Fully Draw Yarn Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440196 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Fully Draw Yarn Market Size

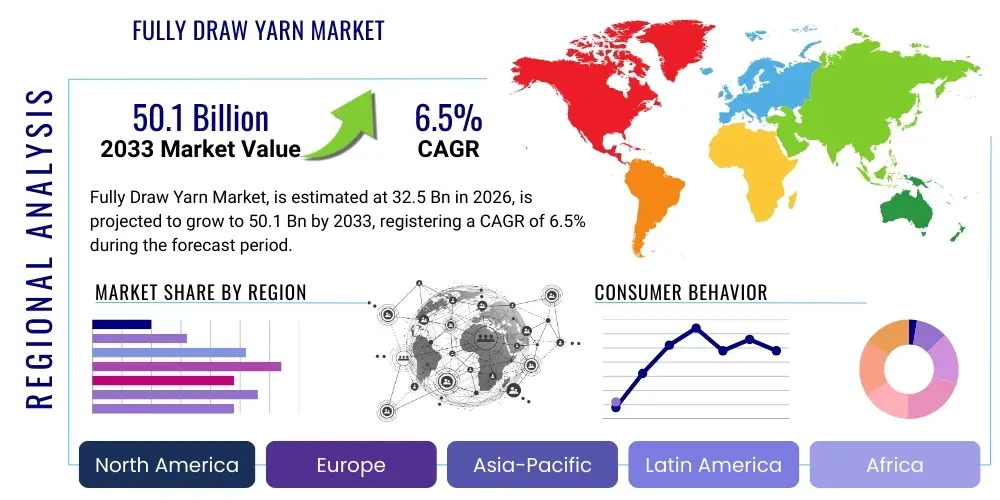

The Fully Draw Yarn Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 32.5 Billion in 2026 and is projected to reach USD 50.1 Billion by the end of the forecast period in 2033.

Fully Draw Yarn Market introduction

The Fully Draw Yarn (FDY) market encompasses the production and distribution of polyester yarn that is fully drawn during the spinning process, resulting in a stable, strong, and lustrous filament. This manufacturing method allows for the creation of yarn with excellent tenacity, high uniformity, and minimal shrinkage, making it ideal for a wide array of textile applications. FDY is a key intermediate product in the textile value chain, serving as a foundational material for various fabrics and garments.

Major applications for Fully Draw Yarn include apparel such as sportswear, activewear, innerwear, and fashionable garments, where its smooth texture and strength are highly valued. Beyond clothing, FDY is extensively used in home furnishings for items like curtains, upholstery, and bed linens, offering durability and aesthetic appeal. Furthermore, its robust properties make it suitable for industrial textiles, including automotive interiors, conveyor belts, and filtration fabrics. The versatility of FDY, coupled with its consistent quality, positions it as a critical component in both conventional and technical textile sectors.

Benefits of Fully Draw Yarn are numerous, ranging from its superior strength and abrasion resistance to its excellent dyeability and dimensional stability. These characteristics contribute to longer-lasting products, vibrant colors, and consistent fabric quality, meeting the stringent demands of modern textile production. Key driving factors for the FDY market include the ever-increasing global demand for textiles and apparel, a rising consumer preference for comfortable and durable clothing, and the continuous technological advancements in manufacturing processes that improve yarn quality and production efficiency. Additionally, the expansion of the automotive and home furnishing industries further fuels the market's growth, solidifying FDY's indispensable role in the global economy.

Fully Draw Yarn Market Executive Summary

The global Fully Draw Yarn (FDY) market is experiencing dynamic shifts, driven by evolving consumer preferences and technological innovation. Business trends indicate a strong move towards sustainable manufacturing practices and the development of specialty FDY variants that offer enhanced functional properties, such as moisture-wicking, anti-bacterial, or UV-resistant qualities. Manufacturers are increasingly investing in automation and advanced spinning technologies to optimize production efficiency, reduce costs, and maintain a competitive edge. Strategic collaborations and mergers are also becoming prevalent as companies seek to expand their market reach and leverage complementary strengths, consolidating market leadership and fostering innovation in yarn development.

Regional trends highlight the Asia Pacific region as the dominant force in the FDY market, largely due to the presence of major manufacturing hubs in China, India, and Southeast Asian countries. These regions benefit from lower labor costs, extensive raw material availability, and a large consumer base, driving both production and consumption. North America and Europe, while mature markets, are focusing on premium, high-performance FDY products and sustainable textile solutions, with significant emphasis on circular economy principles and eco-friendly manufacturing. Latin America and the Middle East & Africa are emerging as promising markets, exhibiting considerable growth potential fueled by urbanization, increasing disposable incomes, and developing textile industries.

Segmentation trends reveal a sustained demand for polyester FDY, which remains the backbone of the market due to its cost-effectiveness and versatility. However, there is a growing interest in FDY made from other materials like nylon and polypropylene, particularly for specialized applications requiring specific performance attributes. By application, the apparel sector continues to be the largest consumer, but industrial textiles and home furnishings are showing robust growth as manufacturers explore new uses and innovative product designs. The market is also seeing a diversification in denier counts, with a focus on ultra-fine denier yarns for lightweight, high-performance fabrics and coarser denier for durable industrial applications, catering to a broader spectrum of end-use requirements.

AI Impact Analysis on Fully Draw Yarn Market

The integration of Artificial Intelligence (AI) into the Fully Draw Yarn (FDY) market is poised to revolutionize various aspects of its value chain, addressing critical user questions related to efficiency, quality, sustainability, and market responsiveness. Users are keen to understand how AI can mitigate production inefficiencies, reduce waste, and improve the consistency of yarn quality, which are persistent challenges in textile manufacturing. There's also significant interest in AI's role in predictive maintenance for machinery, aiming to minimize downtime and extend equipment lifespan. Furthermore, stakeholders are looking at AI for enhanced supply chain visibility, inventory optimization, and more accurate demand forecasting, which are crucial for navigating volatile market conditions and ensuring timely delivery of products.

The deployment of AI technologies is expected to lead to more intelligent manufacturing processes. This includes leveraging machine learning algorithms to analyze vast datasets from production lines, identifying patterns that inform real-time adjustments to spinning parameters, thereby optimizing yarn properties and reducing defects. AI-powered visual inspection systems can detect even minute flaws in the yarn, ensuring higher quality standards than traditional methods. Beyond production, AI offers opportunities for innovative product development, such as simulating the performance of new yarn compositions or predicting market acceptance of novel textile applications, accelerating the design-to-market cycle and fostering a culture of data-driven innovation within the industry.

Moreover, AI holds significant promise for enhancing sustainability within the FDY market. By optimizing energy consumption in manufacturing processes and enabling more precise control over resource utilization, AI can contribute to a reduced environmental footprint. Users are particularly interested in how AI can support the adoption of circular economy principles, for instance, by tracing material flows, optimizing recycling processes for textile waste, and facilitating the development of FDY from recycled content. The overarching expectation is that AI will empower manufacturers to achieve greater operational excellence, deliver superior products, and adapt more swiftly to dynamic market demands, ultimately fostering a more resilient and environmentally responsible FDY industry.

- AI-driven predictive maintenance for spinning machinery, reducing downtime and maintenance costs.

- Enhanced quality control through AI-powered visual inspection systems for defect detection.

- Optimized production parameters via machine learning for improved yarn consistency and reduced waste.

- AI-enabled demand forecasting and supply chain optimization, leading to better inventory management.

- Accelerated R&D in new yarn compositions and functional properties through AI simulations.

- Improved energy efficiency and resource utilization in manufacturing processes with AI analytics.

- Facilitation of circular economy practices through AI-driven material tracing and recycling optimization.

DRO & Impact Forces Of Fully Draw Yarn Market

The Fully Draw Yarn (FDY) market is significantly influenced by a complex interplay of drivers, restraints, opportunities, and broader impact forces that shape its growth trajectory and competitive landscape. Key drivers propelling the market include the robust expansion of the global textile and apparel industry, fueled by a growing population and increasing disposable incomes, particularly in emerging economies. The rising demand for performance-enhancing fabrics in sportswear and activewear, which often utilize FDY for its strength and smooth texture, further contributes to market growth. Additionally, continuous technological advancements in spinning and drawing processes lead to higher quality and more cost-effective FDY production, making it an attractive material for diverse applications.

However, the market also faces notable restraints. Volatility in raw material prices, primarily crude oil derivatives used in polymer production, poses a significant challenge, impacting manufacturing costs and profit margins. Stringent environmental regulations concerning wastewater treatment, energy consumption, and chemical usage in textile processing can add to operational expenses and restrict production capacities. Intense competition from manufacturers in low-cost regions and the availability of alternative yarn types also create pressure on pricing and market share. Furthermore, trade barriers and geopolitical tensions can disrupt supply chains and hinder market expansion, requiring manufacturers to adopt flexible and resilient business strategies.

Opportunities for growth in the FDY market are abundant, particularly in the development of sustainable FDY products made from recycled polyester or bio-based polymers, aligning with global environmental concerns and consumer preferences for eco-friendly goods. The burgeoning market for smart textiles and wearable technology presents new avenues for specialized FDY with integrated conductive or sensory properties. Expanding into untapped emerging markets in Africa and Latin America offers significant growth potential as their textile industries mature. Customization and product differentiation, focusing on niche applications and value-added functionalities, also represent strategic opportunities for market players to capture new segments and enhance profitability. These opportunities encourage innovation and investment in advanced manufacturing techniques and sustainable practices, ensuring the long-term viability and competitiveness of the FDY sector.

Segmentation Analysis

The Fully Draw Yarn (FDY) market is comprehensively segmented to provide a detailed understanding of its diverse components and growth dynamics. These segmentations allow for a granular analysis of market trends, consumer preferences, and strategic opportunities across various product types, materials, applications, and end-use industries. Understanding these distinct segments is crucial for market players to tailor their product offerings, marketing strategies, and investment decisions effectively, ensuring they remain competitive and responsive to the evolving demands of the global textile industry.

- By Type:

- Semi-Dull FDY

- Bright FDY

- Cationic FDY

- Full-Dull FDY

- By Material:

- Polyester FDY

- Nylon FDY

- Polypropylene FDY

- Viscose FDY

- Specialty Fibers FDY

- By Application:

- Apparel (Sportswear, Activewear, Innerwear, Fashion Apparel)

- Home Furnishings (Curtains, Upholstery, Bed Linens, Carpets)

- Industrial Textiles (Automotive Interiors, Filtration, Conveyor Belts, Ropes)

- Technical Textiles (Medical Textiles, Geo-textiles, Protective Clothing)

- By End-Use Industry:

- Textile and Apparel Industry

- Automotive Industry

- Home Furnishing Industry

- Medical Industry

- Construction Industry

- By Denier:

- Fine Denier (e.g., <50D)

- Medium Denier (e.g., 50D-150D)

- Coarse Denier (e.g., >150D)

Value Chain Analysis For Fully Draw Yarn Market

The value chain for the Fully Draw Yarn (FDY) market is a multi-stage process, beginning with the sourcing of raw materials and extending through complex manufacturing steps to reach the end consumer. The upstream analysis focuses on the acquisition and processing of primary raw materials. This typically involves the petrochemical industry, which supplies purified terephthalic acid (PTA) and monoethylene glycol (MEG) for polyester FDY, or caprolactam for nylon FDY. These chemicals are then polymerized to create polyester chips or nylon chips, forming the foundational input for yarn production. The efficiency and cost-effectiveness of this initial stage significantly impact the overall profitability and sustainability of the entire value chain, as raw material prices are often subject to global commodity market fluctuations.

Midstream activities involve the core manufacturing processes of FDY. This stage encompasses the melting of polymer chips, extrusion through spinnerets to form filaments, and the subsequent drawing and winding processes. During drawing, the filaments are stretched to align molecular structures, imparting high tenacity and desired mechanical properties. Advanced technologies like high-speed spinning and automated winding machines are crucial for maintaining consistent quality and high production volumes. Downstream analysis then examines the subsequent processing of FDY into finished textile products. This includes weaving, knitting, dyeing, and finishing operations performed by fabric manufacturers, garment makers, and producers of home furnishings or industrial textiles. Each step adds value by transforming the yarn into a functional and aesthetically pleasing end-product, tailored to specific consumer or industrial demands.

The distribution channel for Fully Draw Yarn is multifaceted, encompassing both direct and indirect sales approaches. Direct distribution often involves large-scale FDY manufacturers selling directly to major textile mills, garment factories, or industrial clients through long-term contracts and bulk orders. This approach fosters strong B2B relationships and ensures a steady supply chain. Indirect distribution, on the other hand, utilizes intermediaries such as wholesalers, distributors, and agents who play a crucial role in reaching smaller manufacturers, niche markets, and diverse geographical locations. These intermediaries manage logistics, inventory, and provide market access, particularly in fragmented markets or regions with complex distribution networks. E-commerce platforms are also emerging as a significant channel, enabling manufacturers to reach a broader customer base and streamline order processing, thereby enhancing market penetration and operational efficiency across the global FDY market.

Fully Draw Yarn Market Potential Customers

The Fully Draw Yarn (FDY) market caters to a diverse range of potential customers, primarily businesses within the broader textile and manufacturing sectors that rely on high-quality synthetic yarns for their production processes. The largest segment of end-users consists of textile mills and fabric manufacturers who purchase FDY in bulk to weave or knit into various types of fabrics. These fabrics then become raw materials for garments, home textiles, and industrial applications. Within this segment, customers range from large integrated textile groups to smaller specialized weaving units, all seeking FDY for its consistent quality, strength, and aesthetic properties that enable them to produce competitive finished goods.

Another significant group of potential customers includes garment manufacturers, particularly those specializing in activewear, sportswear, innerwear, and fashionable clothing. These manufacturers value FDY for its smooth hand-feel, excellent drape, and consistent dye uptake, which are crucial for producing apparel that meets consumer expectations for comfort, durability, and style. The growing global demand for performance-oriented clothing, driven by health and wellness trends, makes this a particularly dynamic customer segment. Furthermore, manufacturers of home furnishings such as curtains, upholstery fabrics, carpets, and bed linens also represent key buyers, as FDY contributes to the longevity, color retention, and ease of care required in household textile products.

Beyond traditional textile applications, the Fully Draw Yarn market also serves various industrial sectors. This includes the automotive industry, where FDY is used in car seat fabrics, headliners, and interior trim due to its durability and resistance to wear. Manufacturers of technical textiles, which encompass products for filtration, geotextiles, medical textiles, and protective clothing, also constitute important customers. These industries require FDY with specific performance characteristics, such as high tenacity, chemical resistance, or UV stability. Therefore, FDY suppliers often work closely with these specialized customers to develop customized yarn solutions that meet their precise technical specifications and regulatory requirements, driving innovation and diversification within the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 32.5 Billion |

| Market Forecast in 2033 | USD 50.1 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Reliance Industries, Indorama Ventures, Sinopec Yizheng Chemical Fibre, Far Eastern New Century, Zhejiang Fulida, Tongkun Group, Jiangsu Sanfangxiang Group, Xinfengming Group, Dystar, Luthai Textile, Weiqiao Textile, Huafu Top Dyed Melange Yarn, Arvind Limited, Vardhman Textiles, Raymond, Bombay Rayon Fashions, Grasim Industries, PT Apac Inti Corpora, TEIJIN FRONTIER CO., LTD., Hyosung TNC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fully Draw Yarn Market Key Technology Landscape

The Fully Draw Yarn (FDY) market is characterized by a dynamic and evolving technology landscape, where continuous innovation is crucial for achieving superior product quality, enhancing production efficiency, and meeting diverse application demands. A fundamental technological pillar involves advanced spinning and drawing processes. Modern FDY production facilities leverage high-speed spinning machines capable of producing yarn at significantly increased rates while maintaining consistent denier and tenacity. These systems often integrate sophisticated drawing zones that precisely control tension and temperature, ensuring the yarn achieves optimal molecular orientation and crystalline structure for desired strength and elongation properties. Automation and robotics are increasingly being deployed throughout the manufacturing line, from raw material handling to packaging, reducing labor costs and minimizing human error.

Another significant area of technological advancement lies in the development of specialty and functional FDY. Manufacturers are employing advanced polymer science and additive technologies to engineer yarns with enhanced performance characteristics. This includes incorporating masterbatches during the spinning process to impart properties such as UV resistance, flame retardancy, anti-microbial features, or moisture-wicking capabilities. Furthermore, bicomponent and multicomponent spinning technologies allow for the creation of composite filaments with distinct properties in a single yarn, opening up new possibilities for smart textiles and high-performance technical applications. These innovations are driven by a growing demand for value-added textiles that offer more than just basic functionality, catering to specialized industrial and consumer markets.

Digitalization and Industry 4.0 principles are profoundly transforming the FDY production landscape. The integration of sensors, real-time data analytics, and Artificial Intelligence (AI) enables precise monitoring and control of every stage of the manufacturing process, from polymerization to winding. This allows for predictive maintenance, anticipating equipment failures before they occur, thereby minimizing downtime and maximizing operational uptime. Moreover, AI and machine learning algorithms are being utilized to optimize process parameters, identify quality deviations, and even forecast demand, leading to improved production planning and inventory management. Sustainable manufacturing technologies, such as energy-efficient machinery, closed-loop water systems, and processes for recycling textile waste into new FDY, are also gaining prominence, reflecting the industry's commitment to environmental responsibility and circular economy principles. These technological advancements collectively drive competitiveness and innovation within the global Fully Draw Yarn market.

Regional Highlights

- Asia Pacific (APAC): Dominates the Fully Draw Yarn market with significant manufacturing capacities, particularly in China, India, and Southeast Asian countries. The region benefits from low labor costs, abundant raw material availability, and a large domestic consumer base for textiles and apparel. It is also a key exporter of FDY globally.

- Europe: Characterized by a focus on high-quality, specialty, and sustainable FDY production. European manufacturers emphasize innovation, premium products, and adherence to stringent environmental regulations, catering to niche markets and high-performance textile applications.

- North America: A mature market with a strong emphasis on technical textiles, automotive textiles, and performance wear. Manufacturers here prioritize advanced technology, automation, and sustainable practices, often importing bulk FDY and focusing on value-added processing.

- Latin America: An emerging market showing significant growth potential, driven by increasing urbanization, rising disposable incomes, and developing domestic textile industries. Countries like Brazil and Mexico are key players, with growing demand for both apparel and industrial applications of FDY.

- Middle East and Africa (MEA): A developing market with increasing investments in textile manufacturing, particularly in countries like Turkey and Egypt. The region is witnessing a rise in consumer demand for apparel and home furnishings, creating new opportunities for FDY producers and importers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fully Draw Yarn Market.- Reliance Industries

- Indorama Ventures

- Sinopec Yizheng Chemical Fibre

- Far Eastern New Century

- Zhejiang Fulida

- Tongkun Group

- Jiangsu Sanfangxiang Group

- Xinfengming Group

- Dystar

- Luthai Textile

- Weiqiao Textile

- Huafu Top Dyed Melange Yarn

- Arvind Limited

- Vardhman Textiles

- Raymond

- Bombay Rayon Fashions

- Grasim Industries

- PT Apac Inti Corpora

- TEIJIN FRONTIER CO., LTD.

- Hyosung TNC

Frequently Asked Questions

Analyze common user questions about the Fully Draw Yarn market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Fully Draw Yarn (FDY) and its primary advantages?

Fully Draw Yarn (FDY) is polyester yarn that is fully stretched and oriented during manufacturing, resulting in a stable, strong, and lustrous filament. Its primary advantages include high tenacity, excellent dimensional stability, superior dyeability, and a smooth, consistent texture, making it ideal for various textile applications.

Which industries are the major consumers of Fully Draw Yarn?

The major consumers of Fully Draw Yarn are the textile and apparel industry (for sportswear, activewear, fashion), home furnishing industry (for curtains, upholstery), and various industrial textile sectors (automotive interiors, filtration, technical textiles) due to its durability and versatility.

What are the key factors driving the growth of the FDY market?

Key growth drivers include the increasing global demand for textiles and apparel, rising consumer preference for comfortable and durable clothing, continuous technological advancements in yarn manufacturing processes, and the expansion of the automotive and home furnishing industries globally.

How is sustainability impacting the Fully Draw Yarn market?

Sustainability is profoundly impacting the FDY market by driving demand for eco-friendly products made from recycled polyester or bio-based polymers. Manufacturers are investing in sustainable production technologies, energy-efficient processes, and closed-loop systems to reduce environmental footprint and meet consumer and regulatory expectations.

What role does AI play in the Fully Draw Yarn manufacturing process?

AI enhances FDY manufacturing through predictive maintenance for machinery, AI-powered quality control systems for defect detection, optimization of production parameters via machine learning for improved consistency, and intelligent demand forecasting, leading to greater efficiency, reduced waste, and higher product quality.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager