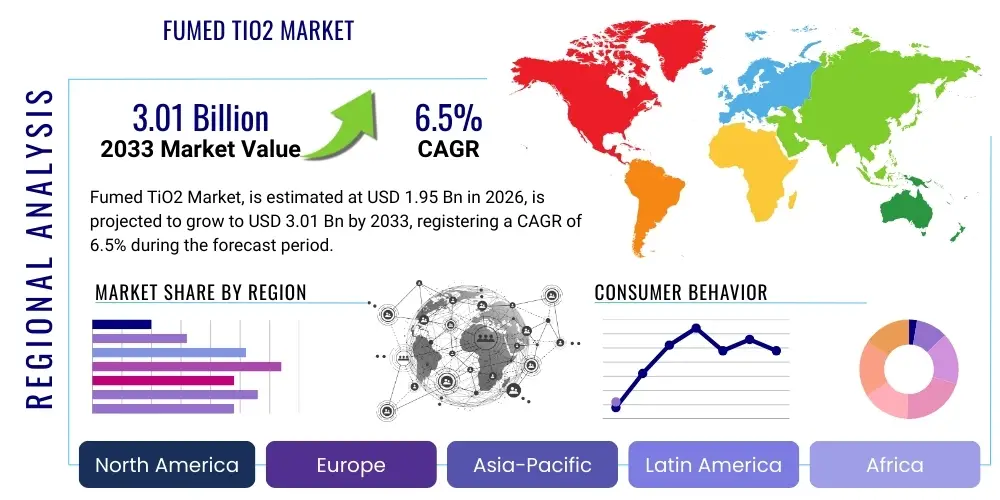

Fumed TiO2 Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431719 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Fumed TiO2 Market Size

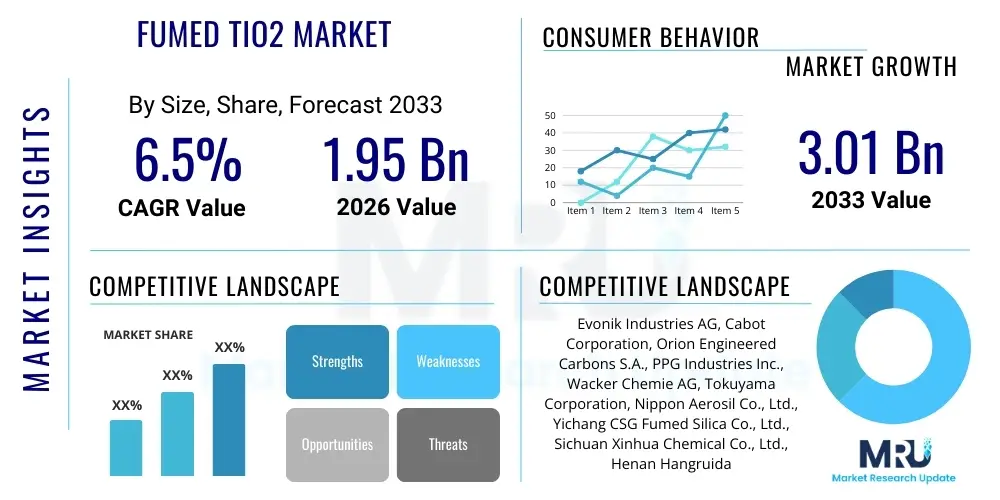

The Fumed TiO2 Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1,950.5 Million in 2026 and is projected to reach USD 3,095.8 Million by the end of the forecast period in 2033.

Fumed TiO2 Market introduction

The Fumed TiO2 market encompasses high-purity, synthetic titanium dioxide produced through the flame hydrolysis of titanium tetrachloride. This process yields extremely fine, non-porous particles with a high surface area, making Fumed TiO2 a crucial additive in specialized applications requiring superior viscosity control, reinforcement, thixotropy, and anti-settling properties. Unlike standard rutile or anatase grades used primarily for pigmentation, Fumed TiO2 is valued for its functional performance, particularly in transparent or translucent systems where clarity must be maintained alongside rheological modification. Its unique physical structure, often forming a stable network of aggregates, provides exceptional performance characteristics in demanding environments.

Fumed TiO2 finds extensive utility across diverse industrial sectors, primarily driven by its application as a thickening agent, stabilizer, and reinforcing filler. Major applications include high-performance coatings, where it improves scratch resistance, gloss retention, and application properties; advanced silicone elastomers and sealants, where it serves as a crucial reinforcing filler significantly enhancing mechanical strength, tear resistance, and temperature stability; and specialized printing inks, where it meticulously controls flow characteristics and prevents the settling of pigments during storage and application. Furthermore, its chemical inertness, high thermal resistance, and exceptional purity make it an ideal and often required material for use in pharmaceutical carriers, high-end cosmetics, and specific electronic encapsulation compounds.

Key market driving factors include the escalating global demand for high-solid and solvent-free coatings, which rely heavily on Fumed TiO2 for precise rheological control without introducing unnecessary volume or volatile organic compounds (VOCs), thereby complying with stricter environmental standards. The rapid expansion of the construction sector, particularly in the Asia Pacific region, necessitates high-performance, long-lasting sealants and industrial adhesives, further stimulating demand for Fumed TiO2 as a crucial strengthening additive. Additionally, continuous innovations in additive manufacturing and 3D printing technologies are creating new, specialized applications where fine particle fillers are required to achieve dimensional stability, high-resolution finish, and tailored material strength. The superior technical benefits over conventional alternatives solidify its indispensability in numerous high-value, specialized markets.

Fumed TiO2 Market Executive Summary

The Fumed TiO2 market is characterized by robust growth, primarily propelled by increasing sophistication in end-user requirements for rheology control, high-level reinforcement, and thermal stabilization across the coatings, adhesives, and elastomers industries. Business trends indicate a strong emphasis on strategic capacity expansion, particularly in APAC, coupled with vertical integration and strategic partnerships among leading manufacturers to secure the supply of critical raw materials like Titanium Tetrachloride and to optimize the energy-intensive flame hydrolysis production processes. Key market players are heavily investing in tailored, surface-modified grades, such as advanced hydrophobic variants, to specifically address specialized application challenges in clear coats, advanced composite matrixes, and high-pfrequency electronic components, thereby driving premium pricing and market differentiation.

Regional trends highlight the Asia Pacific (APAC) region as the dominant and fastest-growing market globally, largely attributed to rapid, large-scale industrialization, massive construction and infrastructure projects, and the establishment of global manufacturing bases for electronics and automotive production in key nations like China, India, and Southeast Asia. North America and Europe, while representing mature industrial markets, demonstrate stable and substantial demand, driven by stringent regulatory environments favoring high-quality, high-performance Fumed TiO2 grades used extensively in advanced automotive coatings, aerospace materials, and sophisticated medical devices. Growth in these established regions is predominantly focused on formulating next-generation products, often tied to the transition toward electric vehicles (EVs) and smart technology integration.

Segment trends reveal that the Coatings, Inks, and Composites segment continues to command the largest market share by volume, driven by the versatile requirement for Fumed TiO2 in both pigmented and transparent systems for anti-corrosion and aesthetic protective layers. Crucially, the Elastomers and Silicones segment is projected to exhibit the highest Compound Annual Growth Rate (CAGR) throughout the forecast period. This acceleration is fueled by the rising adoption of specialized silicone rubber components in high-reliability applications, including the aerospace sector, advanced automotive wiring harnesses, and high-voltage transmission equipment, where Fumed TiO2 acts as a critical strengthening, anti-sagging, and dielectric enhancing agent. Furthermore, the market for hydrophobic Fumed TiO2 is generally outpacing that of the hydrophilic grade, reflecting the global industrial shift towards solvent-free, moisture-resistant, and high-solid formulations that require superior dispersion in non-polar organic media.

AI Impact Analysis on Fumed TiO2 Market

User inquiries related to AI’s influence on the Fumed TiO2 sector are frequently focused on optimizing the highly complex and energy-intensive flame hydrolysis synthesis process, predicting material performance across a myriad of formulations, and automating demanding quality control procedures. A recurring concern among manufacturers is whether machine learning algorithms can provide breakthroughs in reducing the significant high-temperature energy input inherent in the manufacturing process, thereby lowering production costs and improving sustainability metrics. Furthermore, users expect AI to significantly accelerate the research and development lifecycle for novel surface modifications and functionalized grades tailored for emerging applications in semiconductors and specialized medical polymers, demanding superior purity and predictable rheological behavior.

The integration of AI, particularly predictive analytics and machine learning, is expected to revolutionize supply chain resilience by dynamically forecasting demand fluctuations across diverse, often volatile, end-user markets (e.g., construction vs. high-end electronics). This allows for highly optimized inventory management of both finished products and sensitive raw materials like titanium tetrachloride. In the production environment, the deployment of advanced sensor arrays coupled with AI-driven process control systems promises real-time feedback loops to maintain reactor stability, ensuring optimal temperature and flow conditions, which are paramount for achieving the consistent, ultra-fine particle size distribution and desired high surface area characteristic of premium Fumed TiO2 grades. This enhanced precision minimizes batch variability and maximizes product yield.

- Enhanced R&D Efficiency: AI models accelerate the simulation and prediction of optimal synthesis conditions (temperature, feed rate, quench rate) for specific particle properties, drastically reducing the number of costly physical experiments required for new product development.

- Automated Quality Control: Machine vision and learning algorithms analyze high-resolution microscopic images of Fumed TiO2 batches instantly, detecting subtle irregularities in primary particle aggregation, structure density, and dispersion characteristics with greater precision than traditional manual methods.

- Predictive Maintenance and Safety: AI algorithms continuously monitor the operational parameters of highly demanding flame hydrolysis reactors and peripheral equipment, predicting potential component failures and minimizing costly unplanned downtime, while improving safety protocols.

- Supply Chain and Inventory Optimization: Leveraging machine learning to provide accurate, real-time forecasting of demand across multiple, fragmented segments (coatings, electronics, medical), allowing for precision planning in raw material procurement and optimized inventory holding levels.

- Process Energy Modeling: AI tools are utilized to create digital twins and computational models of the entire production facility, enabling the identification and optimization of energy inefficiencies, leading to critical, although challenging, reductions in the high energy input required for the pyrogenic manufacturing method.

DRO & Impact Forces Of Fumed TiO2 Market

The Fumed TiO2 market operates under the influence of several critical Drivers, Restraints, and Opportunities (DRO), which collectively dictate market expansion, competitive behavior, and pricing strategies. The principal market driver is the continually escalating technological demand for high-performance specialty chemicals across rapidly evolving sectors, including electric vehicle components, sophisticated composite materials, and advanced electronics packaging. In these high-tech applications, Fumed TiO2 is indispensable for delivering superior mechanical reinforcement, thermal stability, and precise rheological modification, attributes which simpler alternatives cannot consistently provide. This performance-driven requirement is further amplified by global urbanization and corresponding infrastructure growth, sustaining the need for premium adhesives, sealants, and long-life protective coatings.

Despite the strong demand drivers, the market faces significant structural restraints, most notably the inherently high production cost associated with the flame hydrolysis method. This process is intensely energy-consuming, contributing substantially to operational expenses, and is highly reliant on Titanium Tetrachloride (TiCl4), a raw material that demands high purity, is corrosive to handle, and whose market price and supply chain are frequently subject to volatility. The capital expenditure required for maintaining and expanding pyrogenic production facilities is also substantial, posing high barriers to entry for new competitors. Moreover, manufacturers must constantly contend with competitive pressure from functionally similar, often lower-cost alternative rheological additives, such such as specialized fumed silica grades and modified organic clay thickeners, requiring Fumed TiO2 suppliers to aggressively justify their product's premium based on verifiable performance advantages.

Looking forward, significant market opportunities are concentrated around the ongoing development and commercialization of next-generation functionalized Fumed TiO2 grades. This involves advancements in surface chemistry and particle engineering to create tailored materials optimized for specific, high-margin niche applications, such as transparent UV-curable coatings, advanced bio-compatible materials for medical devices, and functional conductive inks for printed electronics. The burgeoning global market for renewable energy technologies, specifically photovoltaic cell manufacturing and energy storage systems, represents a major untapped potential where the unique electrical and thermal properties of Fumed TiO2 are highly valued. Strategic market expansion and sustainable growth for key players will depend heavily on their ability to invest in process efficiencies and proprietary surface modification technologies to overcome cost barriers and secure competitive advantages in these emerging high-value application areas.

Segmentation Analysis

The Fumed TiO2 market is meticulously segmented to reflect the diverse structural and functional requirements of various industrial sectors, providing a detailed framework for market sizing and strategic planning. Segmentation by grade is fundamental, differentiating the naturally formed hydrophilic variety, which readily disperses and stabilizes in aqueous and polar systems, from the chemically treated hydrophobic variety, which is optimized for superior compatibility, reduced moisture absorption, and excellent dispersion in non-polar organic media, such as high-solids solvent coatings and specialized plastic compounds. This functional distinction dictates product selection across numerous end-use applications, profoundly influencing procurement patterns.

The segmentation based on application outlines the primary functional roles Fumed TiO2 performs, spanning precise rheology control (viscosity modification and shear-thinning), mechanical reinforcement (increasing the hardness and tear strength of elastomers), and anti-settling/stabilization (preventing pigment separation in liquid formulations). Finally, the end-use industry segmentation provides insight into the major demand pools, with Coatings, Elastomers, Adhesives, and Cosmetics being the most influential sectors. Analyzing these segments reveals which industries are driving volume growth (Coatings) versus those prioritizing technical sophistication and high price points (Elastomers and Electronics), guiding manufacturer investment strategies.

- By Grade:

- Hydrophilic Fumed TiO2 (Untreated)

- Hydrophobic Fumed TiO2 (Surface-Treated)

- By Application:

- Rheology Control and Thixotropy

- Mechanical Reinforcement and Strengthening

- Anti-Settling, Stabilization, and Suspension Aids

- Others (e.g., Flowability Enhancement in Powders, UV Protection)

- By End-Use Industry:

- Coatings, Paints, and Pigment Dispersions

- Elastomers and Specialized Silicone Rubber

- Adhesives and High-Performance Sealants

- Plastics and Advanced Composite Resins

- Cosmetics, Personal Care, and Pharmaceuticals

- Electronics and Electrical Encapsulation

- Others (e.g., Filtration, Catalytic Support)

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Rest of Europe)

- Asia Pacific (China, Japan, India, South Korea, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of LATAM)

- Middle East & Africa (Saudi Arabia, UAE, South Africa, Rest of MEA)

Value Chain Analysis For Fumed TiO2 Market

The Fumed TiO2 value chain commences with the highly specialized and regulated Upstream activities, focusing on the procurement, purification, and secure handling of key raw materials, predominantly high-purity Titanium Tetrachloride (TiCl4). This segment also includes the sourcing of high-purity oxygen and hydrogen necessary to generate the required flame energy. The production stage—pyrogenic flame hydrolysis—is central to the value chain, involving significant capital investment in custom-built reactors and demanding stringent safety and environmental controls. Success at this stage relies heavily on proprietary technology and process optimization to manage the high energy consumption while ensuring perfect particle formation, which sets the fundamental performance quality of the final product.

The Midstream segment involves post-production refinement, which is crucial for adding specific functional value. This includes surface modification technologies, primarily using silane or siloxane treatments, to transform the base hydrophilic material into hydrophobic grades required by most industrial organic systems (e.g., solvent coatings, silicone rubber). Processing also includes de-aeration, milling, and specialized packaging to control bulk density and reduce dusting, crucial factors for end-user handling. The Distribution Channel then bridges manufacturers and thousands of global formulators. Direct sales models are typically employed for servicing large-volume customers in the silicone and coatings industry, facilitating customized product specifications and direct technical consultation to optimize formulation performance.

Conversely, the vast network of indirect channels, comprising specialized regional chemical distributors and authorized agents, is vital for reaching small-to-mid-sized enterprises (SMEs) and dispersed formulators across geographic areas, offering crucial inventory management and local technical support. The Downstream segment encompasses the diverse End-Use industries—Coatings, Elastomers, Adhesives, and Cosmetics—where the material is incorporated to deliver essential functional enhancements such as increased viscosity stability, superior mechanical strength, and anti-sagging properties. The material's final perceived value is ultimately determined by its performance success in these downstream applications, necessitating close collaboration throughout the value chain to ensure product suitability and sustained market demand.

Fumed TiO2 Market Potential Customers

Potential customers for Fumed TiO2 are broadly categorized into industries requiring materials with precise rheological behavior and enhanced structural integrity, spanning everything from heavy industry to specialized medical device manufacturing. The largest segment of buyers consists of formulators within the High-Performance Coatings and Paints sector, including manufacturers of automotive clear coats, marine anti-fouling systems, and industrial protective coatings. These customers utilize Fumed TiO2 to achieve superior application properties, preventing pigment settling during storage and ensuring film thickness uniformity on complex geometries, while also providing UV stabilization and scratch resistance.

Another major customer group includes manufacturers of Adhesives and Sealants, particularly those producing high-end silicone, polyurethane, and epoxy systems used in construction, automotive assembly, and electronics potting. For these applications, Fumed TiO2 is critical for imparting the necessary thixotropic body required for vertical application, precise dispensing, and gap-filling without slumping, ensuring the structural integrity of the cured material. The demand is particularly acute from manufacturers focused on producing materials for modern, lightweight vehicle construction and architectural glazing.

Furthermore, the Elastomers and Silicone Rubber industry constitutes a highly strategic customer base. Companies manufacturing advanced silicone components, such as high-voltage insulators, medical tubing, and aerospace gaskets, rely on Fumed TiO2 as an essential reinforcing agent. It dramatically increases the mechanical properties—hardness, tensile strength, and tear resistance—of the base polymer, enabling the final product to withstand extreme temperatures and mechanical stress. Niche but high-value customers also include pharmaceutical companies and cosmetics formulators that purchase ultra-high-purity grades for drug delivery systems, advanced sunscreens, and textural modifiers in premium personal care products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1,950.5 Million |

| Market Forecast in 2033 | USD 3,095.8 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Evonik Industries AG, Cabot Corporation, P-chem, China National Bluestar (Group) Co., Ltd., Tokuyama Corporation, Kobo Products, Inc., PPG Industries, Inc., Wacker Chemie AG, Daicel Corporation, Fuji Titanium Industry Co., Ltd., Tronox Holdings plc, The Chemours Company, Venator Materials PLC, Shandong Dawn Titanium Industry Co., Ltd., ISK (Ishihara Sangyo Kaisha, Ltd.), Kronos Worldwide, Inc., Tego Titanium Co. Ltd., Henan Billions Chemicals Co., Ltd., JFE Mineral Co., Ltd., Cinkarna Celje d.d. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fumed TiO2 Market Key Technology Landscape

The Fumed TiO2 market is intrinsically linked to the sophistication of its proprietary manufacturing technology, which is overwhelmingly dominated by the pyrogenic method, specifically the flame hydrolysis of titanium tetrachloride (TiCl4). This core technology operates at extremely high temperatures (exceeding 1000°C), demanding rigorous process engineering to ensure the rapid, homogeneous reaction and subsequent controlled cooling necessary to produce ultrafine, non-porous primary particles. Current technological focus is directed less at revolutionary changes to the core method and more towards incremental, high-impact refinements in process instrumentation and control systems. Key advancements include using advanced mass flow controllers and proprietary burner designs to achieve tighter control over the flame stoichiometry and quench rates, which are critical determinants of the final product's particle size distribution and aggregation morphology, directly influencing thixotropy and reinforcement efficiency.

A second crucial area of technological development lies in post-synthesis functionalization, essential for expanding the utility of Fumed TiO2 beyond aqueous systems. The process of surface modification, predominantly involving chemical grafting using various organosilicon compounds such as silanes or silicone oils, converts the naturally hydrophilic surface to a hydrophobic one. Innovation in this area centers on developing novel, efficient surface treatment agents that offer superior coverage and compatibility with a wider range of high-performance organic matrices, including specialized engineering plastics and high-solids polyurethane systems. Successful surface treatment technologies minimize agglomeration, ensure easy dispersion during formulation, and maximize the long-term stability of the final product, directly unlocking high-value applications in moisture-sensitive electronics and automotive components.

Emerging technology trends are heavily influenced by the adoption of Industry 4.0 principles, including pervasive sensing, computational modeling, and artificial intelligence integration. Manufacturers are increasingly implementing Computational Fluid Dynamics (CFD) models to simulate the complex high-temperature flow and reaction dynamics within the reactor environment, allowing for predictive optimization of output quality and identification of energy bottlenecks. Furthermore, advanced inline analytical technologies, such as laser diffraction and dynamic light scattering, coupled with AI-driven data processing, are enabling continuous, real-time quality assurance. This shift towards a data-centric, adaptive manufacturing paradigm is vital for meeting the ultra-high purity and consistency specifications required by rapidly growing sectors such as semiconductor manufacturing, where even minor batch variations are unacceptable.

Regional Highlights

The global Fumed TiO2 market displays significant regional variation, primarily driven by industrial maturity, manufacturing concentration, and local regulatory environments. Asia Pacific (APAC) currently holds the dominant market share and is forecast to maintain the highest Compound Annual Growth Rate (CAGR) throughout the projection period. This supremacy is directly attributable to the explosive growth in infrastructure development, massive residential and commercial construction activities in China and India, and the region's entrenched status as the primary global manufacturing hub for electronics, consumer goods, and the burgeoning electric vehicle sector. The sheer volume of industrial production necessitates vast quantities of Fumed TiO2 for coatings, adhesives, and specialized silicone applications.

North America and Europe represent established, mature markets characterized by stable, yet high-value, consumption patterns. Demand in these regions is less volume-driven and more performance-focused, stimulated by strict regulatory mandates pertaining to environmental protection, particularly concerning low-VOC and solvent-free coatings, which rely heavily on advanced rheological additives like Fumed TiO2. European companies often lead in proprietary functionalization technologies and sustainable manufacturing practices, targeting high-margin segments such as aerospace coatings, specialized medical polymers, and high-end cosmetics, where stringent quality standards and traceability are paramount. The stable replacement cycle of infrastructure and the robust automotive aftermarkets further sustain demand in these regions.

- Asia Pacific (APAC): Leads the market in consumption volume and growth rate; driven by high industrial output, urbanization, and major infrastructure investments in key countries including China, India, and South Korea, particularly strong in electronics and construction sealants.

- North America: Mature market focused on high-specification applications, strong demand from the aerospace, automotive (EV components), and medical device sectors; stable consumption of specialized hydrophobic grades for solvent-borne and high-solids systems.

- Europe: Characterized by a strong focus on regulatory compliance, sustainability, and advanced material research; high adoption of Fumed TiO2 in high-performance coatings (especially for renewable energy equipment) and the highly regulated pharmaceutical/cosmetics industries.

- Latin America (LATAM): Exhibits moderate, steady growth, primarily supported by economic stabilization and localized manufacturing expansion, particularly in Brazil and Mexico, with demand concentrated in industrial coatings and basic construction adhesives.

- Middle East & Africa (MEA): Growth is primarily linked to large-scale government-backed infrastructure and construction projects, alongside significant demand from the regional petrochemical sector for specialized protective coatings capable of withstanding harsh environmental and chemical exposure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fumed TiO2 Market.- Evonik Industries AG

- Cabot Corporation

- P-chem

- China National Bluestar (Group) Co., Ltd.

- Tokuyama Corporation

- Kobo Products, Inc.

- Wacker Chemie AG

- Daicel Corporation

- Fuji Titanium Industry Co., Ltd.

- Tronox Holdings plc

- The Chemours Company

- Venator Materials PLC

- Shandong Dawn Titanium Industry Co., Ltd.

- ISK (Ishihara Sangyo Kaisha, Ltd.)

- Kronos Worldwide, Inc.

- Tego Titanium Co. Ltd.

- Henan Billions Chemicals Co., Ltd.

- JFE Mineral Co., Ltd.

- Cinkarna Celje d.d.

- Xiamen Caisheng Chemical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Fumed TiO2 market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Fumed TiO2 primarily used for, considering its high surface area?

Fumed TiO2 is primarily utilized as a functional additive for rheology control, serving as a highly effective thickening, anti-sagging, and thixotropic agent, and as a reinforcing filler to significantly improve the mechanical strength of silicone elastomers and adhesives.

Which geographical region is expected to experience the fastest growth in the Fumed TiO2 market?

The Asia Pacific (APAC) region is projected to register the fastest growth, driven by rapid industrialization, large-scale construction activities, and the high concentration of manufacturing bases for electronics and automotive production.

How does the hydrophobic grade of Fumed TiO2 differ in application from the hydrophilic grade?

The hydrophobic grade, achieved through surface treatment, offers superior dispersion and stability in non-polar, organic systems like solvent-based coatings and plastic compounds, enhancing moisture resistance, whereas the hydrophilic grade is optimized for aqueous and polar media.

What are the main restraints impacting the growth and profitability of the Fumed TiO2 market?

The primary restraints include the high capital and operational costs associated with the energy-intensive flame hydrolysis production process, coupled with the volatility and hazardous handling requirements of the key raw material, Titanium Tetrachloride (TiCl4).

In which emerging technology sector is Fumed TiO2 finding new significant applications?

Fumed TiO2 is finding increasing utilization in advanced electronics and specialized components for electric vehicles (EVs), particularly in high-performance silicone compounds used for thermal management, battery sealing, and cable insulation due to its mechanical and dielectric properties.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager