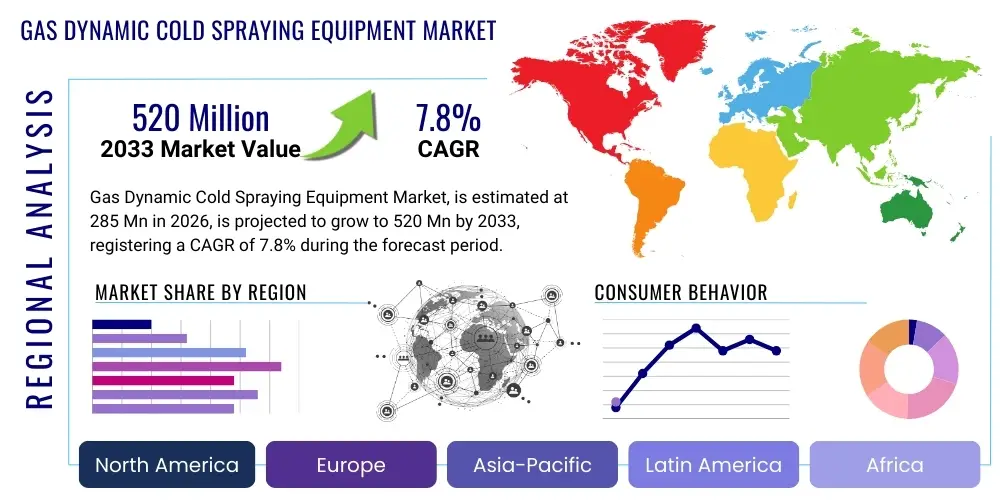

Gas Dynamic Cold Spraying Equipment Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440232 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Gas Dynamic Cold Spraying Equipment Market Size

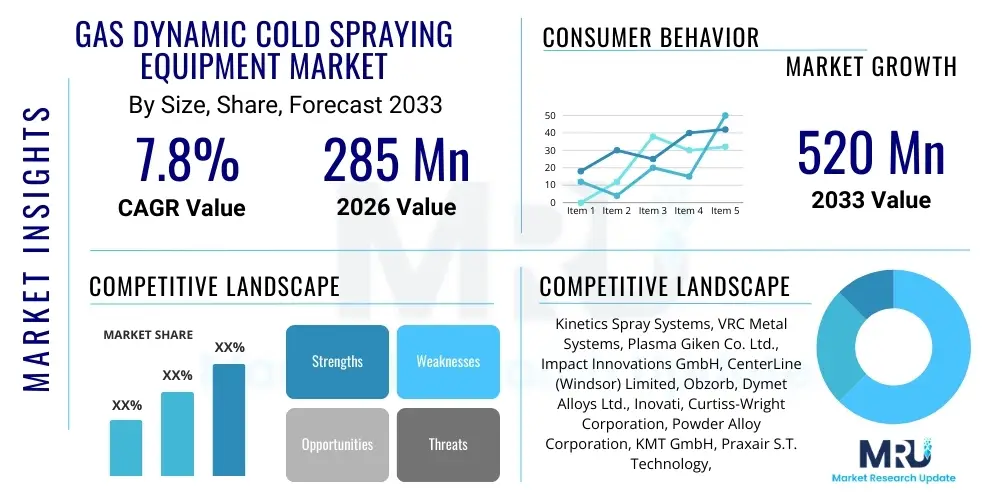

The Gas Dynamic Cold Spraying Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 285 million in 2026 and is projected to reach USD 520 million by the end of the forecast period in 2033.

Gas Dynamic Cold Spraying Equipment Market introduction

The Gas Dynamic Cold Spraying Equipment Market encompasses the tools and systems utilized in the cold spray deposition process, a revolutionary surface engineering technology. This process involves accelerating powdered materials to supersonic speeds through a de Laval nozzle, causing them to plastically deform and bond upon impact with a substrate, without melting. Unlike traditional thermal spray techniques, cold spraying maintains the solid state of the feedstock material, preserving its original microstructure and properties, which is crucial for sensitive materials and applications where heat-induced changes are detrimental.

The equipment itself typically includes a gas heater, a powder feeder, a spray gun (nozzle), and a control system, all designed for precise control over gas pressure, temperature, powder flow, and gun manipulation. These systems are integral to industries demanding high-performance coatings, repairs, and additive manufacturing capabilities. Major applications span aerospace, automotive, marine, defense, electronics, and biomedical sectors, where the need for enhanced corrosion resistance, wear protection, thermal management, and electrical conductivity is paramount.

Key benefits of gas dynamic cold spraying include its ability to deposit a wide range of materials, including metals, alloys, and composites, with minimal thermal stress and oxidation. This leads to dense, high-integrity coatings with superior adhesion and mechanical properties. The market is primarily driven by the increasing demand for advanced materials in critical applications, the need for cost-effective repair solutions for high-value components, and the growing adoption of additive manufacturing techniques that leverage cold spray's unique capabilities for near-net-shape fabrication and material combination. Furthermore, stricter environmental regulations pushing for cleaner, more energy-efficient coating processes also contribute to market expansion.

Gas Dynamic Cold Spraying Equipment Market Executive Summary

The Gas Dynamic Cold Spraying Equipment Market is poised for significant expansion, driven by its inherent advantages over conventional thermal spray methods, particularly in preserving material integrity and offering versatile application possibilities. Current business trends indicate a robust investment in research and development, focusing on automation, process optimization, and the expansion of material compatibility. Manufacturers are increasingly integrating artificial intelligence and machine learning into control systems for enhanced precision, real-time monitoring, and predictive maintenance, thereby improving operational efficiency and coating quality. The push towards Industry 4.0 paradigms is fostering the development of smarter, interconnected cold spray systems capable of seamless integration into modern manufacturing workflows. Moreover, there is a distinct trend towards modular and customizable equipment designs, catering to specific industry needs and enabling greater flexibility for end-users.

Regionally, North America and Europe currently dominate the market due to their advanced manufacturing infrastructure, significant aerospace and defense sectors, and strong emphasis on technological innovation and material science research. However, the Asia Pacific region is rapidly emerging as a high-growth market, propelled by accelerating industrialization, increasing investments in automotive and electronics manufacturing, and a burgeoning demand for advanced materials in countries like China, India, Japan, and South Korea. Latin America and the Middle East & Africa are also showing promising growth potential, albeit from a smaller base, as industrialization efforts and infrastructure development create new opportunities for specialized coating and repair technologies.

Segmentation trends highlight a growing demand for high-pressure cold spray systems due to their ability to achieve superior coating density and adhesion, making them ideal for critical structural applications. Low-pressure systems, while offering cost-effectiveness, continue to find applications in less demanding scenarios. In terms of material types, aluminum and copper alloys are consistently high-demand segments due to their widespread use across various industries. However, the use of nickel, titanium, and superalloys is seeing an upward trend, especially in aerospace and energy sectors requiring extreme temperature and corrosion resistance. The market is also experiencing increased adoption across diverse end-user industries, with aerospace and defense remaining pivotal, while automotive, biomedical, and oil & gas sectors are witnessing substantial growth as they seek durable, high-performance surface solutions.

AI Impact Analysis on Gas Dynamic Cold Spraying Equipment Market

User questions related to AI's impact on the Gas Dynamic Cold Spraying Equipment Market frequently revolve around the potential for enhanced process control, material optimization, and predictive maintenance. Users are concerned with how AI can minimize defects, reduce material waste, and improve the overall efficiency and repeatability of the cold spray process. There is a strong expectation that AI will lead to more intelligent systems capable of self-correction and adaptive spraying parameters, ultimately lowering operational costs and increasing productivity. Furthermore, inquiries often touch upon the role of AI in quality assurance, real-time diagnostics, and the development of new material combinations, aiming to unlock advanced coating functionalities and expand the application scope of cold spray technology.

- AI-driven real-time parameter optimization for superior coating quality and consistency.

- Predictive maintenance algorithms for cold spray equipment, reducing downtime and extending machine lifespan.

- Enhanced defect detection and quality control through machine vision and learning.

- Accelerated material discovery and process development for novel cold spray applications.

- Automated robotic cold spray systems with adaptive path planning and self-correction capabilities.

- Optimization of feedstock material usage, leading to reduced waste and improved cost-efficiency.

- Personalized process recipes and recommendations based on material characteristics and desired coating properties.

- Simulation and modeling advancements for predicting coating behavior and system performance.

DRO & Impact Forces Of Gas Dynamic Cold Spraying Equipment Market

The Gas Dynamic Cold Spraying Equipment Market is significantly influenced by a confluence of driving forces, inherent restraints, and emerging opportunities, all of which contribute to its dynamic growth trajectory. The primary drivers include the escalating demand for high-performance materials in critical industries such as aerospace, automotive, and defense, where superior wear resistance, corrosion protection, and thermal stability are imperative. The non-thermal nature of cold spray, which preserves the metallurgical integrity of both the feedstock and substrate, is a key advantage fueling its adoption. Additionally, the growing focus on extending the lifespan of existing components through advanced repair and refurbishment techniques, rather than costly replacements, further propels market expansion. The versatility of cold spray in depositing a wide array of metallic and composite materials, coupled with its environmental benefits of avoiding toxic fumes and high energy consumption associated with thermal methods, also acts as a significant catalyst for market growth.

Despite these strong drivers, the market faces several restraining factors. The high initial capital investment required for cold spray equipment can be a barrier for smaller enterprises or those with limited budgets, hindering broader adoption. The complexity of the cold spray process, which demands specialized technical expertise for operation, parameter optimization, and quality control, also presents a challenge. Furthermore, the limited availability of standardized codes and certification for cold sprayed components, particularly in highly regulated industries, can slow down its full-scale implementation. Competition from well-established conventional thermal spray technologies and the ongoing need for extensive research and development to expand material compatibility and application envelopes also pose restraints.

However, the market is rich with opportunities that are expected to mitigate these restraints and accelerate growth. The increasing integration of automation and robotics with cold spray systems is simplifying operations and reducing the need for extensive manual intervention, making the technology more accessible. The burgeoning field of additive manufacturing presents a substantial opportunity for cold spray to fabricate complex geometries and graded materials, particularly for repair and hybrid manufacturing. The development of portable and handheld cold spray systems is opening up new possibilities for field repairs and on-site applications, expanding market reach. Moreover, continued innovation in feedstock material development, including novel composite powders and nanomaterials, is broadening the scope of applications and enhancing coating performance, ensuring a robust future for gas dynamic cold spraying equipment in a diverse array of advanced industrial processes.

Segmentation Analysis

The Gas Dynamic Cold Spraying Equipment market is segmented to provide a granular understanding of its various facets, enabling stakeholders to identify specific growth areas and market dynamics. These segments are primarily defined by the type of equipment, the material used for spraying, the pressure system employed, and the diverse applications across different end-user industries. Analyzing these segments helps in understanding the technological preferences, material demands, and industrial adoption patterns that characterize the market's evolution.

- By Equipment Type

- Portable Cold Spray Systems

- Industrial Cold Spray Systems

- Robotic Cold Spray Systems

- By Material Type

- Aluminum and its Alloys

- Copper and its Alloys

- Nickel and its Alloys

- Titanium and its Alloys

- Steels

- Ceramics and Composites

- Others (e.g., Zinc, Tin, Lead)

- By Pressure Type

- High-Pressure Cold Spray Systems

- Low-Pressure Cold Spray Systems

- By Application/End-User Industry

- Aerospace and Defense

- Automotive

- Oil and Gas

- Medical and Biomedical

- Electronics and Semiconductors

- Marine

- Power Generation

- General Industrial (e.g., tooling, machinery repair)

- Research and Development

Value Chain Analysis For Gas Dynamic Cold Spraying Equipment Market

The value chain for the Gas Dynamic Cold Spraying Equipment Market is a complex ecosystem involving several stages, beginning from raw material sourcing and extending to end-user applications and after-sales services. Upstream analysis focuses on the supply of critical components and feedstock materials essential for the manufacturing of cold spray systems. This includes suppliers of high-pressure gas systems, gas heaters, powder feeders, robotic arms, control systems, and specialized de Laval nozzles. Furthermore, the availability and quality of various metallic, ceramic, and composite powders, which are the core consumables for the cold spray process, play a crucial role. Innovation and cost-effectiveness in these upstream segments directly influence the final product's performance and market competitiveness, with advancements in powder metallurgy and gas compression technologies driving efficiency improvements.

Midstream activities involve the manufacturing, assembly, and integration of these components into complete cold spray systems. This stage requires significant engineering expertise in fluid dynamics, thermodynamics, material science, and automation. Manufacturers design, produce, and test the equipment, ensuring compliance with industry standards and performance specifications. This segment also includes specialized system integrators who may customize solutions for specific industrial applications, incorporating robotics, automation, and advanced software for process control. Research and development institutions also play a vital role here, collaborating with manufacturers to innovate new equipment designs, optimize spray parameters, and expand the range of compatible materials and applications, thereby pushing the technological boundaries of cold spraying.

Downstream analysis covers the distribution channels, sales, and after-sales support for the cold spray equipment. Distribution primarily occurs through direct sales channels, given the specialized nature and high investment of the equipment, allowing manufacturers to provide direct technical support and consultation. Indirect channels, through specialized distributors and agents, are also utilized, particularly in regions where manufacturers do not have a direct presence. These channels are crucial for market penetration and reaching a wider customer base. After-sales services, including installation, training, maintenance, and technical support, are integral to ensuring customer satisfaction and long-term equipment performance. The successful functioning of this value chain, from raw material to end-use and service, is essential for the sustained growth and adoption of gas dynamic cold spraying technology across various industries globally.

Gas Dynamic Cold Spraying Equipment Market Potential Customers

Potential customers for Gas Dynamic Cold Spraying Equipment primarily comprise industries and organizations that require advanced surface engineering solutions for component repair, protection, and fabrication. These end-users are characterized by their stringent demands for material performance, durability, and cost-effectiveness in maintaining critical infrastructure and high-value assets. Key sectors include aerospace and defense, where cold spray is utilized for repairing turbine blades, landing gears, and other structural components, as well as for applying protective coatings against wear and corrosion on aircraft parts. The military also leverages this technology for repairing battle-damaged equipment and for protective coatings on various defense platforms, reducing logistical burdens and extending operational readiness.

The automotive industry represents another significant customer segment, employing cold spray for engine component repair, enhancing wear resistance of braking systems, and applying lightweight protective coatings. In the oil and gas sector, cold spray is crucial for repairing pipelines, valves, and drilling equipment exposed to harsh corrosive and abrasive environments, significantly extending their service life and reducing operational downtime. The medical and biomedical sector utilizes cold spray for creating biocompatible coatings on prosthetics and surgical instruments, as well as for developing novel implantable devices with enhanced properties. Furthermore, general manufacturing industries, including those involved in tooling, heavy machinery, and power generation, are increasingly adopting cold spray for component refurbishment and surface enhancement, driven by the desire to improve operational efficiency and reduce replacement costs for expensive parts. Research institutions and universities also represent potential customers, focusing on material science research, process optimization, and the development of new cold spray applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 285 Million |

| Market Forecast in 2033 | USD 520 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces | >|

| Segments Covered | >|

| Key Companies Covered | Kinetics Spray Systems, VRC Metal Systems, Plasma Giken Co. Ltd., Impact Innovations GmbH, CenterLine (Windsor) Limited, Obzorb, Dymet Alloys Ltd., Inovati, Curtiss-Wright Corporation, Powder Alloy Corporation, KMT GmbH, Praxair S.T. Technology, Inc., Unique Thermal Solutions, Oerlikon Metco, Castolin Eutectic, SciLab Cold Spray, ASB Industries, Inc., Titomic, H.C. Starck Solutions, Sprimag |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gas Dynamic Cold Spraying Equipment Market Key Technology Landscape

The technological landscape of the Gas Dynamic Cold Spraying Equipment market is characterized by continuous innovation aimed at enhancing process efficiency, expanding material capabilities, and improving coating quality. A central aspect involves advancements in gas heater designs, focusing on achieving higher gas temperatures and pressures while maintaining energy efficiency and system stability. This directly impacts the particle velocity and kinetic energy, which are critical for effective bonding. Development of novel de Laval nozzle geometries and materials is also crucial, enabling more precise control over the gas flow dynamics and particle acceleration, leading to denser and more uniform coatings. Furthermore, integrated powder feeders are becoming more sophisticated, offering greater accuracy in powder flow rate and consistency, which is vital for process repeatability and material deposition efficiency.

Automation and robotics play an increasingly significant role in the technological evolution of cold spray. Robotic arms are commonly integrated with cold spray guns to provide precise and repeatable motion control, enabling complex component geometries to be coated or repaired with high accuracy and minimal human intervention. This shift towards automation not only enhances productivity and safety but also ensures consistency in coating application, reducing the variability often associated with manual processes. Advanced control systems incorporating sensors, real-time data acquisition, and feedback loops are becoming standard, allowing for dynamic adjustment of spray parameters during operation to compensate for environmental changes or substrate variations, thereby optimizing the coating process in real-time.

The integration of digital technologies, such as Artificial Intelligence (AI) and Machine Learning (ML), is revolutionizing process optimization and quality assurance. AI algorithms are being developed to analyze vast datasets from cold spray experiments, predicting optimal spray parameters for new materials or geometries, and identifying potential defects before they occur. This predictive capability significantly reduces trial-and-error costs and speeds up process development. Moreover, advanced diagnostics tools, including in-situ monitoring of particle velocity and temperature, and sophisticated post-deposition analysis techniques, are becoming more refined. These technological advancements collectively contribute to making gas dynamic cold spraying a more reliable, versatile, and economically viable solution for a wider range of industrial applications, driving its further market penetration.

Regional Highlights

- North America: This region holds a significant share of the Gas Dynamic Cold Spraying Equipment Market, driven by robust investments in aerospace, defense, and automotive industries. The presence of major research institutions and leading manufacturers, coupled with high adoption rates of advanced manufacturing technologies, positions North America as a key market. The United States, in particular, leads in R&D and application diversification.

- Europe: Europe represents another dominant market, fueled by strong manufacturing bases in Germany, France, and the UK, especially within the automotive, energy, and general industrial sectors. Strict environmental regulations encourage the adoption of cleaner coating technologies like cold spray, while ongoing innovation in material science and engineering further supports market growth across the continent.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, attributed to rapid industrialization, increasing governmental investments in infrastructure development, and the burgeoning manufacturing sectors in China, India, Japan, and South Korea. The expanding automotive and electronics industries, coupled with a rising demand for advanced repair and surface protection solutions, are key drivers.

- Latin America: This region is experiencing steady growth, primarily driven by increasing investments in the oil and gas sector in countries like Brazil and Mexico, which require robust coating solutions for equipment longevity. The automotive industry also contributes to the demand for cold spray equipment as it seeks to enhance component durability.

- Middle East and Africa (MEA): The MEA market is exhibiting emerging potential, particularly within the oil and gas, defense, and power generation industries. Countries in the Gulf Cooperation Council (GCC) are investing heavily in industrial diversification and infrastructure, creating new opportunities for advanced surface engineering technologies, although the market is currently smaller in scale compared to developed regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gas Dynamic Cold Spraying Equipment Market.- Kinetics Spray Systems

- VRC Metal Systems

- Plasma Giken Co. Ltd.

- Impact Innovations GmbH

- CenterLine (Windsor) Limited

- Obzorb

- Dymet Alloys Ltd.

- Inovati

- Curtiss-Wright Corporation

- Powder Alloy Corporation

- KMT GmbH

- Praxair S.T. Technology, Inc.

- Unique Thermal Solutions

- Oerlikon Metco

- Castolin Eutectic

- SciLab Cold Spray

- ASB Industries, Inc.

- Titomic

- H.C. Starck Solutions

- Sprimag

Frequently Asked Questions

Analyze common user questions about the Gas Dynamic Cold Spraying Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is gas dynamic cold spraying equipment?

Gas dynamic cold spraying equipment utilizes a non-thermal process to deposit powdered materials onto a substrate at supersonic speeds. Unlike traditional thermal spray methods, it avoids melting the feedstock, preserving material properties and minimizing thermal stress, making it ideal for sensitive applications and high-performance coatings.

What are the primary advantages of cold spray over traditional thermal spray techniques?

The main advantages include the preservation of feedstock material microstructure and properties due to the absence of melting, minimal thermal stress on the substrate, reduced oxidation, and the ability to deposit a wider range of materials, leading to denser coatings with superior adhesion and mechanical integrity, while also being more environmentally friendly.

Which industries are the major end-users of gas dynamic cold spraying technology?

Key end-user industries include aerospace and defense for component repair and protective coatings, automotive for engine and chassis part enhancement, oil and gas for corrosion and wear protection, medical and biomedical for biocompatible coatings, and general manufacturing for extending machinery lifespan and improving surface characteristics.

What are the key factors driving the growth of the cold spraying equipment market?

Market growth is primarily driven by increasing demand for high-performance materials in critical applications, the economic benefits of component repair and refurbishment over replacement, advancements in additive manufacturing, and growing environmental concerns favoring cleaner coating processes. Technological innovations in equipment and materials also play a significant role.

How is AI impacting the development and application of gas dynamic cold spraying equipment?

AI is transforming the cold spray market by enabling real-time parameter optimization for enhanced coating quality, facilitating predictive maintenance for equipment longevity, improving defect detection through machine vision, and accelerating material discovery and process development. This leads to more efficient, precise, and reliable cold spray operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager