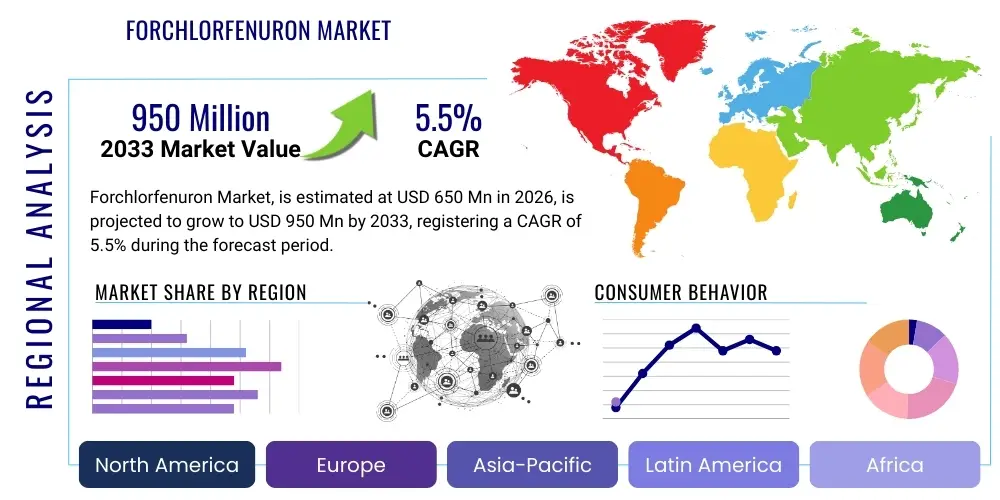

Forchlorfenuron Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434934 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Forchlorfenuron Market Size

The Forchlorfenuron Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 950 Million by the end of the forecast period in 2033.

Forchlorfenuron Market introduction

The Forchlorfenuron market involves the production and distribution of N-(2-chloro-4-pyridyl)-N'-phenylurea (CPPU), a highly effective synthetic cytokinin plant growth regulator (PGR). This chemical compound is essential in modern agriculture, primarily utilized to promote cell division, differentiation, and lateral bud growth, significantly enhancing fruit size, quality, and overall crop yield. Its application spans diverse crops, including kiwifruit, grapes, melons, and various ornamental plants, making it a critical tool for commercial growers aiming for efficiency and profitability in high-value horticulture.

The product description highlights its mechanism of action, which mimics natural plant hormones to accelerate growth processes, particularly in the post-flowering stage. Major applications include fruit thinning reduction, increasing fruit set, and improving the marketability of produce by ensuring uniform size and appearance. The widespread adoption of intensive farming practices and the necessity to maximize yield from limited arable land are key driving factors accelerating market expansion.

Benefits derived from Forchlorfenuron use encompass improved crop quality, extended shelf life for certain fruits, and significant economic advantages for farmers due to higher yields per hectare. Global food security concerns, coupled with rising consumer demand for visually appealing, larger produce, continuously fuel the demand for effective PGRs. However, the market must navigate challenges related to stringent regulatory approval processes, particularly concerning maximum residue limits (MRLs) set by major importing nations, which necessitates advanced application techniques and controlled usage.

Forchlorfenuron Market Executive Summary

The Forchlorfenuron market is poised for steady growth, underpinned by favorable business trends emphasizing agricultural output maximization and precision farming. Key business trends include the consolidation of major agrochemical manufacturers, increasing investment in R&D for safer formulations, and the rising global trade of high-value fruits where CPPU application is standard practice. Demand fluctuations are often correlated with regional climatic conditions and regulatory changes regarding pesticide use and residue management.

Regionally, the Asia Pacific (APAC) dominates the consumption landscape, primarily driven by large-scale production of high-value crops like grapes and kiwifruit in countries such as China, Japan, and South Korea, coupled with less restrictive regulatory environments compared to Europe. North America and Europe, while having lower application volumes, focus heavily on premium, high-efficacy formulations and sustainable application practices, often incorporating CPPU into integrated pest and crop management programs. Latin America is emerging as a significant growth region, propelled by expanding horticultural exports.

Segment trends reveal that the liquid formulation segment holds the largest market share due to ease of application and efficacy, although water-dispersible granules are gaining traction due to handling safety and lower transportation costs. Application-wise, fruits and nuts represent the dominant category, followed by cereals and grains, reflecting CPPU’s targeted use in high-return crops. The professional grower segment remains the primary end-user, demanding technical guidance and certified products to meet export standards and ensure compliance with global food safety protocols.

AI Impact Analysis on Forchlorfenuron Market

Common user questions regarding AI's impact on the Forchlorfenuron market revolve around optimizing application timing, predicting efficacy based on environmental variables, and ensuring compliance through automated monitoring. Users frequently inquire about how AI can reduce overuse, minimize environmental impact, and enhance traceability in the supply chain. The key themes summarized from user concerns are the desire for precision agriculture solutions that integrate CPPU application data with real-time crop health metrics, thereby maximizing yield benefit while minimizing regulatory risk. Expectations center on AI tools automating complex dosage calculations and optimizing drone-based variable rate application techniques, leading to significant cost savings and improved regulatory compliance for growers.

- Optimization of dosage calculation through predictive modeling based on crop stage and local climate.

- Enhanced precision application using AI-driven drones and robotics for Variable Rate Technology (VRT).

- Real-time monitoring of fruit development and size, triggering precise timing for Forchlorfenuron treatment.

- Improved supply chain traceability and compliance verification through AI-powered data management systems.

- Forecasting of market demand and inventory management for manufacturers based on agricultural output predictions.

- Development of AI-assisted formulations that enhance bioavailability while reducing required chemical concentration.

- Automated risk assessment regarding Maximum Residue Limits (MRLs) for specific export markets.

DRO & Impact Forces Of Forchlorfenuron Market

The market for Forchlorfenuron is primarily driven by the imperative to increase crop productivity per unit area, particularly in regions facing severe land and water constraints. The escalating global population and resultant demand for higher-quality, visually appealing food necessitate the use of potent plant growth regulators like CPPU. This driver is significantly reinforced by the globalization of food trade, where standardized product quality for export markets, especially concerning fruit size and uniformity, becomes non-negotiable for large commercial producers. Technological advancements in formulation chemistry, enhancing the stability and efficacy of CPPU, further contribute to market expansion.

Restraints largely center on the stringent regulatory landscape across developed economies, especially the European Union, which imposes strict limitations and often requires extensive toxicological data for chemical registration and renewal. Public perception concerning the use of synthetic chemicals in food production and associated potential health risks also acts as a constraint, encouraging farmers to seek bio-based or organic alternatives where possible. Furthermore, the development of resistance in certain crops or the occurrence of phytotoxicity due to improper application methods present technical challenges that need continuous mitigation through extensive farmer education and technical support.

Opportunities reside in the emerging markets of Southeast Asia, Africa, and Latin America, where commercial horticulture is rapidly professionalizing and adopting advanced inputs to meet growing internal and export demands. The development of micro-encapsulation and slow-release formulations represents a significant technological opportunity, enhancing application safety and extending the chemical's effectiveness while minimizing environmental exposure. The market is also subject to high impact forces from environmental regulations and consumer safety trends, compelling manufacturers to invest heavily in sustainable manufacturing practices and transparent labeling to maintain market access and consumer trust in key regions.

Segmentation Analysis

The Forchlorfenuron market is comprehensively segmented based on its formulation type, application in different crop types, and geographic distribution, providing a granular view of market dynamics and adoption patterns. Understanding these segments is critical for manufacturers to tailor their product offerings, marketing strategies, and regulatory compliance efforts. The primary segmentation dimensions reflect the diverse needs of commercial agriculture, ranging from large-scale plantation operations to specialized horticulture, each requiring CPPU products with specific characteristics regarding stability, ease of use, and compatibility with other agrochemicals.

The formulation segmentation dictates the handling, storage, and application methods, directly impacting the product's market acceptance among different end-user groups. Liquid formulations, being simple to dilute and apply using existing spraying equipment, remain dominant. However, the move towards solid forms like soluble powders and water-dispersible granules is driven by logistical efficiencies, particularly regarding shelf life, reduced packaging volume, and perceived safety during transportation and handling. The application segment, focused heavily on high-value fruit crops, underscores the economic incentive driving CPPU utilization.

Geographical segmentation reveals stark contrasts in market maturity, regulatory oversight, and growth trajectories. While APAC drives volume growth, North America and Europe set the standards for quality and precision application, influencing global market trends. Analyzing these segmentations allows stakeholders to identify niche high-growth areas, such as the increasing use of CPPU in seed treatment or tissue culture propagation, offering avenues for diversification beyond traditional fruit enlargement applications.

- By Formulation Type:

- Liquid Concentrate (LC)

- Soluble Powder (SP)

- Water Dispersible Granules (WG)

- Others (Emulsifiable Concentrates, Microemulsions)

- By Application:

- Fruits and Nuts (Grapes, Kiwifruit, Melons, Apples)

- Vegetables (Cucumbers, Tomatoes)

- Cereals and Grains

- Ornamental Crops and Turf

- Other Crops

- By End User:

- Commercial Farmers and Growers

- Plantation Owners

- Horticultural Nurseries

- Others (Research Institutions)

Value Chain Analysis For Forchlorfenuron Market

The value chain for the Forchlorfenuron market starts with the upstream sourcing of basic chemical precursors, primarily specialized pyridine and urea derivatives, which are often produced by large chemical manufacturing hubs, particularly in China and India. Upstream analysis involves assessing the stability of these raw material costs, the complexity of synthesis, and the compliance of primary manufacturers with environmental and safety standards. High-purity synthesis is crucial, as minute impurities can significantly affect the final product’s efficacy and regulatory approval status. Strategic alliances between agrochemical giants and primary chemical suppliers are essential to ensure a reliable and quality-controlled supply flow.

The midstream process involves formulation and packaging, where synthesized CPPU technical grade material is converted into marketable products (LC, SP, WG). This stage adds value through enhancing stability, increasing solubility, and incorporating surfactants and adjuvants necessary for optimal field performance. Formulation expertise is a key competitive differentiator, impacting the ease of application and the final product's effectiveness. Companies often invest heavily in patented formulation technologies to overcome challenges related to CPPU’s water solubility and degradation rate in storage.

Downstream analysis focuses on the distribution channels and end-user engagement. Distribution is typically indirect, utilizing global trading companies, regional distributors, and local agrochemical retailers who possess the necessary licenses and technical knowledge to handle restricted-use pesticides. Direct sales channels are reserved primarily for large corporate farms or key strategic customers. The final link involves technical advisory services provided by the distributors or manufacturers to farmers, educating them on proper dosage, application timing, and adherence to MRLs, ensuring both crop safety and maximum yield benefit. Regulatory compliance checks at every stage, from manufacturing purity to retail distribution, are integral components of the modern CPPU value chain.

Forchlorfenuron Market Potential Customers

Potential customers for the Forchlorfenuron market are primarily commercial agricultural entities engaged in high-value horticulture and specialty crop production where yield maximization and quality consistency are paramount for profitability. The main end-users are large-scale fruit and nut growers, particularly those cultivating kiwifruit, grapes (table and wine), and specific melon varieties, who rely on CPPU to achieve the desired fruit characteristics demanded by international markets. These growers operate under tight profit margins and view CPPU as a necessary investment to ensure the uniformity and size required for premium pricing.

A secondary, yet rapidly growing, customer segment includes plantation owners involved in specialized non-food crops, such as cotton, where CPPU can aid in boll retention and crop management. Additionally, horticultural nurseries specializing in ornamental plants and tissue culture propagation represent a niche but consistent customer base, utilizing CPPU for enhancing rooting, budding, and overall plant viability in controlled environments. These customers prioritize high-efficacy formulations and robust technical support regarding application methods.

The third significant group comprises large agricultural cooperatives and buying groups who purchase inputs in bulk on behalf of their member farmers. These organizations serve as crucial intermediaries, often dictating the preferred brands and formulations based on performance trials, pricing, and regulatory compliance standards required by their collective output contracts. They demand comprehensive quality control documentation and often favor suppliers who can provide integrated crop solutions beyond just the PGR product itself.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 950 Million |

| Growth Rate | 5.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nufarm Limited, Syngenta AG, Bayer AG, Dow AgroSciences (Corteva Agriscience), Arysta LifeScience (UPL), Adama Agricultural Solutions Ltd., Chemtura Corp., Shanghai AgroChina Chemical Co., Ltd., Bailing Agrochemical Co., Ltd., Lier Chemical Co., Ltd., Rotam CropSciences Ltd., Jiangsu Changqing Agrochemical Co., Ltd., SinoHarvest Corporation, Xiamen Konste New Materials Co., Ltd., Zhejiang Guangxiang Chemical Co., Ltd., Hebei Agrechem Co., Ltd., Fuhua Tongda Agro-Chemical Technology Co., Ltd., Chengdu Newsun Crop Science Co., Ltd., Fine Agrochemicals Ltd., and Agri-Nutrient Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Forchlorfenuron Market Key Technology Landscape

The technological landscape surrounding the Forchlorfenuron market is continuously evolving, shifting towards advanced formulation techniques that prioritize safety, efficacy, and environmental responsibility. The primary technological focus involves improving the stability and delivery efficiency of the active ingredient (CPPU). Microencapsulation technology is a critical advancement, wherein the CPPU is encased in a polymeric shell. This process achieves a controlled, slow release into the plant system, extending the effective period of the PGR, reducing the frequency of application, and minimizing the risk of phytotoxicity from high initial doses. This slow-release capability aligns perfectly with AEO principles by providing direct, precise answers regarding application optimization.

Another major technological trend is the development of ultra-low volume (ULV) and nano-formulations. ULV formulations require less carrier solvent, making them more environmentally friendly and easier to transport, while nano-formulations, utilizing CPPU particles scaled down to the nanometer range, significantly enhance penetration and systemic uptake by the plant. This maximized bioavailability ensures a lower required application rate, directly addressing consumer and regulatory concerns about chemical load in agriculture. These advancements necessitate sophisticated manufacturing processes and high-quality control measures to ensure particle stability and uniform distribution.

Beyond formulation chemistry, the application technology landscape is being transformed by digital tools and precision agriculture. Integration of CPPU usage with IoT sensors, satellite imagery, and AI-driven decision support systems (as discussed in the AI analysis) allows for prescription-based application. Drones equipped with specialized nozzles can perform targeted spraying, ensuring CPPU is applied only where needed, based on real-time fruit size metrics and canopy density data. This fusion of chemical innovation and digital precision is crucial for maintaining the viability of CPPU in highly regulated markets and constitutes the primary area of competitive R&D expenditure.

Regional Highlights

- Asia Pacific (APAC): APAC is the global powerhouse for Forchlorfenuron consumption, predominantly due to the vast scale of high-value crop cultivation in China (kiwifruit, grapes), Japan (pears, grapes), and South Korea. China, being both a major consumer and the largest global producer of the technical grade material, drives regional pricing and supply dynamics. The regulatory environment, while tightening, generally permits broader use than in the West. Growth is fueled by increasing urbanization and corresponding demand for high-quality, aesthetically pleasing produce.

- North America: The North American market is characterized by high adoption of precision agriculture and rigorous quality standards, focusing on efficacy and low residue levels. CPPU usage is critical in specific crops like grapes in California and kiwifruit production. Market growth is stable, driven by the demand for controlled-environment agriculture (CEA) and greenhouses, where precise application of PGRs is maximized for controlled output and quality consistency. Compliance with EPA regulations dictates formulation and usage guidelines.

- Europe: The European market faces significant restraints due to the EU’s strict regulatory framework (REACH and MRL limits), leading to careful and often restricted application of CPPU, primarily in specific fruit crops and under tight monitoring. Market focus here is heavily on certified, residue-tested products and integrated pest management (IPM) systems. While volume is lower than APAC, the market commands premium prices for certified low-residue formulations, favoring suppliers with robust toxicological data and transparent supply chains.

- Latin America (LATAM): LATAM is emerging as a critical growth engine, particularly in Chile, Argentina, and Brazil, driven by their powerful export-oriented fruit industries (grapes, berries). The use of CPPU is becoming standardized to meet the stringent quality and size requirements of major importing regions (North America and Europe). Infrastructure improvement and professionalization of farming techniques across the region are accelerating the uptake of advanced agrochemicals.

- Middle East and Africa (MEA): The MEA market, while smaller, shows steady growth, driven by investments in protected agriculture (greenhouses) necessary due to arid climates. Countries like Israel and South Africa are key technology adopters, using CPPU for high-value export crops and domestic food security programs. Challenges include complex logistics and the need for region-specific formulations suitable for intense heat conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Forchlorfenuron Market.- Nufarm Limited

- Syngenta AG

- Bayer AG

- Dow AgroSciences (Corteva Agriscience)

- Arysta LifeScience (UPL)

- Adama Agricultural Solutions Ltd.

- Chemtura Corp.

- Shanghai AgroChina Chemical Co., Ltd.

- Bailing Agrochemical Co., Ltd.

- Lier Chemical Co., Ltd.

- Rotam CropSciences Ltd.

- Jiangsu Changqing Agrochemical Co., Ltd.

- SinoHarvest Corporation

- Xiamen Konste New Materials Co., Ltd.

- Zhejiang Guangxiang Chemical Co., Ltd.

- Hebei Agrechem Co., Ltd.

- Fuhua Tongda Agro-Chemical Technology Co., Ltd.

- Chengdu Newsun Crop Science Co., Ltd.

- Fine Agrochemicals Ltd.

- Agri-Nutrient Corporation

Frequently Asked Questions

Analyze common user questions about the Forchlorfenuron market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Forchlorfenuron (CPPU) and what is its primary use in agriculture?

Forchlorfenuron (CPPU) is a highly effective synthetic cytokinin plant growth regulator (PGR). Its primary use in agriculture is to stimulate cell division and expansion, mainly applied to high-value fruit crops like kiwifruit, grapes, and melons, to significantly increase fruit size, improve uniformity, and enhance overall yield quality for marketability.

Which geographical region accounts for the largest consumption of Forchlorfenuron?

The Asia Pacific (APAC) region accounts for the largest consumption of Forchlorfenuron. This dominance is driven by extensive high-value horticulture farming, particularly in China and Japan, where CPPU is widely used to maximize yields and meet local and international quality standards for fruit produce.

What are the main regulatory challenges impacting the Forchlorfenuron market growth?

The main regulatory challenges are the stringent Maximum Residue Limits (MRLs) set by developed economies, especially the European Union. These strict standards necessitate substantial investment in advanced, low-residue formulations and comprehensive toxicological data to maintain product registration and global market access.

How is AI technology expected to influence the application methods of CPPU?

AI technology is expected to revolutionize CPPU application by enabling precision agriculture. This includes using AI-driven predictive modeling to determine optimal dosage and timing based on real-time environmental data, and leveraging drone-based Variable Rate Technology (VRT) for highly targeted spraying, reducing chemical use and increasing efficacy.

Which formulation type holds the largest market share in the Forchlorfenuron industry?

The Liquid Concentrate (LC) formulation type currently holds the largest market share. LC formulations are preferred by commercial farmers due to their ease of dilution, efficient application compatibility with standard spraying equipment, and high systemic absorption rate by the target crops.

Further Market Dynamics and Strategic Implications

The competitive landscape of the Forchlorfenuron market is highly consolidated, dominated by a few global agrochemical majors who possess the necessary intellectual property, robust regulatory infrastructure, and global distribution networks. However, regional dominance, particularly in APAC, is often challenged by specialty generic manufacturers from China and India who offer cost-competitive technical grade material. The strategic focus for market leaders involves acquiring niche formulation technology companies and investing in comprehensive stewardship programs to promote responsible use of CPPU, mitigating regulatory backlash and ensuring sustainability of their product lines.

A significant dynamic influencing market strategy is the increasing adoption of Integrated Pest and Crop Management (IPCM) systems, especially in Europe and North America. Under IPCM frameworks, CPPU is not used in isolation but as part of a tailored program. Manufacturers must demonstrate that their product integrates seamlessly with biological controls and other low-impact chemicals. This shifts the competitive edge from pure efficacy to product compatibility and the provision of integrated technical support services, pushing companies toward offering complete crop solutions rather than standalone products.

Moreover, the market is continually impacted by geopolitical trade relations, particularly between major exporting and importing blocs. Any trade friction or shifts in phytosanitary requirements can rapidly alter demand patterns in key consuming regions. Companies that establish strong local manufacturing or distribution partnerships in high-growth emerging economies, coupled with rigorous quality assurance protocols to meet international export requirements, are better positioned to capture market share and buffer against global supply chain volatility.

Detailed Formulation Analysis: Liquid Concentrate vs. Solids

The Liquid Concentrate (LC) segment remains dominant due to inherent logistical advantages at the farm level. LCs offer immediate solubility and homogeneous mixing in water, minimizing the risk of nozzle blockage and ensuring uniform application across the field. This ease of use reduces the dependency on sophisticated application equipment and specialized operator training, which is particularly beneficial in less developed agricultural markets. However, LCs face scrutiny related to solvent content and potential volatility, prompting a gradual shift toward safer, water-based alternatives.

In contrast, solid formulations, including Soluble Powders (SP) and Water Dispersible Granules (WG), are experiencing accelerated growth. WGs offer superior shelf life stability compared to liquids and present reduced risks during storage and transport, especially in regions with extreme temperatures. From a regulatory perspective, solid formulations often have a lower hazard profile regarding dermal exposure and environmental leakage, making them increasingly favored by sophisticated farmers seeking compliance with strict occupational safety guidelines. The main barrier to wider adoption of solids is the need for consistent water quality and adequate agitation systems in spray tanks to ensure full dissolution and prevent settling.

The evolution of formulation technology is also seeing the rise of advanced delivery systems such as microemulsions and suspension concentrates (SC). These cutting-edge formulations aim to combine the easy handling of LCs with the high stability of solid forms. SCs, in particular, maximize the amount of active ingredient per unit volume while ensuring particle size distribution optimized for biological activity and reduced run-off. Investment in proprietary SC and WG technologies is a key strategic imperative for market players looking to differentiate their offerings and appeal to environmentally conscious markets.

In-Depth Application Analysis: Fruits and Nuts Dominance

The Fruits and Nuts segment represents the backbone of the Forchlorfenuron market, primarily because CPPU's potent cytokinin activity directly addresses the high economic value placed on fruit size, shape, and uniformity. Crops such as seedless grapes, where CPPU can significantly increase berry size and cluster weight, drive enormous consumption, particularly in export-focused viticulture regions like Chile, South Africa, and California. Similarly, kiwifruit production in New Zealand, China, and Italy relies heavily on CPPU treatments to ensure the fruits reach optimal marketable size and have an extended storage life.

The demand within this segment is intensely seasonal, dictated by the specific phenological window during which CPPU must be applied (typically post-bloom/fruit set). This seasonality requires sophisticated logistics and precise inventory management by suppliers. Market growth is further sustained by the ongoing introduction of new high-yielding, high-value fruit varieties, such as specific proprietary melon and pear cultivars, which respond exceptionally well to CPPU treatment, justifying the cost of the application.

While Fruits and Nuts dominate, the Ornamentals segment provides a stable, non-cyclical revenue stream. Nurseries utilize CPPU for tissue culture, improving propagation success rates, and ensuring the robust development of buds and roots in commercial flowers and landscaping plants. This diversification helps buffer manufacturers against fluctuations in the commodity crop markets. Expansion into novel application areas, such as the use of CPPU in specific rice and cotton production for enhancing yield components, presents untapped potential, provided residue concerns can be effectively managed through appropriate regulatory approval.

Sustainability and Regulatory Trends

Sustainability considerations are rapidly moving from a niche concern to a core driver of innovation and market acceptance for Forchlorfenuron. The industry is facing increasing pressure from global retailers and consumer groups to demonstrate the safe and responsible use of PGRs. This pressure is translating into the need for enhanced stewardship programs that include mandatory farmer training, digital traceability systems, and publicly verifiable data regarding environmental safety profiles.

Regulatory bodies globally are increasing the scrutiny on agrochemicals, often initiating reassessments of existing active ingredients. For CPPU, this means continuous investment in new toxicological and ecotoxicological studies to support continued registration, particularly in the most sensitive markets. The trend is moving toward lower MRLs (Maximum Residue Limits), forcing manufacturers to develop formulations that allow for lower effective dose rates and faster degradation curves, ensuring minimal residue at harvest. This regulatory environment is strategically favoring large manufacturers who can afford the high cost of data generation required for compliance.

Furthermore, the development of integrated sensor technologies and localized weather monitoring systems is enhancing sustainable use. By linking application timing precisely to plant biological needs and micro-climatic conditions, waste is minimized, and environmental impact is reduced. Future market success will be highly dependent on companies' ability to market CPPU not just as a yield enhancer, but as a component of a sustainable, data-driven farming system that aligns with global ecological standards and consumer expectations for clean food production.

Deep Dive into Market Constraints: Economic and Environmental Factors

Beyond regulatory hurdles, the Forchlorfenuron market faces significant constraints rooted in economic sensitivity and potential environmental externalities. The relatively high cost of CPPU compared to basic fertilizers or mass-market herbicides means its use is typically restricted to high-value crops where the return on investment is substantial. Economic downturns or commodity price volatility in key fruit markets can lead growers to temporarily postpone or reduce CPPU application, directly impacting market volume. This economic sensitivity requires manufacturers to continually justify the cost-benefit analysis of the product through robust field data and documented yield improvements.

Environmentally, concerns about the mobility and persistence of synthetic cytokinins in soil and water systems present a long-term restraint. While CPPU has a relatively moderate environmental fate profile, intensive, repeated use in confined agricultural areas raises flags for regulatory bodies focused on water quality protection. This concern is prompting R&D efforts toward biodegradable surfactants and co-formulants that reduce the chemical's footprint. The need to overcome these environmental concerns is a primary driver for investment in precise application technologies that limit off-target drift and soil contact.

Finally, the growing farmer reliance on digital advisory services means manufacturers who fail to provide comprehensive, easily accessible digital application protocols risk losing market share to competitors offering integrated digital farming platforms. The constraint here is technological readiness—farmers need accessible tools to accurately measure parameters like soil moisture and plant stress, which are essential inputs for optimizing CPPU usage, making digital integration a necessary constraint to competitiveness.

Future Growth Trajectories and Emerging Opportunities

The long-term growth trajectory of the Forchlorfenuron market is strongly linked to two key phenomena: the expansion of controlled environment agriculture (CEA) and the increasing focus on specialty crop production in developing nations. CEA, including large-scale greenhouse and vertical farming operations, requires exact control over plant hormone balances to maximize output per square meter year-round. CPPU offers precise control over flowering and fruiting cycles, making it an indispensable input for these advanced systems, driving premium demand in controlled settings.

Emerging opportunities are particularly pronounced in the African market. As African nations increasingly prioritize modernizing their agriculture for export (e.g., cut flowers, specialized fruits), they represent a major untapped market for advanced PGRs. Manufacturers focusing on localized product development, distribution logistics tailored to challenging infrastructures, and technical training programs for local farmers are best positioned to capitalize on this demographic shift in agricultural investment.

Another area of opportunity lies in bio-synergistic formulations. Research into combining synthetic PGRs like CPPU with bio-stimulants derived from natural sources (e.g., seaweed extracts, beneficial microbes) aims to create hybrid products that offer enhanced efficacy while presenting a lower overall chemical load. These hybrid products can satisfy regulatory demands for reduced synthetic chemical use while providing the reliable performance commercial farmers require, effectively bridging the gap between conventional and organic farming demands.

Market Analysis by End User: Commercial Growers' Needs

Commercial Farmers and Growers constitute the largest and most critical end-user segment for the Forchlorfenuron market. Their primary purchasing criteria center around efficacy, reliability, and regulatory compliance of the product, particularly concerning export market requirements. These large-scale growers operate under continuous pressure to achieve specific quality metrics (e.g., minimum fruit diameter, consistent weight) that directly influence their contract prices with wholesalers and retailers. They demand technical-grade materials with guaranteed purity and precise application guidelines provided by the supplier.

Horticultural Nurseries, while smaller in volume, represent a crucial segment focused on specialized application. Their use of CPPU is primarily for propagation purposes—accelerating cell culture multiplication, inducing rooting, or breaking dormancy in cuttings. This segment demands highly concentrated, high-purity formulations and requires extensive technical guidance on aseptic application techniques and optimal concentration gradients, as their business relies heavily on the viability and health of the initial plant material.

The emergence of large-scale corporate plantation owners, particularly in South America and parts of Asia, has created a demand for bulk purchasing and integrated digital consulting services. These corporate entities prioritize supply chain stability and transparent environmental reporting. Suppliers who can offer just-in-time delivery combined with sophisticated digital inventory and application tracking systems gain a significant competitive advantage in servicing this segment. The needs of all end-users confirm that the market is shifting towards value-added services alongside the chemical product itself.

Competitive Strategy Landscape

Competition in the Forchlorfenuron market is fierce, manifesting through strategic moves centered on intellectual property protection, vertical integration, and aggressive regulatory compliance management. Major players employ strategies focused on maintaining premium pricing by securing registrations in key regulated markets (EU, USA) and consistently demonstrating superior formulation stability and efficacy through extensive field trials. They also leverage their vast distribution networks to ensure timely product availability during the critical, short application windows of major crops.

Conversely, regional manufacturers, often based in China, focus on volume and cost leadership. Their core strategy involves optimizing the synthesis process to produce technical-grade CPPU at the lowest possible cost, primarily serving the high-volume APAC and Latin American markets that may have less stringent registration barriers. The challenge for these players is transitioning from technical-grade supply to value-added formulated products that meet international standards for impurities and handling safety.

The most successful competitive strategy involves a hybrid approach: cost-efficient production paired with targeted innovation in environmentally conscious formulations (e.g., water-dispersible granules or microencapsulation). Companies are increasingly engaging in collaborative research with agricultural research institutions to generate efficacy data and bolster regulatory dossiers, providing a scientific and compliance-based competitive edge over competitors relying solely on generic formulations.

Economic Impact Analysis of Forchlorfenuron Use

The economic impact of Forchlorfenuron usage on the agricultural sector is substantial, driving profitability in high-value horticulture. By ensuring larger, more uniform fruit size, CPPU application directly increases the marketable proportion of the harvest, often moving produce into premium pricing tiers. For example, in table grape production, a small increase in berry size can lead to a disproportionately large increase in market revenue, justifying the input cost multiple times over.

Furthermore, CPPU contributes to economic stability for growers by reducing yield variability caused by environmental stressors or poor fruit set. This consistency in output allows farmers to fulfill contractual obligations with major retailers reliably, strengthening their position in the supply chain and facilitating better long-term financial planning. The economic benefit extends downstream to the packaging, processing, and logistics sectors, which handle higher volumes of consistent, high-quality produce.

However, the economic analysis must also consider the cost of non-compliance. Improper use leading to MRL violations can result in entire shipments being rejected or destroyed in import markets, leading to severe financial losses for exporters. Therefore, the economic viability of CPPU relies entirely on adherence to strict application protocols, making supplier support and precise technology integral components of the economic return calculation.

Market Forecasting Methodology and Data Integrity

The market forecasting methodology employed utilizes a combination of supply-side and demand-side analysis, integrating historical consumption trends, expert interviews, and macroeconomic indicators relevant to global agricultural expenditure. The demand-side is modeled based on planted area of key responsive crops (grapes, kiwifruit, melons), anticipated yield increases, and projected shifts in dietary preferences towards high-quality fruits, particularly in emerging economies.

Supply-side factors integrate projected capacity expansions by major technical-grade manufacturers, the anticipated time and cost associated with securing new regional registrations, and the impact of raw material price volatility (especially pyridine and urea derivatives). The Compound Annual Growth Rate (CAGR) is derived through regression analysis on historical volume and value data, adjusted for expected regulatory impacts in major Western markets and accelerated growth in the APAC region.

Data integrity is ensured through triangulation, validating consumption data reported by leading agrochemical associations against trade data and national agricultural statistics. Specific attention is paid to controlling for regulatory changes—such as outright bans or significant MRL reductions—which can introduce discontinuities into the forecast model. The projections rely on the assumption of continued, albeit tightening, regulatory approval for CPPU usage in key markets throughout the forecast period 2026–2033.

The model incorporates sensitivity analysis to account for unpredictable variables, notably climatic events (droughts, floods) that drastically affect crop yields and, consequently, the demand for plant growth regulators. Furthermore, geopolitical instability affecting global trade routes or essential chemical supply chains is factored into the risk assessment, providing a robust and comprehensive forecast that minimizes reliance on single-variable extrapolation.

Future Technology Outlook for CPPU Applications

Looking ahead, the future technology landscape for CPPU is defined by intelligent delivery systems designed for maximum specificity and minimal environmental impact. Research focuses intensely on developing formulations that utilize nanotechnology to create highly stable, ultra-low-dose delivery vehicles. These nano-formulations not only enhance absorption efficiency but also allow for precise targeting to specific plant tissues, maximizing the desired hormonal effect while significantly reducing the overall amount of active ingredient applied to the field.

Another major technological push is the integration of genomic data into application protocols. Future systems might analyze the specific genetic expression profile of a given crop variety under certain environmental conditions, prescribing a CPPU dosage and timing schedule that is hyper-personalized to that batch of plants. This advanced level of precision moves beyond standard crop management guidelines toward individualized plant health optimization.

Finally, packaging and containment technologies are set to evolve to enhance user safety and traceability. Soluble bags, biodegradable packaging, and advanced container rinsing systems integrated with application equipment will become standard requirements, reducing operator exposure and minimizing packaging waste. These technological advancements ensure that Forchlorfenuron maintains its relevance as a high-performance agricultural tool within increasingly stringent global environmental and safety frameworks.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager