Fruit and Vegetable Enzymes Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437512 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Fruit and Vegetable Enzymes Market Size

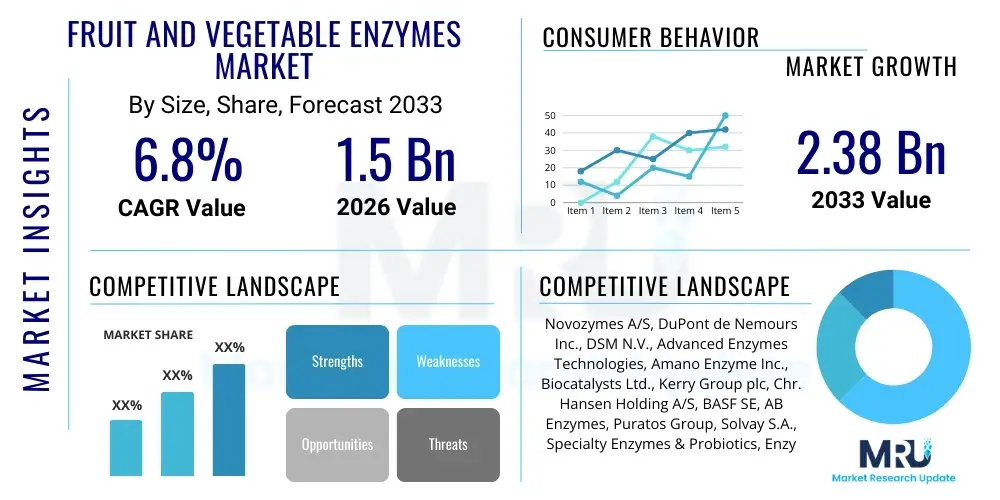

The Fruit and Vegetable Enzymes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.38 Billion by the end of the forecast period in 2033.

Fruit and Vegetable Enzymes Market introduction

The Fruit and Vegetable Enzymes Market encompasses the production, distribution, and utilization of catalytic proteins derived primarily from fruit and vegetable sources, or produced by microbial fermentation for application in processing these materials. These specialized enzymes, including pectinase, cellulase, amylase, and protease, are vital biological tools that facilitate numerous industrial processes, predominantly within the food and beverage sectors. The intrinsic ability of these enzymes to perform specific biochemical reactions under mild conditions (temperature, pH) makes them superior alternatives to harsh chemical treatments, enhancing efficiency, improving product quality, and reducing environmental impact across the value chain. Key applications range from juice clarification and enhanced extraction of bioactive compounds to improved texture modification and waste utilization in agricultural processing.

Product descriptions within this market focus on enzyme specificity and purity, often tailored for distinct applications such as optimizing mash filtration in wine production or increasing the yield of essential oils. Major applications are concentrated in the production of clear fruit juices, vegetable purées, purees, and the preparation of functional food ingredients. The inherent benefits include superior organoleptic qualities in finished products, preservation of nutritional integrity, and streamlining of complex industrial separation processes. Furthermore, the market benefits significantly from the accelerating consumer demand for natural, clean-label ingredients, positioning fruit and vegetable derived enzymes as essential components in modern food technology.

Driving factors propelling market expansion include global population growth necessitating higher food processing throughput, increasing investments in functional foods and nutraceuticals, and stringent regulatory environments promoting sustainable and enzyme-based processing methods. Technological advancements in enzyme engineering and immobilization techniques further enable customized enzyme cocktails with improved stability and efficiency. The versatility of these biocatalysts allows for their application in optimizing processes such as peeling, blanching, fermentation, and detoxification of raw plant materials, solidifying their role as indispensable processing aids in the food, cosmetic, and pharmaceutical industries.

Fruit and Vegetable Enzymes Market Executive Summary

The Fruit and Vegetable Enzymes Market is characterized by robust growth, driven primarily by evolving consumer preferences for natural food ingredients and the necessity for sustainable, high-efficiency processing solutions across global food industries. Business trends indicate a strong move toward specialization, where key manufacturers are investing heavily in R&D to develop novel, highly specific enzyme blends optimized for exotic fruits or challenging vegetable matrices, enhancing extraction yields for premium ingredients like antioxidants and dietary fibers. Strategic partnerships focusing on backward integration, linking enzyme producers directly with raw material suppliers and end-product manufacturers, are becoming prevalent to ensure quality control and supply chain resilience. Furthermore, the adoption of proprietary fermentation technologies is enabling cost-effective, large-scale production of specialized microbial enzymes mimicking those derived from plants.

Regional trends highlight the Asia Pacific (APAC) region as the fastest-growing market, spurred by rapid urbanization, increasing per capita consumption of processed foods and beverages, particularly fruit juices, and substantial growth in regional bioprocessing capacities, notably in China and India. North America and Europe, while mature markets, continue to lead in terms of technological adoption and demand for premium, high-purity enzymes used in specialized dietary supplements and clean-label products. Regulatory harmonization efforts in these established economies are also facilitating the market entry of novel enzyme products, ensuring consumer safety and boosting cross-border trade. Demand in Latin America is also accelerating, driven by the expansion of the regional beverage industry and increased focus on utilizing local fruit crops efficiently.

Segment trends underscore the dominance of Pectinase within the product type segmentation due to its indispensable role in juice clarification, especially for apple, grape, and citrus products. Application-wise, the food and beverage industry remains the largest segment, with significant growth projected in the nutraceuticals sector, where enzymes are used to enhance the bioavailability of plant-derived compounds. The rising acceptance of immobilized enzyme technology is also trending across segments, offering manufacturers reusable catalysts, thereby lowering operational costs and improving process control. This combined focus on natural sourcing, technological innovation, and application diversification ensures the continued upward trajectory of the Fruit and Vegetable Enzymes Market through the forecast period.

AI Impact Analysis on Fruit and Vegetable Enzymes Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Fruit and Vegetable Enzymes Market often revolve around optimizing enzyme discovery, enhancing fermentation processes, predicting enzyme stability in industrial environments, and personalizing dietary recommendations based on enzyme requirements. Users are keen to understand how AI-driven bioinformatics can accelerate the identification of novel, high-performance enzyme variants from vast genomic and proteomic databases of plant and microbial sources. Concerns frequently touch upon the investment required for integrating AI platforms and the availability of skilled personnel capable of managing complex algorithms for strain optimization and process parameter tuning. The overarching expectation is that AI will dramatically reduce R&D cycles and significantly improve the yield and consistency of enzyme manufacturing, leading to superior product performance at lower costs for end-users in food and pharma industries.

The application of Machine Learning (ML) algorithms is revolutionizing enzyme engineering by predicting the structural changes required to improve catalytic activity, thermal stability, and resistance to inhibitors, which are critical features for large-scale industrial use. By analyzing historical data from bioreactors, AI models can precisely adjust variables such as temperature, pH, nutrient feed rate, and oxygen levels in real-time, achieving optimal microbial growth and maximum enzyme production yields during the fermentation stage. This predictive modeling capability minimizes batch failures and reduces energy consumption, directly impacting the operational expenditure of enzyme manufacturers. Consequently, AI is transforming enzyme production from a labor-intensive, trial-and-error process into a highly automated, data-driven domain.

Furthermore, AI is playing a vital role in enhancing quality control and traceability within the enzyme supply chain. Computer vision and sensor data analyzed by AI can rapidly assess the purity and concentration of enzyme preparations, ensuring compliance with stringent regulatory standards like those set by the FDA and EFSA. In the consumer space, AI-powered nutritional platforms can analyze an individual's diet and potential digestive sensitivities, recommending specific fruit or vegetable enzyme supplements (e.g., bromelain, papain) to aid digestion or maximize nutrient absorption. This personalization trend, driven by advanced data analytics, is creating new, highly segmented demand pools for specialized enzymes and driving demand for high-purity, standardized products.

- AI-driven optimization of microbial fermentation parameters (pH, temperature, oxygen) for maximized enzyme yield.

- Accelerated discovery of novel thermostable and pH-resistant enzyme variants through bioinformatics and machine learning.

- Predictive modeling of enzyme performance and stability in diverse food matrices and processing conditions.

- Enhanced quality control and purity assessment using AI-powered spectroscopic analysis and computer vision systems.

- Development of personalized enzyme supplements based on individual genomic and dietary data analysis.

DRO & Impact Forces Of Fruit and Vegetable Enzymes Market

The Fruit and Vegetable Enzymes Market is propelled by significant drivers, notably the widespread adoption of enzyme technology to replace traditional chemical processes, adhering to global sustainability mandates and the growing consumer demand for natural, minimally processed food products. Restraints, however, include the high capital expenditure required for sophisticated enzyme manufacturing and purification facilities, alongside the sensitivity of enzymes to environmental factors such as temperature and pH, which necessitates careful handling and storage. Opportunities abound in exploring novel applications in sectors like biofuel production from fruit and vegetable waste, and developing highly thermostable enzymes suitable for extreme processing conditions. These factors converge to shape the overall impact forces on market trajectory, pushing manufacturers toward continuous technological refinement and application diversification.

Key drivers center on regulatory support for bio-based industrial practices, particularly in developed economies, which favor enzyme use over chemical agents to minimize chemical residues in final products. The efficiency gains offered by enzymes—such as increased juice yield (up to 20% in some fruit types) and faster processing times—provide strong economic incentives for adoption across the beverage and food processing industries. Furthermore, the rising awareness regarding the health benefits associated with plant-derived enzymes, such as improved digestion and anti-inflammatory properties (e.g., bromelain from pineapple), is fueling the dietary supplements segment. This intrinsic link between consumer health trends and functional food development is a powerful market accelerator.

Conversely, significant restraints hinder growth, particularly the complex global intellectual property landscape surrounding novel enzyme strains, which can restrict widespread adoption and lead to lengthy legal disputes. Another considerable challenge is the inherent cost instability of raw materials (fruits and vegetables, or microbial growth media), which affects the profitability of enzyme manufacturing, especially for highly specific, low-volume enzymes. Overcoming these restraints necessitates continuous innovation in enzyme immobilization and encapsulation technologies, enhancing enzyme stability and reusability, thereby mitigating replacement frequency and reducing overall operational costs for end-users. The overall impact force matrix suggests a strong positive trajectory, albeit with moderate volatility influenced by supply chain constraints and regulatory shifts regarding GMO-derived enzymes.

Segmentation Analysis

The Fruit and Vegetable Enzymes Market is comprehensively segmented based on product type, source, application, and formulation, providing a granular view of market dynamics and specialized demand areas. The market segmentation reflects the diverse utility of these biocatalysts across various industrial processes, with each segment experiencing growth driven by unique technological requirements and consumer trends. Product types like Pectinase and Amylase command significant market shares, while the sourcing distinction (plant vs. microbial) defines production costs and regulatory acceptance. Understanding these segments is crucial for stakeholders to tailor their product offerings, align with specific industry needs, such as maximizing juice clarity or improving dough texture, and target high-growth regions like Asia Pacific where industrial food processing is rapidly scaling.

The application segment, spanning from food and beverage processing to nutraceuticals and cosmetics, demonstrates the versatility of fruit and vegetable enzymes. The food and beverage sector utilizes enzymes predominantly for clarification, extraction, and fermentation, demanding bulk volumes of cost-effective, high-activity enzymes. Conversely, the nutraceutical and pharmaceutical segments require high-purity, standardized enzyme preparations (like specific proteases and lipases) often used in encapsulation or tablet forms to enhance digestive health or act as anti-inflammatory agents. This distinction drives manufacturing specifications and pricing strategies across the market. The formulation type—liquid versus solid—also plays a critical role, influencing logistics, shelf-life, and ease of integration into different industrial machinery.

Analyzing sub-segments reveals that within the food and beverage application, the juice and beverage industry is the primary consumer, relying heavily on pectinases and cellulases to hydrolyze structural components in fruit pulp, leading to higher yields and reduced viscosity. The trend toward developing customized, multi-enzyme systems (cocktails) is accelerating, allowing processors to simultaneously tackle complex matrices, such as tropical fruit blends containing high levels of complex carbohydrates and structural fibers. Geographical segmentation further emphasizes regional specialization, with North America and Europe focusing on premium, functional enzyme products, while APAC concentrates on high-volume production enzymes for mass-market processing, showcasing distinct demand patterns and competitive landscapes globally.

- By Product Type:

- Pectinase

- Amylase

- Cellulase

- Protease

- Lipase

- Others (Oxidase, Phytase)

- By Source:

- Plant Source (e.g., Papain, Bromelain)

- Microbial Source (Fermentation-derived)

- By Application:

- Food and Beverages

- Juice and Nectar Processing (Clarification, Extraction)

- Baking and Confectionery

- Brewing and Fermentation

- Dairy Processing

- Nutraceuticals and Dietary Supplements

- Cosmetics and Personal Care

- Animal Feed

- Pharmaceuticals and Medical Applications

- By Formulation:

- Liquid

- Powder/Solid

- Immobilized Enzymes

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, Japan, India, Australia, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East and Africa (South Africa, GCC Countries, Rest of MEA)

Value Chain Analysis For Fruit and Vegetable Enzymes Market

The Value Chain for the Fruit and Vegetable Enzymes Market begins with upstream activities focused on sourcing raw materials, primarily encompassing agricultural produce (fruits and vegetables) or highly specialized microbial strains used for large-scale fermentation. Upstream analysis involves R&D for strain improvement, optimizing media composition, and ensuring the consistent supply of high-quality, non-GMO substrate materials. Manufacturers invest significantly in bioprocess engineering to maximize enzyme yield and activity during the fermentation or extraction stage. Controlling material purity and biological safety at this initial stage is paramount, as it directly impacts the final enzyme efficacy and regulatory compliance, particularly regarding food-grade standards.

The midstream process involves enzyme isolation, purification, and formulation. After fermentation or extraction, crude enzymes undergo rigorous purification steps, including chromatography and ultrafiltration, to remove impurities and concentrate the active enzyme component. Formulation activities convert the purified enzyme into stable forms, typically liquid concentrates or standardized powders, often incorporating stabilizers or encapsulating agents to enhance shelf stability and performance in diverse industrial environments. This stage adds significant value through proprietary processing techniques and quality assurance protocols, transforming a biological output into a marketable, high-specification industrial product.

Downstream analysis focuses on distribution channels and end-user engagement. Distribution channels are typically specialized, relying on cold-chain logistics due to the temperature sensitivity of many enzymes. Direct channels involve manufacturers supplying large-scale food and beverage processors (e.g., major juice companies) who integrate the enzymes directly into their production lines. Indirect channels involve collaboration with specialized industrial ingredient distributors who service smaller businesses and manage complex inventory needs across diverse geographies. The success of the downstream activities hinges on providing robust technical support and customized enzyme solutions that address specific application challenges faced by end-users, such as optimizing yield in a new fruit variety or overcoming filtration issues in wine production.

Fruit and Vegetable Enzymes Market Potential Customers

The potential customers for Fruit and Vegetable Enzymes span across various major industries requiring biocatalytic enhancements for product processing, yield optimization, and quality improvement. The primary consumer base consists of large-scale food and beverage manufacturers, specifically those operating in the juice, wine, brewing, and bakery sectors. These buyers seek enzymes like pectinase for juice clarification and extraction, and amylase for starch hydrolysis in brewing. Their buying decisions are heavily influenced by enzyme activity units, formulation stability, cost-effectiveness, and compliance with stringent food safety certifications (ISO 22000, HACCP). These industrial clients require reliable, bulk supply and often engage in long-term procurement contracts with manufacturers.

A rapidly expanding segment of potential customers includes nutraceutical and dietary supplement producers. These buyers demand highly purified, pharmaceutical-grade enzymes such as bromelain and papain, used for digestive aid supplements and formulations targeting inflammation management. Unlike the food industry, these customers prioritize enzyme purity, standardized dosage, non-allergenic status, and strong clinical backing. They utilize enzymes primarily in powder or encapsulated forms and their purchasing is often driven by consumer health trends, particularly the increasing interest in natural, plant-derived health solutions, making R&D capabilities and regulatory expertise of the enzyme supplier critical factors.

Secondary, yet significant, customer bases include the cosmetic and personal care industries, utilizing enzymes for gentle exfoliation (in skin peels and masks) and formulation stabilization, and the animal feed sector, where enzymes enhance the digestibility of vegetable-based feed ingredients, improving nutrient absorption and animal health. Furthermore, emerging customers are found in biochemical and waste management industries seeking cellulases and other complex enzymes for biofuel production (e.g., cellulosic ethanol) and the sustainable breakdown of agro-industrial residues. These diverse end-users collectively drive the demand for a broad portfolio of enzymes, ranging from cost-efficient industrial grades to premium, high-purity specialties.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.38 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Novozymes A/S, DuPont de Nemours Inc., DSM N.V., Advanced Enzymes Technologies, Amano Enzyme Inc., Biocatalysts Ltd., Kerry Group plc, Chr. Hansen Holding A/S, BASF SE, AB Enzymes, Puratos Group, Solvay S.A., Specialty Enzymes & Probiotics, Enzybel International S.A., IFF (International Flavors & Fragrances), Antozyme Biotech Pvt. Ltd., Enzyme Development Corporation, Sanyo Chemical Industries, Inc., Codexis, Inc., Creative Enzymes. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fruit and Vegetable Enzymes Market Key Technology Landscape

The Fruit and Vegetable Enzymes Market relies heavily on sophisticated biotechnology and engineering techniques to ensure the commercial viability and functional superiority of its products. Key technologies are centered around optimizing the source material, improving bioprocessing efficiency, and enhancing the enzyme's stability during application. Microbial fermentation technology remains the bedrock of large-scale enzyme production, where advanced bioreactor design and precise process control (utilizing technologies like Continuous Flow Synthesis) ensure maximum expression of target enzymes from engineered fungal or bacterial strains. Genetic engineering and directed evolution techniques are increasingly employed to modify enzyme structures, resulting in variants with superior activity, increased resistance to temperature and pH variations, and specific substrate affinity tailored for complex fruit matrices like tropical fruits or high-acid citrus products.

A pivotal technological advancement driving market efficiency is enzyme immobilization. This process involves affixing enzymes to an inert support material (such as porous resins, silica, or magnetic nanoparticles), preventing them from being washed away during continuous industrial processing. Immobilization dramatically improves the operational stability and reusability of the catalysts, significantly lowering processing costs and facilitating easier separation from the final product, which is particularly critical in applications requiring ultra-pure output, such as pharmaceutical intermediaries or infant nutrition ingredients. Furthermore, encapsulation technologies, utilizing liposomes or polymer matrices, are being refined to protect the enzyme integrity during storage and delivery, especially for digestive supplements that must survive the harsh environment of the human stomach before reaching the intestine.

In addition to production and stability enhancements, the market leverages advanced analytical techniques to define product quality and application success. High-throughput screening (HTS) systems rapidly assess thousands of enzyme variants for desirable properties, drastically speeding up the R&D pipeline. Spectroscopic methods, coupled with bioinformatics, are used for precise activity measurement and quality assurance, ensuring batch-to-batch consistency—a non-negotiable requirement for major industrial customers. The integration of digital technologies, including sensors and real-time monitoring systems in bioreactors, forms part of Industry 4.0 standards, allowing manufacturers to leverage vast amounts of operational data to further refine enzyme production protocols, moving toward fully autonomous, predictive manufacturing environments.

Regional Highlights

- North America: This region is characterized by high consumption of processed foods, established regulatory infrastructure (FDA compliance), and significant R&D spending, positioning it as a key market for specialized and high-ppurity enzymes. The demand is heavily skewed towards nutraceuticals and digestive health supplements, driving innovation in plant-derived enzymes like bromelain and papain. The U.S. remains the dominant consumer, driven by large commercial juice and wine industries that heavily rely on advanced pectinase and cellulase systems for efficient processing and clean labeling. Furthermore, strict food safety standards encourage the use of microbial enzymes as process aids, reducing reliance on chemical alternatives.

- Europe: Europe is a mature but highly influential market, largely driven by rigorous sustainability goals and the demand for clean-label, natural ingredients, heavily supported by EFSA regulations. Key countries like Germany, France, and the Netherlands lead in technological adoption, particularly in brewing, dairy, and fruit processing, focusing on high-efficiency enzyme cocktails for maximizing yield from local crops (e.g., apples, grapes, potatoes). The strong presence of major global enzyme manufacturers (like Novozymes and DSM) contributes to continuous innovation, especially concerning immobilized enzymes and the development of non-GMO certified microbial strains, serving a highly conscious consumer base.

- Asia Pacific (APAC): APAC is projected to exhibit the fastest growth rate, fueled by demographic shifts, increasing middle-class spending, and the rapid expansion of the food and beverage industry, particularly in China and India. The region is a significant consumer of enzymes for mass-market applications such as fruit juice clarification and stabilization in tropical fruit processing. While cost-competitiveness is a key factor, there is a growing trend toward high-quality enzymes to meet export standards. Government initiatives supporting biotechnology and the burgeoning local enzyme manufacturing base further catalyze market expansion across Southeast Asia.

- Latin America (LATAM): The LATAM market growth is intrinsically linked to its vast agricultural output and thriving local beverage industry, especially in Brazil and Argentina, which are major producers of citrus fruits, sugarcane, and wine. Enzymes, particularly pectinases and proteases, are essential for managing large volumes of raw agricultural produce, enhancing extraction, and improving fermentation efficiency. Market penetration is accelerating as local processors recognize the economic advantages of enzyme use, leading to increased foreign investment in local distribution networks and processing technology upgrades.

- Middle East and Africa (MEA): This region is an emerging market with substantial untapped potential. Growth is driven by increasing industrialization in food manufacturing (especially in the GCC countries and South Africa) aimed at reducing reliance on imports and ensuring local food security. Enzyme utilization is focused on applications that improve shelf stability and processing quality in challenging climatic conditions, such as those related to water scarcity and high temperatures. Investment in local processing plants, coupled with strategic partnerships with global enzyme suppliers, is essential for unlocking the full market potential in MEA.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fruit and Vegetable Enzymes Market.- Novozymes A/S

- DuPont de Nemours Inc. (now IFF/Danisco)

- DSM N.V.

- Advanced Enzymes Technologies

- Amano Enzyme Inc.

- Biocatalysts Ltd.

- Kerry Group plc

- Chr. Hansen Holding A/S

- BASF SE

- AB Enzymes

- Puratos Group

- Solvay S.A.

- Specialty Enzymes & Probiotics

- Enzybel International S.A.

- IFF (International Flavors & Fragrances)

- Antozyme Biotech Pvt. Ltd.

- Enzyme Development Corporation

- Sanyo Chemical Industries, Inc.

- Codexis, Inc.

- Creative Enzymes

Frequently Asked Questions

Analyze common user questions about the Fruit and Vegetable Enzymes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of pectinase enzymes in industrial settings?

Pectinase enzymes are primarily utilized in the food and beverage industry for juice clarification, maceration of fruit pulp, and improving filtration rates in the production of fruit juices, ciders, and wines. They degrade pectin, reducing viscosity and enhancing yield and clarity. AEO focus: Juice clarification, enhanced filtration, and yield improvement in beverage processing.

How does enzyme immobilization benefit the fruit and vegetable processing market?

Enzyme immobilization involves binding enzymes to inert supports, which significantly increases their stability, extends their lifespan, and allows for continuous reuse in production cycles. This technique drastically reduces operational costs, simplifies separation from the final product, and enhances process control and consistency. AEO focus: Cost reduction, enzyme reusability, enhanced stability, and continuous process optimization.

Which regulatory bodies govern the use of food-grade enzymes derived from fruits and vegetables?

The use of food-grade enzymes is governed by major international bodies, including the U.S. Food and Drug Administration (FDA), the European Food Safety Authority (EFSA), and the Joint FAO/WHO Expert Committee on Food Additives (JECFA). Regulations ensure safety, proper labeling, and define permissible production methods, including those involving genetically modified microorganisms. AEO focus: FDA, EFSA, JECFA compliance, food safety, and processing aid classification.

What are the key differences between plant-sourced and microbially-sourced fruit and vegetable enzymes?

Plant-sourced enzymes (e.g., bromelain from pineapple, papain from papaya) are extracted directly from the produce and offer natural appeal, but supply can be volatile. Microbially-sourced enzymes are produced via fermentation (using fungi or bacteria) and offer superior consistency, scalability, cost-effectiveness, and often better thermal stability for industrial applications. AEO focus: Source reliability, scalability, thermal stability, and natural origin labeling differentiation.

What role do Fruit and Vegetable Enzymes play in the growing nutraceutical market?

In the nutraceutical market, enzymes are used primarily as digestive aids to enhance the breakdown and absorption of nutrients, proteins, and fibers from the diet. Specific enzymes like proteases are incorporated into supplements to support digestive health and potentially offer anti-inflammatory benefits, addressing the demand for plant-derived functional ingredients. AEO focus: Digestive health supplements, nutrient absorption enhancement, anti-inflammatory agents, functional food ingredients.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager