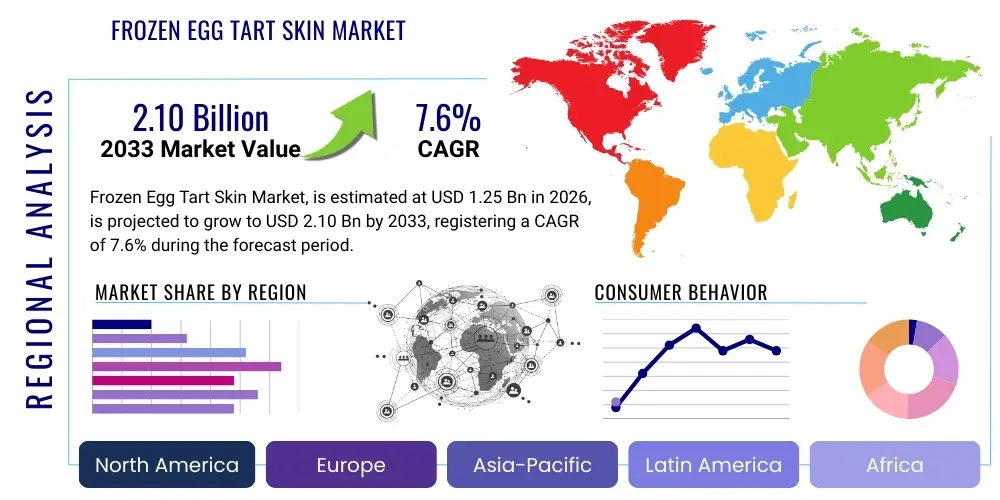

Frozen Egg Tart Skin Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437847 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Frozen Egg Tart Skin Market Size

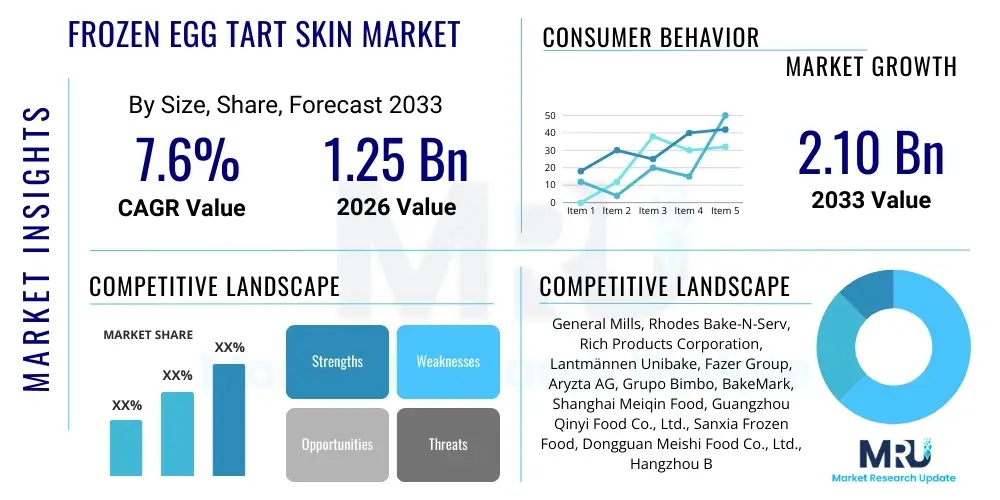

The Frozen Egg Tart Skin Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.6% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 2.10 Billion by the end of the forecast period in 2033.

Frozen Egg Tart Skin Market introduction

The Frozen Egg Tart Skin Market encompasses the production, distribution, and sale of pre-made, standardized pastry shells designed specifically for baking egg tarts. These skins offer substantial convenience to bakeries, restaurants, and household consumers, eliminating the time-intensive process of preparing delicate puff or shortcrust pastry from scratch. The product is typically sold frozen to preserve freshness and structural integrity, requiring only thawing and filling before baking. This segment is characterized by stringent quality control standards regarding flakiness, structural stability post-thaw, and ingredient traceability, catering to a growing consumer demand for authentic, high-quality baked goods that are simple to produce.

Major applications for frozen egg tart skins span commercial bakeries that utilize them for mass production efficiency, foodservice providers seeking consistency and reduced labor costs, and home bakers desiring quick, reliable dessert options. The inherent benefits of these frozen components include significant time savings, uniform product quality across batches, reduced ingredient waste, and longer shelf life compared to scratch-made dough. These benefits directly address critical pain points in the modern food industry, particularly labor shortages and the need for scalable operations without compromising traditional flavor and texture profiles.

Driving factors underpinning the market growth include the rising popularity of Asian fusion cuisine globally, the rapid expansion of convenience food sectors, and evolving consumer lifestyles that prioritize speed and ease of preparation. Furthermore, technological advancements in freezing and preservation techniques ensure that the frozen skins maintain optimal texture—a critical attribute for successful egg tarts. The growing infrastructure for cold chain logistics, particularly in emerging economies, further facilitates the widespread distribution of these temperature-sensitive products, supporting market expansion across diverse geographical regions.

Frozen Egg Tart Skin Market Executive Summary

The Frozen Egg Tart Skin Market is experiencing robust growth driven by accelerating demand from the commercial baking industry and increased adoption by home consumers seeking convenient, high-quality baking solutions. Key business trends indicate a strong focus on automation in production, utilizing advanced spiral freezers and high-speed forming machines to scale operations while maintaining consistent product dimensions and texture. Furthermore, sustainability and clean label trends are influencing manufacturers to explore alternative fats (like palm oil alternatives) and natural preservatives, adapting to health-conscious consumer bases. Strategic partnerships between specialized frozen dough manufacturers and large retail chains (supermarkets and convenience stores) are crucial for market penetration and maximizing cold chain efficiency, cementing the product's place as a staple convenience item in modern grocery retail.

Regionally, Asia Pacific (APAC) continues to dominate the market, anchored by deeply ingrained cultural consumption of egg tarts in regions like Hong Kong, Macau, and Mainland China. However, North America and Europe are exhibiting the fastest growth rates, spurred by increasing exposure to Asian desserts through immigration and global food trends, alongside the established preference for ready-to-use baking ingredients. Regional trends also highlight variation in preferred pastry style; while the classic puff pastry style dominates commercial markets in East Asia, shortcrust variations are seeing niche growth in Western artisanal bakeries seeking a richer, denser base. Expanding distribution networks tailored to ambient storage challenges remain a key focus for global players aiming for cross-regional market saturation.

Segment trends emphasize the prominence of the commercial segment (B2B sales to bakeries and restaurants) due to high volume requirements and stringent consistency needs. Based on product type, the classic Puff Pastry style holds the largest market share, valued for its characteristic layers and lightness, appealing widely to traditional consumer preferences. Conversely, the Shortcrust Pastry segment is demonstrating noteworthy growth, particularly within premium and specialized bakeries offering richer, butter-forward variations. The packaging segment is seeing innovation towards smaller, re-sealable packs designed for individual household use, optimizing convenience and reducing freezer burn, signaling a focused effort to capture the burgeoning retail consumer segment effectively.

AI Impact Analysis on Frozen Egg Tart Skin Market

Common user questions regarding AI's impact often revolve around optimization: "How can AI reduce material waste in large-scale pastry production?" "Can machine learning predict optimal freezing temperatures to preserve texture during long-distance shipping?" and "Will AI-driven consumer insights change flavor and size offerings?" Users are primarily concerned with how automation, predictive analytics, and quality control systems driven by Artificial Intelligence can enhance the efficiency, consistency, and resilience of the cold chain and manufacturing processes for delicate products like frozen egg tart skins. The consensus anticipates that AI will transform quality assurance, making the skins perfectly uniform and minimizing defects caused by human error or fluctuations in ambient processing conditions, thereby solidifying brand consistency and reducing returns.

- AI-driven optimization of mixing and lamination processes, ensuring uniform fat distribution and layer count critical for puff pastry quality.

- Predictive maintenance schedules for high-speed forming and spiral freezing equipment, minimizing unexpected downtime and maximizing throughput.

- Enhanced quality control through computer vision systems detecting subtle cracks, thickness deviations, or discoloration in pre-formed shells before freezing.

- Supply chain risk mitigation using machine learning to forecast demand fluctuations and optimize cold storage inventory levels, reducing spoilage.

- Personalized product development and flavor trend analysis, allowing manufacturers to quickly adapt tart skin specifications (e.g., lower sugar, whole wheat variants) based on real-time demographic data.

- Automated monitoring of critical freezing parameters (temperature, humidity, air speed) to maintain the optimal crystal structure within the dough, guaranteeing flakiness post-baking.

DRO & Impact Forces Of Frozen Egg Tart Skin Market

The Frozen Egg Tart Skin Market is propelled by significant Drivers (D), while facing inherent Restraints (R), and benefitting from substantial Opportunities (O), all shaped by potent Impact Forces. Key drivers include the global shift towards convenient and ready-to-bake products, the expansion of commercial bakery chains needing standardized components, and the increasing global appeal of Cantonese-style dim sum items. These drivers amplify the need for reliable, high-volume production capabilities, positioning frozen components as indispensable solutions. However, the market is restrained by the high operational costs associated with maintaining a robust cold chain logistics network, which is essential for preventing product degradation, alongside consumer perceptions that equate frozen products with inferior quality, though this perception is rapidly diminishing.

Opportunities for growth are abundant, notably through geographical expansion into untapped markets in Latin America and Africa, where cold chain infrastructure is developing rapidly. Product innovation, focusing on specialized variants such as vegan, gluten-free, or low-sugar skins, presents a pathway to capture premium, health-conscious consumer segments. Furthermore, strategic vertical integration by major players to control raw material sourcing (especially flour and specialized fats) can lead to improved cost efficiencies and enhanced supply chain resilience. The interplay between demand for convenience and the necessity for quality creates a dynamic environment where rapid freezing technology and premium ingredient sourcing are competitive differentiators.

The impact forces currently shaping the market are manifold. Technological advancement in blast freezing and packaging materials significantly impacts product quality and shelf stability. Socioeconomic shifts, particularly rising disposable incomes in APAC and the Westernization of diets in emerging markets, drive sustained demand. Regulatory scrutiny over food safety and ingredient transparency compels manufacturers to adopt rigorous certification standards (e.g., HACCP, ISO 22000). Competitive intensity remains high, primarily focused on pricing strategies for bulk commercial orders and continuous innovation in product performance (flakiness, ease of separation). Ultimately, the market trajectory is determined by balancing the cost of maintaining high-quality frozen infrastructure against the continuous surge in consumer demand for quick, authentic, and defect-free baking components.

Segmentation Analysis

The Frozen Egg Tart Skin Market is comprehensively segmented across several critical dimensions, including product type, pastry style, end-user application, and distribution channel, providing a granular view of market dynamics and consumer preferences. This segmentation facilitates targeted strategies by manufacturers, allowing them to tailor production specifications and marketing efforts to specific consumer groups, whether they are high-volume industrial bakeries or individual households. The primary differentiators across these segments relate to scale of usage, desired textural outcomes, and the structural integrity required for different production environments.

The dominance of the Puff Pastry style reflects traditional consumer expectations for a light, flaky base, primarily catering to commercial users who require skins capable of withstanding industrial baking processes. Conversely, segmentation by end-user clearly delineates the massive volume required by the commercial segment (B2B) versus the high-margin, smaller-pack sales characterizing the retail segment (B2C). Understanding these differences is vital for supply chain planning, as B2B contracts often involve specialized bulk packaging (e.g., stackable trays with interleaving paper) optimized for minimal freezer space, whereas B2C packaging prioritizes consumer information and shelf appeal.

- By Product Type:

- Classic Frozen Egg Tart Skin

- Low-Fat Frozen Egg Tart Skin

- Gluten-Free Frozen Egg Tart Skin

- Vegan Frozen Egg Tart Skin

- By Pastry Style:

- Puff Pastry (Dominant)

- Shortcrust Pastry (Niche/Premium)

- By End User:

- Commercial (Bakeries, Restaurants, Hotels, Cafes)

- Retail (Household Consumers)

- By Distribution Channel:

- Supermarkets/Hypermarkets

- Convenience Stores

- Online Retail

- Direct Sales (B2B Supply)

Value Chain Analysis For Frozen Egg Tart Skin Market

The value chain for the Frozen Egg Tart Skin Market begins with upstream activities involving the sourcing and procurement of primary ingredients—flour, specialized fats (butter, margarine, vegetable shortenings), water, and minor ingredients like salt and stabilizing agents. Crucially, the quality of the flour (protein content for puff pastry lamination) and the consistency of the fat are paramount, dictating the final flakiness and structural stability of the product. Upstream suppliers must meet stringent quality metrics and often require long-term contracts to ensure stable pricing and ingredient consistency, especially for specialized non-GMO or organic ingredients, adding a layer of complexity to initial cost management.

The core midstream activity involves specialized manufacturing processes: dough mixing, precise lamination (folding and rolling to create hundreds of layers), cutting and forming the individual tart skins, blast freezing (to lock in freshness quickly), and packaging. This stage is highly capital-intensive, relying on advanced automated machinery—dough sheeters, presses, and high-capacity spiral freezers—to achieve the necessary volume and geometric precision. Operational efficiency at this stage is a major determinant of profitability, where minimizing waste during forming and optimizing freezer cycle times are critical performance indicators, influencing the final cost to the consumer and commercial buyers alike.

Downstream activities center on distribution, sales, and retail. Due to the requirement for continuous temperature monitoring (typically below -18°C), cold chain logistics are the most expensive and complex part of the downstream process. Distribution channels vary significantly between B2B (direct supply to large bakery commissaries) and B2C (via refrigerated trucks to supermarkets and convenience stores). Direct sales offer better control over product handling, while retail channels rely heavily on the integrity of third-party logistics providers and in-store freezer management. Effective marketing and merchandising, often emphasizing convenience and quality, further finalize the value chain interaction with the end consumer, ensuring optimal freezer visibility and rapid inventory turnover at the point of sale.

Frozen Egg Tart Skin Market Potential Customers

The primary consumers and end-users of frozen egg tart skins are bifurcated into two major segments: commercial establishments (B2B) and household consumers (B2C). Commercial customers constitute the largest volume segment, including large-scale industrial bakeries, specialized dim sum restaurants, high-end hotel chains, and catering services. These entities seek consistent, standardized products that drastically reduce labor costs, standardize recipe output across multiple locations, and ensure a reliable supply for high-demand periods. Their purchasing decisions are primarily driven by bulk pricing, consistent quality specifications (size, thickness, layer count), and the manufacturer's capacity for timely, large-volume delivery under strict cold chain controls, viewing the skins as a critical component in maintaining operational efficiency.

The retail sector, encompassing household consumers, is rapidly emerging as a high-growth segment, driven predominantly by convenience and the desire for quick, high-quality home baking. Key demographics include working professionals, millennials experimenting with global cuisines, and families seeking fast dessert solutions. These buyers appreciate the pre-made nature of the skins, eliminating the difficult and messy steps of dough preparation, making the final assembly and baking process straightforward. Their buying behavior is influenced by packaging size (smaller, resealable options), brand reputation for quality (flakiness), and ease of availability in local supermarkets' freezer aisles, demonstrating a willingness to pay a premium for convenience and reliability in the final baked product.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 2.10 Billion |

| Growth Rate | CAGR 7.6% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | General Mills, Rhodes Bake-N-Serv, Rich Products Corporation, Lantmännen Unibake, Fazer Group, Aryzta AG, Grupo Bimbo, BakeMark, Shanghai Meiqin Food, Guangzhou Qinyi Food Co., Ltd., Sanxia Frozen Food, Dongguan Meishi Food Co., Ltd., Hangzhou Baoding Food Co., Ltd., Pastry Star Bakery, Gonnella Baking Co., CSM Bakery Solutions, J&J Snack Foods, Conagra Brands, Tyson Foods (Frozen Division), Kerry Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Frozen Egg Tart Skin Market Key Technology Landscape

The manufacturing of high-quality Frozen Egg Tart Skins relies heavily on specialized food processing and preservation technologies. A foundational technology is high-precision lamination and sheeting equipment, which is critical for creating the hundreds of delicate layers required for authentic puff pastry. These industrial sheeters use automated rollers and folding mechanisms to ensure layer uniformity and minimize dough temperature rise, preventing fat migration which would compromise flakiness. The precision afforded by these systems is directly correlated with the final baked quality, establishing a high barrier to entry for new market participants who lack access to state-of-the-art lamination technology.

Following dough preparation and forming, rapid freezing technology is paramount. Blast freezing or cryogenic freezing systems (often using liquid nitrogen or CO2) are employed to lower the core temperature of the tart skins extremely quickly. This rapid process minimizes the formation of large ice crystals within the dough structure. Large ice crystals degrade the gluten network and damage the delicate pastry layers, leading to a tough or collapsed texture upon thawing and baking. By using ultra-rapid freezing, manufacturers ensure that the water in the dough forms micro-crystals, preserving the integrity and elasticity necessary for the characteristic lift and flakiness of a quality egg tart skin.

Furthermore, advanced packaging technology plays a crucial role in maintaining product quality during extended storage and transit. This includes the use of modified atmosphere packaging (MAP) and specialized freezer-safe films that resist moisture vapor transmission (MVT) and oxygen ingress, preventing freezer burn and oxidative rancidity of the fat components. Robotics are increasingly integrated into the packaging phase to handle the fragile, pre-formed shells gently, minimizing damage and ensuring consistent placement within stackable commercial trays or retail boxes. The integration of IoT sensors within cold storage and transport vehicles provides real-time monitoring of temperature and humidity, ensuring compliance with strict cold chain requirements and generating verifiable proof of quality assurance throughout the distribution cycle.

Regional Highlights

The regional analysis of the Frozen Egg Tart Skin Market reveals stark differences in market maturity, consumer habits, and growth trajectories across global geographies. Asia Pacific (APAC) stands as the undisputed market leader, primarily driven by the entrenched culinary tradition of consuming egg tarts (Daan Tat) in East Asia, particularly in Hong Kong, Macau, China, and Taiwan. The infrastructure for frozen food distribution is highly developed in key urban centers, supporting massive consumption volumes from both commercial bakeries and a highly receptive retail market. Manufacturers in this region often focus on optimizing scalability and providing slight regional variations in pastry texture (e.g., more butter-heavy shortcrust in some localized areas versus the flaky puff pastry predominantly demanded elsewhere). This established demand base provides a strong foundation for sustained market dominance, emphasizing quick-to-market strategies for new, specialized product lines such as whole-grain or reduced-sugar options.

North America and Europe represent the fastest-growing regions, benefiting significantly from increasing globalization of food trends and substantial immigration from Asian countries. The demand in these regions is heavily concentrated in large metropolitan areas with diverse populations and a high density of specialized Asian bakeries and restaurants. The convenience factor is highly valued by Western consumers, driving strong adoption in the retail segment, particularly among busy professionals seeking gourmet results with minimal effort. European growth is additionally boosted by the mature frozen bakery industry, which possesses the existing cold chain infrastructure capable of efficiently handling these sensitive products. Manufacturers entering these markets must navigate stricter food safety regulations and often must reformulate products to align with regional consumer preferences for lower saturated fats or clean label ingredients, which can impact profitability and production complexity.

Latin America (LATAM) and the Middle East & Africa (MEA) currently hold smaller market shares but present substantial long-term growth opportunities. Growth in LATAM is intrinsically linked to ongoing improvements in cold chain logistics and the rising middle-class disposable income, which is fueling demand for imported and exotic convenience foods. In MEA, market penetration is nascent, largely restricted to high-end hospitality sectors and expatriate communities. The key challenge across both regions remains the significant investment required to establish and maintain reliable temperature-controlled distribution channels, especially in geographically dispersed or climatically challenging areas. Success in these emerging markets hinges on strategic partnerships with local distributors who possess established infrastructure and deep local market knowledge, allowing international players to gradually introduce products tailored to emerging local tastes and purchasing power dynamics.

- Asia Pacific (APAC): Market Dominance; Driven by deep cultural integration of egg tarts; High volume B2B consumption; Key markets include China, Hong Kong, and Singapore.

- North America: Rapid Growth; Fueled by culinary globalization and convenience demand; Strong retail adoption; Focus on specialty and premium ingredient skins.

- Europe: Fast Expansion; Leveraging existing mature frozen food distribution network; Regulatory focus on ingredient transparency and quality; Growth concentrated in urban centers (UK, France, Germany).

- Latin America (LATAM): Emerging Market; Growth contingent on cold chain infrastructure development; Focus on affordable, large-scale imported products in urban areas.

- Middle East and Africa (MEA): Niche Growth; Primarily driven by tourism, hospitality sector, and expatriate demand; Significant logistical challenges necessitating high investment in specialized distribution.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Frozen Egg Tart Skin Market.- General Mills

- Rhodes Bake-N-Serv

- Rich Products Corporation

- Lantmännen Unibake

- Fazer Group

- Aryzta AG

- Grupo Bimbo

- BakeMark

- Shanghai Meiqin Food

- Guangzhou Qinyi Food Co., Ltd.

- Sanxia Frozen Food

- Dongguan Meishi Food Co., Ltd.

- Hangzhou Baoding Food Co., Ltd.

- Pastry Star Bakery

- Gonnella Baking Co.

- CSM Bakery Solutions

- J&J Snack Foods

- Conagra Brands

- Tyson Foods (Frozen Division)

- Kerry Group

Frequently Asked Questions

Analyze common user questions about the Frozen Egg Tart Skin market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Frozen Egg Tart Skin Market?

The central growth driver is the increasing global consumer demand for convenience food solutions, particularly in the baking sector, alongside the accelerating popularity and commercialization of traditional Asian desserts worldwide, which necessitates standardized, high-volume components.

How does the cold chain impact the quality and cost of frozen egg tart skins?

The mandatory maintenance of a robust cold chain (consistent freezing temperatures) is critical to preserving the layered structure and flakiness of the pastry. This infrastructure, including blast freezers and specialized transport, represents a significant proportion of the total operational cost, directly influencing the final product price.

Which pastry style holds the largest market share in the frozen egg tart skin industry?

The Puff Pastry style dominates the market share due to its traditional appeal, light, flaky texture, and widespread use by commercial bakeries for authentic Cantonese egg tarts. However, Shortcrust Pastry variants are growing rapidly in niche premium segments.

What technological innovations are most critical for the future production of frozen tart skins?

Key technological advancements include ultra-rapid blast freezing (cryogenic technology) to ensure micro-crystal formation, automated high-precision lamination equipment for layer consistency, and the integration of AI for predictive quality control and waste minimization.

Is the Frozen Egg Tart Skin Market seeing growth in specialized dietary segments?

Yes, driven by health and wellness trends, the market is actively expanding its offerings to include specialized variants such as vegan egg tart skins (using plant-based fats) and gluten-free options, catering to consumers with specific dietary restrictions and preferences.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager