Gamma Seals Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436774 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Gamma Seals Market Size

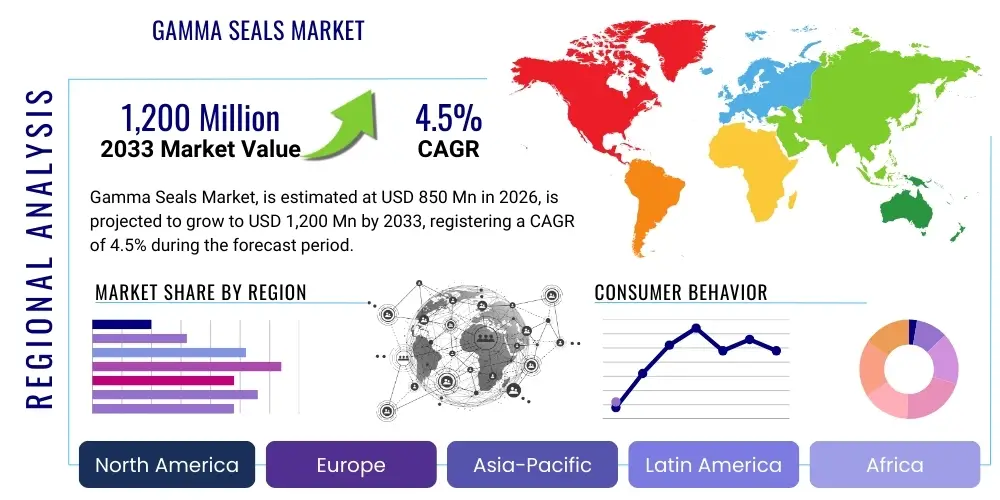

The Gamma Seals Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,200 Million by the end of the forecast period in 2033.

Gamma Seals Market introduction

The Gamma Seals Market encompasses specialized rotary shaft sealing solutions designed primarily for applications involving dust, dirt, and splash protection, serving as an effective secondary seal to retain lubrication and prevent contamination ingress. These non-contacting labyrinth seals typically utilize a pressed metal case and a vulcanized elastomer sealing lip or profile that spins alongside the shaft, deflecting contaminants through centrifugal force. Gamma seals are highly valued in demanding industrial environments where traditional lip seals may fail due to high levels of abrasive particulate matter or excessive run-out.

The primary applications of Gamma seals are widespread across heavy industries, including power transmission systems, electric motors, gearboxes, bearing housings, and agricultural machinery. Their robust construction and ability to function effectively even with slight shaft misalignment make them indispensable in manufacturing, mining, and construction sectors where operational reliability and minimized downtime are critical factors. The inherent design benefits, such as low friction, zero power loss when dry, and extended service life, contribute significantly to the overall efficiency and longevity of the mechanical components they protect.

Market growth is substantially driven by the accelerating demand for industrial automation and machinery requiring reliable sealing solutions capable of operating under harsh conditions. Increased capital expenditure in manufacturing sectors across Asia Pacific, coupled with stringent maintenance protocols aimed at extending equipment lifespan in mature markets like North America and Europe, further propels the adoption of high-performance seals like Gamma seals. Furthermore, technological advancements in material science, leading to seals with enhanced chemical resistance and thermal stability, are opening up new application avenues, especially in the renewable energy sector and specialized heavy transport equipment.

Gamma Seals Market Executive Summary

The Gamma Seals Market demonstrates robust growth driven by continuous industrialization and the critical need for contamination exclusion in rotating equipment across diverse sectors. Key business trends include a strategic shift towards materials offering superior performance metrics, such as enhanced abrasion resistance and wider temperature tolerances, catering to increasingly demanding operational envelopes. Manufacturers are also focusing on offering customized sealing solutions and quick-delivery services to align with the just-in-time inventory strategies adopted by major Original Equipment Manufacturers (OEMs).

Regionally, the market dynamics are characterized by significant growth acceleration in the Asia Pacific (APAC) region, fueled by rapid expansion in manufacturing bases, particularly in China and India, alongside heavy investment in infrastructure and automotive production. North America and Europe, while being mature markets, maintain stable demand driven by replacement cycles, strict adherence to maintenance best practices, and the integration of high-specification machinery requiring premium sealing components. Competitive intensity is moderate, with established global players leveraging patented designs and extensive distribution networks to maintain market share, while regional niche players focus on specific application demands.

In terms of segmentation, the market is primarily categorized by product type (standard profile, heavy-duty profile), material (NBR, FKM, HNBR), and application (Electric Motors, Gearboxes, Pumps). The Electric Motors segment is projected to hold a substantial market share due to global electrification trends and the growing deployment of high-efficiency industrial motors requiring reliable secondary sealing. Material innovation, particularly the rising use of high-performance fluorocarbon elastomers (FKM), is a defining segment trend, addressing applications that require resistance to aggressive chemicals and high operating temperatures, ensuring prolonged sealing effectiveness under extreme stress.

AI Impact Analysis on Gamma Seals Market

Common user inquiries concerning the influence of Artificial Intelligence (AI) on the Gamma Seals market frequently center on how AI-driven predictive maintenance systems affect seal lifespan and replacement cycles, and whether AI can optimize sealing designs for specific operational profiles. Users are primarily concerned with the transition from reactive maintenance to proactive planning, seeking clarity on how sensor data, analyzed by AI algorithms, impacts the demand forecasting for specific seal types. Key themes revolve around supply chain resilience, optimization of inventory levels, and the potential for AI to identify root causes of seal failure (e.g., specific vibration signatures or temperature spikes) that current manual inspections might miss. Users anticipate that AI integration will lead to a decrease in emergency seal replacements but an increase in demand for premium, smart-compatible seals whose performance data can be easily integrated into digital twins of industrial assets.

- AI enables predictive maintenance, reducing catastrophic failures and optimizing the lifespan of Gamma seals installed in rotating machinery.

- Demand forecasting is improved through AI analysis of machinery usage patterns, leading to more efficient inventory management for end-users and manufacturers.

- AI-driven topology optimization techniques can potentially lead to the design of more durable and application-specific Gamma seal profiles, improving sealing integrity.

- Quality control in the manufacturing process can be significantly enhanced using AI-powered vision systems, detecting microscopic flaws in seal materials or profiles.

- Integration of performance data from smart sensors embedded near the seal facilitates real-time condition monitoring, maximizing Mean Time Between Failure (MTBF).

DRO & Impact Forces Of Gamma Seals Market

The Gamma Seals Market is influenced by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO), which collectively constitute the critical impact forces shaping its trajectory. The primary driver is the pervasive requirement for reliable contamination exclusion in industrial machinery, necessitated by increasing operational speeds and the rising cost of downtime, compelling manufacturers to invest in superior sealing technologies. This is complemented by the global trend towards industrial automation (Industry 4.0), where efficiency and long-term asset protection are paramount, significantly boosting the demand for high-integrity components like Gamma seals that minimize friction and prevent premature bearing failure.

However, the market faces significant restraints, notably the intense price competition from substitute products, particularly standard lip seals and other non-contacting labyrinth seals, which may offer a lower initial investment cost, even if they provide less effective contamination protection in harsh environments. Furthermore, the selection and installation complexity of Gamma seals, which require precise fitting and specific housing designs to function optimally, can act as a barrier to adoption in repair or retrofit situations where design modifications are difficult. Economic volatility in major industrial economies can also lead to delays or reductions in capital expenditure for new machinery, impacting OEM demand.

Opportunities for market expansion are centered on the development of specialized seals for emerging high-growth sectors, such as offshore wind turbines, advanced robotics, and electric vehicle powertrain components, which demand seals capable of handling unique environmental and thermal stresses. The drive towards sustainability also presents an opportunity, as seals that reduce friction contribute to overall energy efficiency, appealing to environmentally conscious industries. The impact forces on the market are highly favorable, primarily driven by strict regulatory standards concerning machinery safety and efficiency, technological advancements in material science, and the non-negotiable industry requirement for maximized machinery uptime, ensuring sustained long-term demand for high-performance sealing solutions.

Segmentation Analysis

The Gamma Seals Market is comprehensively segmented based on product design, material composition, and key end-use applications, allowing for a detailed understanding of demand patterns and strategic market positioning. Segmentation by design profile, such as standard V-ring or heavy-duty labyrinth variants, differentiates seals based on their operational severity and specific exclusion capabilities. Material segmentation, which includes traditional nitrile butadiene rubber (NBR), fluorocarbon elastomers (FKM), and specialized compounds like hydrogenated nitrile butadiene rubber (HNBR), reflects the necessary chemical and temperature resistance required by varying industrial processes.

Application-based segmentation is crucial, highlighting the primary industries driving volume, including electric motors, automotive differentials, agricultural machinery, and mining equipment. This analysis reveals that electric motors and gearboxes constitute the largest segment due to their universal use in manufacturing and processing. Furthermore, material selection is increasingly governed by regulatory compliance and the need for prolonged service intervals, pushing demand towards higher-performing elastomers capable of withstanding aggressive lubricants and higher speeds.

- Product Type:

- Standard V-Ring Profiles

- Heavy-Duty Labyrinth Seals

- Customized Profiles

- Material Type:

- Nitrile Butadiene Rubber (NBR)

- Fluorocarbon Elastomer (FKM)

- Hydrogenated Nitrile Butadiene Rubber (HNBR)

- Silicone Rubber (VMQ)

- End-Use Application:

- Electric Motors

- Gearboxes and Transmissions

- Pumps and Compressors

- Agricultural Equipment

- Construction and Mining Machinery

- Automotive (Heavy-duty and Commercial Vehicles)

- Sales Channel:

- Original Equipment Manufacturers (OEMs)

- Aftermarket (MRO)

Value Chain Analysis For Gamma Seals Market

The value chain for the Gamma Seals Market commences with upstream activities involving the sourcing of raw materials, predominantly specialized elastomer compounds (NBR, FKM) and high-grade sheet metal or stamped components for the casing. Key suppliers in this stage are chemical manufacturers and material processing specialists, where quality control and material purity are paramount, directly influencing the final seal performance. Upstream logistics and cost management are critical as fluctuating petrochemical prices can impact the production costs of elastomer compounds. Manufacturers focus on securing long-term contracts with reliable material suppliers to maintain cost stability and ensure consistent material properties across large production batches.

The core manufacturing stage involves precision molding, vulcanization, and metal stamping processes, followed by assembly and rigorous quality testing. Manufacturers invest heavily in automated machinery and proprietary molding techniques to achieve the necessary dimensional accuracy and concentricity critical for effective sealing performance. Downstream activities involve distribution and end-user engagement. Distribution channels are bifurcated into direct sales to large Original Equipment Manufacturers (OEMs) for integration into new machinery, and indirect sales through robust Maintenance, Repair, and Operations (MRO) distributors for aftermarket replacement and service.

The direct channel ensures streamlined delivery and technical consultation for bespoke OEM requirements, often involving large volume, long-term contracts. The indirect distribution network, relying on specialized industrial distributors, plays a crucial role in serving the MRO market, ensuring rapid availability of various seal sizes and materials for immediate operational repairs across global industrial hubs. Effective downstream management, including technical support and rapid response logistics, is essential for capitalizing on the highly profitable aftermarket segment, where minimizing equipment downtime is the primary concern for the final end-users.

Gamma Seals Market Potential Customers

Potential customers for Gamma seals are diverse and span virtually every industry utilizing rotating mechanical equipment requiring reliable bearing protection against contaminants. The largest volume consumers are Original Equipment Manufacturers (OEMs) within the industrial machinery sector, including producers of electric motors, industrial pumps, gear reduction units, and heavy construction equipment. These buyers prioritize long-term reliability, specific material compatibility, and seals that integrate perfectly into their high-volume production lines, necessitating strong technical partnerships with seal manufacturers.

Another major segment comprises the Maintenance, Repair, and Operations (MRO) divisions of large industrial facilities across sectors such as mining, petrochemicals, power generation, and food processing. These end-users are not buying seals for new assemblies but for replacement during scheduled maintenance or breakdown scenarios. Their purchasing decisions are driven by immediate availability, durability in severe operating conditions (dust, moisture, temperature extremes), and performance characteristics that exceed the lifespan of the seals they are replacing, ultimately aiming to reduce the frequency of future maintenance interventions.

Furthermore, the automotive and heavy transport sectors represent significant customers, particularly for seals used in wheel end assemblies, axles, and transmission systems of commercial trucks and agricultural tractors, where exposure to road grime, mud, and fluctuating temperatures is severe. These buyers demand seals that meet stringent performance specifications and regulatory standards for durability and environmental resistance. The core value proposition for all these potential customers is the protection of expensive internal components (like bearings and gears), where the cost of a seal failure vastly outweighs the initial cost of the seal itself.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,200 Million |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SKF, Trelleborg AB, Freudenberg Sealing Technologies, Parker Hannifin Corp, Garlock Sealing Technologies, EagleBurgmann, Angst+Pfister, Hutchinson Worldwide, Seal Company Inc., James Walker, Pioneer Weston, DICHTOMATIK, Precision Polymer Engineering, NOK Corporation, Martin Seals, ElringKlinger, Cinch Seals, Flowserve Corporation, John Crane, AESSEAL. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gamma Seals Market Key Technology Landscape

The technology landscape in the Gamma Seals Market is continuously evolving, primarily driven by innovations in material science and advanced manufacturing processes aimed at enhancing sealing effectiveness and durability. Current technological focus includes the development of next-generation elastomer compounds, such as specialized HNBR and low-friction PTFE-based materials, which offer superior resistance to aggressive synthetic lubricants and significantly higher thermal stability compared to traditional NBR compounds. These advanced materials are essential for applications involving high-speed rotation and extreme temperature variations, often found in modern high-efficiency electric motors and specialized chemical processing pumps.

Furthermore, manufacturing technologies are being optimized through precision molding and vulcanization techniques to ensure exceptionally tight dimensional tolerances, which is critical for the non-contact functionality of the Gamma seal. Laser etching and advanced finishing processes are employed to refine the metal casing components, guaranteeing optimal fit and preventing corrosion. A key development is the integration of proprietary lip profiles that enhance the centrifugal fling action, improving the seal's ability to exclude fine particulate contaminants without generating excess friction or heat.

The trend towards predictive maintenance (Industry 4.0) is also influencing the technology landscape. While Gamma seals themselves are passive mechanical components, their integration into smart bearing housings or motors is facilitated by new housing designs that accommodate embedded sensors (temperature, vibration). This technological alignment ensures that the performance status of the seal environment is continually monitored, allowing for timely replacement before failure occurs, thus maximizing asset availability and justifying the investment in high-performance sealing solutions over generic alternatives.

Regional Highlights

The global Gamma Seals Market exhibits significant regional disparities in terms of market maturity, growth rate, and demand drivers. Asia Pacific (APAC) currently dominates the market and is projected to experience the highest growth rate during the forecast period. This dominance is attributed to massive industrial infrastructure development, rapid expansion of the manufacturing sector (particularly automotive, heavy machinery, and consumer electronics production) in countries like China, India, and Southeast Asian nations, and substantial foreign direct investment into industrial automation projects that require reliable sealing solutions for longevity.

North America and Europe represent mature, yet highly valuable, markets characterized by a strong emphasis on the aftermarket (MRO) segment and strict quality standards. Demand in these regions is driven less by capacity expansion and more by the necessity of upgrading existing equipment with higher-performance seals to meet enhanced efficiency and environmental regulations. Germany, the United States, and Canada are key consumers, where industries like precision machinery manufacturing, aerospace, and advanced robotics maintain high demand for seals with specialized material properties and stringent tolerance specifications. The robust installed base of industrial equipment ensures sustained replacement demand.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging regions showing gradual growth, particularly influenced by investment in mining operations, oil and gas exploration, and regional infrastructure projects. Demand in these areas often focuses on heavy-duty seal profiles designed to withstand harsh, abrasive, and often remote operating environments. While these regions possess lower market volumes compared to APAC, the increasing focus on industrial diversification and localized manufacturing capacity presents notable long-term growth prospects for Gamma seal suppliers.

- Asia Pacific (APAC): Market leader and fastest-growing region, driven by unparalleled growth in manufacturing, industrialization, and high capital expenditure in China and India across machinery and automotive production.

- North America: Mature market characterized by high demand for specialized, high-performance seals, primarily driven by stringent maintenance protocols and the large MRO segment in the aerospace and heavy industrial sectors.

- Europe: Stable growth fueled by advanced machinery production (Germany, Italy) and the focus on industrial efficiency (Industry 4.0), leading to preference for seals optimized for energy saving and extended lifecycles.

- Latin America (LATAM): Emerging market growth concentrated in mining, agriculture, and infrastructure projects, demanding seals capable of resisting severe environmental degradation.

- Middle East & Africa (MEA): Growth tied to investments in petrochemical processing, power generation, and construction sectors, requiring robust sealing solutions for harsh, high-temperature operations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gamma Seals Market.- SKF

- Trelleborg AB

- Freudenberg Sealing Technologies

- Parker Hannifin Corp

- Garlock Sealing Technologies

- EagleBurgmann

- Angst+Pfister

- Hutchinson Worldwide

- Seal Company Inc.

- James Walker

- Pioneer Weston

- DICHTOMATIK

- Precision Polymer Engineering

- NOK Corporation

- Martin Seals

- ElringKlinger

- Cinch Seals

- Flowserve Corporation

- John Crane

- AESSEAL

Frequently Asked Questions

Analyze common user questions about the Gamma Seals market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a Gamma seal compared to a standard lip seal?

A Gamma seal functions as a non-contacting labyrinth or secondary seal, specifically designed to exclude heavy external contaminants like dirt, dust, and moisture from reaching primary shaft seals or bearing lubrication, offering superior protection in severely abrasive environments. Unlike standard lip seals, it generates minimal friction due to its non-contact design under static conditions, preserving energy efficiency.

Which end-use application drives the highest demand for Gamma Seals?

The Electric Motors and Gearboxes segment collectively drives the highest volume demand for Gamma Seals globally. This is due to the ubiquity of these components across all heavy industrial, manufacturing, and automation sectors, necessitating high-integrity sealing to maximize uptime and prevent premature bearing failure caused by contamination ingress.

How do material advancements impact the performance and market adoption of Gamma Seals?

Material advancements, specifically the use of advanced elastomers like FKM and HNBR, significantly improve performance by increasing resistance to aggressive synthetic oils, high operational temperatures, and chemical exposure. This longevity and robustness directly encourage market adoption in high-specification industries, ensuring extended Mean Time Between Failure (MTBF) for critical equipment.

Is the Gamma Seals Market growth primarily driven by OEM sales or the Aftermarket (MRO)?

While OEM sales provide high-volume stability for new machinery builds, the market’s sustained profitability and resilience are heavily influenced by the Aftermarket (MRO) segment. The need for reliable, rapid replacement seals during maintenance cycles across the massive global installed base of industrial machinery ensures continuous, high-margin demand for MRO distribution channels.

What is the current growth forecast (CAGR) for the Gamma Seals Market?

The Gamma Seals Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033, driven by continuous industrialization in the Asia Pacific region and the global trend toward utilizing reliable, contamination-exclusion sealing solutions to extend the operational life of rotating industrial assets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager