Gas Service Carts Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434990 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Gas Service Carts Market Size

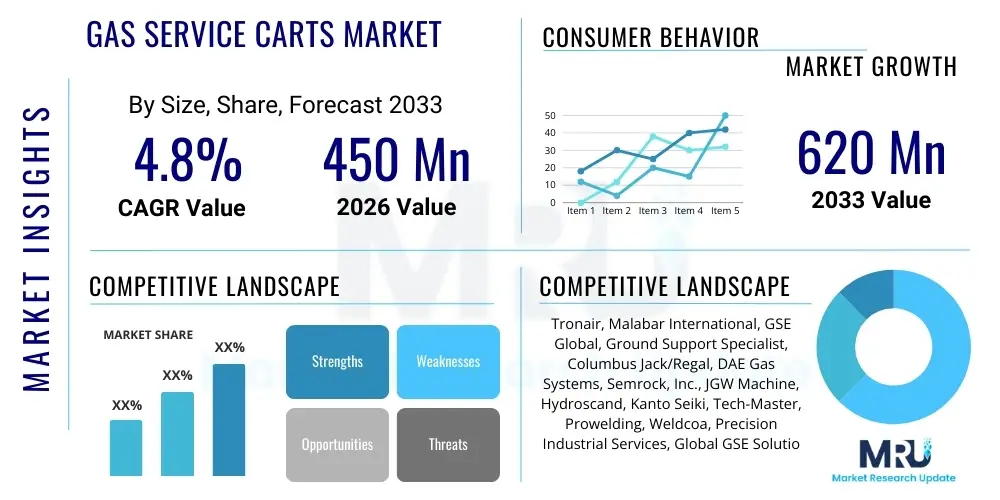

The Gas Service Carts Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 620 Million by the end of the forecast period in 2033.

Gas Service Carts Market introduction

The Gas Service Carts Market encompasses the manufacture and distribution of specialized mobile systems designed for the safe transportation, storage, and controlled delivery of various industrial and specialty gases. These carts are engineered to meet stringent safety standards, often involving high-pressure containment and precise flow control mechanisms. They serve critical roles across diverse sectors, including aviation Maintenance, Repair, and Overhaul (MRO), industrial welding and metal fabrication, pharmaceutical manufacturing requiring inert atmospheres, and large-scale HVAC maintenance. The core utility of these products lies in improving operational efficiency by bringing necessary gas supplies directly to the point of use, thereby minimizing downtime and enhancing worker safety associated with handling heavy, high-pressure gas cylinders.

Gas service carts are differentiated based on their complexity, ranging from simple cylinder transport trolleys to sophisticated units incorporating manifold systems, integrated pressure regulators, flow meters, and digital telemetry for monitoring gas levels and usage. Major applications include filling aircraft struts with nitrogen, purging lines in chemical plants, supplying medical gases in remote field operations, and supporting specialized cutting and welding processes on construction sites. The modular design often allows customization for specific gas types (e.g., oxygen, acetylene, argon, helium) and pressure requirements, making them indispensable assets in environments where fixed piping infrastructure is impractical or insufficient.

The market growth is fundamentally driven by the expansion of global industrial output, particularly in the aerospace and defense sectors where stringent maintenance schedules necessitate reliable gas servicing equipment. Furthermore, enhanced regulatory emphasis on workplace safety, particularly concerning the handling of high-pressure vessels, pushes end-users toward certified, purpose-built carts over makeshift solutions. Key benefits derived from adopting these purpose-built carts include superior mobility, reduced labor costs related to material handling, and significantly improved compliance with safety and environmental regulations. As manufacturing processes become more automated and precise, the demand for highly regulated and efficient gas delivery systems continues to rise.

Gas Service Carts Market Executive Summary

The Gas Service Carts Market is experiencing steady expansion, characterized by a shift towards automation, integrated safety features, and the incorporation of durable, lightweight materials such as specialized alloys and composites. Current business trends indicate a strong focus on custom engineering, particularly to meet the exacting standards of the aerospace MRO segment, which demands highly specialized nitrogen and oxygen service carts. Manufacturers are strategically investing in developing smart carts equipped with IoT sensors for predictive maintenance and inventory management, moving the industry beyond basic transportation equipment toward integrated service solutions. Consolidation activities remain moderate, focused primarily on strengthening distribution networks and acquiring niche technological capabilities in flow control and telemetry systems. The market demonstrates resilience, underpinned by essential maintenance activities across core industrial sectors, insulating it partially from cyclical economic downturns.

Regionally, North America and Europe remain the dominant markets due to the presence of large aerospace and advanced manufacturing bases, alongside rigorous enforcement of occupational safety regulations. Asia Pacific (APAC) is projected to exhibit the highest growth rate, fueled by rapid industrialization, burgeoning automotive and shipbuilding sectors in countries like China and India, and significant investments in aviation infrastructure expansion. Specific regional trends include a heightened demand for explosion-proof and intrinsically safe designs in the Middle East's oil and gas operations, and a preference for highly modular, easily deployable systems in Latin American mining and construction projects. Regulatory divergence across geographies, however, necessitates product adaptation concerning pressure vessel certifications and local transportation laws, influencing market entry strategies.

In terms of segmentation, the manual/mechanically operated carts segment currently holds the largest share but is gradually losing ground to semi-automated and advanced electronic carts that offer precise digital control and logging capabilities. By application, the MRO segment (specifically aviation and heavy equipment repair) is the primary revenue generator, given the high operational standards and necessity of specialized gas delivery for landing gear, tire inflation, and hydraulic accumulator charging. Material segmentation shows a growing adoption of corrosion-resistant stainless steel and engineered plastics, replacing traditional mild steel carts in corrosive or cleanroom environments. The services segment, including calibration, maintenance, and certification of the carts themselves, is emerging as a critical value-added component, generating reliable recurring revenue streams for key market participants.

AI Impact Analysis on Gas Service Carts Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Gas Service Carts market predominantly revolve around three key themes: predictive maintenance integration, optimization of gas inventory and logistics, and enhanced safety monitoring. Users are keenly interested in how AI algorithms can analyze real-time operational data (pressure fluctuations, flow rates, sensor readings) gathered from 'smart' carts to forecast potential equipment failure before it occurs, thereby reducing costly unscheduled downtime, especially in mission-critical applications like aircraft servicing. Furthermore, there is significant interest in using machine learning to optimize the routing and scheduling of carts within large industrial facilities or airport ramps, ensuring the right gas type and quantity are available exactly when needed, minimizing waste and improving technician efficiency. Safety concerns are also prominent, with users seeking AI systems capable of instantly identifying deviations from safe operating parameters, such as abnormal leakage rates or excessive temperatures, triggering immediate autonomous or assisted interventions.

- AI-Powered Predictive Maintenance: Utilizing sensor data from cart components (regulators, valves, gauges) to predict failure points, enabling proactive replacement and maximizing asset uptime.

- Optimized Inventory Management: Machine learning algorithms analyze historical gas usage patterns across different work orders and locations to optimize cylinder replacement schedules and minimize stockouts or overstocking.

- Autonomous Route Planning and Logistics: AI systems calculate the most efficient path for service carts across complex industrial environments, reducing travel time and improving resource allocation for MRO tasks.

- Enhanced Safety Monitoring: Real-time analysis of pressure and flow data to detect micro-leaks or sudden pressure drops, automatically generating alerts and shutdown protocols.

- Digital Documentation and Compliance: AI assists in automatically logging service parameters, ensuring regulatory compliance data is accurately captured and immediately accessible for audits.

DRO & Impact Forces Of Gas Service Carts Market

The Gas Service Carts Market is influenced by a dynamic interplay of factors. Key drivers include the mandatory increase in preventive maintenance activities across critical infrastructure sectors (aerospace, energy) and the global rise in industrial safety standards necessitating certified, mobile gas delivery solutions. However, the market faces restraints such as the significant capital expenditure required for high-pressure certified equipment and the complexities associated with international regulatory compliance regarding pressure vessel transport. Opportunities abound in the burgeoning demand for specialized, ultra-high-purity gas carts required by the semiconductor and advanced materials manufacturing industries. The core impact force driving technological innovation remains safety and efficiency: as labor costs rise and safety penalties become more severe, the incentive to invest in integrated, automated, and digitally monitored carts becomes increasingly compelling.

Segmentation Analysis

The Gas Service Carts Market is segmented across various critical dimensions, allowing manufacturers and service providers to tailor their offerings precisely to specific industry needs and regulatory requirements. Key segmentation includes classifying carts by operational mechanism (Manual, Semi-Automated, Fully Automated), by the type of gas served (Inert Gases, Flammable Gases, Oxidizing Gases, Specialty Mixes), by end-user application (Aerospace MRO, Industrial Manufacturing, Oil & Gas, Healthcare), and by construction material (Stainless Steel, Carbon Steel, Aluminum). This multifaceted approach highlights the diversity within the market, where a specialized aviation nitrogen cart shares few design similarities with a mobile welding cart, yet both fall under the broad category of Gas Service Carts. Understanding these segments is crucial for market entry and strategic investment.

- By Operation Mechanism: Manual/Mechanical, Semi-Automated, Fully Automated/Digital

- By Gas Type: Inert Gases (Nitrogen, Argon), Flammable Gases (Acetylene, Hydrogen), Oxidizing Gases (Oxygen), Specialty and Calibration Gases

- By End-User: Aerospace MRO, Industrial Manufacturing (Welding, Metal Fabrication), Oil & Gas (Purging, Testing), Healthcare/Medical Field Services, Automotive and Transport

- By Material Type: Stainless Steel, Carbon Steel, Aluminum Alloys, Specialized Composites

Value Chain Analysis For Gas Service Carts Market

The value chain for the Gas Service Carts Market begins with the Upstream Analysis, which focuses on the sourcing of critical raw materials and components. This stage involves procuring high-grade metals (stainless steel, specialized alloys) for pressure vessel construction and chassis fabrication, as well as highly specialized components like certified high-pressure regulators, flow meters, manifold systems, and quick-disconnect couplings. Suppliers of certified pressure vessels and sophisticated instrumentation hold significant leverage due to the strict safety and performance specifications required for these components. Quality control and material certification at this stage are paramount, as they directly impact the final product's safety rating and compliance with international standards such as ASME and DOT/ADR.

Moving into the Manufacturing and Assembly phase, core activities include precision welding, system integration, rigorous hydrostatic and pneumatic testing, and regulatory certification (e.g., CE marking or local country approvals). Companies focus on lean manufacturing processes and modular design to allow for product customization and efficient scaling. The design phase often involves close collaboration with end-users, particularly in the aerospace and defense sectors, to ensure the carts meet highly specific operational profiles, often requiring specialized ergonomic and deployment features. Post-production, the Distribution Channel plays a critical role. Due to the high-value and technical nature of the product, distribution is typically handled through specialized industrial equipment distributors (Indirect Channel) who possess the necessary expertise to provide technical support and local servicing, although large multinational corporations often engage in Direct Sales to major MRO centers or government defense agencies.

The Downstream Analysis involves the crucial activities of installation, training, maintenance, and certification services. Given the critical safety nature of high-pressure gas handling, ongoing servicing and re-certification of the carts and their components (especially hoses and pressure relief valves) constitute a vital component of the value chain. This aftermarket service creates enduring revenue streams and strengthens customer loyalty. Direct distribution allows for superior control over the service quality, which is particularly appealing to demanding end-users. Conversely, leveraging local distributors (Indirect Channel) provides broader geographic reach and localized technical responsiveness, which is essential for global industrial markets. The ultimate measure of success in the value chain is the reliable and safe performance of the cart at the end-user site, necessitating robust quality assurance at every transactional touchpoint.

Gas Service Carts Market Potential Customers

Potential customers for Gas Service Carts span a wide array of industrial and technical sectors where controlled, mobile gas supply is non-negotiable for maintenance, fabrication, or operational readiness. The primary segment comprises large Maintenance, Repair, and Overhaul (MRO) facilities, particularly those servicing commercial aviation, military aircraft, and heavy-duty vehicles. These customers require highly reliable carts, often nitrogen and oxygen specific, for critical tasks such as inflating aircraft tires and struts, and testing hydraulic systems. The need for documented compliance and precision flow control drives purchasing decisions in this segment.

A secondary, yet rapidly growing, customer base is found within the Industrial Manufacturing sector, which includes shipbuilding, automotive component manufacturing, large-scale metal fabrication (using argon or acetylene carts), and chemical processing plants (requiring purging gases like nitrogen). These users prioritize durability, ease of maneuverability in congested factory environments, and resistance to harsh operating conditions. Furthermore, utility companies and specialized construction contractors represent important buyers, needing mobile setups for welding pipes, conducting on-site testing, and supplying power generation equipment. The underlying purchasing decision across all these customer groups is centered on safety compliance, reliability, and the resulting enhancement in operational throughput.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 620 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tronair, Malabar International, GSE Global, Ground Support Specialist, Columbus Jack/Regal, DAE Gas Systems, Semrock, Inc., JGW Machine, Hydroscand, Kanto Seiki, Tech-Master, Prowelding, Weldcoa, Precision Industrial Services, Global GSE Solutions, Aviation Ground Support, Air Products and Chemicals, Praxair Technology, Lincoln Electric, ESAB |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gas Service Carts Market Key Technology Landscape

The technology landscape of the Gas Service Carts Market is rapidly evolving from purely mechanical conveyance systems to highly integrated, digitally managed solutions focused on precision and safety. Key technological advancements center around high-pressure fluidics, material science, and embedded electronics. Modern carts increasingly utilize advanced manifold systems that ensure precise pressure reduction and flow control, often incorporating microprocessor-controlled regulators to maintain gas delivery within extremely tight tolerances required for sensitive operations, such as charging aircraft shock struts or supplying gases for ultra-pure welding environments. Material innovations involve the use of specialized, lightweight, and corrosion-resistant alloys (e.g., aerospace-grade aluminum) and high-strength composites for cylinder cradles and chassis, improving mobility while adhering to strict load-bearing safety requirements. These developments are crucial for reducing the physical strain on operators and maximizing the lifespan of the equipment in harsh environments.

The most transformative technology permeating the market is the integration of Internet of Things (IoT) connectivity, transforming traditional carts into 'Smart Carts.' These systems incorporate wireless sensors (Bluetooth or Wi-Fi enabled) that continuously monitor critical parameters such as cylinder pressure, flow rate, ambient temperature, and cart location (via GPS). This data is relayed to centralized maintenance management systems, providing real-time visibility into operational status and gas inventory levels. Furthermore, sophisticated telemetry systems facilitate proactive alerts for system malfunctions or low gas levels, significantly enhancing operational efficiency and reducing the incidence of emergency resupply requirements. This digital overlay also plays a vital role in ensuring compliance, automatically generating usage logs and maintenance histories required by regulatory bodies.

Safety technology also represents a significant area of focus, particularly through the adoption of advanced passive and active safety features. Passive safety includes ergonomic design improvements, such as optimized braking systems, non-marking wheels, and robust anti-tipping mechanisms. Active safety systems encompass features like integrated leak detection sensors calibrated for specific gas types, emergency shut-off valves actuated remotely or automatically upon pressure anomaly detection, and human-machine interface (HMI) displays that provide clear, multilingual operational guidance. The future technological trajectory is moving toward semi-autonomous carts, potentially using guided systems for complex routing within controlled environments, further minimizing human error and maximizing efficiency, thereby justifying the higher investment costs associated with these advanced mobile gas delivery platforms.

Regional Highlights

The regional dynamics of the Gas Service Carts Market are shaped by industrial maturity, regulatory environment, and concentration of high-value maintenance activities.

- North America: Dominates the global market, driven by the massive presence of aerospace and defense MRO operations, particularly in the United States. Stringent safety standards mandated by OSHA and DOT require sophisticated, certified equipment. High adoption of advanced, semi-automated carts and early integration of IoT technology characterize this region.

- Europe: A mature market characterized by robust manufacturing sectors (especially automotive and shipbuilding) and a dense network of certified MRO facilities. Growth is steady, focused on complying with European Pressure Equipment Directive (PED) and utilizing high-quality, durable stainless steel carts for long operational lifecycles. Germany and the UK are key demand centers.

- Asia Pacific (APAC): The fastest-growing region, fueled by unprecedented infrastructure development, expansion of regional aviation fleets, and burgeoning high-tech manufacturing (semiconductors) in countries like China, India, and South Korea. Demand is high for both basic industrial carts and specialized, ultra-high-purity gas delivery systems, necessitating significant regional localization in product offerings.

- Middle East and Africa (MEA): Growth is primarily linked to the expansive oil and gas industry and increasing investment in regional aviation hubs. Demand focuses on explosion-proof certifications and rugged designs capable of enduring extreme temperatures and harsh, corrosive environments, particularly for field testing and purging applications.

- Latin America: Characterized by fragmented demand, with major procurement cycles linked to mining, construction, and localized industrial output. Price sensitivity is higher, often leading to preference for durable, manually operated carts, though Brazil and Mexico show rising demand for specialized MRO equipment due to growing automotive and aviation assembly plants.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gas Service Carts Market.- Tronair

- Malabar International

- GSE Global

- Ground Support Specialist

- Columbus Jack/Regal

- DAE Gas Systems

- Semrock, Inc.

- JGW Machine

- Hydroscand

- Kanto Seiki

- Tech-Master

- Prowelding

- Weldcoa

- Precision Industrial Services

- Global GSE Solutions

- Aviation Ground Support

- Air Products and Chemicals

- Praxair Technology

- Lincoln Electric

- ESAB

Frequently Asked Questions

Analyze common user questions about the Gas Service Carts market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications driving demand for specialized Gas Service Carts?

The primary driver is the Aerospace Maintenance, Repair, and Overhaul (MRO) sector, which requires specialized nitrogen and oxygen carts for servicing aircraft struts, tires, and hydraulic accumulators with high precision and regulatory compliance. Industrial fabrication, specifically large-scale welding, is also a core application.

How is IoT technology transforming the operational efficiency of Gas Service Carts?

IoT integration transforms carts into 'Smart Carts' by enabling real-time monitoring of gas pressure, flow rate, and location via wireless sensors. This data facilitates predictive maintenance, optimizes gas inventory logistics, and ensures immediate compliance logging, significantly reducing downtime and operational costs.

Which regional market is anticipated to show the highest growth rate during the forecast period?

The Asia Pacific (APAC) region is projected to experience the highest growth rate, driven by rapid industrialization, large-scale investment in aviation infrastructure expansion, and burgeoning high-tech manufacturing sectors in China, India, and South Korea, increasing the need for both standard and specialty gas carts.

What are the main regulatory challenges affecting Gas Service Carts manufacturers?

Manufacturers face significant challenges complying with diverse international standards for pressure vessel certification and transportation, such as DOT (US), ADR (Europe), and PED, requiring product customization and rigorous, costly certification processes across different target markets.

What are the key materials used in constructing high-pressure Gas Service Carts?

High-pressure Gas Service Carts primarily utilize specialized corrosion-resistant materials, including high-grade stainless steel and aerospace-grade aluminum alloys. These materials ensure structural integrity, durability, and safety under high operating pressures, particularly in corrosive MRO and industrial environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager