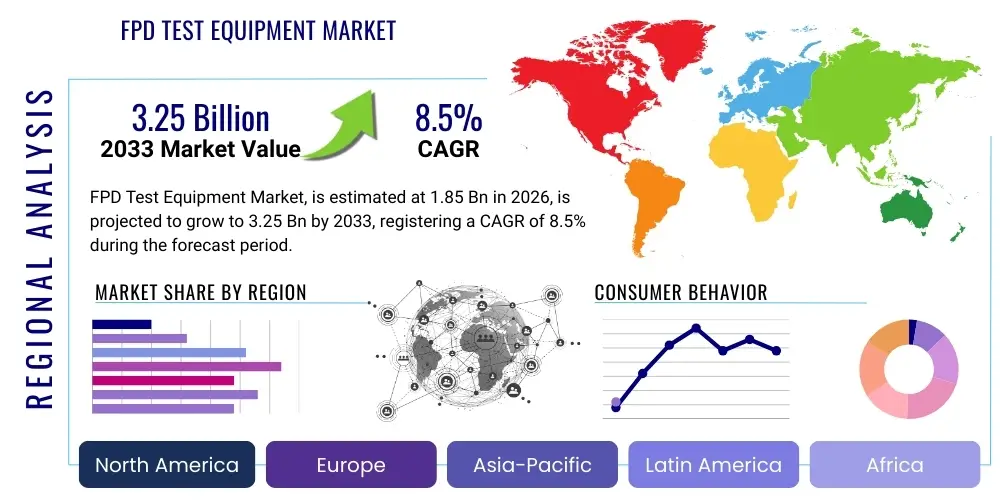

FPD Test Equipment Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440090 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

FPD Test Equipment Market Size

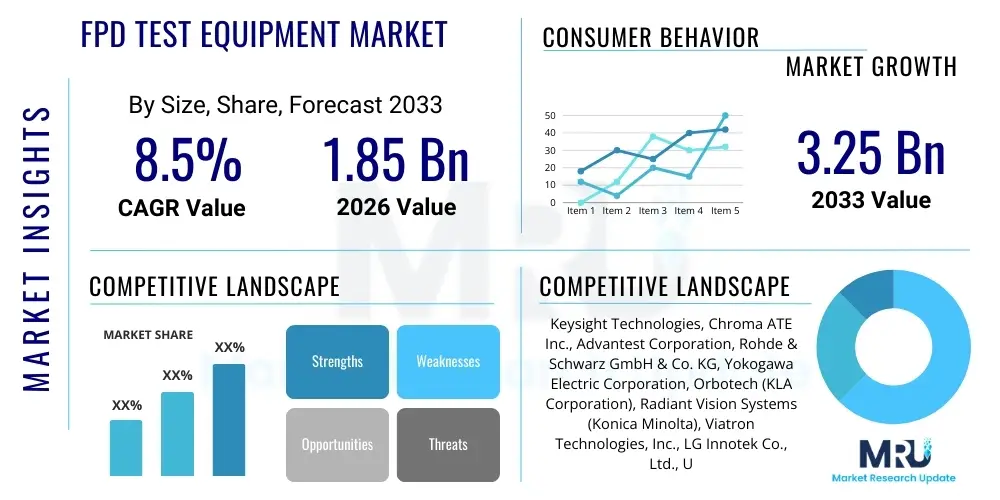

The FPD Test Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 1.85 billion in 2026 and is projected to reach USD 3.25 billion by the end of the forecast period in 2033. This growth trajectory is fueled by the relentless demand for high-quality, advanced flat panel displays across numerous consumer and industrial applications, necessitating sophisticated and precise testing solutions to ensure product performance and reliability.

The continuous innovation in display technologies, including the widespread adoption of OLED, Mini-LED, and the emergence of Micro-LED, mandates increasingly complex and specialized test equipment. Manufacturers are investing heavily in research and development to address evolving display characteristics such such as higher resolutions, faster refresh rates, improved color accuracy, and flexible form factors. This technological arms race directly translates into a surging demand for cutting-edge inspection, measurement, and functional testing apparatus designed to meet these rigorous specifications, thereby underpinning the market's robust expansion over the coming years.

FPD Test Equipment Market introduction

The FPD Test Equipment market encompasses a wide array of specialized machinery and systems designed to inspect, measure, and verify the performance and quality of Flat Panel Displays (FPDs) at various stages of their manufacturing process. Flat panel displays, which include Liquid Crystal Displays (LCDs), Organic Light Emitting Diodes (OLEDs), Mini-LEDs, Micro-LEDs, and Quantum Dot Displays, are critical components in almost all modern electronic devices. The equipment ensures that these displays meet stringent quality standards, detect defects, and validate optical and electrical characteristics before integration into final products.

These sophisticated testing solutions are crucial for maintaining high production yields, reducing manufacturing costs associated with defects, and guaranteeing the superior visual experience consumers expect. Major applications span across consumer electronics like smartphones, tablets, televisions, and laptops, as well as specialized segments such as automotive infotainment systems, medical imaging devices, industrial control panels, and emerging wearable technologies. The benefits derived from FPD test equipment are manifold, including enhanced product reliability, improved display performance, expedited time-to-market for new display technologies, and robust quality control throughout the entire production lifecycle.

The market is primarily driven by several key factors. Firstly, the escalating global demand for advanced displays with higher resolutions, brighter colors, and innovative form factors (e.g., foldable, rollable) continuously pushes the boundaries of testing requirements. Secondly, the rapid evolution of display technologies themselves, particularly the transition from traditional LCDs to more complex OLED and Micro-LED structures, necessitates new, more precise, and versatile testing methodologies. Thirdly, the increasing automation in manufacturing processes and the drive for greater efficiency and yield optimization compel manufacturers to invest in advanced, automated test equipment. Finally, the intensifying competition among display manufacturers to deliver defect-free products further stimulates the adoption of comprehensive FPD test solutions.

FPD Test Equipment Market Executive Summary

The FPD Test Equipment market is experiencing dynamic shifts influenced by overarching business trends, distinct regional developments, and specific segment performances. Business trends are characterized by a strong push towards automation and integration of advanced analytics, including Artificial Intelligence (AI) and Machine Learning (ML), to enhance testing speed, accuracy, and predictive maintenance capabilities. Manufacturers are increasingly seeking integrated solutions that can handle multiple testing parameters simultaneously, reducing cycle times and improving overall operational efficiency. There is also a notable trend towards customization, with test equipment providers developing tailor-made solutions for specific display technologies or unique production line requirements, reflecting the diverse and evolving needs of display panel manufacturers.

Regionally, the Asia Pacific (APAC) continues to dominate the FPD Test Equipment market, largely due to the concentration of major display panel manufacturing hubs in countries like South Korea, China, Taiwan, and Japan. This region is not only a primary production base but also a significant hub for research and development in display technologies, driving substantial investment in cutting-edge testing solutions. While North America and Europe represent smaller manufacturing bases for mass-produced FPDs, they remain crucial markets for high-end, specialized display applications and advanced R&D activities, focusing on innovation in micro-LEDs, augmented reality (AR), and virtual reality (VR) display testing. Emerging economies in Latin America and the Middle East and Africa are showing nascent growth, driven by increasing consumer electronics adoption and local manufacturing initiatives.

Segment-wise, the market is seeing pronounced growth in equipment designed for OLED and Mini-LED display testing, reflecting the widespread adoption of these technologies in premium smartphones, televisions, and IT products. Electrical test equipment, which measures parameters such as luminance, chromaticity, uniformity, and defect detection, continues to hold a significant share due to its foundational role in quality control. Optical test equipment, essential for assessing visual performance and ensuring image quality, is also witnessing robust demand, particularly with the advent of higher resolution and more intricate pixel structures. Functional test equipment, which simulates real-world usage scenarios, is becoming increasingly critical for complex displays with embedded touch sensors and advanced features, emphasizing the need for comprehensive validation across the entire display functionality spectrum.

AI Impact Analysis on FPD Test Equipment Market

User inquiries regarding AI's influence on the FPD Test Equipment market often revolve around its potential to revolutionize efficiency, precision, and data analysis in display manufacturing. Common questions highlight concerns about how AI can mitigate human error, accelerate defect detection, and manage the ever-increasing complexity of modern display technologies. Users are eager to understand how AI will transition testing from reactive fault identification to proactive predictive maintenance and yield optimization. There's also significant interest in AI's capacity to handle massive datasets generated during testing, transforming raw data into actionable insights for process improvement and quality enhancement. The overarching theme is the expectation that AI will deliver smarter, faster, and more autonomous testing solutions.

The integration of Artificial Intelligence into FPD test equipment marks a transformative shift, moving beyond traditional rule-based inspection to intelligent, adaptive, and predictive testing methodologies. AI algorithms, particularly those based on machine learning and deep learning, are enabling test systems to analyze complex visual patterns, identify subtle defects that human inspectors might miss, and even predict potential failures based on historical data. This capability significantly enhances the accuracy and reliability of defect detection, leading to higher manufacturing yields and a substantial reduction in false positives or negatives, which are critical for cost-sensitive high-volume production lines. Furthermore, AI-powered systems can learn from new defect patterns over time, continuously improving their detection capabilities without extensive reprogramming.

Beyond defect detection, AI is optimizing various aspects of the FPD testing process. Predictive analytics, driven by AI, allows for the early identification of equipment wear or drift, enabling proactive maintenance and minimizing costly downtime on production lines. AI also facilitates adaptive testing, where test parameters and sequences can be dynamically adjusted based on real-time data and product variations, ensuring optimal coverage and efficiency for diverse display types. The ability of AI to process and interpret vast amounts of test data quickly and accurately provides manufacturers with unparalleled insights into production bottlenecks, material quality issues, and process variations, thereby empowering data-driven decision-making for continuous process improvement and innovation in display technology.

- Enhanced defect detection accuracy through machine vision and deep learning algorithms.

- Accelerated testing cycles and improved throughput via automated pattern recognition and decision-making.

- Predictive maintenance for test equipment, reducing downtime and operational costs.

- Smart data analysis for root cause analysis and yield optimization in display manufacturing.

- Adaptive testing protocols that self-adjust to varying display specifications and production conditions.

- Reduced reliance on manual inspection, leading to greater consistency and reduced human error.

- Facilitation of complex testing for novel display technologies like Micro-LEDs and flexible OLEDs.

DRO & Impact Forces Of FPD Test Equipment Market

The FPD Test Equipment market is significantly shaped by a confluence of drivers, restraints, opportunities, and broader impact forces. Key drivers include the ever-increasing global demand for high-quality flat panel displays across consumer electronics, automotive, medical, and industrial sectors. The rapid evolution of display technologies, such as the widespread adoption of OLED, Mini-LED, and the emerging Micro-LED, necessitates more sophisticated, precise, and versatile testing solutions. Stringent quality control standards and the imperative for display manufacturers to achieve high production yields while minimizing defects further propel the demand for advanced test equipment. Additionally, the growing trend towards automation and Industry 4.0 initiatives in manufacturing processes pushes companies to invest in integrated, intelligent testing systems that enhance efficiency and reduce human intervention, thereby driving market expansion.

Conversely, several restraints impede the market's growth. The high capital investment required for acquiring and maintaining advanced FPD test equipment can be a significant barrier for smaller manufacturers or those with limited budgets. The rapid pace of technological obsolescence in both display and test equipment industries necessitates frequent upgrades, adding to operational costs and investment risks. Economic uncertainties and global supply chain disruptions, as seen recently, can also impact production schedules and investment decisions, thereby dampening market growth. Furthermore, the complexity of developing universal testing solutions for diverse and rapidly evolving display technologies poses a continuous challenge for equipment manufacturers, requiring substantial R&D expenditure and specialized expertise.

Despite these challenges, numerous opportunities exist for market players. The emergence of new display technologies like Micro-LEDs, flexible displays, transparent displays, and augmented/virtual reality (AR/VR) displays creates entirely new avenues for specialized test equipment development. The integration of IoT and AI/ML capabilities into test equipment presents opportunities for advanced analytics, predictive maintenance, and highly automated testing processes, delivering greater value to manufacturers. Expansion into new application areas for displays, such as smart home devices, digital signage, and advanced automotive cockpits, also broadens the potential customer base. Moreover, the increasing focus on sustainability and energy efficiency in display manufacturing may drive demand for test solutions that optimize power consumption and material usage, opening up niche market segments for innovative equipment providers.

Segmentation Analysis

The FPD Test Equipment market is comprehensively segmented to provide a detailed understanding of its diverse components and evolving dynamics. These segmentations are critical for market participants to identify specific growth areas, tailor product development, and refine market entry strategies. The market is primarily bifurcated by product type, reflecting the different functionalities of test equipment; by display type, acknowledging the varied requirements of distinct display technologies; by application, detailing the end-use industries driving demand; and by end-user, identifying the primary buyers of these sophisticated solutions. Each segment exhibits unique growth trajectories and technological requirements, influenced by industry trends and consumer preferences for display devices across the globe.

Understanding these segments allows for a granular analysis of market demand drivers and technological shifts. For instance, the rise of OLED and Mini-LED displays directly impacts the demand for specific optical and electrical test equipment capable of handling their unique pixel structures and performance characteristics. Similarly, the automotive sector's increasing adoption of advanced displays necessitates robust environmental and functional testing to ensure reliability under harsh conditions. This detailed segmentation analysis not only highlights current market leaders within specific niches but also reveals untapped opportunities and emerging areas of growth, enabling stakeholders to make informed strategic decisions and navigate the complex landscape of the FPD Test Equipment industry effectively.

- By Product Type:

- Electrical Test Equipment

- Optical Test Equipment

- Environmental Test Equipment

- Functional Test Equipment

- Module Test Equipment

- Repair Equipment

- Others (e.g., Burn-in Testers, Probe Stations)

- By Display Type:

- Liquid Crystal Display (LCD)

- Organic Light Emitting Diode (OLED)

- Mini-LED Displays

- Micro-LED Displays

- Quantum Dot Displays

- Flexible Displays

- Transparent Displays

- Others (e.g., E-paper)

- By Application:

- Smartphones and Tablets

- Televisions and Monitors

- Laptops and PCs

- Automotive Displays

- Wearable Devices

- Industrial and Medical Displays

- Signage and Public Displays

- Augmented Reality (AR) and Virtual Reality (VR) Devices

- Others (e.g., Avionics, Smart Home Appliances)

- By End-User:

- Display Panel Manufacturers

- Original Equipment Manufacturers (OEMs)

- Contract Manufacturers

- Research and Development Institutions

- Repair and Maintenance Service Providers

- Others

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For FPD Test Equipment Market

The value chain for the FPD Test Equipment market is a complex ecosystem involving various stages from upstream component suppliers to downstream end-users, highlighting the intricate dependencies within the industry. Upstream activities involve the procurement of highly specialized raw materials, sophisticated electronic components, precision optical elements, advanced sensors, and high-performance computing units. Key suppliers in this segment provide critical sub-systems such as high-resolution cameras, laser sources, motion control systems, robotics, and proprietary software platforms that form the core of modern test equipment. These suppliers are pivotal in dictating the technological capabilities and performance benchmarks of the final test solutions, necessitating strong collaborative relationships and robust supply chain management to ensure quality and timely delivery of components.

Midstream activities primarily encompass the design, engineering, manufacturing, assembly, and rigorous calibration of the FPD test equipment itself. This stage involves significant research and development efforts to innovate testing methodologies, integrate advanced technologies like AI and machine vision, and ensure compatibility with emerging display types. Equipment manufacturers often work closely with display panel manufacturers to customize solutions that meet specific production line requirements and evolving technological challenges. Furthermore, the testing and quality assurance of the test equipment itself are crucial to guarantee its accuracy, reliability, and longevity in demanding manufacturing environments, directly impacting the quality of the FPDs produced.

Downstream activities involve the distribution, installation, post-sales support, and maintenance of the FPD test equipment. Distribution channels are typically a mix of direct sales by the equipment manufacturers to large display panel producers and indirect channels through authorized distributors, system integrators, and value-added resellers for smaller clients or regional markets. Direct distribution allows for closer customer relationships, customization, and comprehensive service, while indirect channels provide broader market reach and localized support. Post-sales services, including calibration, preventative maintenance, software updates, and technical troubleshooting, are critical for ensuring the continuous optimal performance of the equipment and maintaining customer satisfaction throughout the lifecycle of the product. The efficiency and responsiveness of these downstream services significantly influence customer loyalty and repeat business in this specialized market.

FPD Test Equipment Market Potential Customers

The primary potential customers and end-users of FPD test equipment are the major global manufacturers of flat panel displays. These include large-scale producers of LCD, OLED, Mini-LED, and Micro-LED panels for various applications, such as Samsung Display, LG Display, BOE Technology, AU Optronics (AUO), Innolux, Japan Display Inc. (JDI), and China Star Optoelectronics Technology (CSOT). These companies operate extensive fabrication facilities (fabs) that require a vast array of electrical, optical, environmental, and functional test equipment at different stages of their production lines, from component inspection to final product validation. Their demand is driven by the sheer volume of display production, the imperative for high yield rates, and the need to maintain a competitive edge through superior display quality and innovation.

Beyond the core display panel manufacturers, Original Equipment Manufacturers (OEMs) of consumer electronics, automotive systems, and specialized industrial equipment also represent significant potential customers. While many OEMs source complete display modules, some engage in advanced R&D or component-level testing to ensure quality integration and performance in their final products. For instance, automotive OEMs investing heavily in advanced in-car displays may require specialized test equipment to validate display durability and functionality under extreme environmental conditions. Similarly, manufacturers of high-end medical devices or aerospace systems often demand stringent validation processes for their integrated displays, creating a niche market for custom testing solutions.

Furthermore, independent research and development institutions, universities, and contract manufacturing organizations (CMOs) that specialize in display technology innovation or component assembly also constitute an important customer segment. These entities utilize FPD test equipment for material characterization, prototype evaluation, and process optimization. Their demand is often for highly flexible and precise equipment capable of accommodating experimental designs and emerging display concepts. The increasing complexity of display technologies and the continuous drive for innovation across these varied customer groups ensure a consistent and evolving demand for sophisticated FPD test equipment solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.25 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Keysight Technologies, Chroma ATE Inc., Advantest Corporation, Rohde & Schwarz GmbH & Co. KG, Yokogawa Electric Corporation, Orbotech (KLA Corporation), Radiant Vision Systems (Konica Minolta), Viatron Technologies, Inc., LG Innotek Co., Ltd., UDT, Inc. (Universal Display Technology), Semiconductor Equipment and Materials International (SEMI), Eyelit Inc., TES Co., Ltd., Dongbu Lightec Co., Ltd., JFE Engineering Corporation, TOPPAN Forms Co., Ltd., Nikon Corporation, SCREEN Holdings Co., Ltd., Toray Engineering Co., Ltd., Hanmi Semiconductor Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

FPD Test Equipment Market Key Technology Landscape

The FPD Test Equipment market is characterized by a rapidly advancing technological landscape, driven by the relentless innovation in display panel manufacturing and the increasing demand for higher performance and more complex displays. A pivotal technology is high-resolution imaging and machine vision, which employs advanced cameras, sophisticated optics, and image processing algorithms to detect microscopic defects, measure pixel uniformity, and verify color accuracy with unparalleled precision. These systems are crucial for inspecting ultra-high-definition displays, including 4K and 8K resolutions, as well as the intricate pixel structures of OLED and Micro-LED panels, ensuring that every pixel functions as intended before reaching the consumer. The continuous improvement in sensor technology and computing power directly translates into more robust and efficient inspection capabilities.

Another significant technological advancement is the integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms into test equipment. AI-powered systems are revolutionizing defect classification, moving beyond predefined rules to intelligent pattern recognition and predictive analytics. These systems can learn from vast datasets of display images, differentiate between various types of defects (e.g., dead pixels, mura, foreign particles), and even identify subtle deviations that indicate potential future failures. This capability not only enhances the accuracy and speed of inspection but also enables adaptive testing, where the system can optimize test parameters dynamically based on real-time production data, leading to substantial improvements in yield management and overall operational efficiency on the production floor.

Furthermore, the market relies heavily on advanced spectroscopy and photodiode arrays for precise optical measurements, ensuring displays meet specific luminance, chromaticity, and contrast ratio specifications. Robotic automation and precision motion control systems are integral for handling delicate display panels during testing, enabling high throughput and minimizing human error. The increasing adoption of IoT connectivity allows test equipment to be integrated into larger factory automation networks, facilitating real-time data sharing, remote monitoring, and comprehensive big data analytics for process optimization. As display technologies become more flexible, transparent, and integrated into augmented reality (AR) and virtual reality (VR) applications, the development of specialized test methodologies and equipment tailored for these unique form factors and operational environments will continue to drive the technological evolution of this dynamic market.

Regional Highlights

- Asia Pacific (APAC): Dominates the FPD Test Equipment market due to the high concentration of major display panel manufacturing facilities in countries like South Korea, China, Taiwan, and Japan. This region is a global hub for both mass production and advanced R&D in display technology, driving significant investment in cutting-edge test solutions for LCD, OLED, Mini-LED, and Micro-LED production.

- North America: A key region for innovation and high-end display applications, particularly in R&D for advanced display technologies like Micro-LEDs, AR/VR displays, and specialized industrial and medical displays. While large-scale manufacturing is less prevalent, demand for sophisticated, custom-engineered test equipment remains strong, driven by technology development and niche market requirements.

- Europe: Characterized by strong R&D activities and a focus on high-quality, specialized displays for automotive, industrial, and medical sectors. European manufacturers demand highly precise and reliable test equipment to meet stringent quality and safety standards, particularly for displays integrated into critical systems.

- Latin America: An emerging market experiencing gradual growth driven by increasing consumer electronics adoption and some localized manufacturing initiatives. Demand for FPD test equipment is expected to rise as regional economies develop and attract more investment in display assembly and integration.

- Middle East and Africa (MEA): Currently a smaller market, but showing potential for growth due to increasing infrastructure development, urbanization, and growing consumer electronics penetration. As local manufacturing capabilities expand, particularly in assembly and integration, the need for FPD test equipment will correspondingly increase.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the FPD Test Equipment Market.- Keysight Technologies

- Chroma ATE Inc.

- Advantest Corporation

- Rohde & Schwarz GmbH & Co. KG

- Yokogawa Electric Corporation

- Orbotech (KLA Corporation)

- Radiant Vision Systems (Konica Minolta)

- Viatron Technologies, Inc.

- LG Innotek Co., Ltd.

- UDT, Inc. (Universal Display Technology)

- Semiconductor Equipment and Materials International (SEMI)

- Eyelit Inc.

- TES Co., Ltd.

- Dongbu Lightec Co., Ltd.

- JFE Engineering Corporation

- TOPPAN Forms Co., Ltd.

- Nikon Corporation

- SCREEN Holdings Co., Ltd.

- Toray Engineering Co., Ltd.

- Hanmi Semiconductor Co., Ltd.

Frequently Asked Questions

What are FPD test equipment and their primary function?

FPD test equipment are specialized systems used to inspect, measure, and verify the quality and performance of flat panel displays (LCD, OLED, Mini-LED, Micro-LED) throughout their manufacturing process, ensuring they meet strict optical, electrical, and functional standards. Their primary function is defect detection, quality control, and yield optimization for display panels.

What are the main drivers for the FPD Test Equipment market growth?

The key drivers include the escalating global demand for high-quality and advanced display technologies, continuous innovation in display types (e.g., OLED, Mini-LED, Micro-LED), increasingly stringent quality control requirements, and the growing adoption of automation and Industry 4.0 principles in display manufacturing processes.

How is Artificial Intelligence (AI) impacting the FPD Test Equipment market?

AI is transforming the FPD test equipment market by enhancing defect detection accuracy through machine vision and deep learning, accelerating testing cycles, enabling predictive maintenance for equipment, providing smart data analysis for yield optimization, and facilitating adaptive testing protocols, thereby reducing human error and improving overall efficiency.

Which regions dominate the FPD Test Equipment market and why?

The Asia Pacific (APAC) region, particularly countries like South Korea, China, Taiwan, and Japan, dominates the FPD Test Equipment market. This dominance is due to the concentration of major global display panel manufacturing hubs and extensive R&D activities in display technology within these nations.

What are the key challenges faced by the FPD Test Equipment market?

Major challenges include the high capital investment required for advanced test equipment, the rapid pace of technological obsolescence in both display and testing industries, the complexity of developing universal testing solutions for diverse display types, and potential disruptions from global economic uncertainties and supply chain issues.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager