing batch variations and ensuring stricter adherence to regulatory specifications globally.

- AI-driven Predictive Maintenance: Optimizing starch modification equipment uptime and minimizing downtime in highly continuous production facilities.

- Supply Chain Optimization: Utilizing machine learning algorithms to predict volatility in corn, potato, or tapioca prices and optimize raw material procurement strategies.

- Enhanced Quality Control (QC): Real-time analysis of physicochemical parameters (e.g., pH, viscosity profile) during starch processing using sensor data and deep learning models to ensure E1422 consistency.

- Formulation Acceleration: AI-assisted R&D for modeling the interaction of Acetylated Distarach Adipate with various food matrices (e.g., protein, fat, acid) to predict functional performance before extensive physical testing.

- Traceability and Transparency: Implementing AI and blockchain solutions to enhance ingredient traceability from the farm source to the final food product, addressing consumer demand for transparency.

DRO & Impact Forces Of Food Grade Acetylated Distarach Adipate Market

The dynamics of the Food Grade Acetylated Distarach Adipate market are governed by a complex interplay of internal and external forces, collectively summarized as Drivers, Restraints, and Opportunities (DRO), which dictate investment decisions and strategic positioning. The primary Driver remains the continuous expansion of the convenience food sector, driven by lifestyle changes globally, necessitating high-stability starches capable of surviving harsh processing and storage conditions without compromising product texture or structure. Coupled with this is the superior functional profile of E1422, which offers unparalleled resistance to thermal degradation and acid hydrolysis compared to native starches, making it the preferred choice for demanding applications like retorted sauces and low-pH dressings. These functional benefits solidify its critical role as a performance ingredient, supporting the complexity and stability demands of modern food manufacturing processes worldwide.

However, the market faces significant Restraints, most notably the high price volatility of source crops (corn, potato, tapioca), which directly impacts the production cost and profitability margins for starch manufacturers. Additionally, stringent and evolving global regulatory scrutiny on modified food additives, particularly in Europe and certain parts of Asia, requires continuous investment in safety dossiers and regulatory compliance, potentially slowing down market access for new variations or suppliers. Opportunities are primarily centered around the growing demand for plant-based and vegan food alternatives, where modified starches like E1422 are essential for replicating the texture and mouthfeel traditionally provided by animal proteins and fats. Furthermore, targeting emerging economies with underdeveloped cold chains presents a substantial opportunity, as E1422’s freeze-thaw stability becomes a crucial enabler for distributing frozen and refrigerated food products over long distances, addressing regional food security and convenience needs simultaneously.

Impact forces within this market structure include increasing environmental sustainability mandates, pressuring producers to adopt more eco-friendly modification processes and reduce waste streams from starch refining. Supplier bargaining power is moderately high due to the concentration of specialized starch processors who possess the necessary technical expertise for complex modifications like acetylation and cross-linking. Buyer power is also significant, particularly among large multinational food conglomerates that purchase E1422 in bulk and demand specialized specifications and competitive pricing, fostering a highly competitive environment focused on customization and technical support rather than pure commodity pricing. The threat of substitution, while present from other hydrocolloids (like gums or proteins), is mitigated by the cost-effectiveness and unique textural performance of E1422 in specific high-stress applications.

Segmentation Analysis

The Food Grade Acetylated Distarach Adipate market is comprehensively segmented based on its source material, primary function within the food matrix, and the specific application sector where it is utilized. This detailed segmentation allows stakeholders to accurately gauge demand patterns, identify high-growth niches, and strategically tailor product offerings to meet diverse industry needs. The segment defined by Source material—primarily Corn, Tapioca, and Potato—is fundamental, as the original starch source significantly influences the final functional properties, such as gelatinization temperature, viscosity, and clarity, which are crucial factors for suitability in various food types.

The Application segmentation, covering sectors like Bakery & Confectionery, Soups & Sauces, and Convenience Foods, demonstrates the pervasive integration of E1422 across modern food processing. The highest demand typically originates from sectors requiring superior temperature and acid stability, characteristic of canned or sterilized goods. Functionally, E1422 is segmented into roles such as Thickening Agent, Stabilizer, and Emulsifier. The Stabilizer segment often dominates due to E1422’s primary technical advantage: the maintenance of texture and prevention of phase separation, especially during thermal cycling or extended storage, highlighting its value proposition as a preservation and quality control tool.

- Source:

- Corn

- Tapioca

- Potato

- Wheat

- Other Sources (e.g., Rice, Waxy Maize)

- Application:

- Bakery & Confectionery (Fillings, Glazes, Batters)

- Soups, Sauces, and Dressings (Retorted, Low-pH, Shelf-Stable)

- Dairy Products (Yogurts, Frozen Desserts, Cheese Analogues)

- Convenience Foods and Ready Meals (Frozen Entrees, Canned Goods)

- Beverages (Clouding Agents, Emulsion Stabilization)

- Infant Foods

- Function:

- Thickening Agent

- Stabilizer

- Emulsifier

- Gelling Agent

Value Chain Analysis For Food Grade Acetylated Distarach Adipate Market

The value chain for Food Grade Acetylated Distarach Adipate begins with the upstream sourcing and processing of natural raw materials, primarily corn, tapioca, and potato. This initial stage involves cultivation, harvesting, and primary wet milling to extract native starch, which is then refined and purified. The efficiency of this upstream process is vital, as the quality and consistency of the native starch feedstock directly impact the effectiveness of the subsequent modification steps. Key upstream factors include managing crop yield variability, optimizing water and energy usage during milling, and ensuring stable pricing for agricultural commodities, which often requires significant forward integration or long-term procurement agreements by major starch processors to mitigate supply risk and cost fluctuations.

The core of the value chain is the chemical modification process, where the native starch is reacted with acetic anhydride for acetylation and adipic acid for cross-linking, under controlled conditions. This specialized manufacturing stage requires significant capital investment in reaction vessels, drying equipment, and stringent quality control protocols to ensure the final E1422 product meets international food safety and functional specifications (e.g., specific viscosity range, degree of substitution). Downstream analysis focuses on the distribution channels, which are predominantly Business-to-Business (B2B), involving direct sales from large starch manufacturers to major food processors, or indirect distribution through specialized ingredient distributors and agents who manage smaller regional accounts. The choice between direct and indirect channels is often determined by the volume and technical support required by the end-user, with large multinational clients typically utilizing direct procurement for greater control over specifications and logistics.

The distribution logistics are critical, focusing on maintaining bulk packaging standards and preventing contamination, often involving specialized food-grade containers and warehousing. The final stage involves the incorporation of E1422 into finished food products (e.g., frozen meals, sauces) by the end-user food manufacturing sector. Technical service and application support, provided by the starch manufacturers, represent significant value-added components in the downstream chain, assisting customers with formulation challenges and optimizing the use of E1422 for specific textural goals. The overall chain is characterized by a strong emphasis on regulatory compliance and the need for seamless integration between raw material procurement and highly specialized chemical processing.

Food Grade Acetylated Distarach Adipate Market Potential Customers

The potential customers for Food Grade Acetylated Distarach Adipate are overwhelmingly large-scale industrial food processors and manufacturers across various segments where high functional stability and improved texture are prerequisites for product success. These end-users are primarily seeking a reliable, high-performing ingredient that can stabilize complex multi-component systems, particularly those that undergo severe processing steps like UHT sterilization, high-shear mixing, or repeated freeze-thaw cycles. Major buyers include international conglomerates specializing in ready-to-eat meals, frozen food producers who require syneresis control, and manufacturers of shelf-stable sauces and condiments where viscosity must be maintained consistently across a wide range of storage conditions and temperatures, particularly in low pH formulations where native starches would fail rapidly.

Beyond the convenience food sector, potential customers also include major players in the dairy industry, utilizing E1422 in yogurts, cheese products, and frozen dairy desserts for texture modification and stability, often to replace or reduce the usage of higher-cost hydrocolloids or traditional fats. The bakery sector represents another significant buyer base, utilizing E1422 for moisture management in fillings and batters, preventing the 'weeping' of fruit preparations after baking or freezing. Essentially, any food producer requiring an ingredient that delivers consistent viscosity, improves mouthfeel, and crucially enhances the product's resistance to environmental and mechanical stresses during distribution and consumption constitutes a core potential customer, driving consistent B2B demand for this functional starch derivative.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 668.9 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ingredion Incorporated, Cargill, Incorporated, Archer Daniels Midland Company (ADM), Tate & Lyle PLC, Emsland Group, Avebe U.A., Roquette Frères, Grain Processing Corporation (GPC), Visco Starch, SPAC Starch Products (India) Ltd., Everest Starch (Pvt) Ltd., Shandong Fuyang Biotech Co., Ltd., Penford (part of Ingredion), AGRANA Beteiligungs-AG, KMC Kartoffelmelcentralen. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Food Grade Acetylated Distarach Adipate Market Key Technology Landscape

The technology landscape for the Food Grade Acetylated Distarach Adipate market is primarily focused on optimizing the chemical modification processes and enhancing the consistency and quality of the finished product. The core production technology revolves around precise control over the esterification and cross-linking reactions, which typically occur in slurry reactors under specific temperature and pH conditions, utilizing specialized reagents like acetic anhydride and adipic acid. Recent technological advancements emphasize continuous processing techniques over traditional batch methods, allowing for greater throughput, reduced processing time, and superior consistency in the degree of substitution (DS) and cross-link density, which are the fundamental determinants of E1422's functional performance. Furthermore, specialized filtration and washing technologies are crucial for removing residual reagents and ensuring the final product meets the stringent purity standards required for food application, minimizing the presence of unreacted chemicals to undetectable levels.

A significant technological focus area involves the development of hybrid modification techniques that integrate chemical processes with physical or enzymatic methods. While E1422 remains chemically modified, researchers are exploring pre-treatment steps using enzymatic hydrolysis or high-pressure homogenization to subtly alter the native starch structure before chemical modification. This approach aims to create unique textural profiles or enhance the cold-water dispersibility of the final E1422 powder, expanding its functional utility in specific applications like instant soups or cold-mix desserts. Another key technological investment is in advanced analytical chemistry and sensor technology, including Fourier-Transform Infrared Spectroscopy (FTIR) and Nuclear Magnetic Resonance (NMR) spectroscopy, which are deployed for rapid, accurate, and non-destructive quantification of the degree of acetylation and cross-linking, providing immediate feedback for process control and regulatory compliance documentation.

Moreover, drying technology plays an essential role, utilizing flash drying or spray drying techniques to convert the modified starch slurry into a stable, easy-to-handle powder format without compromising the functional integrity established during the wet processing phase. The selection of drying parameters is critical to minimize retrogradation and maintain the desired viscosity profile. The overarching technological trend is the drive toward precision ingredient manufacturing, using highly controlled chemical and physical processes coupled with real-time analytical monitoring, thereby ensuring that the Acetylated Distarach Adipate consistently delivers its high-performance properties necessary for complex food formulations globally, while simultaneously reducing energy consumption and optimizing resource efficiency.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand, production, and regulatory landscape of the Food Grade Acetylated Distarach Adipate market, reflecting diverse consumption patterns and supply capabilities globally. North America and Europe collectively represent mature and high-value markets, characterized by stringent regulatory environments imposed by bodies like the FDA and EFSA, demanding highly consistent and documented product quality. Demand in these regions is driven primarily by the vast production of frozen meals, sophisticated sauces, and innovative dairy alternatives, where E1422’s high stability and texture-enhancing properties are essential for premium product positioning. Manufacturers here focus heavily on optimizing source material (e.g., non-GMO corn, certified potato) to align with evolving consumer preference for transparency and ingredient scrutiny, maintaining market dominance in terms of value contribution.

The Asia Pacific (APAC) region is forecasted to exhibit the fastest growth rate throughout the forecast period, fueled by rapid urbanization, substantial growth in the middle-class population, and consequently, a massive shift towards packaged and processed foods, moving away from traditional cooking methods. Countries like China, India, and Southeast Asian nations are witnessing massive investments in food processing infrastructure, driving the demand for functional stabilizers like E1422 in products ranging from instant noodles and canned foods to regional snack fillings and specialized beverages. Furthermore, APAC, particularly Thailand and Vietnam, serves as a primary hub for tapioca starch production, providing a local advantage in sourcing raw materials for the production of tapioca-based E1422, which is often favored for its high clarity and soft gel texture.

Latin America (LATAM) and the Middle East & Africa (MEA) represent emerging regional markets where consumption is steadily increasing, largely driven by the expansion of multinational food companies and improving retail infrastructure, which facilitates the distribution of shelf-stable and frozen goods. In LATAM, the growth is linked to the expanding bakery and confectionery sectors, while MEA sees steady demand growth tied to the increasing reliance on imported or locally produced packaged goods that must withstand challenging climate conditions (high heat storage) during transit. These regions present opportunities for market penetration through localized manufacturing and tailored ingredient solutions focusing on cost-efficiency and robust performance under challenging storage conditions, supporting continued global expansion of the market.

- North America: High demand driven by the large frozen food industry and preference for highly functional, non-GMO ingredients; focus on high-stability applications like dressings and sauces.

- Europe: Strict regulatory compliance requirements; strong market presence in specialized food applications, including low-fat and clean-label formulations where performance stability is crucial.

- Asia Pacific (APAC): Fastest-growing region due to explosive growth in processed foods, rapid urbanization, and significant local availability of tapioca and corn raw materials.

- Latin America (LATAM): Steady growth linked to increasing consumer purchasing power and expanding domestic food manufacturing capabilities, especially in confectionery and sauces.

- Middle East and Africa (MEA): Emerging market potential driven by infrastructure development and reliance on shelf-stable imported or locally produced packaged goods requiring high stability under varied climatic conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Food Grade Acetylated Distarach Adipate Market.- Ingredion Incorporated

- Cargill, Incorporated

- Archer Daniels Midland Company (ADM)

- Tate & Lyle PLC

- Emsland Group

- Avebe U.A.

- Roquette Frères

- Grain Processing Corporation (GPC)

- Visco Starch

- SPAC Starch Products (India) Ltd.

- Everest Starch (Pvt) Ltd.

- Shandong Fuyang Biotech Co., Ltd.

- AGRANA Beteiligungs-AG

- KMC Kartoffelmelcentralen

- Zhucheng Dongxiao Biotechnology Co., Ltd.

- Global Bio-Chem Technology Group Company Limited

- Qingdao Cerealchem Co., Ltd.

- Universal Starch-Chem Allied Ltd.

- Samyang Genex

- Sunar Misir (Sunar Group)

Frequently Asked Questions

Analyze common user questions about the Food Grade Acetylated Distarach Adipate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Food Grade Acetylated Distarach Adipate (E1422) and what is its primary function?

Acetylated Distarach Adipate (E1422) is a highly functional, chemically modified food starch derived from sources like corn or tapioca. Its primary function is to serve as a high-performance stabilizer and thickener, crucially providing excellent resistance to heat, acid, and mechanical shear, making it essential for stabilizing frozen and retorted food products.

Is Acetylated Distarach Adipate considered safe for consumption, and what are the regulatory limits?

Yes, E1422 is generally recognized as safe (GRAS) by the FDA and is approved for use in the European Union (EU) and numerous other global regulatory bodies. It must adhere to established purity standards and specific usage limits, typically under the 'quantum satis' (QS) principle, meaning it is used only to the extent required to achieve the desired technical effect, ensuring safety across all food categories.

How does E1422 perform compared to other common food stabilizers and thickeners?

E1422 offers superior performance in applications involving low pH (acidic) environments or repeated temperature cycling (freeze-thaw stability) compared to native starches and many non-starch hydrocolloids. Its cross-linked structure prevents viscosity breakdown and moisture separation (syneresis), making it the preferred choice for demanding products like mayonnaise, salad dressings, and frozen prepared meals.

Which raw materials are most commonly used to produce Acetylated Distarach Adipate?

The most common raw material sources for producing E1422 are corn starch, tapioca starch, and potato starch. The choice of source material impacts the final textural properties; for instance, tapioca yields a clearer, softer gel, while corn often provides a more opaque, robust texture. Manufacturers select sources based on desired functionality, cost, and regional availability.

What key trends are currently driving the growth of the E1422 market?

Market growth is predominantly driven by the surging global demand for convenient and ready-to-eat foods that require extended shelf stability and robust performance under harsh processing conditions. Additionally, the need for functional ingredients in the expanding plant-based and dairy-alternative sectors, where E1422 helps replicate traditional texture and mouthfeel, is a significant growth factor.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager