Gas Fracturing Trailer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433789 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Gas Fracturing Trailer Market Size

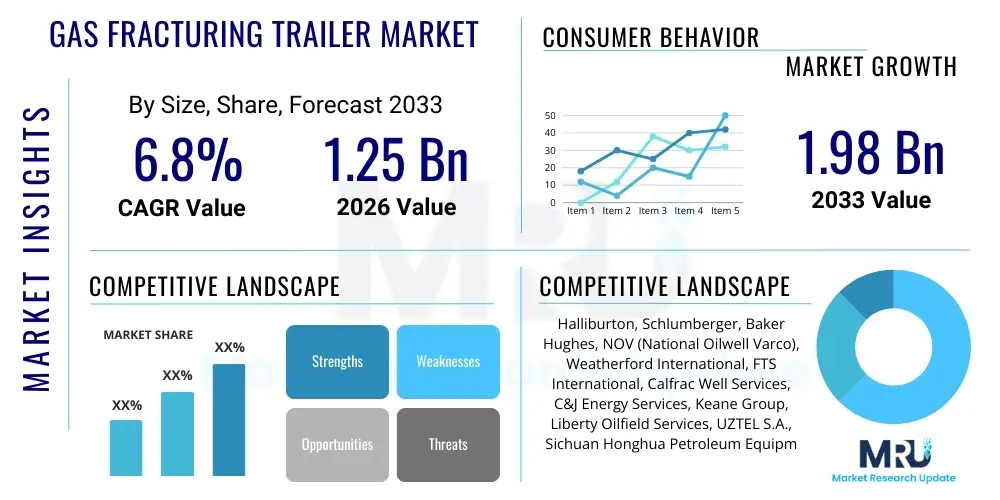

The Gas Fracturing Trailer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $1.25 Billion in 2026 and is projected to reach $1.98 Billion by the end of the forecast period in 2033.

Gas Fracturing Trailer Market introduction

The Gas Fracturing Trailer Market encompasses specialized mobile equipment designed to facilitate hydraulic fracturing operations, primarily used in the extraction of unconventional hydrocarbon resources such as shale gas and tight oil. These trailers house high-pressure pumping units, blending equipment, and various support systems necessary to inject fracturing fluid—typically a mix of water, proppant (sand or ceramic particles), and chemical additives—into subterranean rock formations to create fractures, thereby enhancing permeability and enabling gas flow to the wellbore. The equipment is critical for achieving the high horsepower and pressure ratings required to overcome overburden pressure and initiate deep rock fracturing.

These sophisticated mobile units are engineered for rugged field conditions, emphasizing rapid deployment, reliability, and high efficiency, which are crucial for maximizing uptime in complex drilling schedules. Key applications include multi-stage fracturing in horizontal wells, deep resource exploitation, and re-fracking operations aimed at enhancing production from mature fields. The robust design and mobility of these trailer systems allow service companies to rapidly move large fleets between drilling sites, making them indispensable assets in geographically dispersed unconventional plays across regions like North America and increasingly in the Asia Pacific.

The primary driving factors propelling this market include the sustained global demand for natural gas as a cleaner transitional fuel, ongoing technological advancements increasing the efficiency and safety of fracturing operations (such as automated controls and electric fracturing), and the expansion of drilling activities into previously inaccessible or economically unviable unconventional reserves. The inherent flexibility and scalability offered by trailer-mounted systems ensure their continued dominance over fixed installations, providing substantial benefits in terms of operational cost reduction and speed of deployment for exploration and production (E&P) companies.

Gas Fracturing Trailer Market Executive Summary

The Gas Fracturing Trailer Market is currently characterized by strong resilience driven primarily by renewed investment cycles in key unconventional plays, particularly the Permian Basin and Marcellus Shale in North America. Business trends show a distinct shift toward higher efficiency, lower emission fracturing fleets. Major service companies are increasingly investing in sophisticated equipment capable of operating on dual-fuel or entirely electric power systems to reduce reliance on volatile diesel prices and meet increasingly stringent environmental regulations. This transition necessitates the continuous modernization of fracturing trailer fleets, focusing on higher horsepower (HHP) ratings and advanced automation features to minimize operational footprint and labor requirements.

Regional trends highlight North America's unwavering dominance, accounting for the vast majority of market demand due to mature infrastructure and intensive unconventional resource extraction activities. However, emerging growth is observed in regions like the Middle East (specifically Saudi Arabia and UAE) and parts of Asia Pacific (China and Australia), which are actively exploring their own indigenous shale and tight gas reserves. These newer markets often require specialized trailer configurations tailored to unique geological pressures and logistical constraints. The competitive landscape is intensely focused on technological superiority, with major Original Equipment Manufacturers (OEMs) integrating predictive maintenance using IoT sensors into their trailer designs to improve operational reliability.

Segment trends indicate rapid growth in the Electric/Hybrid power source segment, reflecting the industry's commitment to decarbonization and improved cost management through reduced fuel consumption. Furthermore, the 15,000 PSI and above pressure rating segment is expanding rapidly, driven by the need to fracture deeper and tighter rock formations that require significantly higher injection pressures. Applications in tight oil and shale gas continue to be the backbone of the market, though coal bed methane (CBM) extraction in specific locales also contributes meaningful demand for smaller, purpose-built fracturing units. Manufacturers are prioritizing lightweight, durable materials to enhance payload efficiency and compliance with varying road regulations globally.

AI Impact Analysis on Gas Fracturing Trailer Market

Users frequently inquire about how Artificial Intelligence (AI) and Machine Learning (ML) are optimizing the operational lifecycle and efficiency of gas fracturing trailers. Common themes revolve around predictive maintenance schedules, maximizing pump uptime, automating complex blending and pressure control sequences, and enhancing safety protocols through real-time data analysis. Key concerns address the integration cost of advanced sensor arrays and AI platforms into existing legacy fleets, data security risks associated with cloud-based analytics, and the necessity for specialized personnel training to interpret and act upon AI-generated insights. Users expect AI to reduce non-productive time (NPT) significantly by forecasting equipment failure, thereby extending the service life of high-wear components like fluid ends and plungers. They also anticipate substantial improvements in operational consistency by using ML algorithms to dynamically adjust proppant concentration and fluid viscosity in response to downhole pressure readings, optimizing the fracture geometry for maximum hydrocarbon recovery.

- Real-Time Predictive Maintenance: AI monitors vibration, temperature, and pressure data from trailer components (pumps, engines) to forecast failures, minimizing costly downtime.

- Optimized Pumping Schedules: Machine learning algorithms dynamically adjust pump rates and pressure profiles based on real-time reservoir response, maximizing fracture effectiveness.

- Automated Blending Control: AI systems precisely control proppant and additive injection rates, ensuring consistent slurry quality regardless of changing operating conditions.

- Operational Efficiency Enhancement: Algorithms optimize fuel consumption and engine performance across the fracturing fleet, reducing operational expenditure (OPEX).

- Safety and Risk Reduction: AI detects anomalous operational parameters indicative of potential hazards, triggering automated shutdowns or alerts faster than human operators.

- Enhanced Fleet Management: AI provides centralized, data-driven insights into the performance and required deployment sequence of multiple fracturing trailers across a basin.

DRO & Impact Forces Of Gas Fracturing Trailer Market

The dynamics of the Gas Fracturing Trailer Market are governed by a complex interplay of internal market drivers promoting technological advancement and external constraints related to commodity volatility and regulatory scrutiny. A primary driver remains the continuous pursuit of energy independence by major consuming nations, coupled with the proven economic viability of extracting unconventional resources using high-volume hydraulic fracturing techniques. Restraints are predominantly centered on the cyclical nature of the oil and gas industry, where sharp fluctuations in benchmark prices (WTI and Brent) directly impact E&P capital expenditure, slowing down new fleet purchases and modernization projects. Opportunities, conversely, are abundant in the transition towards sustainable operations, specifically through the electrification of fracturing fleets and the deployment of advanced automation systems that promise significant long-term operational cost savings and superior environmental performance.

Impact forces currently skew positively towards technological adoption. The bargaining power of suppliers, particularly those providing specialized high-performance steel and engine components, remains moderate but is tempered by the standardization of fracturing unit designs. The bargaining power of buyers (large service companies) is high due to consolidation in the service sector and their ability to demand highly customized, high-specification equipment, often leveraging large-volume contracts. The threat of substitutes, primarily non-trailer-based fracturing methods or non-fracking techniques, is low given the scalability and proven efficacy of trailer-mounted systems in large-scale shale operations. However, regulatory shifts towards zero-emission targets pose a significant external threat, compelling rapid innovation in trailer design.

Market saturation in established regions encourages competition based on technological differentiation, efficiency, and reliability, rather than sheer volume. Manufacturers must therefore concentrate heavily on R&D to deliver units that offer reduced noise pollution, improved fuel flexibility (e.g., CNG/LNG utilization), and enhanced mobility suitable for increasingly restrictive logistical environments. The global shift in energy preference towards natural gas, perceived as a lower-carbon fossil fuel compared to coal, provides a foundational market support structure for gas-specific fracturing technology.

- Drivers: Intensified global unconventional resource exploration and production; rapid technological advancements enhancing pump efficiency and pressure capabilities; increasing adoption of multi-well pad drilling techniques requiring highly mobile and powerful equipment; strategic shift towards natural gas as a critical transition fuel.

- Restraints: Severe regulatory environment concerning water usage, emissions, and seismic activity associated with hydraulic fracturing; high capital expenditure required for purchasing and maintaining advanced trailer fleets; volatility in natural gas and oil commodity prices affecting investment decisions; supply chain disruptions impacting the availability of critical, specialized components.

- Opportunities: Growing demand for electric and natural gas powered (Tier 4/5 compliant) fracturing trailers; expansion into untapped international shale reserves (e.g., Argentina, China); integration of advanced data analytics and AI for operational optimization; development of modular, containerized fracturing units for remote and challenging terrains.

- Impact Forces: High bargaining power of large service company buyers; moderate threat of new entrants due to high capital requirements and specialized expertise; moderate to high rivalry among existing competitors driving price and technology innovation; moderate threat of substitutes mitigated by the proven scale of hydraulic fracturing.

Segmentation Analysis

The Gas Fracturing Trailer Market is segmented based on several technical and operational criteria, allowing for a precise understanding of industry dynamics and purchasing patterns. Key segmentation criteria include the type of trailer configuration, reflecting the required operational horsepower and mobility; the pressure rating, which dictates suitability for shallow versus ultra-deep resource extraction; the power source, capturing the industry's move toward greener energy solutions; and the specific application, defining the geological target resource. Each segment exhibits unique growth trajectories influenced by regional drilling activity and prevailing environmental standards.

The segmentation by power source, specifically the rise of electric and hybrid fracturing fleets, is fundamentally reshaping the market landscape. Electric fracturing trailers, driven by turbine or grid power, offer significantly reduced emissions, noise levels, and fuel costs compared to traditional diesel fleets. While the initial capital cost is higher, the long-term operational savings and ESG compliance benefits are driving rapid adoption, particularly in environmentally sensitive areas and high-volume, continuous operations. This shift signals a major technological inflection point for OEMs.

Furthermore, the segmentation by pressure rating is crucial. As E&P companies target deeper, tighter rock formations, the demand for ultra-high-pressure trailers (15,000 PSI and above) capable of reliably handling complex fluid dynamics and extreme stress is escalating. This demands specialized material science and robust engineering in pump design and trailer frame construction. Understanding these segment dynamics is vital for manufacturers to tailor their product offerings and strategic investments in R&D.

- By Type: Single Trailer, Multi-Trailer (Dual Pump)

- By Pressure Rating: 10,000 PSI, 15,000 PSI, Above 15,000 PSI

- By Power Source: Diesel Engine, Natural Gas/Dual Fuel, Electric/Hybrid

- By Application: Shale Gas, Tight Oil, Coal Bed Methane (CBM)

Value Chain Analysis For Gas Fracturing Trailer Market

The value chain for the Gas Fracturing Trailer Market begins with the upstream activities involving the sourcing of specialized raw materials, crucial components such as high-strength steel alloys for pump frames, high-pressure fluid ends, and powerful turbine or reciprocating engines. Key suppliers in this phase include specialized component manufacturers for transmissions, fluid control systems, and complex electronics. This upstream segment is characterized by specialized expertise and limited suppliers for critical parts, influencing the final cost and manufacturing lead times of the trailers. Efficient supply chain management and strategic partnerships with component providers are essential to mitigate price volatility and ensure quality control.

The manufacturing and assembly phase constitutes the core middle segment, where OEMs design, fabricate, and integrate the complex mechanical, hydraulic, and electronic systems onto the mobile trailer chassis. This phase is capital and technology intensive, requiring advanced welding, testing, and system integration capabilities. Distribution channels predominantly involve direct sales and long-term service agreements between the OEM and major oilfield service companies (OFS), who act as the primary buyers. Indirect channels, involving third-party distributors or leasing companies, are less common but serve smaller regional operators.

Downstream activities center on the deployment, operation, and maintenance of the fracturing trailers at the well site. This responsibility falls to the OFS companies. The value generated downstream includes operational efficiency, reliability, and the provision of integrated fracturing services to E&P clients. Maintenance and aftermarket services—including the supply of replacement fluid ends, consumables, and periodic overhauls—form a crucial, recurring revenue stream. The ability to provide fast, reliable field service is a major differentiator in securing long-term customer relationships and maximizing the lifetime value of the trailer asset.

Gas Fracturing Trailer Market Potential Customers

The primary consumers and end-users of Gas Fracturing Trailers are major integrated oilfield service (OFS) providers, who own and operate the vast majority of fracturing fleets globally. These companies, such as Schlumberger, Halliburton, and Baker Hughes, purchase highly specialized trailer units directly from OEMs to fulfill complex drilling contracts with major exploration and production (E&P) companies. Their purchasing decisions are driven by fleet capacity needs, technological specifications (e.g., HHP, pressure rating, fuel efficiency), and adherence to global safety and environmental standards, making them high-volume, highly demanding buyers.

Additionally, independent and regional well service companies, particularly those focused on specific unconventional basins (e.g., Permian-focused operators), constitute a significant customer base. While these companies purchase smaller volumes than the global giants, they prioritize specialized units that are optimally configured for local geological conditions and regulatory requirements. Financial institutions and leasing companies specializing in energy equipment also act as indirect customers, acquiring assets for subsequent long-term lease arrangements with operating companies, thereby influencing market demand through financing availability.

Finally, National Oil Companies (NOCs) in regions beginning to exploit unconventional resources, such as in the Middle East, China, and South America, are increasingly becoming direct buyers. These entities often seek turnkey solutions and localized manufacturing partnerships to build domestic service capabilities, representing high-value, government-backed contracts for OEMs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.25 Billion |

| Market Forecast in 2033 | $1.98 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Halliburton, Schlumberger, Baker Hughes, NOV (National Oilwell Varco), Weatherford International, FTS International, Calfrac Well Services, C&J Energy Services, Keane Group, Liberty Oilfield Services, UZTEL S.A., Sichuan Honghua Petroleum Equipment, Saint Gobain, Superior Energy Services, Trican Well Service, ProPetro Holding Corp, Basic Energy Services, DistributionNOW, Pioneer Natural Resources, RPC Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gas Fracturing Trailer Market Key Technology Landscape

The technological landscape of the Gas Fracturing Trailer Market is rapidly evolving, moving away from conventional diesel-only fleets toward highly sophisticated, integrated systems focused on maximizing energy efficiency and minimizing environmental impact. A key technological thrust involves the deployment of turbine-driven and grid-powered electric fracturing (e-frack) fleets. These systems replace traditional high-horsepower diesel engines with electric motors, offering higher torque, better reliability, and the ability to utilize cleaner, cheaper natural gas or direct grid power where available. The integration of advanced power electronics, including variable frequency drives (VFDs), is crucial for managing the immense power output and ensuring precise control over pump rates and pressures, which are vital for complex multi-stage fracturing operations.

Another major technological area is the development of advanced material science for the fluid end components—the section of the pump that handles the high-pressure fluid. Manufacturers are utilizing specialized alloys and surface treatments to withstand extreme abrasive wear from proppant and corrosion from fracturing fluids, extending the service life of these high-cost, frequently replaced parts. Furthermore, automation and digitalization technologies, encompassing IoT sensors, cloud-based telemetry, and integrated control systems (like condition-based monitoring), are becoming standard. These systems provide operators with real-time performance diagnostics, enabling predictive maintenance and optimizing operational parameters remotely, leading to substantial reductions in non-productive time (NPT).

The continuous improvement in pump design, pushing pressures beyond 20,000 PSI in specialized applications, coupled with advancements in blending technology that allow for precise, instantaneous control of proppant loading, defines the current state of the art. Future innovations are expected to focus on fully autonomous trailer operation, reduced footprint designs for constrained well sites, and further integration of digital twins for simulation and training. The ability of OEMs to package high horsepower (typically 5,000 HHP and above per trailer) into road-legal, rapidly deployable units remains a core technological competence and a critical competitive advantage in the dynamic service sector.

Regional Highlights

- North America (United States & Canada): Dominates the global market share due to extensive unconventional reserves (shale gas, tight oil), established infrastructure, and continuous high drilling activity in key basins such as the Permian, Appalachian, and Western Canadian Sedimentary Basin. This region is the early adopter of advanced technologies, including e-frack and dual-fuel fleets, driven by intense competition and rigorous environmental standards. The high density of active fracturing crews necessitates constant fleet modernization.

- Asia Pacific (China & Australia): Represents a rapidly emerging market driven by government initiatives to exploit vast indigenous shale gas resources (especially in China) to meet escalating energy demand and reduce reliance on imported hydrocarbons. While infrastructure development is still maturing, the demand is strong for robust, high-pressure fracturing units capable of handling complex geological settings. Australia's focus on tight gas and CBM also provides niche market opportunities.

- Middle East and Africa (MEA): Shows increasing potential as nations like Saudi Arabia, UAE, and Algeria prioritize developing unconventional reserves to diversify their energy mix and sustain local industrial growth. Demand here is characterized by the need for trailers optimized for high-temperature operations and demanding desert logistics, often sourced through major international OFS companies executing large, multi-year contracts.

- Europe: Characterized by stringent regulatory restrictions and public opposition to hydraulic fracturing, leading to a largely constrained market. Limited activity remains focused on conventional resource maintenance and specific CBM projects, but potential market liberalization in the future, driven by energy security concerns, could provide sporadic demand spikes for specialized, environmentally compliant equipment.

- Latin America (Argentina & Brazil): Driven primarily by the development of the Vaca Muerta shale formation in Argentina, often cited as one of the most significant unconventional plays outside North America. This region demands high-quality, high-capacity fracturing fleets, mirroring the technological specifications seen in the Permian Basin, presenting a strong growth corridor for global OEMs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gas Fracturing Trailer Market.- Halliburton

- Schlumberger

- Baker Hughes

- NOV (National Oilwell Varco)

- Weatherford International

- FTS International

- Calfrac Well Services

- C&J Energy Services

- Keane Group

- Liberty Oilfield Services

- UZTEL S.A.

- Sichuan Honghua Petroleum Equipment

- Saint Gobain

- Superior Energy Services

- Trican Well Service

- ProPetro Holding Corp

- Basic Energy Services

- DistributionNOW

- Pioneer Natural Resources

- RPC Inc.

Frequently Asked Questions

Analyze common user questions about the Gas Fracturing Trailer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for electric (e-frack) gas fracturing trailers?

The primary factor driving demand is the significant reduction in operational expenditure (OPEX) due to lower fuel costs (using natural gas or grid power instead of diesel) combined with substantial environmental benefits, including reduced emissions and noise, aligning with corporate ESG goals and increasing regulatory requirements for cleaner operations.

How do high-pressure rating trailers (15,000 PSI+) differ in application from standard units?

High-pressure trailers are specifically designed for fracturing deeper, tighter, or ultra-hard rock formations that require exceptionally high injection pressures to initiate and propagate fractures effectively. They utilize advanced fluid ends and robust frame structures to handle extreme operational stress, maximizing hydrocarbon recovery in challenging reservoirs like ultra-deep shale gas wells.

Which geographical region dominates the Gas Fracturing Trailer Market, and why?

North America, particularly the United States, dominates the market due to its mature and large-scale unconventional oil and gas industry, centered on prolific basins like the Permian and Marcellus. The sustained high volume of horizontal drilling and multi-stage fracturing operations necessitates continuous high demand for mobile fracturing fleets.

What major technological trends are influencing the manufacturing of new fracturing trailers?

Key technological trends include the integration of AI/IoT for predictive maintenance and real-time operational optimization; the widespread adoption of dual-fuel and electric power systems; and the use of advanced metallurgy in fluid ends to enhance durability and prolong component life under abrasive conditions, improving overall fleet uptime.

What are the main restraints impacting market growth in developed regions like Europe?

Market growth in Europe is severely restrained by stringent environmental regulations, public opposition to hydraulic fracturing, and governmental moratoriums or bans on the technique, limiting exploration and production activities despite the presence of potential shale reserves.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager