Fried puffed food Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437609 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Fried puffed food Market Size

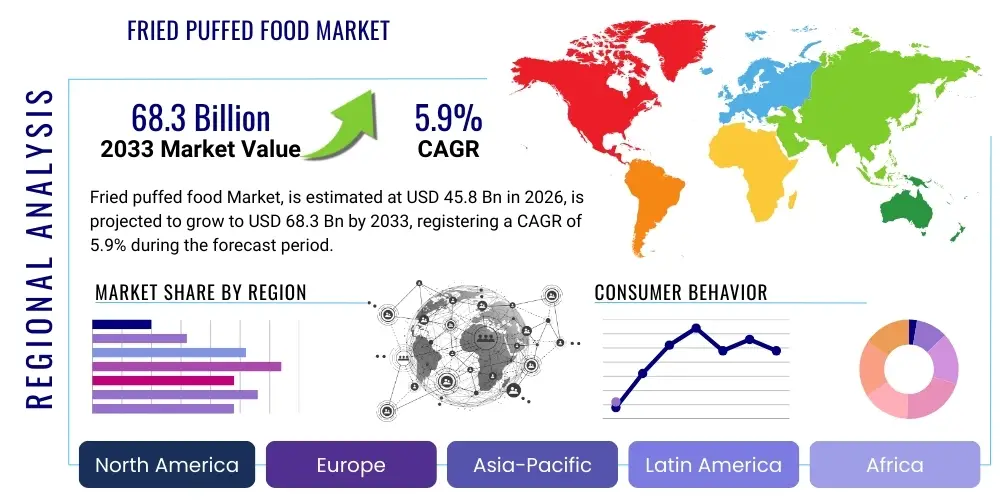

The Fried puffed food Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.9% between 2026 and 2033. The market is estimated at USD 45.8 Billion in 2026 and is projected to reach USD 68.3 Billion by the end of the forecast period in 2033. This consistent growth trajectory is primarily fueled by rising global urbanization, increasing consumer demand for convenient, ready-to-eat snack options, and aggressive product innovation concerning flavors and textures by major market participants.

Fried puffed food Market introduction

The Fried Puffed Food Market encompasses a wide range of snack products created through extrusion and subsequent deep frying processes, resulting in light, crispy, and volumized structures. These products utilize primary ingredients such as corn, potato, wheat, rice, or various legume flours. The manufacturing process involves mixing, cooking, extruding the dough under high pressure, and then rapidly expanding and frying the resultant pellets. These snacks are globally popular dueizing to their appealing texture, palatability, and long shelf life, making them staples in convenience stores and household pantries across demographics.

Major applications of fried puffed foods center on direct consumer snacking, particularly as quick energy boosts, recreational consumption during leisure activities, or as complementary items during meals. The primary benefits driving consumer adoption include unparalleled convenience, cost-effectiveness, and the vast array of available flavor profiles, ranging from savory and spicy to sweet. Furthermore, manufacturers are continually investing in processing technology to improve texture uniformity and reduce oil absorption while maintaining the desired crunch factor, ensuring sustained consumer interest in this category.

Key driving factors supporting market expansion include the increasing disposable incomes in emerging economies, the rising acceptance of Western snacking culture worldwide, and the rapid expansion of organized retail channels, which enhances product accessibility. Moreover, continuous innovation focusing on incorporating healthier ingredients, such as ancient grains, and developing exotic, region-specific flavors is crucial for maintaining competitive edge and overcoming consumer concerns related to high fat and sodium content typically associated with traditional fried snacks. The market remains dynamic, heavily influenced by seasonal trends and marketing intensity.

Fried puffed food Market Executive Summary

The global Fried Puffed Food Market exhibits robust growth, underpinned by fundamental shifts in consumer lifestyles characterized by high demand for convenience and immediate consumption. Business trends highlight a strong focus on strategic mergers and acquisitions among major players to consolidate market share and penetrate niche segments, particularly those focusing on 'better-for-you' attributes such as lower fat content achieved through advanced frying techniques or ingredient substitution. Manufacturers are also heavily utilizing digital marketing and e-commerce platforms to directly engage with consumers and tailor product offerings based on real-time preference data, leading to accelerated product launch cycles.

Regional trends indicate that Asia Pacific (APAC) remains the fastest-growing market due to rapid population growth, increasing urbanization, and burgeoning middle-class expenditure on packaged goods. North America and Europe, while mature, demonstrate resilience driven by premiumization and the demand for innovative, gourmet, or ethnic flavor variants. Regulatory scrutiny regarding trans-fats and sodium levels is influencing manufacturing practices globally, prompting investment in R&D to reformulate classic products without compromising taste or texture, ensuring compliance and consumer acceptance simultaneously.

Segment trends reveal that the potato-based and corn-based puffed snacks segments continue to dominate in terms of market volume, driven by raw material availability and established production infrastructure. However, the legume and multi-grain segments are experiencing higher growth rates, reflecting consumer migration towards perceived healthier or protein-enriched snacking alternatives. The retail segment, including supermarkets and hypermarkets, remains the primary distribution channel, although online retail is gaining significant traction, especially in reaching younger, digitally savvy consumer bases.

AI Impact Analysis on Fried puffed food Market

Analysis of common user questions regarding AI's impact on the Fried Puffed Food Market reveals key themes centered around operational efficiency, personalized product development, and supply chain optimization. Users frequently inquire about how AI can predict consumer flavor trends, automate quality control on high-speed production lines, and optimize oil usage to reduce costs and improve health profiles. Concerns are also raised regarding the initial investment required for AI integration and the displacement of manual labor in traditional manufacturing environments. The overarching expectation is that AI will be the primary driver for achieving both personalization at scale and substantial reductions in waste and energy consumption throughout the supply chain, moving the industry towards smarter, more agile production models.

The introduction of Artificial Intelligence and Machine Learning (ML) is transforming the manufacturing processes within the fried puffed food sector from reactive quality assurance to proactive predictive control. AI algorithms are being deployed to monitor real-time parameters such as frying temperature, oil quality, moisture content, and surface texture during extrusion and frying. This level of precision minimizes product variability, ensuring consistent crunch and flavor delivery across batches. Furthermore, predictive maintenance powered by ML minimizes unexpected equipment failures, significantly boosting operational uptime and overall production throughput, which is critical in a high-volume, low-margin industry.

Beyond the factory floor, AI is revolutionizing market analysis and product innovation. Advanced analytical tools process vast datasets related to social media sentiment, sales performance across various geographic regions, and seasonal consumption patterns to identify emerging flavor preferences before they become mainstream. This allows companies to rapidly prototype and launch highly targeted products, drastically reducing the risk associated with new product introduction. The application of AI in demand forecasting also optimizes inventory management, reducing spoilage of raw materials and finished goods, thereby improving overall profitability and sustainability metrics.

- AI-powered predictive maintenance optimizes extrusion and frying equipment uptime.

- Machine learning algorithms enhance real-time quality control, ensuring consistent texture and moisture.

- AI analyzes social media and sales data to predict and guide flavor trend development.

- Smart sensors minimize oil degradation and optimize oil usage, contributing to healthier products.

- Advanced supply chain planning reduces raw material waste and optimizes distribution logistics.

DRO & Impact Forces Of Fried puffed food Market

The Fried Puffed Food Market is influenced by a powerful interplay of drivers, restraints, and opportunities (DRO) which collectively dictate market trajectory and competitive intensity. The primary drivers include rapid urbanization globally, shifting consumer preference toward convenient, on-the-go snacking solutions, and extensive flavor innovation strategies employed by major snack food companies. These factors ensure a steady and expanding consumer base, particularly in fast-developing markets where time scarcity elevates the value of ready-to-eat options. However, market growth is significantly restrained by increasing consumer awareness regarding health and wellness, leading to concerns over the high fat, calorie, and sodium content typically found in fried snacks. Regulatory bodies in mature markets are also imposing stricter guidelines on nutritional labeling and ingredient usage, adding complexity to manufacturing and formulation efforts.

Opportunities within this market are extensive and center primarily on innovation in processing technology and ingredient sourcing. The most significant opportunity lies in developing 'better-for-you' alternatives, such as non-fried, air-puffed, or baked snacks that mimic the texture and flavor of traditional fried products while offering superior nutritional profiles. Furthermore, leveraging exotic, regional, and plant-based ingredients (like lentils, chickpeas, and ancient grains) allows manufacturers to tap into the growing consumer demand for protein-enriched and functional snacks. Strategic geographic expansion into underserved markets, particularly in Africa and specific parts of Asia, also represents a viable pathway for aggressive market penetration and revenue growth.

The competitive landscape is shaped by several critical impact forces. The threat of substitutes is high, driven by the proliferation of alternative healthy snacks (e.g., nuts, seeds, fresh fruit bars, and baked vegetable chips) that directly compete for consumer share. Intense rivalry among existing players, characterized by aggressive marketing, pricing wars, and rapid flavor diversification, puts constant pressure on profit margins. Supplier power is generally moderate, though specialized ingredient suppliers (e.g., unique flavorings, non-GMO corn) can exert leverage. Conversely, buyer power is high, driven by the availability of numerous options and strong brand loyalty, compelling manufacturers to maintain high quality and competitive pricing to retain market share.

Segmentation Analysis

The Fried Puffed Food Market is broadly segmented based on raw material, product type, flavor, distribution channel, and geography, allowing for nuanced strategic planning and targeted product development. Understanding these segmentation dynamics is crucial for companies aiming to optimize their supply chain and marketing strategies to match specific consumer demographics and preferences. The overall market structure reflects a trend toward diversification, moving away from simple, classic formulations towards complex, specialized products catering to specific dietary or lifestyle needs, such as gluten-free or high-protein options. This diversification ensures that the market remains relevant across diverse global consumer bases, despite health concerns.

Raw material segmentation is critical as it dictates the texture, nutritional value, and primary cost structure of the final product, with potato and corn bases maintaining volumetric dominance. Product type segmentation differentiates between chips, pellets, rings, and extruded shapes, each commanding a distinct price point and consumer appeal. Flavor segmentation, perhaps the most dynamic area, ranges from classic salt and cheese to highly specialized ethnic and fusion flavors, acting as the primary lever for consumer engagement and repeat purchases. Lastly, the distribution channel breakdown indicates the importance of both traditional retail and the rapidly accelerating penetration of e-commerce, forcing omnichannel strategies for maximum market reach.

- By Raw Material:

- Potato-based Puffs

- Corn-based Puffs

- Wheat/Rice-based Puffs

- Multi-grain and Legume-based Puffs (Lentils, Chickpeas)

- By Product Type:

- Chips and Crisps

- Extruded Snacks (Rings, Sticks, Balls)

- Pellet Snacks (Ready-to-Fry/Ready-to-Eat)

- By Flavor:

- Savory (Salted, Cheese, Cream & Onion)

- Spicy (Chili, Hot & Sour, Barbeque)

- Sweet and Hybrid Flavors

- By Distribution Channel:

- Supermarkets and Hypermarkets

- Convenience Stores

- Online Retail

- Specialty Stores

Value Chain Analysis For Fried puffed food Market

The value chain for the Fried Puffed Food Market is intricate, starting from raw material procurement and extending through highly specialized manufacturing processes to final retail distribution. Upstream activities involve sourcing high-quality, specialized starches (corn, potato, etc.) and flavorings. Reliability in sourcing raw materials, often involving complex agricultural contracts, is crucial for maintaining cost stability and ensuring product quality, especially concerning specific traits like non-GMO or organic certification. Manufacturers often integrate backwards partially or establish long-term relationships with key agricultural suppliers to mitigate commodity price volatility and supply chain disruptions, which are common in the agri-food sector.

The core manufacturing stage involves specialized processes, including sophisticated extrusion, precision frying, and flavor coating, demanding significant capital investment in machinery. Efficiency in the manufacturing stage is paramount, focusing on optimizing oil usage, minimizing waste, and achieving rapid throughput. The midstream activities also include stringent quality control measures, packaging design (critical for shelf life and appeal), and adherence to diverse international food safety regulations. Innovation in packaging, such as nitrogen flushing to maintain crispness or use of sustainable, bio-degradable materials, is becoming a differentiator in competitive markets.

Downstream activities are dominated by distribution channels, which include both direct sales to large retail chains and indirect sales through distributors and wholesalers. Direct distribution allows for better control over pricing and shelf placement, whereas indirect channels are essential for penetrating remote or fragmented markets. The rise of e-commerce platforms is restructuring the downstream value chain, reducing the reliance on traditional brick-and-mortar retailers for market access. Successful players must maintain robust logistical networks and leverage digital tools to manage product freshness and rapid inventory turnover, ultimately influencing final consumer pricing and market accessibility.

Fried puffed food Market Potential Customers

The primary consumers and buyers of fried puffed food products span a broad demographic spectrum, reflecting the global accessibility and universal appeal of these snacks. The core demographic includes children and young adults (aged 5 to 35), who are highly motivated by flavor novelty, attractive packaging, and the immediate gratification offered by these convenient snacks. This segment is characterized by high rates of impulse purchasing, heavily influenced by social media trends and targeted marketing campaigns. Manufacturers must continuously invest in new flavor launches and engaging brand narratives to maintain relevance within this critical consumer base.

A second major customer segment comprises working professionals and busy adults (aged 25 to 55) who seek quick, convenient, and portable food options for on-the-go consumption or desk snacking. For this group, convenience and perceived quality—even within the indulgent snack category—are key purchasing criteria. This segment is increasingly driving the demand for premiumized versions, smaller, controlled portion sizes, and products that offer some functional benefits, such as high protein or fiber content, often packaged in resealable formats to cater to flexible consumption patterns throughout the workday.

Finally, institutional buyers, including airlines, hospitality services, vending machine operators, and large corporate cafeterias, represent a significant B2B customer base. These buyers purchase products in bulk, often requiring customized or value-sized packaging solutions and adherence to strict nutritional guidelines, particularly in educational or healthcare settings. The purchasing decisions of institutional customers are driven predominantly by cost-effectiveness, consistency of supply, and compliance with health and safety certifications, often requiring long-term supply contracts with established manufacturers to ensure product availability and standardized quality.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 45.8 Billion |

| Market Forecast in 2033 | USD 68.3 Billion |

| Growth Rate | 5.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | PepsiCo (Frito-Lay), Kellogg Company, Calbee, Inc., General Mills, Mondelez International, Utz Brands, Inc., Snyder's-Lance (Campbell Soup Company), Herr Foods Inc., The Hain Celestial Group, B&G Foods, Inc., Pladis (Yildiz Holding), Intersnack Group GmbH & Co. KG, Old Dutch Foods, Wise Foods, Inc., Shearer's Foods, Diamond Foods (Snyders-Lance), Greendot Health Foods Pvt. Ltd., Balaji Wafers, Prataap Snacks, Maxx Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fried puffed food Market Key Technology Landscape

The technological landscape of the Fried Puffed Food Market is defined by continuous process refinement aimed at improving efficiency, reducing production costs, and crucially, enhancing the nutritional profile of the final product. Extrusion technology remains the foundational process, but innovations involve twin-screw extruders and variable geometry dies, which allow for greater control over texture, density, and shape complexity, facilitating the use of non-traditional, complex raw materials like legume flours. Precise control over temperature and pressure during the extrusion phase is essential to pre-condition the starch adequately, reducing the total fat absorption required during the subsequent frying step and ensuring maximum puff and desired crispness.

Frying technology has seen the most dramatic advancements in response to consumer health concerns and regulatory pressures. Traditional batch frying is increasingly being replaced by continuous vacuum frying systems and specialized continuous fryers with advanced oil management systems. Vacuum frying allows snacks to be cooked at significantly lower temperatures, minimizing the formation of potentially harmful compounds like acrylamide and substantially reducing oil absorption. Furthermore, sophisticated filtration and continuous oil quality monitoring systems extend the lifespan of the cooking oil and ensure consistent flavor delivery, critical for maintaining product integrity across mass production runs.

Beyond the core cooking process, the adoption of high-speed sorting and packaging technology is crucial. Optical sorting equipment, often integrated with AI vision systems, ensures high-quality consistency by rapidly detecting and removing imperfectly puffed or colored pieces, minimizing product rejects and improving final quality. Advanced seasoning and coating drums ensure uniform flavor distribution, while automated, high-speed vertical form-fill-seal (VFFS) machines optimize packaging efficiency, minimize atmospheric exposure, and utilize modified atmosphere packaging (MAP) techniques to extend shelf life without relying heavily on chemical preservatives, catering directly to the demand for cleaner label products.

Regional Highlights

- Asia Pacific (APAC): This region dominates the market in terms of volume consumption and exhibits the highest projected growth rate. The market is fueled by rapidly increasing urbanization, the proliferation of large-format retail, and shifting dietary habits influenced by Western culture. Countries like India, China, and Indonesia are key contributors, driven by vast young populations and rising disposable incomes. Local players are strong, but international companies are aggressively expanding their footprint through strategic partnerships and localization of flavor profiles.

- North America: A mature, highly competitive, and innovative market, North America is characterized by high per capita consumption and strong demand for premium, specialized, and health-focused variations (e.g., organic, non-GMO, protein-enhanced). The US market, dominated by major multinational corporations, is the epicenter for new flavor trends and packaging innovation, often dictating global market standards regarding sustainability and nutritional transparency.

- Europe: The European market demonstrates moderate, steady growth, heavily influenced by strict food safety regulations and a strong consumer preference for natural ingredients and reduced fat/salt options. Western European nations, particularly the UK and Germany, are leading the shift towards baked and air-fried alternatives. Regulatory compliance, specifically concerning acrylamide levels, is a major factor shaping manufacturing investment and product formulation strategies across the continent.

- Latin America (LATAM): This region offers significant growth potential, characterized by increasing economic stability and a large, young population. Consumption patterns are heavily focused on traditional, spicy, and savory flavors. The market is highly price-sensitive, placing significant emphasis on optimizing production costs and leveraging strong localized distribution networks to reach diverse consumer segments across Brazil, Mexico, and Argentina.

- Middle East and Africa (MEA): Currently, the smallest but fastest-evolving market, MEA growth is concentrated in urban centers, driven by increased Western food importation and infrastructure development. The GCC countries show high demand for premium imported snacks, while African nations represent long-term potential where domestic manufacturing capacity is steadily increasing to cater to a rapidly expanding consumer base seeking affordable, packaged convenience foods.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fried puffed food Market.- PepsiCo (Frito-Lay)

- Kellogg Company

- Calbee, Inc.

- General Mills

- Mondelez International

- Utz Brands, Inc.

- Snyder's-Lance (Campbell Soup Company)

- Herr Foods Inc.

- The Hain Celestial Group

- B&G Foods, Inc.

- Pladis (Yildiz Holding)

- Intersnack Group GmbH & Co. KG

- Old Dutch Foods

- Wise Foods, Inc.

- Shearer's Foods

- Diamond Foods (Snyders-Lance)

- Greendot Health Foods Pvt. Ltd.

- Balaji Wafers

- Prataap Snacks

- Maxx Group

Frequently Asked Questions

Analyze common user questions about the Fried puffed food market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected Compound Annual Growth Rate (CAGR) for the Fried Puffed Food Market?

The Fried Puffed Food Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 5.9% between 2026 and 2033, driven by increasing demand for convenience foods and continuous flavor diversification.

How are manufacturers addressing health concerns related to fat content in fried puffed foods?

Manufacturers are investing heavily in advanced processing technologies such as vacuum frying and air-puffing, which significantly reduce the oil absorption while maintaining the desired crispy texture, alongside reformulating products using healthier oil types and non-traditional ingredients like legumes.

Which region holds the largest market share in the Fried Puffed Food Market?

North America currently holds a significant market share due to high consumer spending and established snacking culture; however, the Asia Pacific (APAC) region is projected to be the fastest-growing market due to rapid urbanization and population expansion.

What role does Artificial Intelligence (AI) play in the manufacturing of puffed snacks?

AI is primarily used to optimize manufacturing efficiency through predictive maintenance, enhance quality control by monitoring frying parameters in real-time, and drive product innovation by analyzing consumer trends and predicting successful flavor profiles.

What are the key raw materials used in the production of fried puffed snacks?

The core raw materials include starches derived from corn, potato, wheat, and rice. There is a growing trend toward using multi-grains, lentils, and chickpeas to produce protein-enriched and fiber-rich snack alternatives.

How significant is the influence of social media on puffed food consumption trends?

Social media has a highly significant influence, particularly among younger consumers, serving as a primary platform for driving awareness of new flavor launches, limited-edition products, and international snack trends, directly influencing impulse purchases and product virality.

What major regulatory challenges are faced by the fried puffed food industry globally?

The industry faces regulatory hurdles primarily centered on minimizing trans-fats, reducing overall sodium content, and adhering to strict labeling requirements regarding calorie counts and ingredient transparency, especially in European and North American markets.

Is e-commerce a critical distribution channel for the market?

Yes, e-commerce is becoming an increasingly critical distribution channel, offering convenience and direct access to niche or premium products, especially for younger demographics and bulk purchasers, complementing traditional supermarket distribution.

What is 'better-for-you' positioning in the context of the snack market?

Better-for-you positioning involves marketing snacks with reduced fat, lower sodium, high protein, fiber enrichment, or the incorporation of functional ingredients, aiming to appeal to health-conscious consumers seeking indulgence without significant nutritional compromise.

Which product segment is expected to show the highest growth?

The extruded snacks segment and the multi-grain/legume-based raw material segment are expected to show the highest growth, driven by their versatility in formulation and ability to align with current health and protein trends.

How does the volatile price of agricultural commodities affect the market?

The volatile pricing of staple agricultural commodities like corn, potato, and vegetable oils directly impacts the cost of goods sold and overall profitability. Manufacturers use hedging strategies and long-term procurement contracts to mitigate this financial risk.

What technological advancements are driving manufacturing efficiency?

Key technological advancements include continuous, closed-loop processing systems, advanced sensory equipment for real-time quality checks, and energy-efficient frying systems designed to lower operational costs while maintaining high product throughput and uniformity.

What distinguishes corn-based snacks from potato-based snacks in the market?

Corn-based snacks generally offer a denser texture and are highly conducive to extrusion into various shapes (e.g., rings, sticks), often dominating the cheese-flavored segment. Potato-based snacks, such as chips and crisps, retain dominance in the thin-slice segment and are preferred for classic savory flavors.

What impact does packaging innovation have on shelf life and consumer appeal?

Packaging innovation, including the use of high-barrier films, nitrogen flushing, and resealable bags, is crucial for extending shelf life and preserving crispness. Visually appealing and environmentally sustainable packaging also significantly enhances consumer attraction and brand perception.

How do manufacturers ensure consistent flavor coating across large batches?

Manufacturers utilize advanced, automated seasoning drums and precise liquid flavor spray systems integrated with mass flow control technology. These systems ensure uniform adherence and distribution of dry and wet flavorings across every piece, maintaining batch consistency.

Define the upstream component of the value chain for this market.

The upstream component involves the cultivation, harvesting, and initial processing of primary raw materials, including corn, potatoes, and specific types of edible oils, as well as the procurement of specialized flavoring agents and starches necessary for extrusion.

What are the primary factors driving market growth in emerging economies?

Growth in emerging economies is primarily driven by rapid urbanization, increasing levels of disposable income among the burgeoning middle class, and the expanding presence of modern retail infrastructure, making packaged snacks widely accessible.

Why is product localization crucial for global players in the fried puffed food market?

Product localization is crucial because consumer preferences for flavors and textures vary significantly by region. Successful global players tailor their offerings by incorporating local spices, traditional ingredients, and culturally resonant flavor profiles to maximize market penetration.

What is the threat of substitution in this market?

The threat of substitution is high, stemming from the availability of numerous competing snack categories, including nuts, seeds, yogurt, fresh fruit, and non-fried baked chips, which are often marketed as healthier alternatives and compete directly for the consumer's wallet share.

How is sustainability addressed within the production process?

Sustainability efforts focus on reducing water consumption during processing, minimizing food waste through precise manufacturing, optimizing packaging materials (switching to recyclable or bio-degradable films), and ensuring responsible sourcing of raw materials, particularly palm oil.

Describe the current trend in flavor innovation.

Current flavor trends move beyond traditional staples toward complex, experiential, and fusion flavors. This includes incorporating global cuisines (e.g., Korean BBQ, Peruvian chili), intense heat profiles, and sophisticated sweet and savory combinations to capture adventurous consumer palates.

What specific challenges does the industry face regarding oil management?

The industry faces challenges in maintaining optimal oil quality (low free fatty acids and polar compounds), reducing oil absorption in the final product, and efficiently disposing of spent oil in an environmentally responsible manner, all while managing high energy costs associated with continuous frying.

Why is consistent texture a critical quality factor?

Consistent texture, characterized by the ideal level of crispness and melt-in-the-mouth quality, is a critical factor because it is directly correlated with consumer satisfaction and repeat purchasing behavior. Manufacturing processes are calibrated precisely to control density and moisture content for textural uniformity.

What defines the difference between extruded snacks and pellet snacks?

Extruded snacks are typically cooked and ready-to-eat immediately after frying. Pellet snacks, conversely, are semi-finished, dehydrated products that require the final frying or baking step, usually by smaller snack manufacturers or directly by consumers, offering versatility in downstream preparation.

How is the demand for gluten-free snacks affecting formulation?

The rising demand for gluten-free products is significantly affecting formulation, shifting focus toward naturally gluten-free bases like rice, corn, and specific legume flours (chickpeas, lentils) and requiring strict separation protocols in manufacturing facilities to prevent cross-contamination.

Which segments benefit most from premiumization trends?

Premiumization trends benefit gourmet flavor segments, products featuring specialized ingredients (e.g., ancient grains, artisanal cheeses), and snacks emphasizing functional benefits or unique processing methods like small-batch or hand-cooked styles.

What is the significance of the snacking frequency increase globally?

The increase in global snacking frequency, often replacing traditional mealtimes, is a primary driver for the market, necessitating continuous innovation in portion control, portability, and ingredient quality to address the consumer shift toward smaller, more frequent consumption occasions.

How does technological integration address labor shortages in manufacturing?

Technological integration, particularly through advanced automation, robotics in packaging, and AI-driven quality inspection systems, addresses labor shortages by minimizing the need for manual oversight in repetitive tasks and increasing overall line efficiency and safety.

What impact does the price elasticity of demand have on product pricing?

The demand for basic, core fried puffed snacks is highly price elastic; consumers will readily switch brands based on price or promotional offers. This compels manufacturers to maintain competitive pricing for mainstream products while focusing premiumization efforts on highly differentiated, specialized offerings.

How are food manufacturers navigating the challenge of clean label demands?

Manufacturers are navigating clean label demands by removing artificial colors, flavors, and preservatives; simplifying ingredient lists; and utilizing natural alternatives for preservation and coloring, such as vegetable extracts and natural spices, often highlighting these changes prominently on packaging.

What is the primary function of the extrusion process in puffed food manufacturing?

The primary function of the extrusion process is to cook and plastify the starch-based raw materials under high heat and pressure. When the material exits the die, the sudden pressure drop causes rapid expansion (puffing), determining the final shape and texture of the snack pellet.

In the competitive analysis, what differentiates large multinational corporations from local players?

Multinational corporations leverage vast distribution networks, significant R&D budgets for process innovation, and global branding power. Local players often differentiate themselves through deeper understanding of regional flavor preferences, agility in product launch, and strong, localized supply chain relationships.

What role do wholesalers and distributors play in the market ecosystem?

Wholesalers and distributors play a crucial role in bridging the gap between manufacturers and fragmented retail outlets, especially in developing markets. They manage inventory, provide crucial logistics services, and ensure product reach into remote or smaller retail stores.

How is the market adapting to shifts towards plant-based diets?

The market is adapting by rapidly developing snacks based on plant proteins derived from peas, chickpeas, and lentils. These ingredients naturally elevate the protein content, appealing directly to consumers seeking animal-free, high-protein snacking options without sacrificing the familiar crunchy texture.

What is meant by 'modified atmosphere packaging' (MAP) in this context?

MAP involves replacing the air inside the snack bag with an inert gas, typically nitrogen. This technique minimizes oxidation and inhibits microbial growth, significantly extending the shelf life and preserving the crispness of the fried product without relying on chemical preservatives.

How do manufacturers manage the high energy consumption associated with frying?

Manufacturers are employing energy recovery systems, installing high-efficiency continuous fryers, and utilizing integrated process controls to precisely manage heating cycles and oil recirculation, aiming to reduce the massive natural gas or electric energy inputs required for continuous high-temperature cooking.

What is the consumer expectation regarding portion control in packaged snacks?

Consumer expectation is shifting toward flexible portion control. This includes both multi-serve, family-sized bags and smaller, individual grab-and-go packs, allowing consumers to manage calorie intake more easily and reducing waste from opened, uneaten large packages.

How does the quality of edible oil impact the final product?

The quality and type of edible oil (e.g., sunflower, palm, canola) critically impact the final product's flavor profile, stability, fat content, and overall nutritional labeling. Maintaining low polarity levels in the oil is essential for reducing harmful compound formation and ensuring a clean taste.

What are the key drivers for innovation in packaging materials?

The key drivers for packaging material innovation are increasing consumer and regulatory pressure for sustainability (biodegradable, recyclable plastics), the need for enhanced barrier properties to extend shelf life, and demands for tamper-evident and easy-to-open designs.

Why is consistent supply chain management critical for the market?

Consistent supply chain management is critical due to the perishable nature of ingredients and the high volume required by continuous production lines. Efficient logistics minimize disruptions, reduce inventory holding costs, and ensure freshness upon reaching the consumer, which is paramount for taste integrity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager