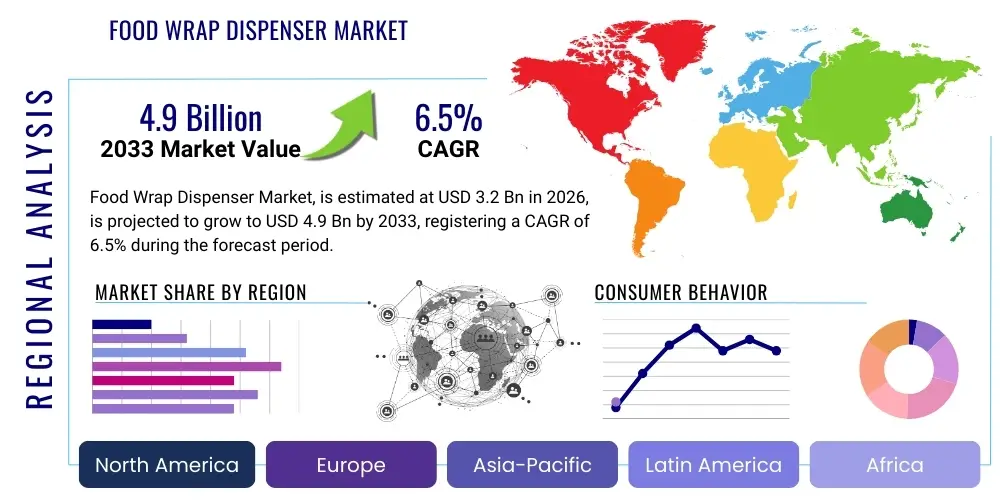

Food Wrap Dispenser Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436419 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Food Wrap Dispenser Market Size

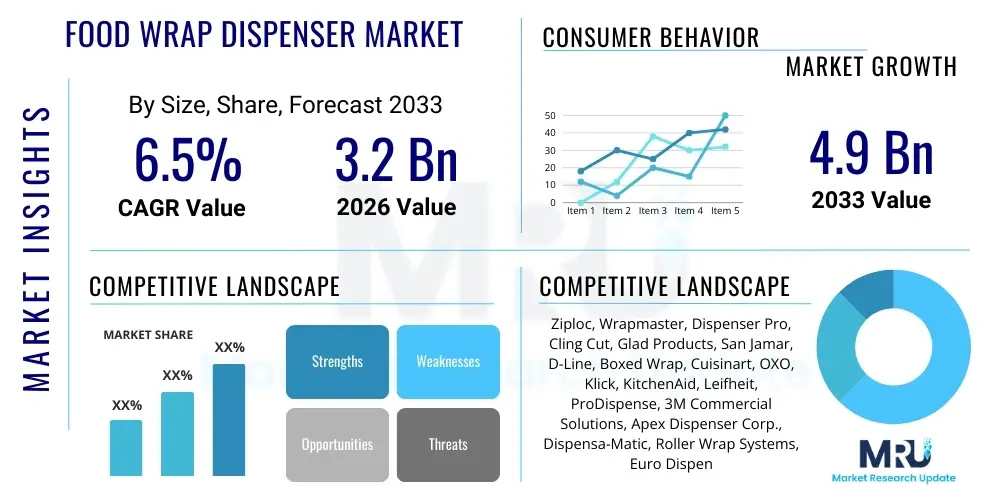

The Food Wrap Dispenser Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 3.2 billion in 2026 and is projected to reach USD 4.9 billion by the end of the forecast period in 2033.

Food Wrap Dispenser Market introduction

The Food Wrap Dispenser Market encompasses the manufacturing, distribution, and sale of devices designed to store, manage, and facilitate the cutting of various food wrapping materials, including plastic film (cling wrap), aluminum foil, and parchment paper. These devices range from simple, manual box-style dispensers integrated with cutting slides to advanced, automated, or wall-mounted systems utilized heavily in commercial kitchen environments. The primary function of these products is to enhance efficiency, reduce material waste, and improve hygiene standards during food preparation, storage, and handling processes, making them essential tools across consumer and commercial sectors.

The core product classification includes dispensers designed for specific wrap types, such as foil dispensers, plastic wrap dispensers, and multi-roll units capable of holding several different materials simultaneously. Key features driving product evolution include enhanced cutting mechanisms—such as bidirectional cutters, concealed safety blades, and magnetic attachments—aimed at improving user safety and the cleanliness of the cut. Major applications span residential kitchens, where ease of use is paramount, to large-scale professional settings like restaurants, catering services, cafeterias, and industrial food processing units where speed and durability are critical requirements.

Market growth is significantly bolstered by the increasing focus on food safety regulations globally, coupled with a steady rise in home cooking and packaged food consumption, especially post-pandemic. The benefits offered by modern dispensers—including reduced contamination risk, precise portion control, and reduced labor time—are substantial driving factors. Moreover, the adoption of sustainable materials in both the wraps and the dispensers themselves (e.g., bamboo, recycled plastics) is creating new avenues for market penetration, aligning with broader consumer trends toward environmental consciousness. The transition from disposable cardboard box dispensers to durable, ergonomic, and reusable systems represents a major ongoing trend in the industry.

Food Wrap Dispenser Market Executive Summary

The Food Wrap Dispenser Market is characterized by robust growth, driven primarily by stringent food hygiene standards in the commercial sector and sustained demand for convenient, ergonomic kitchen solutions in the residential segment. Key business trends include product premiumization, focusing on durable materials like stainless steel and high-grade plastics, and the integration of smart features such as magnetic mounting and touchless dispensing mechanisms in high-end models. Furthermore, strategic alliances between dispenser manufacturers and food wrap producers are optimizing supply chain efficiency and promoting bundled product offerings. Companies are heavily investing in patented cutting technology to differentiate their products and secure competitive advantages in crowded consumer appliance markets.

Regionally, North America and Europe maintain dominance, attributed to high levels of commercial food service activity and strong consumer spending power directed toward sophisticated kitchen gadgets. However, the Asia Pacific (APAC) region is demonstrating the highest growth trajectory, fueled by rapid urbanization, the proliferation of modern retail infrastructure, and increasing disposable incomes leading to greater adoption of Western-style kitchen organization tools. Restraints, such as the persistent preference for low-cost, disposable cardboard solutions in certain emerging markets, are being offset by increasing awareness regarding the long-term cost-effectiveness and superior performance of durable dispenser models.

Segmentation trends indicate that dispensers designed for plastic wrap hold the largest market share by material, though the aluminum foil dispenser segment is showing accelerated growth due to its widespread use in heavy-duty commercial food preservation and cooking. By end-user, the commercial segment (restaurants, hotels) remains the primary revenue driver, demanding industrial-grade robustness and multi-roll capacity. Conversely, the residential segment is focused on aesthetically pleasing, compact, and easy-to-clean designs. The shift towards sustainable and eco-friendly dispensing solutions, often utilizing biodegradable wraps, is a critical segment trend influencing future product development and marketing strategies across all geographies.

AI Impact Analysis on Food Wrap Dispenser Market

User queries regarding the impact of Artificial Intelligence (AI) on the Food Wrap Dispenser Market primarily revolve around automation, inventory management, and personalized consumer experiences. Users frequently ask if AI could lead to fully automated, hands-free dispensing in smart kitchens, how AI-driven analytics could optimize material usage in large commercial operations, and whether manufacturers are utilizing AI for predictive maintenance of complex, motorized dispensing systems. The consensus concern centers on whether AI integration justifies the potential increase in product cost, especially for a relatively low-tech kitchen appliance. Overall, users expect AI to transition dispensing from a manual task to a seamless, integrated component of the smart kitchen ecosystem, particularly in high-volume commercial settings where reducing waste and optimizing workflow is crucial.

- AI-Powered Inventory Tracking: Automated monitoring of remaining wrap length, triggering reorder alerts for commercial kitchens via IoT integration.

- Predictive Maintenance: AI algorithms analyzing motor performance in automated dispensers to anticipate failures and schedule maintenance, maximizing operational uptime.

- Optimized Cutting Parameters: Using machine learning to adjust cutting speed and length based on historical usage patterns and object size (e.g., in industrial food packaging lines).

- Smart Home Integration: Voice-activated dispensing in residential units, enabling hands-free operation integrated with existing smart home platforms (e.g., Alexa, Google Home).

- Demand Forecasting: AI aiding manufacturers in accurately predicting regional demand for specific dispenser types (foil vs. plastic) based on demographic shifts and culinary trends.

- Quality Control in Manufacturing: AI vision systems ensuring precise alignment and functionality checks during the assembly of complex mechanical components within dispensers.

DRO & Impact Forces Of Food Wrap Dispenser Market

The Food Wrap Dispenser Market dynamics are shaped by a confluence of driving factors, persistent restraints, and significant market opportunities, collectively defining the impact forces influencing strategic decision-making. Key drivers include the global prioritization of food hygiene and preservation, which necessitates efficient and contamination-free wrapping solutions. Technological advancements, particularly the introduction of safety-focused, concealed-blade cutting systems and aesthetic designs suitable for modern kitchens, continuously stimulate consumer upgrades. However, the market faces restraints such as the dominance of existing, inexpensive, built-in solutions (the cardboard box cutter) and the challenge of standardizing wrap roll sizes globally, which can complicate universal dispenser design and adoption. Opportunities emerge strongly in the sustainable materials sector and the integration of dispensers into the growing smart kitchen environment, particularly targeting the lucrative catering and ready-meal preparation sectors.

The impact forces are substantial, particularly concerning competitive intensity. The market features numerous small, regional manufacturers competing primarily on price, alongside established appliance giants focusing on brand recognition and innovative features. Supplier power is moderate, as materials like ABS plastic, stainless steel, and cutting blades are sourced from fragmented global markets, allowing manufacturers some leverage in procurement. Buyer power is high in the residential segment due to low switching costs and a vast array of available product choices, forcing manufacturers to emphasize quality and differentiation. Regulatory pressure, especially in terms of materials handling and safety standards in commercial food service, acts as a continuous external force driving product design improvements.

Furthermore, the threat of substitutes is relatively low for high-volume commercial operations, where dedicated, durable dispensers are irreplaceable for efficiency. However, in the residential market, the basic cardboard wrap box remains a viable substitute, constraining the growth of expensive, high-end residential dispensers. The threat of new entrants is moderate; while manufacturing precision is required, entry barriers for simple plastic or magnetic models are relatively low, leading to intense competition and downward pressure on pricing, especially in the mass market segment. Successfully navigating these forces requires manufacturers to focus on intellectual property related to cutting mechanism safety and proprietary material compatibility.

Segmentation Analysis

The Food Wrap Dispenser Market is segmented based on the type of wrap material accommodated, the cutting mechanism utilized, the material composition of the dispenser itself, and the primary end-user application. This multi-faceted segmentation helps to accurately gauge demand across various economic and operational environments, ranging from budget-conscious household consumers to industrial-grade food service providers. The material segmentation (Plastic Wrap, Aluminum Foil, Wax/Parchment Paper) reveals diverse usage patterns, with plastic wrap dispensers dominating overall volume due to ubiquity in short-term food storage. However, segmentation by end-user (Residential vs. Commercial) highlights that Commercial applications drive higher average selling prices (ASPs) due to the need for robust construction and larger capacity.

- By Wrap Material:

- Plastic Wrap Dispenser (Cling Film)

- Aluminum Foil Dispenser

- Parchment/Wax Paper Dispenser

- Multi-Roll Dispenser (Combination Units)

- By Cutting Mechanism:

- Slide Cutter/Bi-directional Cutter

- Fixed Blade Cutter (Safety Concealed)

- Serrated Edge Cutter (Basic)

- Automated/Motorized Cutter

- By Dispenser Type/Mounting:

- Countertop/Portable Dispenser

- Wall-Mounted Dispenser

- Drawer Insert Dispenser

- Magnetic Dispenser

- By Material Composition:

- Plastic (ABS, Polypropylene)

- Metal (Stainless Steel, Aluminum)

- Wood/Bamboo

- Hybrid Materials

- By End-User:

- Residential (Households)

- Commercial (Hotels, Restaurants, Cafeterias, Catering Services)

- Industrial (Food Processing Plants, Large-scale Packaging)

Value Chain Analysis For Food Wrap Dispenser Market

The value chain for the Food Wrap Dispenser Market begins with upstream activities, involving the procurement and processing of raw materials such as various types of plastics (e.g., ABS, PP for bodies, Nylon for internal gears), metals (stainless steel for blades and housing), and specialty materials like magnets and spring mechanisms. This stage is critical as the quality and durability of the dispenser heavily rely on material selection. Manufacturers often face volatility in polymer pricing, necessitating efficient global sourcing strategies and long-term contracts with large-scale resin and steel suppliers. Innovation at this stage focuses on using recycled or bio-based plastics to meet sustainability demands, particularly from European and North American retail buyers.

Midstream activities involve core manufacturing, including injection molding, metal stamping, blade sharpening, assembly, and quality control. Specialized processes, such as the precision engineering of the slide cutting mechanism and the integration of internal springs for tension control, are key areas of technological expertise. Manufacturers often employ lean manufacturing principles to minimize waste and optimize production cycles, particularly for high-volume standard countertop models. Downstream activities involve distribution, which is bifurcated into direct and indirect channels. Direct channels are becoming increasingly important through e-commerce platforms (DTC), allowing manufacturers greater control over branding and pricing, particularly for premium, aesthetically driven residential products.

The indirect distribution channel leverages wholesalers, major retail chains (e.g., Walmart, Target, specialized kitchen stores), and commercial equipment distributors that supply the hospitality and food service industries. For commercial-grade dispensers, specialized distributors often provide installation, maintenance, and bulk supply services, adding significant value. Channel selection is heavily influenced by the end-user; residential sales are primarily retail and e-commerce driven, while commercial sales depend on specialized B2B procurement networks. Effective supply chain management, minimizing transit damage for potentially delicate cutting mechanisms, and ensuring compliance with regional safety certifications (e.g., FDA compliance for food-contact materials) are paramount throughout the distribution phases.

Food Wrap Dispenser Market Potential Customers

The primary customer base for the Food Wrap Dispenser Market is broadly segmented into residential consumers seeking organizational and efficiency improvements in their homes, and commercial operators requiring industrial durability and high-speed functionality. Residential end-users often prioritize aesthetic appeal, ease of cleaning, and compact storage solutions, such as magnetic or drawer-insert models. They are highly responsive to marketing emphasizing kitchen organization, safety features (concealed blades), and premium materials (stainless steel look or bamboo finish), often purchasing through major big-box retailers or online marketplaces. Purchase decisions in this segment are typically influenced by price point, brand trust, and user reviews regarding the cutting efficacy.

The commercial segment constitutes the largest revenue opportunity, driven by continuous high-volume usage. This group includes hotels, restaurants, cafes (HoReCa), institutional kitchens (schools, hospitals), and large-scale catering businesses. These buyers demand robust, often wall-mounted or oversized multi-roll dispensers made of durable materials like heavy-gauge stainless steel. Their purchasing criteria focus rigorously on operational uptime, compliance with health and safety codes, compatibility with industrial-sized wrap rolls, and the longevity of the cutting mechanism under continuous use. Procurement is often centralized, involving specialized equipment dealers or direct contracts with manufacturers, emphasizing reliability and bulk pricing.

A rapidly growing segment includes professional food processors and meal kit delivery services. These industrial buyers require automated or semi-automated dispensing solutions integrated directly into their packaging lines. Their focus is on achieving millimeter-precise cutting, minimum material wastage, and seamless integration with conveyor belt systems. This segment offers high value due to the technical complexity and large volume of units required, pushing the boundaries of technological innovation within the dispenser market towards motorized and sensor-driven solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.2 billion |

| Market Forecast in 2033 | USD 4.9 billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ziploc, Wrapmaster, Dispenser Pro, Cling Cut, Glad Products, San Jamar, D-Line, Boxed Wrap, Cuisinart, OXO, Klick, KitchenAid, Leifheit, ProDispense, 3M Commercial Solutions, Apex Dispenser Corp., Dispensa-Matic, Roller Wrap Systems, Euro Dispenser Group, Wrapology. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Food Wrap Dispenser Market Key Technology Landscape

The technology landscape of the Food Wrap Dispenser Market is continually evolving, moving beyond simple box-and-serrated-edge designs to incorporate advanced mechanisms focused on safety, efficiency, and material handling. A core technological advancement is the widespread adoption of the bidirectional slide cutter, replacing exposed serrated edges. These cutters utilize a small, concealed blade housed within a carriage that slides smoothly across the length of the wrap, ensuring a clean, straight cut without the risk of injury associated with traditional tearing. Materials engineering also plays a vital role, with manufacturers developing specialized friction pads and tensioning systems internally to maintain optimal tautness of the wrap, preventing bunching or sticking during the cutting process, particularly important for thin plastic films.

In the commercial and high-end residential sectors, motorized and automated dispensing technologies are gaining traction. These systems often utilize infrared sensors or proximity detection to dispense and cut pre-set lengths of wrap with the wave of a hand, significantly improving hygiene standards by eliminating manual contact, a critical requirement in food service environments. These automated units are typically powered by rechargeable batteries or AC current and often include digital interfaces for adjusting cutting parameters and tracking usage statistics. Integration with IoT platforms is the next frontier, allowing commercial managers to remotely monitor inventory levels and usage patterns, leading to optimized procurement and reduced waste.

Furthermore, innovative mounting solutions represent a key technological area. Magnetic adhesion systems allow dispensers to be easily attached to metallic kitchen surfaces (e.g., refrigerators or utility carts), maximizing countertop space. Manufacturers are also applying principles of ergonomic design and material science to improve the stability of non-mounted units, ensuring they remain firmly in place during aggressive pulling and cutting actions. The focus remains on making the technology highly durable, maintenance-free, and seamlessly integrated into the operational flow of both professional and home kitchens, prioritizing efficiency and the consistent delivery of a straight, clean cut regardless of the wrap material type.

Regional Highlights

- North America: This region holds a significant share of the global market, driven by high consumer spending on kitchen appliances, a strong culture of household organization, and the large scale of its commercial food service sector. The United States and Canada exhibit high demand for premium, multi-functional, and aesthetically pleasing dispensers, often incorporating stainless steel designs and advanced magnetic mounting. Strict food safety standards in restaurants and institutional settings necessitate the widespread use of durable, professional-grade wrapping solutions, fueling the commercial segment.

- Europe: Europe is characterized by stringent regulatory environments regarding food contact materials and hygiene, promoting the adoption of high-quality, long-lasting dispensing equipment. Countries such as Germany and the UK lead in product innovation, focusing heavily on eco-friendly dispenser materials (e.g., bamboo and recycled plastics) and sophisticated cutting mechanisms. Consumer preferences skew toward European-designed brands emphasizing minimalism, integrated kitchen solutions (drawer inserts), and modular systems for various wrap types.

- Asia Pacific (APAC): APAC is the fastest-growing region due to rapid urbanization, increasing middle-class income, and the expansion of modern retail and organized food service industries, particularly in China, India, and Southeast Asia. While price sensitivity remains a factor, the professionalization of the culinary sector and the shift away from traditional, less hygienic food storage methods are rapidly driving the adoption of standardized dispensers. E-commerce penetration is a key driver for market expansion in the residential segment.

- Latin America (LATAM): Growth in LATAM is steady but constrained by economic variability. However, rising investment in the hospitality sector and the expansion of international hotel chains are creating sustained demand for commercial-grade dispensers. Mexico and Brazil are key markets, showing a gradual shift from basic to more functional, durable dispensing solutions, largely mirroring North American product trends but often at a more competitive price point.

- Middle East and Africa (MEA): The MEA market is largely influenced by significant investment in luxury hotel development and large commercial catering services, particularly in the Gulf Cooperation Council (GCC) countries. High per capita income in the GCC allows for the adoption of premium, sophisticated dispensers. In Africa, market penetration is lower, but opportunities exist within the expanding urban centers and professional food processing facilities that require efficient, large-volume wrap handling equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Food Wrap Dispenser Market.- Ziploc (S. C. Johnson & Son, Inc.)

- Wrapmaster (A part of Cofresco Foodservice)

- Dispenser Pro

- Cling Cut

- Glad Products (The Clorox Company)

- San Jamar

- D-Line

- Boxed Wrap

- Cuisinart

- OXO

- Klick

- KitchenAid

- Leifheit

- ProDispense

- 3M Commercial Solutions

- Apex Dispenser Corp.

- Dispensa-Matic

- Roller Wrap Systems

- Euro Dispenser Group

- Wrapology

Frequently Asked Questions

Analyze common user questions about the Food Wrap Dispenser market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate (CAGR) for the Food Wrap Dispenser Market?

The Food Wrap Dispenser Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 6.5% during the forecast period from 2026 to 2033, driven by commercial sector demand and kitchen organization trends.

Which cutting mechanism is considered the safest and most efficient in modern food wrap dispensers?

The bidirectional slide cutter mechanism is widely considered the safest and most efficient, as it features a concealed blade and ensures a clean, straight cut across various wrap materials without the user directly touching the sharp edge.

How does the commercial segment differ from the residential segment in terms of dispenser requirements?

The commercial segment requires high durability, large multi-roll capacity, robust materials (like stainless steel), and often wall-mounted designs, prioritizing efficiency and compliance with health regulations over aesthetic appeal, which is paramount in the residential market.

What impact is sustainability having on the design of food wrap dispensers?

Sustainability is driving manufacturers to utilize durable, reusable materials such as recycled plastics, stainless steel, and bamboo for dispenser construction, moving away from disposable components and supporting the use of biodegradable or compostable wrap films.

Which region currently dominates the Food Wrap Dispenser Market, and which is growing fastest?

North America and Europe currently dominate the market in terms of revenue share due to high consumer spending and established commercial food service sectors, while the Asia Pacific (APAC) region is projected to register the fastest growth rate.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager