Fume Hood Air Flow Monitors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436817 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Fume Hood Air Flow Monitors Market Size

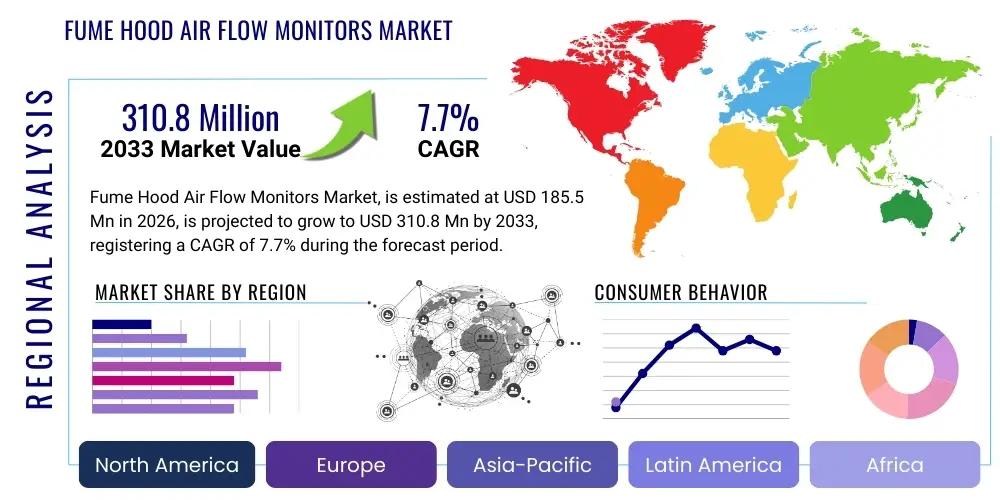

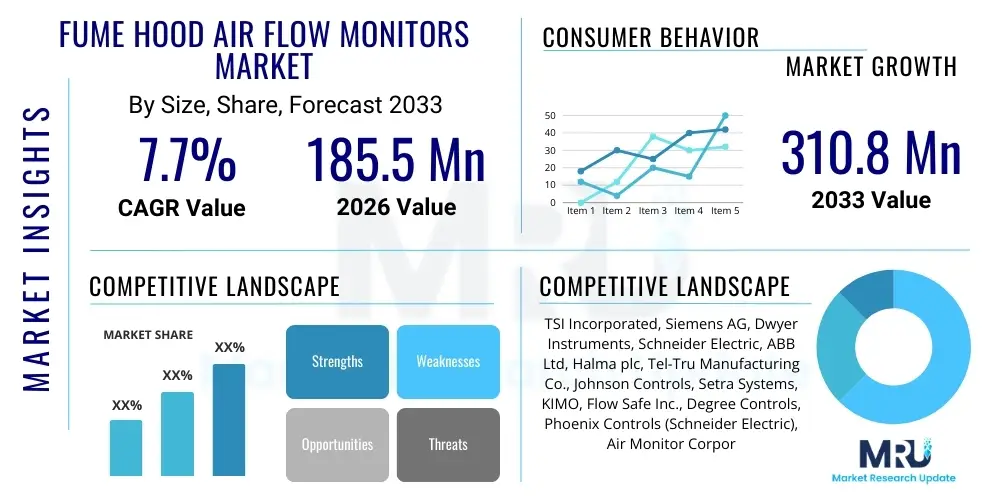

The Fume Hood Air Flow Monitors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.7% between 2026 and 2033. The market is estimated at USD 185.5 Million in 2026 and is projected to reach USD 310.8 Million by the end of the forecast period in 2033.

Fume Hood Air Flow Monitors Market introduction

The Fume Hood Air Flow Monitors Market centers on safety-critical instrumentation designed to continuously measure, display, and alarm the face velocity or static pressure differential within laboratory fume hoods. These devices are indispensable components in research laboratories, academic institutions, pharmaceutical manufacturing facilities, and chemical processing plants where hazardous airborne materials are handled. The primary function of these monitors is to ensure that the fume hood operates within established regulatory safety parameters, typically maintaining adequate capture velocity to protect personnel from exposure to toxic fumes, vapors, and particulate matter.

Fume Hood Air Flow Monitors are critical for verifying compliance with international standards such as ASHRAE 110 and relevant OSHA regulations, thereby minimizing liability and maximizing worker safety. Key products include digital airflow monitors, analog gauges, pressure transducers, and integrated control systems that link directly to building management systems (BMS) for centralized monitoring and energy optimization. Major applications span chemistry, biology, materials science, and cleanroom environments where controlled atmospheric conditions are mandatory. Benefits derived from deploying these monitors include enhanced laboratory safety, precise compliance documentation, reduced energy consumption through optimized airflow control, and improved operational efficiency.

Driving factors fueling market growth include stringent global safety regulations regarding airborne contaminants, increased investment in laboratory infrastructure across emerging economies, and the growing focus on sustainability and energy efficiency in HVAC systems. Furthermore, the rising adoption of sophisticated VAV (Variable Air Volume) fume hood systems necessitates advanced monitoring solutions to maintain stable airflow regardless of sash position, pushing demand for high-accuracy, integrated smart monitoring technologies capable of real-time data logging and remote diagnostics.

Fume Hood Air Flow Monitors Market Executive Summary

The Fume Hood Air Flow Monitors Market is experiencing robust expansion driven by mandatory laboratory safety compliance and the proliferation of advanced VAV systems aimed at energy reduction. Business trends highlight a strong shift towards digital, networked monitoring solutions that integrate seamlessly with building automation and laboratory information management systems (LIMS). Key strategic movements include mergers and acquisitions focused on consolidating specialized sensor technology and control systems expertise, allowing major industrial automation players to capture a larger share of the laboratory safety vertical. Furthermore, manufacturers are increasingly offering calibration and maintenance services bundled with their monitoring solutions, establishing recurring revenue streams and strengthening customer loyalty in highly regulated environments.

Regional trends indicate North America and Europe currently dominate the market due to established regulatory frameworks, high R&D spending in the pharmaceutical and biotech sectors, and a strong culture of workplace safety enforcement. However, the Asia Pacific (APAC) region is projected to register the highest CAGR, primarily fueled by substantial government investment in scientific research, rapid expansion of academic laboratories, and burgeoning growth in China and India’s domestic chemical and life sciences industries. Demand in APAC is characterized by a high need for cost-effective, yet reliable, monitoring solutions as compliance standards tighten across these emerging markets.

Segment trends show the differential pressure monitoring segment maintains a significant market share due to its reliability and proven performance in traditional Constant Air Volume (CAV) hoods. However, the velocity sensor segment, particularly utilizing hot-wire anemometry and thermal dispersion technologies, is exhibiting faster growth, aligning with the uptake of VAV systems where precise face velocity measurement is crucial for safe operation. End-use segment analysis indicates that the Pharmaceutical and Biotechnology sector remains the largest consumer, driven by intense regulatory scrutiny and the sheer volume of volatile compounds handled. Conversely, academic and research institutions represent a high-volume demand segment, increasingly adopting entry-level digital monitors to meet fundamental safety requirements across large campus laboratory networks.

AI Impact Analysis on Fume Hood Air Flow Monitors Market

User queries regarding AI's impact on Fume Hood Air Flow Monitors predominantly revolve around three key themes: predictive maintenance, optimization of VAV control algorithms, and autonomous safety compliance reporting. Users are highly interested in how machine learning can analyze historical air flow data, ambient lab conditions, and HVAC system performance to predict potential failures in monitoring equipment or drifts in hood containment efficiency before they lead to safety breaches. A significant concern is whether AI integration will increase the cost and complexity of existing infrastructure, contrasting the desire for advanced, hands-free optimization against maintaining ease of use and calibration in critical safety applications. Expectations are high for AI to move beyond simple data logging, enabling dynamic adjustments to minimize energy draw while guaranteeing consistent regulatory compliance across variable workloads.

The integration of Artificial Intelligence transforms passive monitoring systems into proactive, predictive safety platforms. AI algorithms can process vast datasets generated by airflow monitors—including trend data, alarm history, and environmental variables—to identify subtle operational patterns indicative of impending mechanical failure (e.g., fan motor wear, duct blockage, or sensor drift). This capability significantly extends the lifespan of monitoring equipment and minimizes laboratory downtime. Furthermore, in VAV systems, AI provides highly refined supervisory control, adjusting exhaust fan speed and damper positions based on real-time occupancy and operational risk profiles, thereby maximizing energy savings without compromising the minimum required face velocity established by safety protocols.

Adoption of AI-enhanced monitoring systems will standardize and automate compliance documentation, drastically reducing the labor intensive processes associated with manual log review and regulatory audits. By continuously correlating monitoring data with mandated performance indicators, AI systems can generate audit-ready reports instantaneously, flagging any periods of non-compliance with precise temporal and systemic detail. This evolution not only streamlines regulatory affairs but also elevates the overall safety management maturity level within research and industrial environments, positioning the technology as a crucial step toward fully autonomous, self-calibrating laboratory infrastructure.

- Predictive maintenance scheduling for airflow sensors and exhaust fans.

- Optimization of Variable Air Volume (VAV) control algorithms for energy efficiency.

- Real-time anomaly detection identifying compromised containment or sensor drift.

- Automated generation of detailed regulatory compliance reports (e.g., ASHRAE 110 verification).

- Integration with building management systems (BMS) for holistic energy control.

- Reduction of false alarms through pattern recognition and environmental noise filtering.

- Enabling remote diagnostics and self-calibration features based on performance modeling.

DRO & Impact Forces Of Fume Hood Air Flow Monitors Market

The Fume Hood Air Flow Monitors market dynamics are governed by a complex interplay of stringent safety regulations (Drivers), high initial capital investment and recalibration requirements (Restraints), and the vast potential for integration into smart lab environments (Opportunities). The primary impact force accelerating market adoption is the globally uniform necessity for protecting laboratory personnel from hazardous exposure, often dictated by governmental occupational safety bodies like OSHA, enforcing the continuous monitoring of containment devices. Conversely, the market faces friction from end-users who perceive advanced monitoring systems as high-cost liabilities due to the frequency and precision required for validation and calibration in highly regulated settings, necessitating specialized service personnel.

Drivers: The market is fundamentally propelled by increasing regulatory pressure worldwide to ensure laboratory safety and operational compliance. Specifically, the expansion of pharmaceutical and biotechnology R&D activities, particularly in gene therapy and novel chemistry, generates a greater need for highly reliable containment solutions monitored by sophisticated devices. Furthermore, the global push toward sustainability mandates the adoption of VAV fume hoods, which inherently require precise, dynamic air flow monitoring to achieve energy reduction targets while maintaining minimum safety velocity, thus creating direct demand for advanced digital monitors and controllers that can interface with modern HVAC systems.

Restraints: Significant barriers to market growth include the substantial initial capital expenditure required for installing advanced monitoring and control systems, especially when retrofitting older laboratory infrastructure. Moreover, the long-term operational cost associated with mandated annual calibration and certification of these precision instruments presents a financial constraint for smaller academic or clinical laboratories with limited budgets. A lack of technical expertise among laboratory personnel regarding the sophisticated calibration and data interpretation of advanced digital monitors also poses a challenge, often requiring reliance on third-party specialists, adding complexity and cost.

Opportunities: Major opportunities lie in the integration of Fume Hood Air Flow Monitors into the broader ecosystem of the Internet of Things (IoT) and smart laboratory infrastructure. Developing wireless, battery-powered monitoring solutions that reduce installation complexity and leverage cloud-based data analytics platforms for remote monitoring and centralized fleet management represents a significant growth vector. Furthermore, addressing the energy consumption concern by offering monitors explicitly designed to facilitate optimal, energy-saving VAV operations through predictive, AI-enhanced control offers a compelling value proposition to large institutional customers focused on LEED certification and operational efficiency improvements.

Impact Forces: The overall impact forces are strongly positive. Regulatory enforcement acts as a non-negotiable pull factor, ensuring continuous demand for baseline monitoring solutions. Technological advancement, particularly in high-precision, low-maintenance sensor technology (e.g., MEMS sensors, non-contact flow sensors), is mitigating the historical restraint of high calibration costs. The synergy between safety requirements and energy conservation goals (driven by VAV hood adoption) reinforces the necessity of advanced, highly accurate air flow monitoring systems, making them indispensable components of modern, efficient laboratory design. The confluence of these forces ensures sustained market growth focused on digital and integrated solutions.

Segmentation Analysis

The Fume Hood Air Flow Monitors market is structurally segmented based on the type of product, the monitoring technology employed, the type of fume hood configuration, and the primary end-user application. Understanding these segments is crucial for manufacturers to tailor their product development strategies and for end-users to select appropriate monitoring solutions aligning with specific safety protocols and operational requirements. The segmentation highlights the transition from simple, analog warning systems to complex, digital, and networked monitoring platforms capable of integrating into centralized building management systems for enhanced safety and resource optimization. This structural breakdown reveals high growth potential in segments supporting VAV technology.

Analysis by Product Type demonstrates the dominance of the digital display monitors segment, replacing traditional analog indicators due to their precision, data logging capabilities, and ability to interface with alarms and control systems. Technology segmentation shows a rapid shift toward high-accuracy velocity sensors, particularly thermal and hot-wire technologies, which are essential for the instantaneous and dynamic feedback required by VAV systems. Pressure differential monitors remain crucial, especially for older Constant Air Volume (CAV) hoods and specialized applications requiring pressure cascade control. The end-user analysis confirms the strong investment patterns within highly regulated sectors such as pharmaceuticals and academic research, which continuously drive volume and demand for high-specification equipment.

The segmentation by Fume Hood Type clearly delineates the market into requirements for CAV and VAV systems. While CAV systems still constitute a large installed base requiring robust, standardized pressure-based monitors, the VAV segment is the main driver of innovation and high-value product sales. VAV systems demand sophisticated control loops that integrate high-speed velocity sensing with advanced logic controllers, ensuring safe face velocity is maintained even as the sash position changes, thereby demanding premium, interconnected flow monitors capable of rapid response times and advanced diagnostics to meet energy saving targets without compromising safety containment.

- By Product Type:

- Digital Display Monitors

- Analog Indicators (Gauges)

- Integrated Control Systems (Controllers)

- By Technology:

- Velocity Sensors (Thermal Anemometers, Hot-Wire)

- Differential Pressure Monitors (Manometers, Transducers)

- By Fume Hood Type:

- Constant Air Volume (CAV) Fume Hoods

- Variable Air Volume (VAV) Fume Hoods

- By End User:

- Pharmaceutical and Biotechnology Companies

- Academic and Research Institutions

- Chemical and Petrochemical Industries

- Clinical and Diagnostic Laboratories

- Government and Forensic Laboratories

Value Chain Analysis For Fume Hood Air Flow Monitors Market

The value chain for Fume Hood Air Flow Monitors begins with the upstream raw material suppliers, predominantly providers of high-precision electronic components, sensor materials (e.g., specialized plastics, metals, ceramic substrates), and microprocessors necessary for digital signal processing. Upstream analysis focuses on securing reliable sourcing of sophisticated pressure transducers and thermal sensor elements, as the performance and longevity of the final monitor directly depend on the quality and calibration stability of these core components. Manufacturers must maintain stringent quality control over semiconductor components and specialized wiring harnesses to ensure the instruments meet required intrinsic safety and operational tolerances for laboratory use.

The midstream involves the core manufacturing, assembly, and software integration phases. This is where market differentiators such as proprietary calibration algorithms, user interface design, and networking capabilities are developed. Distribution channels play a critical role, often relying on specialized laboratory equipment distributors, HVAC system integrators, and safety equipment vendors. Direct sales are common for high-volume institutional contracts or specialized VAV control projects, where direct integration support is necessary. Indirect distribution via certified resellers and international partners is essential for reaching diverse global end-users and ensuring localized installation and maintenance support, particularly in highly fragmented APAC markets.

Downstream activities center on installation, commissioning, annual calibration, and maintenance services, which often generate significant post-sale revenue. Since these monitors are regulatory-critical devices, annual re-certification (e.g., according to ASHRAE 110) must be performed by certified technicians, creating a steady service market. Potential customers (end-users) are deeply reliant on timely service and compliance documentation, making the aftermarket support segment a strategic area for competitive differentiation. Key considerations downstream include rapid response to alarm conditions and efficient integration of monitor data into laboratory management systems.

Fume Hood Air Flow Monitors Market Potential Customers

The primary customers for Fume Hood Air Flow Monitors are organizations operating laboratories and controlled environments where hazardous materials necessitate strict containment protocols. The most demanding and high-volume buyers are the Pharmaceutical and Biotechnology industries, which utilize vast numbers of fume hoods for drug discovery, process development, and quality control. These customers prioritize highly accurate, networked VAV-compatible monitors that facilitate extensive data logging for regulatory audit trails and support energy-saving initiatives inherent in large-scale R&D facilities. The constant introduction of new chemistries and increasing regulatory oversight ensures sustained demand from this sector.

Academic and Research Institutions constitute another major segment, characterized by budget sensitivity but high unit demand across large campuses. These buyers seek durable, user-friendly monitors that offer sufficient accuracy to meet basic safety compliance (OSHA/local regulations) while often requiring less sophisticated networking capabilities than their industrial counterparts. Government and forensic laboratories, including environmental protection agencies and public health facilities, represent stable customers requiring guaranteed performance and high reliability, often opting for devices with long-term calibration stability to minimize service intervals.

Furthermore, specialized industries such as Chemical and Petrochemical processing plants, semiconductor manufacturing facilities, and certain advanced materials science labs also function as critical end-users. These environments often handle highly volatile or corrosive substances, requiring monitors with robust construction, chemical resistance, and, in some cases, intrinsic safety ratings (explosion-proof certification). Procurement decisions are heavily influenced by adherence to site-specific safety standards and integration compatibility with existing legacy process control systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 185.5 Million |

| Market Forecast in 2033 | USD 310.8 Million |

| Growth Rate | 7.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TSI Incorporated, Siemens AG, Dwyer Instruments, Schneider Electric, ABB Ltd, Halma plc, Tel-Tru Manufacturing Co., Johnson Controls, Setra Systems, KIMO, Flow Safe Inc., Degree Controls, Phoenix Controls (Schneider Electric), Air Monitor Corporation, Vaisala, Testo SE & Co. KGaA, Rotronic AG, Trane Technologies, Ruskin Company, Fluke Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fume Hood Air Flow Monitors Market Key Technology Landscape

The technological evolution of Fume Hood Air Flow Monitors is primarily focused on enhancing accuracy, speed of response, and connectivity, moving away from mechanical and simple pneumatic systems toward highly digitized solutions. Differential pressure monitoring, historically the backbone of airflow verification, relies on highly sensitive transducers that measure the pressure drop across specific points (like the static pressure in the duct) to infer flow, or across a precise restrictor plate. While reliable for constant flow systems, the technology faces limitations in the rapid, non-linear environment of VAV hoods where instantaneous face velocity readings are paramount. Consequently, the focus is shifting towards more direct measurement techniques.

Modern solutions heavily leverage thermal measurement technologies, particularly hot-wire or thermal dispersion anemometers. These sensors provide highly accurate face velocity readings with minimal pressure drop, offering the quick response time necessary for dynamic VAV control systems to react effectively to sash movements. The latest advancements include micro-electromechanical systems (MEMS) flow sensors, which are highly miniaturized, offer rapid response, and can be integrated directly into monitor circuitry at lower manufacturing costs, promising improved long-term stability and reduced maintenance requirements compared to traditional probes. These sensors are increasingly coupled with advanced digital signal processing (DSP) to filter out noise and turbulence inherent in complex hood designs.

Connectivity and integration are central to the current technology landscape. Next-generation monitors are equipped with communication protocols such as BACnet, Modbus, and Ethernet/IP, enabling seamless integration with facility Building Management Systems (BMS) and HVAC controllers. This capability facilitates centralized monitoring, remote diagnostics, and coordinated energy management across an entire facility's laboratory safety infrastructure. The adoption of wireless communication standards (e.g., LoRaWAN or proprietary low-power mesh networks) is also emerging to simplify retrofits and reduce the installation cost and complexity associated with hardwired systems in established laboratory spaces, further enhancing data accessibility and operational flexibility.

Regional Highlights

The Fume Hood Air Flow Monitors Market exhibits distinct characteristics across major global regions, reflecting variances in regulatory stringency, R&D investment levels, and industrial infrastructure maturity. North America and Europe currently represent the most substantial market share due to their mature pharmaceutical and biotechnology sectors, coupled with rigorous enforcement of occupational health and safety standards by regulatory bodies such as OSHA, the European Agency for Safety and Health at Work (EU-OSHA), and equivalent national entities. These regions lead in the adoption of advanced, integrated VAV monitoring systems, driven by high labor costs and the necessity for sophisticated energy management in institutional settings. Demand here is focused on precision, network capability, and lifetime cost of ownership, including calibration services.

North America, particularly the United States, is characterized by a strong presence of global pharmaceutical giants and leading academic research universities, creating a consistent high-value demand for top-tier monitoring equipment and comprehensive service contracts. European adoption is slightly more fragmented due to varying national regulations, but the overall trend favors standardized compliance systems and technology focused on sustainability (e.g., energy efficient lab certifications). The replacement cycle for older laboratory equipment is relatively active in both regions, providing a steady market for retrofit solutions that update existing CAV hoods with modern digital monitoring capabilities, often requiring specialized communication interfaces to link with legacy building control platforms.

The Asia Pacific (APAC) region is poised for the most rapid growth, attributed primarily to massive state investment in scientific and technological research across China, India, South Korea, and Southeast Asian nations. The rapid construction of new academic institutions, clinical research organizations (CROs), and domestic chemical manufacturing hubs is fueling high-volume demand for Fume Hood Air Flow Monitors. While initial purchases in some sub-regions may favor cost-effective, standard digital monitors, the increasing presence of multinational pharmaceutical companies and tightening governmental regulatory requirements (e.g., China’s emphasis on environmental safety) are rapidly elevating the demand for high-specification, compliance-ready VAV monitoring systems. Localization of production and service infrastructure is critical for capturing market share in APAC.

Latin America (LATAM) and the Middle East and Africa (MEA) represent emerging markets with significant potential, though currently smaller in size. In LATAM, growth is driven by expanding healthcare sectors and governmental efforts to enhance R&D capabilities, leading to gradual investment in updated laboratory safety infrastructure. The MEA region is characterized by substantial investment in energy and petrochemical research centers, alongside the burgeoning development of specialized medical and research city initiatives, particularly in the Gulf Cooperation Council (GCC) countries. These markets often demand rugged, reliable monitoring equipment capable of operating in challenging environmental conditions, prioritizing stability and ease of local maintenance over highly advanced, complex networking features seen in North America or Europe.

- North America: Dominant market share; driven by stringent OSHA regulations, extensive pharmaceutical R&D, and high adoption of VAV systems for energy efficiency.

- Europe: Mature market; emphasis on workplace safety directives, strong academic research funding, and focus on sustainability standards in lab design.

- Asia Pacific (APAC): Highest projected CAGR; fueled by rapid expansion of research infrastructure in China and India, increasing governmental regulation, and large-scale academic investments.

- Latin America (LATAM): Emerging demand; driven by expanding clinical research and modernization of existing government and academic laboratories.

- Middle East and Africa (MEA): Growth centered around major oil/gas research facilities and biomedical initiatives in GCC nations; preference for robust, reliable equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fume Hood Air Flow Monitors Market.- TSI Incorporated

- Siemens AG

- Dwyer Instruments

- Schneider Electric

- ABB Ltd

- Halma plc

- Tel-Tru Manufacturing Co.

- Johnson Controls

- Setra Systems

- KIMO

- Flow Safe Inc.

- Degree Controls

- Phoenix Controls (A division of Schneider Electric)

- Air Monitor Corporation

- Vaisala

- Testo SE & Co. KGaA

- Rotronic AG

- Trane Technologies

- Ruskin Company

- Fluke Corporation

- Accutrol LLC

- Magnehelic Gauges (A product line of Dwyer Instruments)

- Honeywell International Inc.

- Sentry Air Systems

- Fuji Electric Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Fume Hood Air Flow Monitors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a Fume Hood Air Flow Monitor?

The primary function is to continuously measure the face velocity or static pressure of a fume hood and provide visual and audible alarms if the air containment performance falls below established regulatory safety limits, ensuring laboratory personnel protection.

How do Variable Air Volume (VAV) fume hoods impact the demand for advanced monitors?

VAV hoods dynamically change airflow based on sash position to save energy. This dynamism requires highly accurate, rapid-response velocity sensors and digital controllers (like those utilizing thermal anemometers) to ensure safe face velocity is maintained at all times, driving demand for technologically advanced monitoring systems.

What is the key difference between Differential Pressure Monitors and Velocity Sensors in fume hood applications?

Differential Pressure Monitors measure the pressure drop across components to infer flow and are common in older Constant Air Volume (CAV) systems. Velocity Sensors (e.g., hot-wire or thermal) directly measure the air speed at the hood face, offering faster, more precise data critical for optimizing VAV system performance and compliance verification.

How frequently should Fume Hood Air Flow Monitors be calibrated?

Fume Hood Air Flow Monitors and associated control systems should typically be calibrated and certified annually, in accordance with laboratory operational protocols and standards such as ASHRAE 110, to ensure consistent accuracy and regulatory compliance.

Which end-user segment represents the highest growth opportunity for advanced fume hood monitoring solutions?

The Pharmaceutical and Biotechnology sector, along with large Academic and Research Institutions, represent the highest growth opportunity, driven by increased R&D investment, stringent GxP compliance requirements, and the widespread adoption of energy-efficient, interconnected smart laboratory infrastructure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager