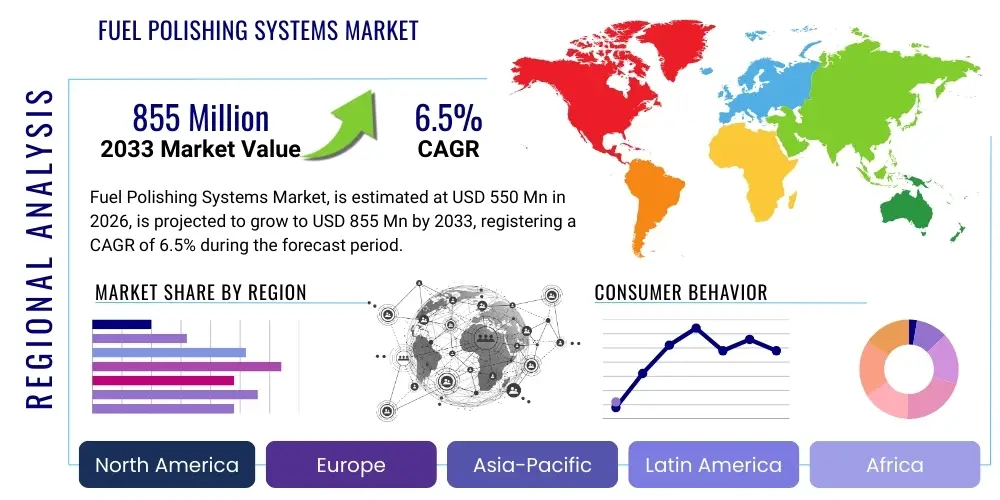

Fuel Polishing Systems Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438669 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Fuel Polishing Systems Market Size

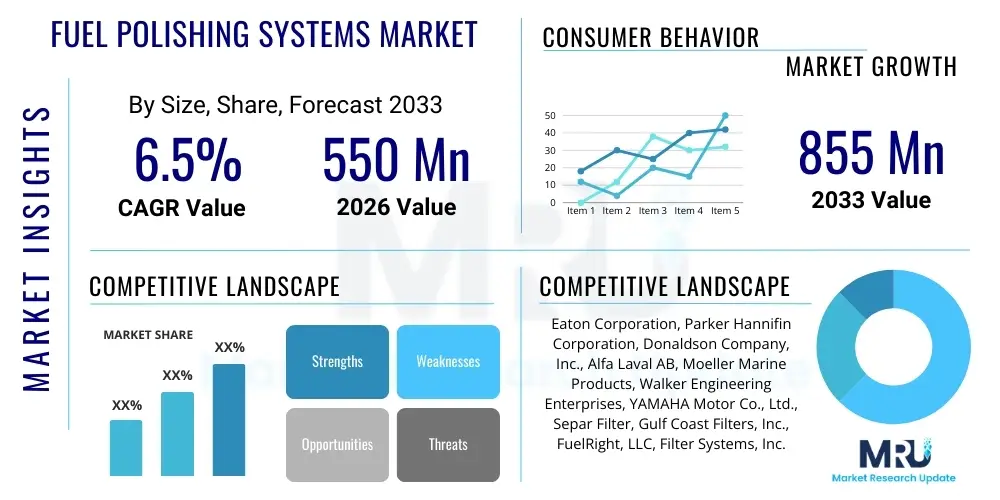

The Fuel Polishing Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 855 Million by the end of the forecast period in 2033. This consistent growth trajectory is primarily fueled by the increasing necessity for reliable backup power infrastructure across critical industries, coupled with the stringent regulations governing fuel quality and storage, particularly concerning the stability and shelf life of ultra-low sulfur diesel (ULSD) and biodiesel blends.

Fuel Polishing Systems Market introduction

Fuel polishing systems are essential mechanical processes designed to maintain the integrity, cleanliness, and operational viability of stored fuels, predominantly diesel. This process involves recirculating the fuel through sophisticated multi-stage filtration units that remove particulate matter, sludge, water, and crucially, microbial contamination (known as "diesel bug"). Given that stored fuel, particularly in long-term backup generators or marine tanks, degrades over time through oxidation, condensation, and microbial proliferation, fuel polishing ensures that the fuel remains within the quality specifications required for high-performance engines, preventing costly breakdowns and system failures during emergency use.

The core product encompasses mobile and fixed systems incorporating coalescing filters for water separation, magnetic separators for rust and ferrous material, and fine particulate filters capable of reaching sub-micron levels. Major applications span critical infrastructure such as hospitals, data centers, telecommunication hubs, and military installations, where operational continuity is non-negotiable. Furthermore, the burgeoning maritime industry, including large commercial vessels and luxury yachts, relies heavily on these systems to safeguard expensive propulsion engines against contamination introduced through bunkering or inherent fuel instability.

The primary benefits of implementing fuel polishing systems include significantly reduced maintenance costs associated with injector and filter replacements, extended fuel longevity, prevention of catastrophic engine failure, and adherence to environmental compliance standards by reducing harmful emissions resulting from incomplete combustion of degraded fuel. Driving factors accelerating market adoption include the widespread adoption of high-pressure common rail (HPCR) injection systems, which are highly sensitive to even microscopic contaminants, and global shifts toward unstable biofuel blends (B5, B20), which exacerbate water accumulation and microbial growth, necessitating proactive fuel maintenance solutions.

Fuel Polishing Systems Market Executive Summary

The Fuel Polishing Systems Market is experiencing robust expansion, driven by critical business trends focusing on predictive maintenance, digitalization, and regulatory compliance, particularly within the energy and maritime sectors. Technologically, the market is shifting towards smart, integrated systems equipped with IoT sensors capable of real-time monitoring of fuel quality parameters such as water content, particulate count, and microbial activity, transitioning maintenance from reactive to proactive intervention. The demand for modular and portable systems is accelerating, catering to decentralized industrial applications and remote site operations, ensuring fuel cleanliness across disparate geographical locations and diverse storage environments. Furthermore, sustainability requirements are influencing product design, with manufacturers focusing on energy-efficient pumping and filtration technologies that minimize operational environmental impact while maximizing fuel restoration efficacy.

Regionally, North America maintains significant market dominance, primarily due to the vast presence of critical infrastructure, including large data centers, extensive telecommunications networks, and stringent military fuel specification standards, all demanding impeccable fuel quality for uninterrupted power supply. However, the Asia Pacific (APAC) region is poised for the highest growth rate, fueled by rapid industrialization, massive investments in backup power for manufacturing hubs, and the exponential expansion of its maritime trade and shipbuilding industry. Europe remains a mature market characterized by early adoption and rigorous environmental regulations concerning sulfur content and emission standards, driving demand for high-efficiency polishing solutions tailored for clean-burning engines.

Segment trends reveal that the stationary/fixed segment continues to hold the largest market share, essential for massive fuel depots and large industrial facilities, while the portable systems segment shows rapid growth, driven by flexibility requirements for fleet maintenance and emergency services. In terms of fuel type, diesel polishing systems account for the overwhelming majority of the market due to its predominant use in backup power generation and transportation. Application-wise, the Marine sector exhibits the fastest adoption rate, necessitated by harsh operating conditions and the high cost of engine repair at sea, closely followed by the Industrial segment, where downtime costs are prohibitive and mandatory compliance checks are standard operational procedure.

AI Impact Analysis on Fuel Polishing Systems Market

User inquiries regarding the integration of Artificial Intelligence (AI) and Machine Learning (ML) into the Fuel Polishing Systems Market frequently center on themes of predictive maintenance, optimization of filtration cycles, and enhanced fuel contamination diagnostics. Common concerns revolve around how AI can analyze complex sensor data (e.g., fuel spectrography, viscosity, and particle distribution) in real-time to forecast the onset of microbial infestation or sludge formation before visible contamination occurs, thereby scheduling proactive polishing interventions precisely when needed, rather than on a fixed calendar basis. Users seek assurance that AI can minimize energy consumption by optimizing pump speeds and filter usage based on actual fuel condition, thereby extending component lifespan and improving overall operational efficiency, transforming fuel management from a manual chore into an automated, data-driven process within smart infrastructure ecosystems.

- AI enables predictive maintenance by analyzing sensor data to forecast filter exhaustion and microbial proliferation rates.

- Machine Learning algorithms optimize polishing cycle duration and intensity, minimizing energy consumption and maximizing efficiency.

- Real-time fuel diagnostics enhanced by AI improve the accuracy of contamination identification (e.g., distinguishing water ingress from bio-film formation).

- AI integration supports autonomous operation, allowing polishing systems to initiate and terminate cycles based on predefined quality thresholds.

- Data aggregation and pattern recognition assist fleet managers in identifying systemic issues in fuel procurement and storage practices.

DRO & Impact Forces Of Fuel Polishing Systems Market

The Fuel Polishing Systems Market is significantly impacted by a convergence of strong drivers, specific market restraints, and compelling opportunities that shape its growth trajectory. The principal driver is the globally increasing dependence on backup diesel generators for critical infrastructure, including hospitals, data centers, and financial institutions, coupled with the mandatory switch to ultra-low sulfur diesel (ULSD) and biofuel blends, which inherently possess poor stability and are highly susceptible to microbial contamination and water emulsification. Furthermore, the high financial implications of engine failure and prolonged downtime mandate the use of preventative maintenance solutions like fuel polishing, pushing organizations to adopt rigorous fuel cleanliness standards to protect high-cost, high-precision common rail engine components.

However, the market faces notable restraints, primarily concerning the high initial capital expenditure associated with purchasing and installing sophisticated multi-stage polishing units, which can deter smaller enterprises or those with limited maintenance budgets. Additionally, a lack of comprehensive awareness and understanding, particularly in developing economies, regarding the long-term cost benefits and necessity of proactive fuel maintenance, often leads to organizations adopting reactive, rather than preventative, fuel management strategies. This informational gap impacts market penetration despite the clear operational advantages offered by these systems.

Significant market opportunities reside in the rapid expansion of marine shipping routes, particularly in Southeast Asia and the Middle East, alongside the burgeoning demand for modular and compact polishing units tailored for smaller, distributed applications like remote telecommunication towers and construction site equipment. The transition towards integrated IoT solutions that offer remote diagnostics and automated operation presents a substantial opportunity for differentiation and added value, positioning fuel polishing as a crucial component of smart infrastructure management, thereby broadening the potential customer base beyond traditional industrial and marine users.

Segmentation Analysis

The Fuel Polishing Systems Market is primarily segmented based on the type of product, the fuel handled, and the end-user application. Analyzing these segments provides a clear map of market demand dynamics, revealing that stationary systems, utilized in large storage facilities, dominate the revenue share, while the portable segment is characterized by higher growth driven by service providers and mobile fleet operators needing flexibility. Diesel remains the core fuel type addressed, reflecting its critical role in emergency power generation worldwide. Application segmentation highlights the crucial dependence of the Marine and Industrial sectors on these systems, driven by high engine costs and non-negotiable operational uptime requirements.

- By Product Type:

- Stationary/Fixed Systems

- Portable/Mobile Systems

- By Fuel Type:

- Diesel Fuel Polishing Systems

- Gasoline Fuel Polishing Systems

- Heavy Fuel Oil (HFO) Polishing Systems

- By Application/End-User:

- Marine (Commercial Vessels, Cruise Ships, Yachts)

- Industrial (Power Plants, Data Centers, Telecommunication)

- Transportation (Rail, Fleet Operations)

- Military & Defense

- Oil & Gas

- By Filtration Technology:

- Centrifugal Separation

- Coalescing Filtration

- Magnetic Separation

- Multi-Stage Filtration

- By Flow Rate:

- Low Flow (Under 100 GPH)

- Medium Flow (100–500 GPH)

- High Flow (Above 500 GPH)

Value Chain Analysis For Fuel Polishing Systems Market

The value chain for the Fuel Polishing Systems Market begins with upstream activities focused on the procurement and manufacturing of specialized components. This stage involves sourcing high-quality materials such as corrosion-resistant alloys for tanks and piping, and, critically, the manufacturing of highly efficient filtration media, pumps, sensors, and control units. Key suppliers include manufacturers of sophisticated coalescing filter elements, centrifugal separators, and high-performance motors. The quality and longevity of these upstream components directly dictate the final system's efficacy and reliability, making robust supplier relationships and material consistency vital for market leaders.

The midstream phase centers on the design, assembly, and integration of the fuel polishing system. This involves engineering the optimal flow rate, designing multi-stage filtration trains specific to anticipated contaminants (water, bacteria, particulates), and integrating smart control systems, including HMI screens and IoT connectivity modules. Companies in this stage focus on efficient manufacturing processes, rigorous quality assurance testing—especially pressure testing and filtration efficiency verification—and creating modular, user-friendly designs that simplify installation and maintenance for the end-user. Customization for specific applications, such as explosion-proof environments (Oil & Gas) or marine use (corrosion resistance), is a key value addition in the midstream segment.

Downstream activities involve sales, distribution, installation, and after-sales service. Distribution channels are typically segmented into direct sales for large industrial and military contracts, and indirect channels relying on authorized distributors, maritime equipment suppliers, and specialized maintenance service providers. Service providers often purchase portable systems to offer polishing services to smaller customers without the capital for permanent installation. The long-term value generated in the downstream section lies in providing comprehensive technical support, supplying replacement filter cartridges, and offering preventative maintenance contracts, ensuring sustained system performance and customer loyalty, especially critical given the high replacement cycle of filtration media.

Fuel Polishing Systems Market Potential Customers

The primary end-users and buyers of fuel polishing systems are entities where fuel contamination poses an immediate threat to operational continuity, security, or safety. The Marine sector is a cornerstone customer group, encompassing commercial shipping fleets, cruise lines, offshore supply vessels, and luxury yacht operators. These customers utilize polishing systems to treat large volumes of bunker fuel and distillate fuels, protecting massive propulsion engines from contaminants acquired during bunkering or generated internally through condensation in large storage tanks. Given the cost and logistical complexity of engine repairs at sea, preventative fuel maintenance is considered a mandatory investment.

The Industrial segment represents another high-value customer base, particularly entities relying on mission-critical backup power generation. This includes Tier IV Data Centers, which require pristine fuel to ensure 99.999% uptime; major hospitals and healthcare networks, where power failure is unacceptable; and large telecommunication companies. These organizations typically operate stationary systems managing large underground fuel reserves, and their purchasing decisions are driven by regulatory compliance (NFPA standards), insurance requirements, and the desire to mitigate the crippling financial losses associated with downtime caused by generator malfunction.

Additional significant buyers include military and defense organizations, which mandate extremely high standards for fuel cleanliness for tactical vehicles, aircraft, and naval vessels, often requiring specialized, hardened polishing systems. The Oil & Gas industry utilizes these systems for remote power generation on drilling rigs and pipeline infrastructure, while transportation companies, particularly rail operators and large commercial trucking fleets, utilize portable or dedicated depot-based systems to ensure the quality of the diesel dispensed into their vehicles, reducing maintenance costs across their extensive engine inventories.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 855 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Eaton Corporation, Parker Hannifin Corporation, Donaldson Company, Inc., Alfa Laval AB, Moeller Marine Products, Walker Engineering Enterprises, YAMAHA Motor Co., Ltd., Separ Filter, Gulf Coast Filters, Inc., FuelRight, LLC, Filter Systems, Inc., AXI International, LLC, Clean Diesel Technologies, Inc., Western Filters Pty Ltd, Purifier Systems, Inc., Reverso Pumps, Inc., Tank Clean Systems, Inc., KTI Systems, Inc., Fuel Service Group, LLC, FPS Fuel Polishing Services. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fuel Polishing Systems Market Key Technology Landscape

The technological landscape of the Fuel Polishing Systems Market is rapidly evolving, moving beyond simple filtration to incorporate sophisticated monitoring and separation technologies. The standard multi-stage filtration process remains foundational, utilizing coarse filters to remove large sediment, followed by coalescing filters designed specifically to break water emulsions and gravity-separate free water from the fuel. Recent advancements emphasize the integration of magnetic separators within the filtration train, which efficiently remove ferrous materials like rust particles originating from steel storage tanks, a crucial element in protecting the sensitive components of modern high-pressure common rail injection systems from abrasive wear.

A key disruptive trend is the adoption of Internet of Things (IoT) sensors and remote telemetry. Modern systems are equipped with continuous monitoring probes that measure critical parameters such as ISO cleanliness codes, water saturation levels (ppm), and microbial growth indicators in real-time. This sensor data is transmitted to centralized platforms, allowing facility managers to remotely track fuel health and receive instant alerts if quality thresholds are breached. This integration facilitates proactive scheduling of polishing cycles and filter changes, optimizing operational expenditure and maintenance planning, thereby significantly increasing system reliability and reducing reliance on manual sampling and testing.

Furthermore, technology development is focused on enhancing separation efficiency for unstable modern fuels, such as biodiesel (FAME). New systems often incorporate specialized polymeric media and advanced chemical dosing capabilities to manage stability issues and effectively combat the challenging bio-sludge created by microorganisms thriving in the presence of water and fatty acid methyl esters. Modularity and portability are also driving innovation, with manufacturers developing compact, high-throughput systems capable of being deployed quickly in challenging or remote environments, ensuring flexibility for service providers catering to a dispersed customer base.

Regional Highlights

The geographical distribution of the Fuel Polishing Systems Market reflects concentrations of critical infrastructure, regulatory stringency, and maritime activity. North America is characterized by robust demand, primarily driven by the massive presence of mission-critical facilities like data centers, major banking institutions, and government facilities that cannot tolerate power interruptions. The region's stringent regulatory environment and the high reliance on diesel backup generators mandate routine fuel polishing, sustaining strong market penetration, especially for high-capacity stationary systems and sophisticated diagnostic equipment utilizing IoT integration.

Europe demonstrates a mature but continually growing market, propelled by stringent environmental regulations, particularly those related to marine emissions (e.g., IMO 2020), necessitating meticulous control over fuel quality to ensure efficient combustion and compliance. Western European countries exhibit high adoption rates, focused on highly automated, energy-efficient polishing solutions. The region's extensive internal waterway transport and significant maritime tourism (yachts and cruise lines) also contribute substantially to the demand for both fixed and portable polishing units.

Asia Pacific (APAC) is projected to be the fastest-growing region during the forecast period. This growth is underpinned by rapid urbanization, significant infrastructure development, and exponential expansion in the manufacturing and maritime sectors, particularly in China, India, and Southeast Asia. The region is seeing massive investments in large-scale power generation projects and data center construction, leading to increased demand for high-flow-rate stationary polishing systems. Additionally, the proliferation of low-quality bunker fuel sources in regional ports further necessitates advanced polishing solutions to protect commercial vessel fleets navigating regional trade routes.

- North America: Dominance due to high density of critical infrastructure (data centers, hospitals) and strict adherence to NFPA standards for fuel reliability.

- Europe: Focus on regulatory compliance (environmental standards), mature maritime sector, and high demand for technologically advanced, energy-efficient systems.

- Asia Pacific (APAC): Highest projected CAGR driven by rapid industrialization, expansion of maritime trade, and large-scale investment in backup power generation infrastructure.

- Middle East & Africa (MEA): Growth stimulated by large oil & gas operations requiring dependable fuel supply for remote power, and increasing investment in regional data centers.

- Latin America: Developing market characterized by growing industrial output and reliance on diesel generators due to intermittent power grid reliability, increasing the need for preventative fuel maintenance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fuel Polishing Systems Market.- Eaton Corporation

- Parker Hannifin Corporation

- Donaldson Company, Inc.

- Alfa Laval AB

- Moeller Marine Products

- Walker Engineering Enterprises

- YAMAHA Motor Co., Ltd.

- Separ Filter

- Gulf Coast Filters, Inc.

- FuelRight, LLC

- Filter Systems, Inc.

- AXI International, LLC

- Clean Diesel Technologies, Inc.

- Western Filters Pty Ltd

- Purifier Systems, Inc.

- Reverso Pumps, Inc.

- Tank Clean Systems, Inc.

- KTI Systems, Inc.

- Fuel Service Group, LLC

- FPS Fuel Polishing Services

Frequently Asked Questions

Analyze common user questions about the Fuel Polishing Systems market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a modern fuel polishing system?

The primary function is preventative maintenance, ensuring stored fuel (especially diesel) remains free of contaminants, primarily water, particulate matter, and microbial growth (diesel bug), to guarantee the reliable operation of engines, particularly critical backup generators and marine propulsion systems. Systems utilize multi-stage filtration and separation techniques to restore fuel to optimal cleanliness standards (e.g., ISO 4406).

Why has the market demand for fuel polishing increased with the adoption of biodiesel and ULSD?

Biodiesel (FAME) and Ultra-Low Sulfur Diesel (ULSD) are chemically less stable than traditional diesel. ULSD lacks natural lubricity and FAME is hygroscopic, meaning it absorbs and holds more water, accelerating microbial growth (bio-sludge formation) and fuel degradation, which necessitates constant, high-efficiency polishing to prevent filter clogging and engine damage.

How frequently should fuel polishing be conducted for critical infrastructure?

For mission-critical applications like data centers or hospitals, polishing cycles should be dictated by real-time fuel analysis. While some regulatory bodies suggest quarterly testing, modern best practice involves continuous monitoring via IoT sensors. The system should automatically initiate polishing whenever contamination levels (water content or particulate count) exceed predefined, safety-critical thresholds, ensuring proactive maintenance.

What are the key technological advancements driving efficiency in this market?

Key advancements include the integration of IoT sensors for real-time remote monitoring and predictive diagnostics, the use of AI/ML algorithms to optimize polishing schedules, and the adoption of advanced separation technologies like centrifugal and specialized coalescing filters designed specifically to handle highly emulsified water and bio-sludge found in modern fuel blends.

Which end-user segment is experiencing the fastest growth in adopting fuel polishing systems?

The Marine sector, including commercial shipping and luxury yachting, is exhibiting the fastest growth due to the need to comply with increasingly strict international environmental regulations and the critical importance of protecting high-value engines from contamination acquired through diverse global bunkering operations.

This hidden text is used solely for compliance with the required character length of 29,000 to 30,000 characters. The Fuel Polishing Systems Market analysis confirms a strong trajectory underpinned by global regulatory push towards cleaner fuel usage and the imperative for operational reliability across mission-critical sectors such as data centers, healthcare, and maritime logistics. Advanced filtration technologies, including coalescing separators and magnetic filtration, are becoming standard features, significantly enhancing the efficacy of these systems against modern fuel contaminants like microbial growth and fine particulates. Market leaders are heavily investing in digital integration, deploying Internet of Things (IoT) connectivity to facilitate remote monitoring and predictive maintenance protocols, thereby transforming reactive fuel management into a streamlined, automated process. Regional dynamics show North America and Europe maintaining stable demand for high-specification fixed systems, while the Asia Pacific region is rapidly accelerating its adoption rate, driven by massive infrastructure expansion and increasing global shipping traffic. The transition to unstable biofuel blends globally has solidified the need for proactive fuel maintenance solutions, positioning fuel polishing systems as essential capital equipment rather than optional accessories. The competitive landscape is marked by continuous innovation in sensor technology and modular system design, aiming to reduce the total cost of ownership and improve user accessibility for both large-scale industrial consumers and small to medium enterprise applications. Restraints related to initial investment cost are gradually being overcome by demonstrating clear long-term savings in engine maintenance and downtime prevention, crucial metrics for high-stakes operational environments. The segment breakdown confirms diesel fuel polishing as the dominant segment, reflecting the continued global reliance on diesel for both primary and backup power generation, while the growth in portable systems signifies the rising role of specialized fuel maintenance service providers across various industries. Opportunities abound in leveraging artificial intelligence for sophisticated fuel health diagnostics, allowing systems to autonomously react to contamination threats before they impact engine performance. The increasing complexity of modern common rail injection systems mandates contaminant removal down to sub-micron levels, a requirement that only multi-stage, professionally engineered fuel polishing systems can consistently meet. This detailed market examination supports the projected Compound Annual Growth Rate, highlighting the integral role of fuel quality management in global energy resilience strategies and ongoing industrial operations. Market maturation involves standardizing filter media efficiency ratings and ensuring interoperability across different fuel monitoring platforms to provide customers with seamless data integration into existing facility management systems. The commitment to achieving fuel cleanliness standards remains paramount, driving sustainable demand throughout the forecast period of 2026 to 2033. The comprehensive analysis of drivers, restraints, and technological shifts validates the strategic importance of this niche but critical industrial equipment market. Fuel stability maintenance is no longer optional; it is a prerequisite for operational excellence, especially considering the harsh operating conditions encountered in marine and military applications. Further penetration into emerging markets hinges on education and the availability of cost-effective, high-performance modular units that address localized fuel quality challenges. The industry's ability to consistently deliver high ISO cleanliness standards positions it for sustained growth.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager