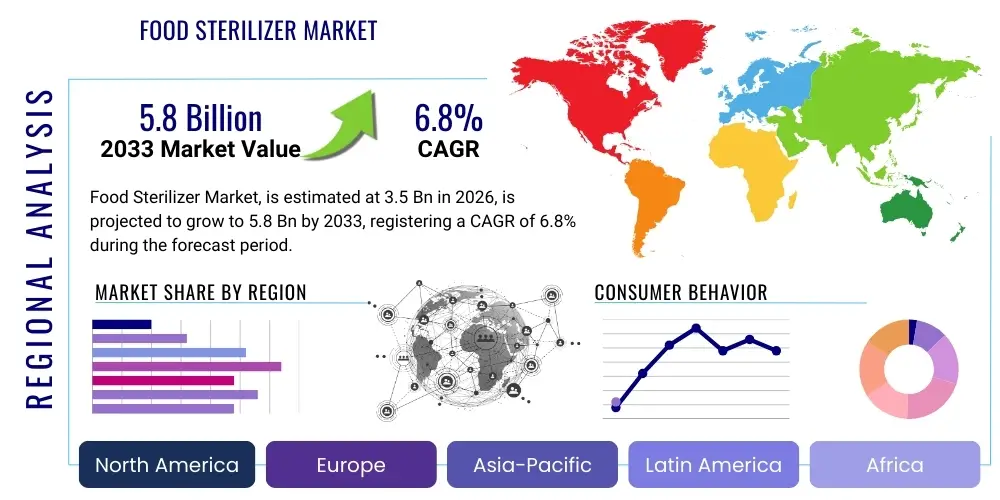

Food Sterilizer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439955 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Food Sterilizer Market Size

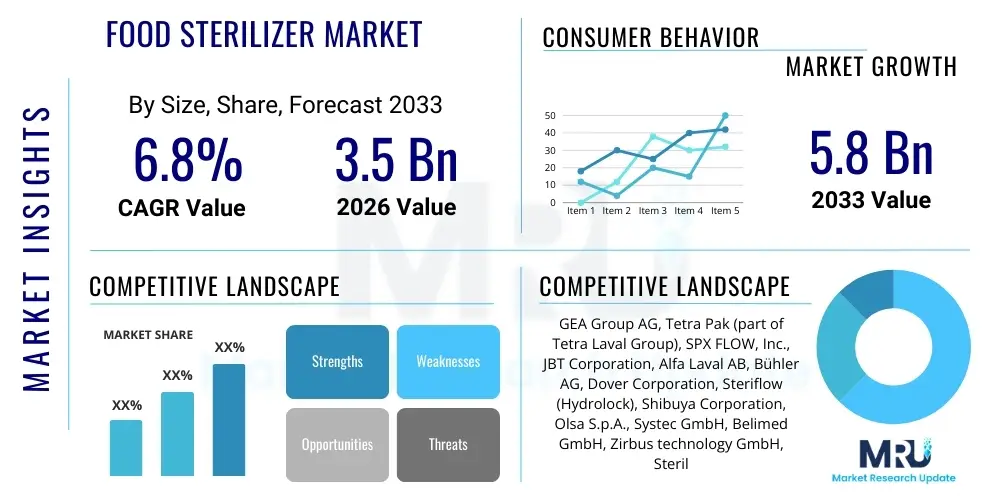

The Food Sterilizer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 3.5 billion in 2026 and is projected to reach USD 5.8 billion by the end of the forecast period in 2033. This growth is primarily fueled by increasing consumer demand for processed and packaged food products, coupled with stringent food safety regulations globally. The expanding food and beverage industry, particularly in emerging economies, is driving significant investment in advanced sterilization technologies to ensure product quality and extend shelf life.

Food Sterilizer Market introduction

The Food Sterilizer Market encompasses equipment and systems designed to eliminate or reduce microbial contaminants, such as bacteria, yeasts, molds, and spores, from food products to ensure their safety, extend shelf life, and maintain sensory quality. These sterilizers utilize various methods, predominantly thermal (e.g., UHT, retort, pasteurization), but also non-thermal techniques like high-pressure processing (HPP) and pulsed electric fields (PEF). Key products include autoclaves, retorts, aseptic filling systems, ultra-high temperature (UHT) processors, and plate heat exchangers, each tailored for specific food matrices and packaging types. The core objective is to deliver food products that are microbiologically safe for consumption over an extended period without requiring refrigeration in many cases, making them suitable for widespread distribution and storage.

Major applications of food sterilizers span across a wide spectrum of the food and beverage industry. These include the dairy sector for milk and milk-based products, the beverage industry for juices, ready-to-drink teas, and sports drinks, and the processed food segment for canned fruits, vegetables, meats, and sauces. Furthermore, they are critical in the production of baby foods, ready meals, and specialized dietary products, where food safety is paramount. The benefits derived from effective food sterilization are multi-faceted, ranging from significantly enhanced food safety through pathogen inactivation to considerable extensions of product shelf life, which reduces food waste and enables broader market access. Sterilization also helps in preserving nutritional value and sensory attributes, although method selection is crucial to minimize heat-induced degradation.

The market is primarily driven by several powerful factors, including the escalating global population and increasing urbanization, which fuel the demand for convenient, long-lasting, and safe packaged food products. Furthermore, the rising awareness among consumers regarding foodborne illnesses and the growing emphasis on health and hygiene have prompted food manufacturers to adopt more robust sterilization protocols. Strict food safety regulations imposed by governmental and international bodies, such as the FDA and EFSA, mandate rigorous sterilization standards, compelling industry players to invest in advanced and compliant sterilization technologies. Continuous technological advancements aimed at improving energy efficiency, automation, and minimizing impact on product quality also serve as significant market accelerators, fostering innovation and adoption across the sector.

Food Sterilizer Market Executive Summary

The Food Sterilizer Market is currently undergoing dynamic shifts, propelled by evolving consumer preferences, stringent regulatory landscapes, and rapid technological advancements. Business trends highlight a pronounced move towards automation and integration of smart technologies, such as IoT and AI, to enhance operational efficiency, precision, and traceability in sterilization processes. Manufacturers are increasingly focusing on developing energy-efficient and environmentally sustainable sterilization solutions to meet corporate social responsibility goals and reduce operational costs. There is also a growing demand for customized sterilization equipment that can handle a diverse range of food products and packaging formats, pushing innovation in flexible and adaptable systems. Strategic collaborations and mergers and acquisitions are frequently observed as companies seek to consolidate market share, expand product portfolios, and penetrate new geographical regions.

Regional trends indicate significant growth opportunities in emerging economies, particularly across Asia Pacific, Latin America, and the Middle East & Africa. These regions are experiencing rapid urbanization, rising disposable incomes, and a burgeoning middle class, leading to a surge in demand for processed and packaged foods. Consequently, local food processing industries are expanding and investing heavily in modern sterilization infrastructure. In contrast, mature markets such as North America and Europe, while still significant, are characterized by a focus on technological upgrades, regulatory compliance, and the adoption of advanced, non-thermal sterilization methods that preserve food quality more effectively. The emphasis in these regions is on innovation in food safety and extending the shelf life of premium and functional food products, often driven by sophisticated consumer demands.

Segmentation trends within the market reveal a notable shift towards advanced sterilization technologies. While conventional thermal methods like UHT and retort sterilization continue to dominate due to their proven effectiveness and cost-efficiency, there is a burgeoning interest and adoption of non-thermal processing techniques such as High-Pressure Processing (HPP) and Pulsed Electric Field (PEF). These technologies are gaining traction for their ability to maintain the sensory attributes, nutritional value, and fresh-like quality of food products, catering to the growing consumer preference for minimally processed foods. The dairy and beverage sectors remain dominant application areas, yet the demand from the processed food segment, including ready meals and canned goods, is expanding rapidly. Batch and continuous processing modes are also evolving, with continuous systems gaining preference in large-scale operations for their higher throughput and integrated automation capabilities.

AI Impact Analysis on Food Sterilizer Market

Common user questions regarding AI's impact on the Food Sterilizer Market often revolve around how artificial intelligence can enhance operational efficiency, improve food safety, reduce costs, and facilitate predictive maintenance within sterilization processes. Users are keen to understand the extent to which AI can automate decision-making, optimize energy consumption, and provide real-time insights into process parameters. Concerns frequently arise about the initial investment required for AI integration, the complexity of implementation, and the need for specialized data scientists or engineers. There is a general expectation that AI will lead to more precise and consistent sterilization outcomes, significantly minimizing human error and ensuring higher product quality and safety standards. Furthermore, users anticipate AI's role in addressing labor shortages and enabling more sustainable practices through resource optimization, while also questioning its capability to adapt to diverse food products and evolving regulatory demands.

AI's integration into food sterilization systems promises a transformative impact across several key operational areas. For instance, predictive analytics powered by AI algorithms can analyze vast datasets from sensors and historical performance logs to forecast potential equipment failures, enabling proactive maintenance rather than reactive repairs. This not only minimizes costly downtime but also extends the operational lifespan of sterilizers, leading to significant cost savings. Furthermore, AI can optimize energy usage by dynamically adjusting sterilization parameters based on real-time product characteristics and environmental conditions, ensuring optimal energy consumption without compromising safety or quality. Such intelligent optimization contributes directly to reducing operational expenditures and aligning with sustainability goals, making the sterilization process more economically viable and environmentally responsible.

Beyond predictive maintenance and energy optimization, AI can profoundly enhance food safety and quality control. Machine learning models can analyze various parameters, including temperature, pressure, flow rates, and product composition, to detect anomalies or deviations from optimal sterilization profiles in real-time. This allows for immediate corrective actions, preventing under-processing or over-processing and ensuring consistent product quality. AI-driven vision systems can also be integrated into packaging and post-sterilization inspection processes to detect defects or contamination with unprecedented accuracy and speed. Moreover, AI can support traceability systems by integrating data across the entire supply chain, providing comprehensive records for regulatory compliance and rapid response in case of product recalls. This level of intelligent oversight significantly elevates the overall reliability and safety of sterilized food products in the market.

- AI-driven predictive maintenance reduces equipment downtime and extends lifespan of sterilizers.

- Real-time process optimization through AI algorithms enhances energy efficiency and resource utilization.

- Enhanced quality control and anomaly detection via machine learning ensures consistent product safety.

- Automation of sterilization parameter adjustments leads to greater precision and reduced human error.

- Improved traceability and supply chain transparency for better regulatory compliance and recall management.

- AI-powered vision systems for post-sterilization inspection increase accuracy in defect detection.

- Data-driven insights from AI help in optimizing product formulations and processing recipes.

- Reduction in operational costs through minimized waste, energy savings, and efficient resource allocation.

DRO & Impact Forces Of Food Sterilizer Market

The Food Sterilizer Market is shaped by a complex interplay of drivers, restraints, and opportunities, alongside various impact forces that continuously influence its trajectory. Key drivers include the ever-increasing global demand for processed and packaged food products, largely fueled by urbanization, busy lifestyles, and the need for convenient, long-lasting meal solutions. Furthermore, the rising consumer awareness regarding food safety and the imperative to prevent foodborne illnesses compel manufacturers to adopt robust sterilization technologies. Stringent food safety regulations imposed by national and international authorities worldwide, which mandate specific sterilization standards and microbial reduction targets, serve as a significant regulatory push for market growth. Technological advancements in sterilization equipment, aiming for higher efficiency, automation, and better preservation of food quality, also actively drive market expansion and innovation.

Despite the strong growth drivers, the market faces several notable restraints. One of the primary barriers is the substantial capital investment required for purchasing and installing advanced sterilization equipment, which can be particularly challenging for small and medium-sized enterprises (SMEs). Moreover, the operational costs associated with sterilization, including energy consumption, water usage, and specialized maintenance, can be significant. The complexity of regulatory compliance and the need for highly skilled personnel to operate and maintain sophisticated sterilization systems also pose challenges. Additionally, certain sterilization methods, particularly thermal ones, can sometimes lead to undesirable changes in the sensory attributes (taste, texture, color) and nutritional value of food products, which can be a concern for consumers preferring minimally processed or fresh-like foods. Addressing these restraints often requires innovative solutions in equipment design and process optimization.

Opportunities within the Food Sterilizer Market are abundant and diverse, offering pathways for sustained growth and technological evolution. The emergence and growing adoption of novel non-thermal sterilization methods, such as High-Pressure Processing (HPP), Pulsed Electric Field (PEF), and cold plasma, present significant opportunities as they can sterilize food while better preserving its fresh-like quality, nutritional content, and sensory appeal. These technologies cater to the rising consumer demand for minimally processed and natural foods. Furthermore, the untapped potential in developing economies, characterized by expanding food processing industries and improving supply chain infrastructures, offers substantial market penetration opportunities. The increasing integration of automation, IoT, and artificial intelligence into sterilization systems promises enhanced efficiency, precision, and data-driven insights, opening avenues for smart and connected food processing. The growing focus on sustainable processing solutions, including energy-efficient designs and reduced water consumption, also presents a key area for innovation and market differentiation, aligning with global environmental concerns and corporate responsibility initiatives.

Impact forces on the Food Sterilizer Market are dynamic and multifaceted. Economic shifts, such as inflation or recession, can influence investment decisions in new equipment. Geopolitical events and trade policies can disrupt supply chains for components or impact market access. Environmental concerns, particularly around energy consumption and waste generation, are pushing manufacturers towards greener technologies. Sociocultural trends, like increasing health consciousness and demand for convenience, directly influence product development and the adoption of specific sterilization methods. Technological advancements, from material science to digital integration, continuously redefine the capabilities and limitations of sterilization equipment. Regulatory changes, especially in food safety and labeling, frequently necessitate adaptations in processing techniques and compliance measures. Lastly, unforeseen global events, such as pandemics, can dramatically alter consumer behavior and supply chain resilience, driving demand for shelf-stable and safely processed foods.

Segmentation Analysis

The Food Sterilizer Market is segmented across various critical dimensions, providing a granular view of its structure, dynamics, and growth potential. These segmentations allow for a deeper understanding of market trends, consumer preferences, and technological shifts across different product types, applications, operating modes, and technologies. Analyzing these segments helps stakeholders identify lucrative niches, tailor product development strategies, and optimize market entry approaches. The diversity in sterilization needs across the food industry, driven by varying product characteristics, regulatory requirements, and desired shelf life, necessitates this multi-faceted segmentation. This comprehensive breakdown highlights the versatility and adaptability of sterilization solutions required to meet the evolving demands of a global food supply chain, from raw material processing to final product packaging and distribution, ensuring safety and quality at every stage.

- By Type:

- Thermal Sterilization:

- Ultra-High Temperature (UHT) Sterilization

- Retort Sterilization (Batch & Continuous)

- Pasteurization (often preceding sterilization or for milder treatments)

- High-Temperature Short-Time (HTST)

- Infrared Heating

- Non-Thermal Sterilization:

- High-Pressure Processing (HPP)

- Pulsed Electric Field (PEF)

- Irradiation (e.g., Gamma, E-beam)

- Cold Plasma

- Ozone Sterilization

- Filtration (for liquids)

- Chemical Sterilization (less common for direct food contact, more for equipment):

- Ethylene Oxide

- Hydrogen Peroxide (Aseptic packaging)

- Thermal Sterilization:

- By Application:

- Dairy & Beverages:

- Milk & Dairy Products (yogurt, cream, flavored milk)

- Juices & Nectars

- Carbonated Soft Drinks

- Functional Beverages

- Bottled Water

- Alcoholic Beverages (e.g., beer, wine)

- Processed Food:

- Canned Fruits & Vegetables

- Canned Meats & Seafood

- Sauces, Soups & Dressings

- Ready Meals & Convenience Foods

- Baby Food

- Meat, Poultry & Seafood:

- Processed Meats (e.g., sausages, deli meats)

- Packaged Poultry Products

- Pre-cooked Seafood

- Bakery & Confectionery:

- Packaged Cakes & Pastries

- Jellies & Jams

- Snack Bars

- Fruits & Vegetables (Packaged & Preserved)

- Other Applications (e.g., Pet Food, Pharmaceutical Ingredients)

- Dairy & Beverages:

- By Operating Mode:

- Batch Sterilizers

- Continuous Sterilizers

- By Technology:

- Autoclaves & Retorts

- Aseptic Filling Systems

- UHT Systems

- Plate Heat Exchangers

- Scraped Surface Heat Exchangers

- Tubular Heat Exchangers

- Others (e.g., HPP Systems, PEF Systems)

- By End-User:

- Food & Beverage Manufacturing Companies (Large, Medium, Small)

- Catering Services & Institutions

- Retail & Supermarkets

- Food Service Industries

- Pharmaceutical Industry (for food-grade ingredients)

Value Chain Analysis For Food Sterilizer Market

The value chain for the Food Sterilizer Market begins with upstream activities, involving the procurement of essential raw materials and components from various suppliers. This includes specialized metals like stainless steel for construction, high-precision electronic components for control systems, sensors for monitoring temperature and pressure, and advanced materials for seals and insulation. Manufacturers rely on a network of specialized suppliers for pumps, valves, heat exchangers, and automation software that form the core of sophisticated sterilization equipment. The quality and reliability of these upstream components are paramount, as they directly impact the performance, longevity, and safety of the final sterilizer units. Strong supplier relationships, often involving long-term contracts and quality assurance agreements, are critical to ensuring a steady supply of high-grade materials and managing production costs effectively.

The manufacturing stage involves the design, assembly, and rigorous testing of food sterilization systems. This phase typically includes research and development to innovate new technologies and improve existing ones, engineering for customization to specific client needs, precision fabrication of various components, and meticulous assembly into functional units. Quality control and assurance are embedded throughout the manufacturing process, from initial component inspection to final product validation, ensuring adherence to stringent industry standards and regulatory requirements such as HACCP and FDA guidelines. Leading manufacturers often leverage advanced manufacturing techniques, including robotic welding and automated assembly lines, to enhance efficiency, reduce production lead times, and maintain consistent quality across their product lines. This stage also includes the development of user interfaces and control software, making the systems intuitive and efficient for operators.

Downstream activities in the Food Sterilizer Market primarily focus on distribution, sales, installation, and after-sales services. Distribution channels can be direct, where manufacturers sell directly to large food and beverage producers, or indirect, involving a network of distributors, agents, and value-added resellers, particularly for smaller clients or in specific geographical regions. Direct sales allow for closer client relationships and custom solutions, while indirect channels provide broader market reach. Post-sale, installation and commissioning services are crucial, often requiring specialized technical teams to ensure proper integration into the client's production line. Furthermore, comprehensive after-sales support, including maintenance contracts, spare parts availability, technical troubleshooting, and operator training, is vital for ensuring the continuous and optimal performance of the equipment throughout its lifecycle. The effectiveness of these downstream activities significantly influences customer satisfaction and brand loyalty.

Food Sterilizer Market Potential Customers

The primary potential customers for food sterilizers are diverse entities within the vast food and beverage manufacturing ecosystem. Large-scale food and beverage corporations, often operating multiple production facilities globally, represent a significant segment. These companies require high-capacity, highly automated, and technologically advanced sterilization systems to process immense volumes of products such as dairy, juices, canned goods, and ready meals. Their stringent quality control standards, extensive product portfolios, and need for seamless integration into complex production lines drive demand for customized, efficient, and reliable solutions. These major players prioritize operational efficiency, reduced downtime, and compliance with global food safety regulations, making investments in cutting-edge sterilization technology a strategic imperative for maintaining market leadership and ensuring consumer trust.

Medium and small-sized enterprises (SMEs) within the food processing sector also constitute a vital customer base, albeit with different requirements. While they may not demand the same capacity as large corporations, SMEs increasingly seek sterilization solutions that are cost-effective, easy to operate, and scalable to their growing production needs. For many SMEs, particularly those focusing on niche markets like organic products, artisanal foods, or local specialties, the ability to extend shelf life without compromising product integrity is crucial for expanding their distribution reach and competitiveness. They often look for flexible equipment that can handle diverse product batches and provide an efficient return on investment, making them receptive to modular systems or those with lower initial capital outlay but high operational reliability. The shift towards convenience foods and packaged snacks even from smaller producers fuels their demand for appropriate sterilization technologies.

Beyond traditional food and beverage manufacturers, other sectors present significant potential for food sterilizer adoption. These include the catering and institutional food service industry, where bulk preparation and long shelf life are essential for efficiency and safety in settings like hospitals, schools, and corporate cafeterias. Pharmaceutical companies, particularly those involved in producing food-grade ingredients, nutraceuticals, or medical foods, also require specialized sterilization solutions to meet their stringent purity and safety standards. Furthermore, research and development institutions, as well as food technology incubators, regularly invest in smaller, versatile sterilization units for product innovation, process optimization, and pilot-scale testing. The pet food industry, driven by similar food safety concerns and consumer demand for high-quality, processed pet foods, also represents a growing segment for food sterilizer manufacturers, demonstrating the broad applicability of these crucial technologies across various industries.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 billion |

| Market Forecast in 2033 | USD 5.8 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GEA Group AG, Tetra Pak (part of Tetra Laval Group), SPX FLOW, Inc., JBT Corporation, Alfa Laval AB, Bühler AG, Dover Corporation, Steriflow (Hydrolock), Shibuya Corporation, Olsa S.p.A., Systec GmbH, Belimed GmbH, Zirbus technology GmbH, Steriltechnik AG, FME Food Processing, ALLIEDFLEX Technologies, Inc., Sterigenics (part of Sotera Health), Cryovac (part of Sealed Air Corporation), Syntegon Technology GmbH, Shinagawa Machinery Works Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Food Sterilizer Market Key Technology Landscape

The Food Sterilizer Market is characterized by a dynamic and evolving technology landscape, with continuous innovation driving advancements in efficiency, safety, and product quality preservation. Traditional thermal sterilization methods, while proven, are constantly being refined. Ultra-High Temperature (UHT) processing systems, for example, are evolving with more precise temperature control and shorter processing times to minimize heat-induced degradation of nutrients and sensory attributes in liquid foods like milk and juices. Retort sterilization technology is also seeing improvements, with manufacturers developing more energy-efficient models, enhanced automation for load and unload systems, and precise temperature and pressure distribution within the retorts to ensure uniform sterilization for canned and pouched products. These advancements often involve sophisticated sensor technology and control algorithms to monitor and adjust critical process parameters in real-time, thereby optimizing throughput and reducing energy consumption.

A significant area of innovation lies in the realm of non-thermal sterilization technologies, which are gaining considerable traction due to their ability to preserve the 'fresh-like' quality, nutritional integrity, and sensory appeal of food products. High-Pressure Processing (HPP) systems, for instance, utilize extremely high pressures to inactivate microorganisms while maintaining molecular structures, making them ideal for delicate foods, ready meals, and juices. Pulsed Electric Field (PEF) technology is another promising non-thermal method, employing short bursts of high-voltage electrical pulses to create microscopic pores in cell membranes, effectively inactivating microbes without significant heat generation. Other emerging technologies include cold plasma, which uses ionized gases to sterilize surfaces and packaging, and advanced filtration techniques that can remove microorganisms from liquids without thermal exposure. These technologies are crucial for meeting the growing consumer demand for minimally processed, 'clean label' food products that offer extended shelf life.

Beyond the core sterilization methods, the technological landscape is increasingly influenced by digitalization and automation. The integration of Industry 4.0 principles, including the Internet of Things (IoT), artificial intelligence (AI), and advanced analytics, is transforming sterilizer operations. IoT sensors embedded within equipment provide real-time data on temperature, pressure, flow rates, and machine performance, enabling predictive maintenance, remote monitoring, and proactive problem-solving. AI and machine learning algorithms are being employed to optimize sterilization cycles, predict equipment failures, and analyze quality control data for continuous improvement. Furthermore, advanced automation systems facilitate seamless integration of sterilizers into complete processing lines, reducing manual intervention, enhancing operational efficiency, and ensuring higher levels of food safety and traceability. The development of energy-efficient designs, utilization of renewable energy sources, and sustainable practices in water management are also becoming critical aspects of the key technology landscape, reflecting the industry's commitment to environmental responsibility.

Regional Highlights

- North America: This region represents a mature yet highly innovative market for food sterilizers, characterized by stringent food safety regulations and a strong emphasis on automation and advanced processing technologies. The increasing consumer demand for convenience foods, ready-to-eat meals, and organic products drives continuous investment in state-of-the-art sterilization equipment. Manufacturers here focus on integrating IoT, AI, and predictive maintenance solutions to enhance operational efficiency and reduce energy consumption. High-Pressure Processing (HPP) and other non-thermal technologies are gaining significant traction as consumers prioritize fresh-like quality and nutritional integrity in their food choices. The presence of major food and beverage corporations also contributes to the sustained demand for high-capacity, reliable sterilization systems, fostering a competitive environment for technology innovation and adoption across the United States and Canada.

- Europe: Europe is another key market, distinguished by its robust regulatory framework, high food safety standards, and strong inclination towards sustainable and energy-efficient processing solutions. Countries like Germany, France, and Italy are leading in the adoption of advanced thermal and non-thermal sterilization techniques, driven by a consumer base that values both product quality and environmental responsibility. There is a significant focus on research and development to innovate new sterilization methods that minimize the impact on food attributes while maximizing shelf life. The demand for aseptic processing and packaging solutions is particularly strong, catering to the growing market for dairy products, fruit juices, and ready-to-drink beverages. Regulatory directives from the European Food Safety Authority (EFSA) play a crucial role in shaping market trends and technological advancements within the region, pushing for continuous improvement in food processing safety and efficiency.

- Asia Pacific (APAC): The Asia Pacific region is projected to be the fastest-growing market for food sterilizers, primarily due to rapid urbanization, increasing disposable incomes, and the expansion of the organized retail sector. Countries like China, India, Japan, and Southeast Asian nations are witnessing a surge in demand for processed, packaged, and convenience foods, which directly fuels the need for robust sterilization infrastructure. Investments in new food processing plants and upgrades to existing facilities are widespread, driven by growing populations and evolving dietary preferences. While traditional thermal sterilization methods still dominate, there is a burgeoning interest in adopting advanced technologies, including non-thermal techniques, to cater to increasingly discerning consumers. The region's vast population and emerging middle class present significant growth opportunities for both local and international manufacturers of food sterilizers, making it a critical hub for future market expansion.

- Latin America: Latin America is emerging as a significant market for food sterilizers, propelled by increasing industrialization of the food and beverage sector and rising awareness regarding food safety standards. Countries such as Brazil, Mexico, and Argentina are witnessing substantial investments in modernizing their food processing capabilities to meet both domestic demand and export opportunities. The growth in dairy, juice, and processed meat industries is a key driver for the adoption of sterilization equipment. While cost-effectiveness remains a crucial consideration, there is a growing trend towards adopting more efficient and automated systems to improve product quality and extend shelf life. International trade agreements and the harmonization of food safety regulations with global standards are also influencing the demand for compliant and high-performance sterilization technologies across the region, fostering market development and technological upgrades.

- Middle East and Africa (MEA): The MEA region is demonstrating a steady growth trajectory in the food sterilizer market, driven by increasing government initiatives to enhance food security, diversify economies, and improve public health standards. Rising disposable incomes, coupled with Westernization of dietary patterns, are contributing to a greater demand for packaged and processed foods. Investments in new food processing facilities, particularly in the dairy, beverage, and confectionery sectors, are creating demand for modern sterilization solutions. Challenges such as water scarcity in some areas are also prompting the adoption of more water-efficient sterilization technologies. International partnerships and foreign direct investments are playing a crucial role in introducing advanced equipment and expertise into the region, further accelerating market development and the adoption of sophisticated food safety measures to meet both local consumption needs and growing export ambitions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Food Sterilizer Market.- GEA Group AG

- Tetra Pak (part of Tetra Laval Group)

- SPX FLOW, Inc.

- JBT Corporation

- Alfa Laval AB

- Bühler AG

- Dover Corporation

- Steriflow (Hydrolock)

- Shibuya Corporation

- Olsa S.p.A.

- Systec GmbH

- Belimed GmbH

- Zirbus technology GmbH

- Steriltechnik AG

- FME Food Processing

- ALLIEDFLEX Technologies, Inc.

- Sterigenics (part of Sotera Health)

- Cryovac (part of Sealed Air Corporation)

- Syntegon Technology GmbH

- Shinagawa Machinery Works Co., Ltd.

Frequently Asked Questions

What are the primary benefits of food sterilization?

Food sterilization primarily offers enhanced food safety by eliminating harmful microorganisms, significantly extends product shelf life, reduces food spoilage and waste, and enables broader distribution without refrigeration. It also maintains essential nutritional value and sensory qualities when appropriate methods are employed, ensuring consumer confidence and compliance with stringent health regulations.

How do different food sterilization technologies compare?

Food sterilization technologies broadly fall into thermal (e.g., UHT, retort) and non-thermal (e.g., HPP, PEF) methods. Thermal methods are effective and cost-efficient but can impact sensory attributes. Non-thermal methods preserve fresh-like quality and nutrients better but often require higher capital investment and specific product applications. The choice depends on food type, desired shelf life, and quality parameters.

What drives the growth of the food sterilizer market?

The market's growth is driven by increasing global demand for processed and packaged foods, stringent food safety regulations worldwide, a growing focus on extending product shelf life to reduce waste, and continuous technological advancements in sterilization techniques. Rising consumer awareness about foodborne illnesses and urbanization also contribute significantly to this demand.

What role does sustainability play in food sterilization?

Sustainability is increasingly vital, driving the development of energy-efficient sterilizers and processes that reduce water consumption and waste generation. Manufacturers are focusing on green technologies, optimizing energy use through AI, and exploring alternative sterilization methods with lower environmental footprints. This aligns with corporate social responsibility and consumer demand for eco-friendly practices.

How is AI transforming the food sterilizer industry?

AI is transforming the industry by enabling predictive maintenance for equipment, optimizing sterilization parameters in real-time for energy efficiency and consistent quality, and enhancing food safety through advanced anomaly detection. AI-driven systems improve traceability, reduce human error, and provide data-driven insights for process optimization, leading to more intelligent and resilient food processing operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager