Gabion Basket Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439050 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Gabion Basket Market Size

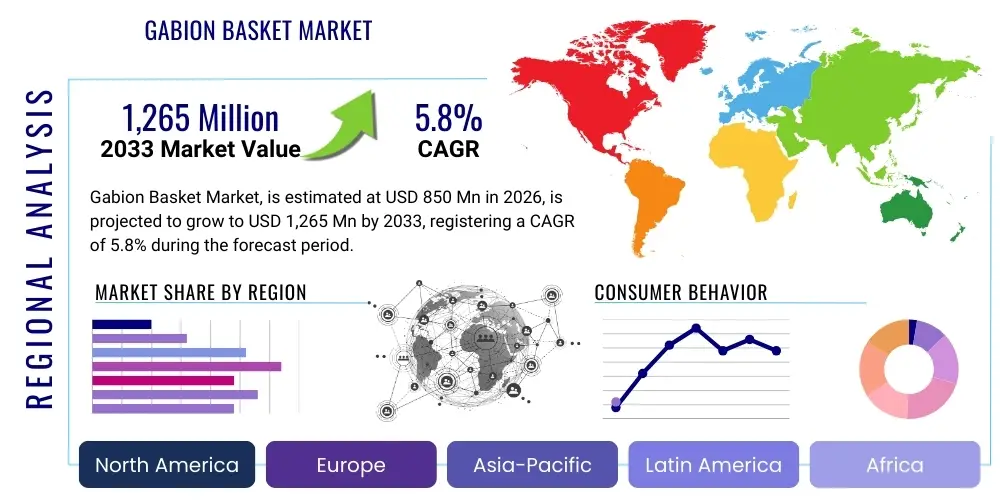

The Gabion Basket Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850 million in 2026 and is projected to reach USD 1,265 million by the end of the forecast period in 2033.

Gabion Basket Market introduction

The Gabion Basket Market encompasses the manufacturing, distribution, and utilization of cage-like structures, typically rectangular or cubic, constructed from galvanized, stainless, or PVC-coated steel wire mesh and subsequently filled with inorganic materials such as stones, rock, concrete, or soil. These versatile, permeable structures serve primarily as engineering elements in civil works, construction, and environmental management applications. Gabions are widely recognized for their structural integrity, flexibility, and permeability, offering superior performance in managing water flow, preventing soil erosion, and stabilizing slopes and embankments, which positions them as a foundational component in modern infrastructure development and ecological restoration projects across the globe.

The core product, the gabion basket, provides an environmentally sustainable and cost-effective alternative to rigid concrete structures, particularly in areas susceptible to seismic activity or differential ground settlement, owing to its inherent flexibility and drainage capabilities. Major applications include the construction of retaining walls, weirs, channel linings, and bridge abutments, essential for maintaining public safety and resilience of critical transportation and utility infrastructure. The durability of the wire mesh, often enhanced with Galfan or heavy galvanization, ensures a long service life even in harsh marine or highly corrosive environments. Furthermore, the aesthetic advantage of natural stone facing allows gabion structures to integrate harmoniously with natural landscapes, driving their adoption in landscaping and architectural design projects as well.

Market growth is predominantly driven by increasing global governmental expenditure on infrastructure development, particularly in developing economies focusing on expanding road networks, flood control mechanisms, and coastal protection schemes. Benefits such as easy installation, minimal foundation preparation requirements, and low environmental impact make gabions highly attractive for rapid deployment in disaster relief and remote construction sites. Additionally, stringent environmental regulations promoting sustainable drainage solutions and erosion mitigation further bolster the demand for gabion structures, ensuring their continued relevance as a critical material in the global construction and geotechnical engineering sectors.

Gabion Basket Market Executive Summary

The Gabion Basket Market is exhibiting robust growth, propelled by significant business trends focusing on sustainable construction materials and resilient infrastructure development. Key business trends include the shift towards high-performance coatings like Galfan and specialized PVC applications to enhance product longevity, alongside increasing utilization of modular and pre-filled gabion systems to reduce on-site labor costs and accelerate project timelines. Geographically, Asia Pacific dominates the market, primarily due to massive ongoing urbanization projects, extensive road and rail network expansion, and critical investments in flood mitigation infrastructure in countries like China and India, making it the central hub for demand and manufacturing innovation. North America and Europe, while mature, show steady growth driven by the replacement of aging infrastructure and the adoption of advanced geotechnical engineering practices for slope stabilization and retaining wall construction.

Segment trends reveal that the Welded Gabion Basket segment is gaining traction, particularly in architectural and landscaping applications where visual aesthetics and precise dimensional stability are paramount, offering a clean, contemporary look compared to traditional woven mesh. However, the Woven Gabion Basket segment, characterized by its superior flexibility and ability to handle large ground movements without failure, remains the dominant choice for critical civil engineering applications such as high retaining walls and deep foundation protection. In terms of material, PVC-coated gabions are witnessing accelerated adoption in coastal and highly acidic soil environments where corrosion resistance is crucial, directly addressing the industry's need for extended asset life cycles and reduced maintenance burdens. End-user trends highlight the construction sector, particularly public works and transportation, as the principal consumer, followed by the mining and agriculture sectors, which utilize gabions extensively for earth retention and stream bank stabilization.

Overall, the market trajectory is highly favorable, underpinned by structural drivers related to climate change resilience and urban density expansion. Manufacturers are actively pursuing automation in mesh production and integrating smart sensors within large gabion structures for real-time monitoring of strain and settlement in high-risk areas. Strategic market consolidation and vertical integration among key players are observed, aimed at controlling the supply chain of raw materials (steel wire) and specialized coatings, ensuring competitive pricing and maintaining high-quality standards necessary for government and large-scale engineering contracts. The future landscape is expected to be characterized by greater product customization and technological integration, further solidifying gabions' role as a vital component in modern earth retention and hydraulic engineering solutions.

AI Impact Analysis on Gabion Basket Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Gabion Basket Market primarily revolve around optimizing logistical efficiencies, automating design processes, and enhancing structural monitoring capabilities. Common questions focus on how machine learning algorithms can predict areas prone to erosion requiring gabion installation, whether AI can optimize stone-filling patterns for maximum structural stability, and the potential for drone-based inspection coupled with AI analysis to assess gabion structure integrity post-disaster. The consensus among these inquiries suggests that AI will not fundamentally change the physical product—the wire cage—but will revolutionize the planning, deployment, and long-term maintenance phases. Key themes include the reduction of planning time through predictive geotechnical modeling, enhanced safety protocols via automated site assessments, and the optimization of material sourcing and inventory management, ensuring that this mature construction material benefits from digital transformation throughout its value chain.

- AI-Powered Geospatial Analysis for identifying optimal locations for erosion control and retaining wall installation.

- Machine learning algorithms optimizing cutting patterns of mesh rolls, minimizing material waste in manufacturing.

- Predictive maintenance schedules determined by analyzing real-time sensor data regarding water pressure and ground settlement within gabion structures.

- Automation of quantity surveying and cost estimation using image recognition to rapidly assess site complexity.

- Integration of AI into Building Information Modeling (BIM) platforms for automated structural design and compliance checks specific to gabion standards.

DRO & Impact Forces Of Gabion Basket Market

The dynamics of the Gabion Basket Market are shaped by powerful Drivers (D) emanating from global infrastructure priorities, Restraints (R) concerning material costs and regulatory complexity, and extensive Opportunities (O) in specialized applications, all culminating in specific Impact Forces. The primary driver is the accelerating frequency of extreme weather events necessitating robust flood control, riverbank protection, and landslide mitigation solutions, where gabions excel due to their permeability and adaptability. Simultaneously, governmental emphasis on resilient and climate-adaptive infrastructure spending fuels demand, particularly in Asia Pacific and Africa. However, the market faces restraints, chiefly the volatility in steel wire prices, which represents the largest component of manufacturing cost, creating uncertainty in long-term contract pricing. Furthermore, the labor-intensive nature of manual stone filling on site, particularly in regions with high labor costs, acts as a brake on rapid expansion, although pre-filled gabions offer a mitigating solution.

Opportunities lie significantly in the growing environmental infrastructure segment, specifically in wetland restoration, ecological landscaping, and bioengineering projects where gabions serve as foundational structures supporting vegetative growth and habitat reconstruction. The development of advanced corrosion-resistant coatings, such as specialized aluminum-zinc alloys (Galfan), presents a substantial opportunity for manufacturers to penetrate high-corrosion markets, including coastal protection and marine environments, commanding premium pricing. The market impact forces are categorized by high buyer power due to the standardized nature of the product and moderate supplier power influenced by global steel supply chains. Regulatory forces, particularly those related to civil engineering safety standards and material longevity certifications (e.g., ASTM, EN standards), significantly influence market entry and product specification, demanding rigorous quality control and technical documentation from all participants.

Segmentation Analysis

The Gabion Basket Market is comprehensively segmented based on product type, material composition, application area, and ultimate end-user industry, reflecting the diverse engineering requirements and environmental conditions across the globe. Understanding these segmentation nuances is crucial for strategic market positioning, as each segment caters to distinct client needs, from critical hydraulic engineering projects requiring flexible, high-tensile wire mesh to architectural installations favoring rigid, aesthetically pleasing structures. The product type dichotomy between woven mesh (double-twisted hexagonal mesh) and welded mesh structures defines suitability based on ground movement tolerance and required structural stiffness. Material segmentation distinguishes between standard galvanized steel, heavily galvanized steel, and polymer-coated options (PVC or HDPE), directly impacting cost and resistance to corrosion and abrasion, guiding selection for specific project environments.

Application segmentation, covering retaining walls, erosion control, channel linings, and bridge protection, highlights the functional versatility of gabions as core geotechnical tools. Retaining walls constitute the largest segment globally due to ubiquitous urban development and transportation infrastructure needs, while erosion control is the fastest-growing segment driven by environmental mandates. End-user analysis identifies construction and civil engineering as the predominant consumers, demanding products that comply with stringent public works specifications, followed by mining and agriculture, which use gabions for access road protection and water management systems, respectively. These segments collectively illustrate a mature but technologically evolving market where specialization in coatings and design methodology is becoming a key differentiator among leading manufacturers vying for public sector contracts and large-scale private developments.

- Product Type:

- Woven Gabion Baskets (Double-Twisted Hexagonal Mesh)

- Welded Gabion Baskets (Welded Wire Mesh)

- Material Type:

- Galvanized Steel Gabions

- PVC Coated Gabions (Polymer Coated)

- Galfan Coated Gabions (Zinc-Aluminum Alloy)

- Application:

- Retaining Walls and Slope Stabilization

- Erosion Control (River and Channel Linings)

- Weirs and Drop Structures

- Bridge Abutments and Headwalls

- Acoustic Barriers and Architectural Use

- End User:

- Construction and Civil Engineering

- Mining

- Agriculture and Forestry

- Landscaping and Architectural

Value Chain Analysis For Gabion Basket Market

The value chain for the Gabion Basket Market begins with the upstream segment, dominated by the procurement and processing of raw materials, primarily low-carbon steel wire rods. This segment is critical as the cost and quality of the finished gabion are heavily dependent on the steel price volatility and the specifications of the wire diameter and tensile strength. Key activities upstream involve steel manufacturing, drawing the wire, and applying the primary anti-corrosion treatment, such as heavy galvanization or the zinc-aluminum (Galfan) coating. Manufacturers often engage in long-term supply agreements or backward integration to stabilize costs and ensure consistent material quality, as wire quality directly determines the structural performance and service life of the finished product, especially under continuous load or exposure to corrosive environments.

The midstream stage involves the actual manufacturing process, including weaving or welding the wire mesh into the standardized or custom basket forms. This stage requires specialized automated machinery for high-volume production, focusing on minimizing defects in the mesh structure and ensuring accurate panel dimensions for ease of assembly on-site. Manufacturers offering PVC-coated baskets introduce a complexity layer here, requiring dedicated coating lines to apply the polymer jacket over the galvanized wire, which adds significant value by extending the product's life in harsh conditions. Efficient manufacturing, coupled with rigorous quality assurance checks (e.g., adherence to mesh opening size, panel connection integrity), is paramount to meeting geotechnical standards and securing certifications necessary for public works contracts.

The downstream segment covers distribution and final installation. Gabions are distributed through a mix of direct sales to large civil engineering firms and indirect channels via specialized construction material distributors and local resellers. Due to the bulk and weight of the wire cages (even when flat-packed), logistics and transportation efficiency significantly influence the final installed cost. Direct channels are crucial for large-scale, complex projects requiring technical consulting, design support, and just-in-time delivery. Installation often involves specialized civil contractors who manage the preparation of the foundation, assembly of the baskets, and critical process of stone filling—which, while simple, requires specific grading and compaction techniques to achieve the designed structural performance. Training and technical support regarding correct assembly procedures are vital elements provided by the manufacturers in this final stage of the value chain.

Gabion Basket Market Potential Customers

The primary consumers and end-users of gabion baskets are entities involved in large-scale infrastructure development, environmental protection, and land management, demanding robust, flexible, and durable earth retention and hydraulic solutions. Government public works departments and agencies, including national and local departments of transportation, water resource management authorities, and environmental protection agencies, represent the most significant customer segment. These governmental bodies utilize gabions extensively for projects such as highway slope stabilization, construction of bridge retaining walls, protection of crucial public utility corridors, and implementation of major flood defense schemes. The procurement process in this sector is characterized by strict adherence to specifications, requiring suppliers to demonstrate high-quality certifications, proven product longevity, and competitive, transparent bidding processes based on standardized metrics.

Another substantial customer base consists of large civil engineering and construction firms that execute these public and private infrastructure projects. These companies often specify gabions for their inherent advantages in geotechnical applications, valuing the ease of assembly, the flexibility they offer in settling terrain, and their rapid deployment capabilities which help in adhering to aggressive construction schedules. Specific projects include the development of new housing estates requiring tiered retaining walls, large commercial developments needing ground stabilization, and major highway widening projects involving extensive cut and fill operations. For these customers, logistical efficiency—getting the right product sizes and quantities delivered accurately and on time—is as critical as the product quality itself, driving demand for manufacturers with strong distribution networks.

Furthermore, specialized segments such as mining and quarrying operations, agriculture, and high-end landscaping represent niche but growing customer groups. Mining companies employ gabions for temporary and permanent applications, including stabilizing waste dumps, protecting haul roads, and constructing access ramp retaining walls in challenging topographical environments. In agriculture and forestry, customers utilize gabions for stream bank rehabilitation, constructing check dams for sediment control, and managing irrigation channels to prevent water course erosion. For these specialized buyers, the permeability of gabions and their capability to integrate with natural vegetation for bioengineering solutions provides a sustainable advantage over impermeable alternatives, aligning with increasing corporate and agricultural focus on environmental stewardship and sustainable resource management.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 million |

| Market Forecast in 2033 | USD 1,265 million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Maccaferri, Betafence, River Supply Inc., Gabion Technologies, Officine Maccaferri S.p.A., GKM, Shandong Zhonglu Steel Co. Ltd., Wire Mesh Corp., Zhongshan Weijun Metal Mesh Co., Limited, HESCO Group, Geofabrics Australasia, W.A.S. Gabion, Bekaert, Terra Aqua, The Gabion Company, TenCate Geosynthetics, Saint-Gobain, ZCL Composites, Partha Gabion, Shanghai Metal Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gabion Basket Market Key Technology Landscape

The Gabion Basket Market, while rooted in a relatively simple engineering concept, is increasingly influenced by advanced material science and fabrication technologies aimed at extending product life and improving structural performance. A pivotal technological element is the development and commercial adoption of high-performance anti-corrosion coatings. Standard hot-dip galvanization is being supplemented, and in high-stakes projects often replaced, by Galfan coatings (a zinc-aluminum alloy) which offer superior protection, typically extending the lifespan of the wire by two to three times compared to standard zinc coating. Furthermore, specialized UV-stabilized PVC and HDPE coatings are technologically optimized for chemical resistance and abrasion defense, making them essential for marine, acid mine drainage, and high-velocity water applications, where traditional metallic coatings quickly degrade.

In terms of manufacturing, automation in the weaving and welding processes is key to maintaining competitive pricing and high-quality consistency. Advanced double-twist weaving machinery ensures the production of highly flexible hexagonal mesh with zero-slip junctions, critical for maintaining structural integrity under dynamic loading or ground movement—a superior technical feature over single-twist meshes. For welded gabions, the technology focuses on precision resistance welding to ensure every intersection point possesses maximum shear strength, coupled with automated flattening and folding machinery to ensure accurate, space-saving delivery. These manufacturing advancements allow for precise dimensional control, which is mandatory for integration with modern construction techniques and adherence to tight tolerances specified in major civil engineering blueprints.

A burgeoning technological trend involves the integration of geosynthetics and monitoring systems within gabion structures. Geotextiles and geogrids are frequently used in conjunction with gabions for enhanced soil reinforcement and filtration behind retaining walls, preventing fine soil migration while maintaining drainage capacity. More sophisticated applications include the embedment of fiber optic strain gauges and piezometers within critical gabion walls (e.g., those protecting critical infrastructure or installed in landslide-prone areas). This technology allows engineers to continuously monitor internal strain, pore water pressure, and structural settlement in real-time. This provides predictive data, enabling proactive maintenance and significantly improving the overall safety and reliability of gabion installations, transforming them from passive structures into smart, monitored geotechnical assets.

Regional Highlights

The Gabion Basket Market exhibits significant regional disparities in demand and utilization, primarily dictated by infrastructural development phases, regulatory environments related to civil engineering standards, and the prevalence of geological hazards. Asia Pacific (APAC) stands out as the global leader in both consumption and manufacturing volume, driven by unprecedented rates of urbanization and massive public investments in transportation networks (e.g., high-speed rail, extensive highway systems) across China, India, and Southeast Asian nations. These countries face chronic challenges related to monsoons, flash floods, and coastal erosion, making gabions indispensable tools for managing water flow and stabilizing vulnerable slopes adjacent to newly constructed infrastructure. The region also benefits from lower manufacturing costs, making locally produced galvanized and PVC-coated gabions highly competitive globally.

North America and Europe represent mature markets characterized by replacement demand, infrastructure renewal, and stringent environmental compliance. In North America, demand is consistent, focused heavily on the use of gabions for highway embankment stability, river training works, and commercial landscaping, often utilizing high-specification, premium products such as Galfan-coated and custom-welded baskets for enhanced longevity and aesthetic appeal. European growth is stimulated by the adoption of gabions in bioengineering solutions, where they are integral to ecological restoration projects and sustainable urban drainage systems (SUDS). Regulatory frameworks within the EU emphasizing biodiversity and sustainable material sourcing further underpin the steady demand for standardized, certified gabion products.

Latin America, the Middle East, and Africa (MEA) are emerging regions offering substantial long-term growth potential. Latin America’s demand is driven by mining activities, which require extensive earth retention structures for operational safety, and national infrastructure projects aimed at improving connectivity. The Middle East sees specific demand in coastal defense projects and desert environment stabilization, requiring highly corrosion-resistant coatings due to saline and harsh conditions. Africa's market expansion is tied directly to foreign direct investment in basic infrastructure—roads, dams, and flood mitigation projects—where gabions' low cost, simplicity of construction, and reliance on locally sourced stone filler offer distinct logistical and economic advantages over complex concrete alternatives, making the region a key focus for global manufacturers seeking future expansion.

- Asia Pacific (APAC): Dominates the market due to large-scale infrastructure projects, urbanization, and critical needs for flood control and landslide mitigation, especially in China and India.

- North America: Driven by infrastructure replacement, adherence to high engineering standards, and strong demand for specialized products in transportation and commercial construction sectors.

- Europe: Characterized by steady adoption in environmental engineering, sustainable drainage systems (SUDS), and retaining walls for road renewal, emphasizing compliance with EU material sustainability regulations.

- Latin America: Growth fueled by expansion in the mining sector and governmental investments in core transportation infrastructure and slope stability projects.

- Middle East & Africa (MEA): Emerging markets with significant long-term potential, focusing on basic infrastructure development, coastal protection, and utilizing gabions for cost-effective, easily deployable solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gabion Basket Market.- Maccaferri

- Betafence

- River Supply Inc.

- Gabion Technologies

- Officine Maccaferri S.p.A.

- GKM

- Shandong Zhonglu Steel Co. Ltd.

- Wire Mesh Corp.

- Zhongshan Weijun Metal Mesh Co., Limited

- HESCO Group

- Geofabrics Australasia

- W.A.S. Gabion

- Bekaert

- Terra Aqua

- The Gabion Company

- TenCate Geosynthetics

- Saint-Gobain

- ZCL Composites

- Partha Gabion

- Shanghai Metal Corporation

Frequently Asked Questions

Analyze common user questions about the Gabion Basket market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between woven gabions and welded gabions?

Woven gabions use double-twisted hexagonal mesh, providing flexibility crucial for geotechnical applications where ground settlement or differential movement is anticipated, such as in high retaining walls or unstable slopes. Welded gabions use rigid, square-grid mesh, offering superior dimensional stability and aesthetic appeal, making them preferred for architectural landscaping and static, low-height retaining structures.

How do gabions contribute to sustainable and resilient infrastructure?

Gabions are permeable, allowing water to drain through the structure, which prevents hydrostatic pressure buildup—a major cause of failure in rigid walls. They are often filled with locally sourced stone, minimizing transportation costs and carbon footprint, and they can integrate effectively with vegetation (bioengineering), offering an environmentally sound solution for erosion control and slope stability.

Which type of coating offers the best corrosion resistance for marine or coastal applications?

For highly corrosive environments like coastal areas or industrial zones, PVC (Polyvinyl Chloride) coated gabions typically offer the best long-term protection. The polymer jacket shields the underlying galvanized or Galfan wire from direct chemical and salt exposure, significantly extending the service life of the structure far beyond that of standard heavily galvanized wire alone.

What major regulatory standards govern the quality and specification of gabion baskets in global markets?

Globally, gabion quality is primarily regulated by standards set by organizations like the American Society for Testing and Materials (ASTM) and European Norms (EN), particularly those relating to mesh tensile strength, coating thickness (e.g., zinc mass per surface area), and wire diameter tolerances. Compliance with these specifications is mandatory for securing most large public works and civil engineering contracts.

How does the volatile price of steel wire impact the overall Gabion Basket Market?

Steel wire is the major cost component of a gabion basket; therefore, high volatility in steel prices creates procurement and manufacturing challenges. Rising steel costs can reduce profitability margins for manufacturers and potentially increase the installed cost for end-users, affecting the competitiveness of gabions compared to concrete alternatives, although the long-term cost benefits usually mitigate this impact.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager