Freezer Liner Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433380 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Freezer Liner Market Size

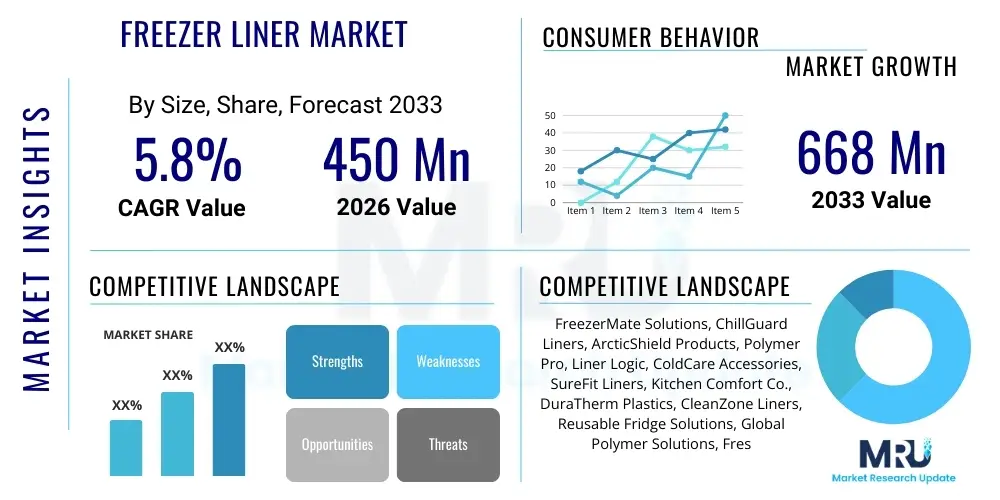

The Freezer Liner Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 668 Million by the end of the forecast period in 2033.

Freezer Liner Market introduction

The Freezer Liner Market encompasses various protective and organizational products designed to line the internal surfaces of freezers, preventing spills, minimizing cleanup time, and protecting the appliance from damage caused by ice buildup or sharp items. These products range from simple, non-slip mats made of flexible plastic polymers to custom-fit, heavy-duty liners for large commercial cold storage units. The primary function of a freezer liner is to enhance hygiene by creating a barrier against food contaminants and condensation, thereby prolonging the lifespan and efficiency of the freezing unit.

The core product offerings within this market segment utilize materials such as food-grade polyethylene (PE), polyethylene terephthalate (PET), and various types of silicone or rubber compounds, selected for their durability, low-temperature resilience, and non-toxic properties. Major applications span residential consumers seeking easier maintenance of home refrigerators and freezers, and commercial sectors including grocery stores, restaurants, hospitals, and specialized cold chain logistics providers. The convenience factor associated with simply removing and cleaning or replacing a liner, rather than deep-cleaning the freezer cavity, is a significant driver of consumer adoption across all end-use segments.

Key market benefits include enhanced sanitation, reduced operational downtime for cleaning in commercial settings, improved organization, and protection against corrosion or staining. Driving factors fueling market expansion are the increasing global ownership of advanced freezing appliances, growing consumer focus on food safety and kitchen hygiene, and the proliferation of convenience-oriented household accessories. Furthermore, continuous product innovation, particularly the introduction of antimicrobial and BPA-free liners, is steadily expanding the addressable market.

Freezer Liner Market Executive Summary

The Freezer Liner Market exhibits robust growth driven primarily by surging demand from the residential sector coupled with stringent hygiene regulations in the commercial food service industry. Current business trends indicate a strong shift towards e-commerce distribution channels, enabling niche manufacturers to reach a broader global consumer base, especially for customizable and specialty liner products. Material innovation is a crucial trend, with manufacturers increasingly focusing on sustainable, reusable, and high-durability polymers that offer superior thermal stability and ease of cleaning, thereby enhancing product value proposition and attracting environmentally conscious consumers.

Regional trends highlight North America and Europe as mature markets characterized by high consumer spending on household convenience products and early adoption of innovative freezer accessories. Conversely, the Asia Pacific (APAC) region is poised to demonstrate the fastest growth rate, fueled by rapid urbanization, increasing disposable incomes, and the corresponding rise in modern household appliance penetration, particularly in emerging economies like China and India. Manufacturers are strategically expanding their operational footprints in APAC to capitalize on the vast, untapped consumer base seeking practical household solutions.

Segment trends reveal that the material type segment is undergoing transformation, moving away from conventional plastics toward flexible silicone and advanced polyethylene derivatives offering features like anti-skid surfaces and enhanced flexibility for easy installation. In terms of end-use, the commercial segment, particularly institutional kitchens and cold storage logistics, is prioritizing heavy-duty, customized liners to meet industrial standards for load-bearing capacity and sustained sanitation. The convergence of convenience, hygiene, and organizational needs across all user demographics is solidifying the market's trajectory through the forecast period.

AI Impact Analysis on Freezer Liner Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Freezer Liner Market primarily revolve around how advanced analytics can optimize the highly conventional manufacturing and supply chain processes associated with these low-tech goods. Common questions focus on AI’s role in predicting regional demand fluctuations, optimizing material procurement (especially sustainable polymers), automating quality control in fabrication, and enhancing the efficiency of inventory management for diverse product lines (sizes, materials, colors). Users also express interest in AI-driven predictive maintenance for manufacturing equipment used to cut and seal liner materials, thereby minimizing production downtime and maintaining cost efficiencies necessary for competitive pricing.

The direct application of AI within the consumer interaction space is expected to involve personalized product recommendations based on individual freezer models and usage patterns, potentially through augmented reality tools utilized by retail platforms. Indirectly, AI and Machine Learning (ML) algorithms are playing a critical role in market forecasting, allowing major producers to accurately gauge the seasonal demand peaks for various liner specifications—such as those tailored for deep freezers versus refrigerator freezer compartments. This foresight minimizes obsolescence risks and ensures efficient allocation of manufacturing capacity, leading to a more streamlined and responsive global supply chain for freezer accessories.

Furthermore, AI-powered systems are crucial for analyzing vast datasets related to customer feedback and product durability, allowing manufacturers to quickly iterate on material compositions and design improvements. This continuous feedback loop, facilitated by AI analytics, enables the creation of "smart liners" that might incorporate subtle indicators for replacement or cleaning based on usage data, though such products remain nascent. Overall, the impact is centered on operational efficiency, demand responsiveness, and subtle enhancement of product quality, rather than fundamental changes to the product itself.

- AI-driven optimization of polymer extrusion and fabrication processes, reducing material waste.

- Predictive maintenance schedules for high-volume cutting and sealing machinery, ensuring continuous production.

- Enhanced supply chain visibility and demand forecasting using ML algorithms to match inventory with seasonal consumer purchasing patterns.

- Personalized e-commerce recommendations for liner specifications based on consumer appliance type and size detected via visual search tools.

- Automated quality control inspections utilizing computer vision systems to detect flaws in material thickness or coating integrity.

DRO & Impact Forces Of Freezer Liner Market

The Freezer Liner Market dynamics are governed by a complex interplay of Drivers, Restraints, and Opportunities, collectively forming the Impact Forces that dictate market growth trajectory. The primary Driver is the escalating consumer awareness regarding food safety and appliance longevity, leading to proactive measures like using liners to maintain freezer hygiene and prevent costly damage from spills or ice chiseling. This is strongly supported by the convenience factor, as busy households and commercial kitchens increasingly seek low-effort maintenance solutions. Key Restraints include the perception among certain cost-sensitive consumer segments that freezer liners are a non-essential accessory, alongside growing environmental concerns regarding the use and disposal of non-biodegradable polymer products, which places pressure on manufacturers to innovate materials.

Opportunities in the market are largely centered on material science and application diversification. The shift towards manufacturing customizable, tailored liners that fit specific high-end refrigerator models provides a significant opportunity for premium pricing and market differentiation. Furthermore, the development and mass production of genuinely biodegradable or highly recyclable materials that meet stringent food-grade standards could neutralize the environmental restraint, unlocking considerable growth in sustainability-focused markets like Western Europe. The strategic integration of antimicrobial technologies into liner materials offers an additional value proposition, attracting institutional and healthcare end-users.

The Impact Forces, therefore, favor innovation. While the underlying product concept is simple, the market’s responsiveness to environmental pressures (restraint) creates an imperative for material scientists (opportunity) to develop advanced, eco-friendly products (driver). Successfully navigating the raw material costs and consumer price sensitivity associated with these advanced materials will determine which companies achieve market leadership. Regulatory environments concerning food contact materials also exert a powerful impact, ensuring only certified and safe products are commercially viable, thereby favoring established manufacturers with robust compliance protocols.

Segmentation Analysis

The Freezer Liner Market is comprehensively segmented based on material type, product type, end-use application, and distribution channel, providing manufacturers and analysts with detailed insights into specific demand pockets and competitive landscapes. Material composition is crucial, as it dictates the product’s durability, temperature resilience, and price point, with segments ranging from cost-effective polyethylene films to high-performance, flexible silicone mats. Product segmentation distinguishes between mats designed for flat shelves, specialized full-box liners, and vertical dividers or organizers, reflecting the varying organizational needs of consumers and commercial entities.

The end-use segment clearly delineates the demand profiles, separating the high-volume, standardized needs of the residential market from the specialized, large-scale, and durability requirements of the commercial sector, which includes logistics, hospitality, and institutional catering. Analyzing these segments is critical for developing targeted marketing strategies; for instance, the residential segment responds well to convenience and aesthetics, while the commercial sector focuses heavily on regulatory compliance and total cost of ownership (TCO) calculated through product longevity and ease of cleaning.

This granular segmentation allows market participants to tailor their innovation efforts, ensuring that material advancements translate directly into end-user benefits, such as non-slip coatings for commercial freezers or easy-to-trim designs for diverse home appliances. The increasing prominence of e-commerce has also necessitated a robust segmentation analysis concerning distribution, highlighting the rapid growth of online sales channels versus traditional brick-and-mortar retail, thereby influencing inventory logistics and pricing strategies globally.

- By Material Type

- Polyethylene (PE)

- Polypropylene (PP)

- Silicone/Rubber

- Polyethylene Terephthalate (PET)

- Biodegradable Polymers

- By Product Type

- Shelf Mats

- Full Drawer/Box Liners

- Refrigerator Compartment Liners

- Trimmable Sheets

- By End-Use Application

- Residential

- Commercial (Food Service, Hospitality, Retail Cold Storage, Healthcare)

- By Distribution Channel

- Offline (Hypermarkets/Supermarkets, Specialty Stores)

- Online (E-commerce Platforms, Company Websites)

Value Chain Analysis For Freezer Liner Market

The Value Chain for the Freezer Liner Market begins with Upstream Analysis, focusing on the procurement of raw materials, predominantly various grades of plastic polymers (PE, PET, silicone). Key activities include sourcing petrochemical derivatives and ensuring compliance with food-grade and BPA-free standards. Raw material volatility, particularly the price fluctuations of oil and gas which impact polymer costs, significantly influences manufacturing profitability. Manufacturers must establish strong, reliable relationships with large-scale chemical producers to secure consistent quality and favorable pricing, especially for specialized materials like antimicrobial coatings or sustainably sourced polymers.

The midstream involves the core manufacturing processes: extrusion, molding, precision cutting, and specialized surface treatments (like anti-slip texturing). This stage requires significant capital investment in advanced machinery capable of handling various material thicknesses and ensuring product uniformity. Efficiency in this stage, particularly minimizing material waste through optimized cutting patterns, is crucial for maintaining competitive pricing. Manufacturers often incorporate packaging and labeling services in-house before products move to the distribution phase.

Downstream Analysis focuses on the distribution channels, which are bifurcated into direct and indirect methods. Direct distribution involves sales to large commercial clients (e.g., cold storage chains, hospital groups) or through the manufacturer’s own branded e-commerce site. Indirect distribution is highly crucial for the residential segment, relying heavily on third-party channels such as mass retailers (Walmart, Target), home appliance specialty stores, and major global e-commerce platforms (Amazon, Alibaba). The success in the downstream sector hinges on effective logistics management and targeted retail placements, maximizing product visibility to the intended end-user across both physical and digital storefronts.

Freezer Liner Market Potential Customers

The Potential Customers for the Freezer Liner Market are diverse, spanning both high-volume institutional buyers and individual household consumers, each driven by distinct purchasing criteria. The largest segment remains the household end-user, who buys the product primarily through retail or e-commerce for personal convenience, aiming to simplify the routine task of cleaning home freezers and maintain a high standard of kitchen hygiene. For this demographic, ease of use (trimmable, flexible), aesthetic appeal (color options), and price point are critical purchasing determinants.

The commercial sector represents a highly valuable B2B customer base, encompassing a range of organizations that operate large, specialized freezing equipment. Key buyers here include food service establishments (restaurants, catering companies), retail supermarkets with extensive frozen food sections, and the broader cold chain logistics industry. These buyers prioritize industrial-grade durability, compliance with health and safety regulations, flame retardancy (in some specific applications), and the ability to source custom-sized liners for non-standard equipment, making long-term supply contracts a common procurement method.

Furthermore, institutional customers such as hospitals, university cafeterias, and governmental food distribution centers represent a stable, high-demand segment. Their purchasing decisions are heavily influenced by bulk pricing, certifications related to material safety (e.g., NSF certification), and the ability of the liner to withstand frequent, rigorous cleaning protocols. Manufacturers targeting the commercial market must therefore focus their sales efforts on demonstrating TCO benefits, regulatory compliance, and superior material strength over product aesthetics.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 668 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | FreezerMate Solutions, ChillGuard Liners, ArcticShield Products, Polymer Pro, Liner Logic, ColdCare Accessories, SureFit Liners, Kitchen Comfort Co., DuraTherm Plastics, CleanZone Liners, Reusable Fridge Solutions, Global Polymer Solutions, FreshSeal Protection, The Home Organization Group, Cold Storage Essentials, Eco-Clean Products, Sentinel Liners, Specialized Appliance Accessories, FlexiChill Industries, FrostSafe Materials |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Freezer Liner Market Key Technology Landscape

The technology landscape for the Freezer Liner Market, while rooted in polymer manufacturing, is increasingly focused on material enhancement and functional innovation rather than radical disruptive shifts. The primary technological advancements concern the development of specialized polymer formulations, particularly those achieving enhanced low-temperature flexibility and crack resistance, crucial for maintaining integrity in harsh freezer environments. A key focus area is the integration of advanced antimicrobial and antifungal additives directly into the polymer matrix during the extrusion process. These additives inhibit the growth of bacteria and mold, significantly improving the sanitary features of the liner, which is highly valued in both residential and institutional settings, thereby supporting higher ASPs (Average Selling Prices).

Another pivotal technological area is precision manufacturing and thermoforming capabilities. Modern production facilities utilize high-speed CNC (Computer Numerical Control) cutting and vacuum thermoforming technologies to create perfectly contoured, custom-fit liners for specific appliance brands and models. This moves the market beyond generic, trimmable sheets toward premium, tailor-made solutions, reducing installation effort and improving aesthetic integration. Furthermore, the development of multi-layered co-extrusion films allows manufacturers to combine different polymers into a single liner structure, optimizing for surface properties (e.g., non-slip top layer) and core strength (e.g., puncture-resistant substrate).

The future technology outlook includes integrating sustainable manufacturing practices, focusing on closed-loop recycling processes for industrial plastic waste and the commercial scaling of bio-based or compostable polymers that retain the necessary cold-tolerance and durability characteristics. Research is also ongoing into "smart" coatings that might change color or texture to indicate cleaning needs or material wear, leveraging micro-encapsulation or sensor technologies. However, the commercial viability of such high-tech features must be carefully balanced against the typically low retail price point of freezer liners.

Regional Highlights

- North America: North America holds a dominant position in the Freezer Liner Market, characterized by high levels of household disposable income and a robust culture of appliance maintenance and organization. The region demonstrates high demand for convenience products, driving the adoption of premium, custom-fit, and anti-microbial liners. The US and Canada are mature markets where competitive saturation leads manufacturers to focus heavily on product differentiation through features like non-slip textures and eco-friendly materials. Large retail chains and established e-commerce infrastructure facilitate efficient market penetration and high sales volume.

- Europe: Europe represents another significant market, driven primarily by stringent food safety regulations, particularly within the commercial sector (restaurants and cold storage). Western European countries (Germany, UK, France) emphasize sustainability, creating strong demand for liners manufactured from recycled or biodegradable materials. Market growth is stable, supported by high residential appliance penetration and a focus on long-lasting, durable products. Regulatory compliance regarding food contact materials (e.g., EU Regulation 10/2011) significantly influences product design and material selection, favoring certified manufacturers.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region during the forecast period. This rapid growth is attributable to accelerated urbanization, rising middle-class populations, and corresponding increases in the ownership of modern refrigeration and freezing appliances, especially in China, India, and Southeast Asian nations. While the market remains price-sensitive, demand is rapidly shifting toward branded, quality products as hygiene awareness improves. The commercial cold chain logistics sector, booming due to expanding e-commerce food delivery services, is a major institutional buyer driving high-volume sales.

- Latin America (LATAM): The LATAM market is characterized by moderate but steady growth. Demand is concentrated in major urban centers and economies like Brazil and Mexico. Price sensitivity is higher here compared to North America, leading to greater consumption of basic polyethylene liners. However, increasing foreign investment in the retail food sector is driving demand for commercial-grade liners that adhere to international hygiene standards, presenting long-term growth opportunities for established global suppliers.

- Middle East and Africa (MEA): The MEA market is still nascent but expanding, particularly in the Gulf Cooperation Council (GCC) states due to significant investment in the hospitality sector and luxury residential complexes. Growth drivers include high-temperature climatic conditions necessitating reliable cold storage solutions, and the presence of expatriate populations accustomed to modern household accessories. The African segment offers long-term potential, contingent upon improving infrastructure and rising consumer purchasing power.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Freezer Liner Market.- FreezerMate Solutions

- ChillGuard Liners

- ArcticShield Products

- Polymer Pro

- Liner Logic

- ColdCare Accessories

- SureFit Liners

- Kitchen Comfort Co.

- DuraTherm Plastics

- CleanZone Liners

- Reusable Fridge Solutions

- Global Polymer Solutions

- FreshSeal Protection

- The Home Organization Group

- Cold Storage Essentials

- Eco-Clean Products

- Sentinel Liners

- Specialized Appliance Accessories

- FlexiChill Industries

- FrostSafe Materials

Frequently Asked Questions

Analyze common user questions about the Freezer Liner market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary benefit of using a freezer liner?

The primary benefit of a freezer liner is enhanced hygiene and reduced maintenance time. Liners create a protective, easily removable barrier that prevents spills, condensation, and food residue from accumulating directly on the freezer surfaces, significantly simplifying the cleaning process and protecting the appliance from damage or corrosion.

Which materials are commonly used in the manufacturing of high-quality freezer liners?

High-quality freezer liners are typically made from durable, food-grade materials such as flexible polyethylene (PE), silicone rubber, and polyethylene terephthalate (PET). These materials are selected for their non-toxic properties, low-temperature flexibility, resistance to cracking, and non-slip characteristics.

Is the Freezer Liner Market witnessing a shift towards sustainable products?

Yes, there is a clear market trend toward sustainability. Driven by consumer environmental concerns and regulatory pressures, manufacturers are increasingly focusing on developing and marketing liners made from recycled polymers, bio-based plastics, and fully biodegradable materials that maintain the essential cold-tolerance and durability required for freezer use.

How does the commercial segment differ from the residential segment in terms of liner requirements?

The commercial segment, including food service and logistics, demands industrial-grade durability, higher load-bearing capacity, and often requires customized sizes for large walk-in freezers or specialized units. Residential users, conversely, prioritize ease of trimming, aesthetics, anti-microbial features, and accessibility through retail channels.

Which geographical region exhibits the fastest growth rate for the Freezer Liner Market?

The Asia Pacific (APAC) region is projected to experience the fastest market growth. This acceleration is fueled by rapid economic development, increasing appliance ownership rates, growing disposable incomes, and heightened consumer awareness regarding household hygiene and food preservation standards in emerging economies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager