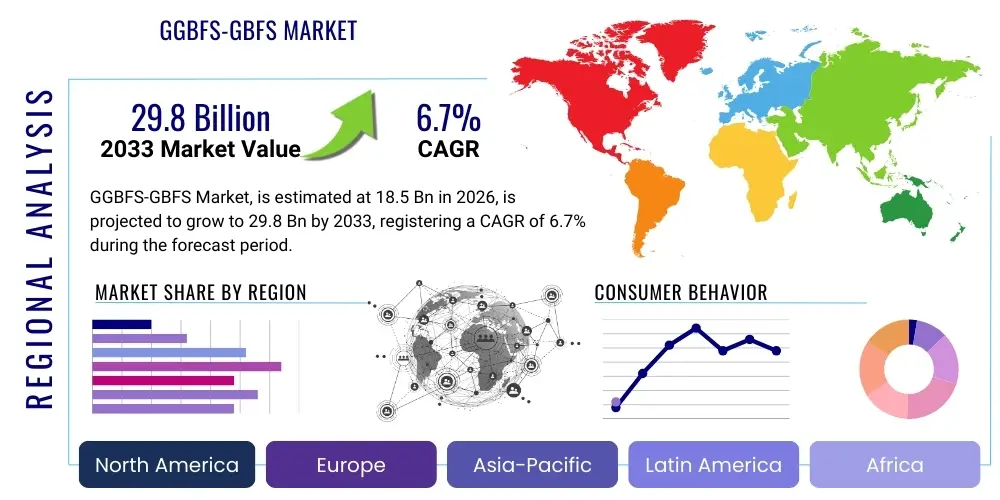

GGBFS-GBFS Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440489 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

GGBFS-GBFS Market Size

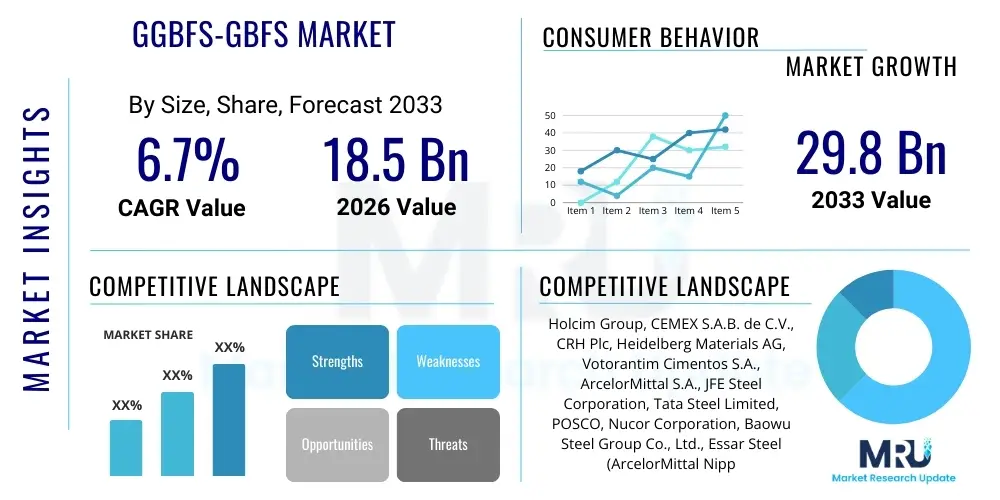

The GGBFS-GBFS Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2026 and 2033. The market is estimated at USD 18.5 Billion in 2026 and is projected to reach USD 29.8 Billion by the end of the forecast period in 2033.

GGBFS-GBFS Market introduction

The GGBFS-GBFS market encompasses a crucial and rapidly evolving segment within the global construction industry, focusing on Ground Granulated Blast-furnace Slag (GGBFS) and its precursor, Granulated Blast-furnace Slag (GBFS). These materials are innovative supplementary cementitious materials (SCMs) derived as valuable by-products from the iron and steel manufacturing process. Specifically, GBFS is formed when molten blast-furnace slag, a non-metallic by-product, is rapidly quenched with water or steam, producing glassy, granular particles with latent hydraulic properties. GGBFS is subsequently created by finely grinding GBFS, a process that significantly increases its surface area and enhances its reactivity, making it a highly effective partial replacement for Ordinary Portland Cement (OPC) in various concrete applications. This transformation of an industrial waste stream into a high-value construction material is central to circular economy principles and sustainable resource management, significantly reducing landfill waste and fostering environmental stewardship within heavy industries.

Major applications of GGBFS-GBFS are extensive and critical for modern infrastructure development, primarily centered around improving the performance and environmental profile of concrete. They are widely utilized in ready-mix concrete production, where their inclusion enhances workability, reduces the heat of hydration, and extends setting times, leading to easier placement and reduced risk of thermal cracking, particularly in mass concrete pours. In the manufacturing of precast concrete elements, GGBFS-GBFS contributes to superior early and long-term strength, improved surface finish, and heightened resistance to aggressive chemical environments, thereby prolonging the service life of pipes, panels, and structural components. Furthermore, GGBFS-GBFS is indispensable in large-scale civil engineering and infrastructure projects, including the construction of bridges, roads, dams, marine structures, and foundations. Its ability to impart exceptional durability, impermeability, and resistance to chloride ingress and sulfate attack makes it an ideal material for structures exposed to harsh or corrosive conditions, ensuring long-term structural integrity and reduced maintenance requirements over their lifecycle.

The market for GGBFS-GBFS is profoundly driven by a confluence of powerful factors, including a global paradigm shift towards sustainable building practices, increasingly stringent environmental regulations, and a heightened focus on reducing the carbon footprint of the construction sector. The inherent technical benefits of GGBFS-GBFS, such as its capacity to develop higher ultimate strength, improve concrete durability against various degradation mechanisms, and enhance workability, provide compelling reasons for its adoption. From an environmental standpoint, substituting OPC with GGBFS-GBFS substantially reduces CO2 emissions, as GGBFS production consumes significantly less energy and generates fewer greenhouse gases compared to clinker manufacturing. Economically, as a reclaimed industrial by-product, GGBFS-GBFS often presents a cost-effective alternative or supplement to conventional cement, offering significant material cost savings for large-scale projects without compromising performance. These combined benefits, coupled with robust global urbanization trends and continuous investments in infrastructure development, are cementing GGBFS-GBFS's position as a vital, growing component of the global construction materials market, ensuring its sustained demand and integration into future building practices worldwide.

GGBFS-GBFS Market Executive Summary

The GGBFS-GBFS market is currently experiencing robust and accelerating growth, fundamentally reshaped by dynamic business trends, distinct regional developments, and expanding application segments. Business trends highlight a pervasive industry-wide commitment to circular economy principles, driving an increasing valorization of industrial by-products like GGBFS-GBFS. This shift transforms what was once considered waste into a valuable resource, reducing environmental impact while simultaneously creating economic opportunities. Cement and concrete manufacturers are strategically integrating GGBFS-GBFS not only to meet stringent green building standards and corporate sustainability objectives but also to enhance product performance through improved durability and strength. A significant trend involves increasing investments in research and development aimed at discovering novel applications, refining material properties, and optimizing production processes, fostering continuous innovation and product diversification across the entire value chain. Furthermore, the market is characterized by a growing number of strategic partnerships and collaborations between major steel producers, who are the primary source of raw slag, and leading construction material suppliers, ensuring a stable and efficient supply chain to meet escalating demand.

From a regional perspective, the Asia Pacific (APAC) region stands out as the predominant force, consistently leading the GGBFS-GBFS market. This dominance is primarily attributed to unprecedented rates of urbanization, colossal government-backed infrastructure development projects (such as China's Belt and Road Initiative and India's ambitious smart cities program), and a booming residential and commercial construction sector across key economies. Europe and North America, while more mature markets, exhibit consistent and healthy growth, underpinned by rigorous environmental policies, well-established green building initiatives, and sustained investments in the maintenance, renovation, and expansion of existing infrastructure. These regions demonstrate a sophisticated understanding and widespread adoption of sustainable construction practices, further solidifying the demand for GGBFS-GBFS. The Middle East and Africa (MEA) and Latin America are also emerging as significant growth hubs, driven by rapidly developing economies, substantial construction booms, and an increasing awareness of sustainable building technologies.

Segment trends within the GGBFS-GBFS market clearly indicate the enduring dominance of its application in general cement and concrete production, which continues to account for the largest share of market consumption. This segment benefits from GGBFS-GBFS's established efficacy in improving concrete performance and environmental credentials. However, the market is also witnessing significant expansion and promising growth trajectories in emerging application areas. These include specialized sectors such as road and pavement construction, where GGBFS-GBFS enhances durability and load-bearing capacity; mine backfilling, for its strength and solidification properties; and the burgeoning field of geopolymer concrete, which offers a completely cement-free, ultra-low carbon alternative using slag. This progressive diversification of applications is a testament to the versatile utility and increasing market acceptance of GGBFS-GBFS, reflecting a robust and resilient market outlook. The cumulative effect of these business, regional, and segmental dynamics paints a picture of a market poised for sustained expansion, integral to the future of sustainable global construction.

AI Impact Analysis on GGBFS-GBFS Market

Stakeholders and end-users within the GGBFS-GBFS market frequently articulate queries and concerns regarding the transformative potential of Artificial Intelligence (AI) in revolutionizing various facets of the industry. Common user questions often revolve around how AI can optimize the complex production processes of GGBFS-GBFS, enhance stringent quality control measures, and streamline intricate supply chain logistics from raw slag sourcing to final product delivery. There is significant interest in AI's capability for predictive analytics regarding material property variations, its potential to foster the development of novel GGBFS-GBFS blends with superior and tailored performance characteristics, and its crucial role in further reducing the overall environmental footprint associated with their production and integration into construction. These inquiries highlight a collective expectation that AI will be a key enabler for greater efficiency, consistency, and sustainability within the sector.

Furthermore, users frequently raise practical considerations and concerns, including the substantial initial investment costs required for implementing sophisticated AI infrastructure and advanced analytical platforms within existing industrial settings. The need for a highly skilled workforce, proficient in data science, machine learning, and process automation, capable of deploying, managing, and interpreting AI-driven solutions, is another recurring theme. Addressing these concerns involves developing clear implementation pathways, demonstrating tangible returns on investment through pilot projects, and investing in workforce training and development programs. Overall, the prevailing sentiment is that while challenges exist, AI is poised to act as a powerful catalyst for innovation, driving GGBFS-GBFS towards even greater levels of operational excellence, product innovation, and environmental responsibility, thereby making these supplementary cementitious materials even more attractive and competitive in the global construction market.

- Enhanced precision and consistency in quality control through AI-driven real-time data analysis and predictive modeling of GGBFS-GBFS chemical and physical properties.

- Optimized grinding and processing operations, where AI algorithms adapt parameters to raw material variability, maximizing energy efficiency and minimizing wear on machinery.

- Advanced supply chain management, utilizing AI for highly accurate demand forecasting, efficient logistics planning, and strategic raw blast-furnace slag procurement, reducing waste and lead times.

- Accelerated development of innovative GGBFS-GBFS formulations and multi-component blends through AI-driven material discovery platforms, tailored for specific performance requirements and niche applications.

- Automated environmental impact assessment, monitoring, and compliance reporting, ensuring adherence to stringent sustainability standards and regulatory mandates with greater accuracy.

- Implementation of predictive maintenance for GGBFS-GBFS processing equipment, minimizing unexpected breakdowns, extending asset lifespan, and improving overall operational uptime.

- Improved resource efficiency by intelligently identifying optimal GGBFS-GBFS replacement ratios in concrete, leading to further reductions in Ordinary Portland Cement usage and associated CO2 emissions.

- Data-driven insights for market analysis, identifying emerging trends, customer preferences, and competitive landscapes to inform strategic business decisions and market positioning.

DRO & Impact Forces Of GGBFS-GBFS Market

The GGBFS-GBFS market is profoundly shaped by a distinct and dynamic interplay of drivers, restraints, opportunities, and pervasive impact forces that collectively dictate its growth trajectory, competitive landscape, and strategic imperatives. A primary and overwhelmingly powerful driver is the escalating global imperative for sustainable construction, fueled by increasing environmental awareness, stringent regulatory frameworks, and ambitious decarbonization targets across industries. Governments and international bodies are actively promoting green building codes and waste valorization initiatives, creating a robust demand for eco-friendly building materials like GGBFS-GBFS. Beyond environmental benefits, the inherent technical advantages of GGBFS-GBFS, such as its ability to significantly enhance concrete strength, durability, resistance to chemical attacks, and reduce heat of hydration, serve as compelling motivations for its widespread adoption. Furthermore, the economic advantage of utilizing an industrial by-product, which often presents a cost-effective alternative or supplement to traditional cement, provides substantial material cost savings for large-scale infrastructure projects where budget efficiencies are critical, thereby amplifying its market appeal.

Despite these robust drivers, the market faces several notable restraints that necessitate strategic mitigation. The fundamental challenge lies in the fluctuating availability of high-quality granulated blast-furnace slag, which is directly dependent on the variable output of the global steel industry, making the supply chain vulnerable to economic cycles and steel production fluctuations. The energy-intensive nature of grinding GBFS into its finer, more reactive GGBFS form, coupled with the significant initial capital investment required for establishing or upgrading processing facilities, can pose considerable financial and operational barriers for new entrants or expanding players. Additionally, a persistent lack of widespread awareness, standardized specifications, or established regulatory support for GGBFS-GBFS in certain developing regions can hinder its broader market penetration and acceptance, requiring dedicated educational and promotional efforts. These constraints underscore the need for resilient supply chain management, technological innovation to improve processing efficiency, and targeted market development strategies.

However, these challenges are effectively counterbalanced by significant opportunities that promise substantial market expansion. Emerging economies, particularly in Asia Pacific, Latin America, and the Middle East & Africa, present immense growth potential due to their rapidly expanding populations, extensive infrastructure development plans, and nascent but growing focus on sustainable building practices. Innovation in material science and processing technologies, such as advancements in grinding efficiency, quality control, and the development of new activation techniques, can further improve GGBFS-GBFS performance and broaden its application spectrum. Opportunities also lie in diversifying its use beyond traditional concrete, exploring new applications in geopolymer concrete, specialized mortars, mine backfill, and waste stabilization. Pervasive impact forces, including evolving environmental legislation (ee.g., carbon pricing mechanisms), global economic conditions influencing construction spending, and the dynamic competitive landscape with other supplementary cementitious materials (like fly ash, silica fume), continually exert influence on market behavior. Successfully navigating these forces requires continuous adaptation, strategic partnerships, and a deep understanding of market dynamics to maintain growth and competitive advantage in this evolving sector.

Segmentation Analysis

The GGBFS-GBFS market is meticulously segmented across various parameters to provide a granular and comprehensive understanding of its diverse applications, distinct material types, and influential end-use industries. This detailed segmentation is crucial for market participants to identify specific niches, assess varying adoption rates, and formulate tailored strategies that effectively address the unique demands and preferences across different geographical regions and industrial contexts. Such an in-depth analysis allows for a precise understanding of the intricate market dynamics, including key growth drivers, emerging trends, and potential challenges specific to each segment, thereby facilitating more accurate forecasting and strategic planning. By dissecting the market into these specialized categories, stakeholders gain invaluable insights into how various factors, ranging from project scale and environmental mandates to technological advancements and economic indicators, influence the consumption patterns and overall market trajectory of GGBFS-GBFS, highlighting its versatile utility and expanding integration within the global construction sector.

- By Type:

- Ground Granulated Blast-furnace Slag (GGBFS): This segment constitutes the finely ground, activated form of GBFS, possessing potent pozzolanic and latent hydraulic properties. It is the most commonly used form as a direct partial replacement for Ordinary Portland Cement in concrete due to its enhanced reactivity and ability to significantly improve concrete durability and strength.

- Granulated Blast-furnace Slag (GBFS): This refers to the coarse, glassy, granular material formed directly from the quenching of molten blast-furnace slag. While it has latent hydraulic properties, it is less reactive than GGBFS and often used as a raw material for GGBFS production, or in bulk applications where fineness is not critical, such as aggregates or for mine backfilling.

- By Application:

- Cement & Concrete Production: The largest application, where GGBFS is blended with OPC to produce sustainable, high-performance concrete, reducing CO2 emissions and improving properties.

- Road & Pavement Construction: Utilized in sub-base layers, asphalt mixes, and concrete pavements to enhance durability, strength, and resistance to freeze-thaw cycles and chemical attack.

- Mine Backfilling: Employed to stabilize excavated mine voids, reducing surface subsidence and improving safety, benefiting from its strength development and cost-effectiveness.

- Waste Stabilization & Solidification: Used to encapsulate hazardous waste, reducing leachate potential and improving environmental safety by forming a stable, solid matrix.

- Water & Wastewater Treatment: Applied in processes requiring pH adjustment, heavy metal removal, or as a filter media, owing to its chemical properties and adsorption capabilities.

- Geopolymer Concrete: A rapidly emerging application where GGBFS is a primary binder, often mixed with fly ash, to create cement-free concrete with superior properties and ultra-low carbon footprint.

- Others (e.g., soil stabilization, abrasive blasting, manufacturing of bricks/blocks): Diverse applications including improving soil bearing capacity, as an abrasive material, or as a raw material for various construction products.

- By End-Use Industry:

- Residential Construction: Used in foundations, structural elements, and precast components for homes and apartment buildings, prioritizing cost-effectiveness and durability.

- Commercial Construction: Applied in high-rise buildings, shopping centers, and office complexes, where high-performance concrete with extended service life is required.

- Industrial Construction: Employed in factories, warehouses, and chemical plants, demanding concrete with enhanced resistance to chemical attack and heavy loads.

- Infrastructure (Bridges, Roads, Dams, Ports, Railways): Critical for large-scale public works projects, where long-term durability, reduced maintenance, and environmental performance are paramount.

- Marine & Coastal Structures: Utilized in piers, jetties, and seawalls due to its exceptional resistance to chloride ingress and sulfate attack in saline environments.

- Agriculture (as a soil conditioner): Increasingly explored for its potential to improve soil pH, nutrient availability, and overall soil health in certain agricultural applications.

Value Chain Analysis For GGBFS-GBFS Market

The value chain for the GGBFS-GBFS market is a complex, multi-stage process that initiates with the upstream segment, fundamentally linked to the global steel manufacturing industry. This initial stage involves the production of molten iron slag as a critical by-product in blast furnaces during iron-making. To generate Granulated Blast-furnace Slag (GBFS), this molten slag is then subjected to rapid quenching with water or steam, which solidifies it into a glassy, granular material. Key upstream players are predominantly major integrated steel producers who manage the entire process from iron ore smelting to the initial transformation of slag into GBFS. Their operational efficiency, production volumes, and commitment to quality control are paramount, as the consistent availability and chemical composition of this raw GBFS directly impact the subsequent stages of the value chain, underscoring the necessity of robust and collaborative relationships between steel manufacturers and GGBFS-GBFS processors to ensure a reliable raw material supply.

Moving downstream, the midstream segment of the value chain focuses on the crucial transformation of raw GBFS into its more reactive and commercially valuable form, Ground Granulated Blast-furnace Slag (GGBFS). This involves sophisticated processing technologies, primarily utilizing high-efficiency grinding systems such as vertical roller mills (VRMs) or advanced ball mills, to achieve the ultra-fine particle size and high specific surface area required for GGBFS to exhibit its optimal pozzolanic and latent hydraulic properties. Companies operating in this segment include specialized GGBFS producers, integrated cement manufacturers who incorporate GBFS grinding capabilities into their plants, and independent processors focused solely on slag beneficiation. This stage is also characterized by rigorous quality control measures, including particle size analysis, chemical composition testing, and reactivity assessments, to ensure the finished GGBFS product consistently meets stringent industry standards and client specifications for performance and environmental compliance, thereby adding significant value to the base material.

The downstream activities encompass the comprehensive distribution and ultimate utilization of the finished GGBFS-GBFS products by various end-users. The primary consumers are cement and concrete manufacturers, ready-mix concrete plants, precast concrete producers, and large-scale civil engineering and construction contractors who strategically incorporate GGBFS into their concrete mixes to achieve enhanced performance characteristics, superior durability, and significant sustainability benefits. Distribution channels for GGBFS-GBFS are multifaceted and strategically designed to ensure widespread market reach and accessibility. Direct sales frequently occur between large GGBFS producers or integrated cement companies and major industrial clients or significant infrastructure projects, facilitating bulk deliveries and customized technical support. Concurrently, indirect channels involve an extensive network of distributors, traders, and regional dealers who play a vital role in supplying GGBFS-GBFS to smaller construction firms, specialized contractors, and diverse geographical markets. This multi-channel approach is essential for addressing the varying logistical, quantity, and technical support requirements of a broad customer base, ensuring efficient market penetration and responsiveness to fluctuating demand across the global construction landscape.

GGBFS-GBFS Market Potential Customers

The GGBFS-GBFS market serves an expansive and increasingly diversified array of potential customers, predominantly situated within the global construction, building materials, and waste management industries. These end-users are collectively driven by a compelling combination of factors, including escalating global mandates for sustainable practices, the widespread adoption of stringent green building certifications, and an overarching imperative to construct resilient, high-performance infrastructure with a significantly reduced environmental footprint. The intrinsic properties of GGBFS-GBFS, such as its proven ability to enhance concrete durability, improve workability and finishability, mitigate alkali-silica reaction (ASR), and reduce thermal cracking in mass concrete pours, render it an exceptionally attractive and versatile additive across numerous applications, thereby substantially broadening its appeal and expanding its customer base within the construction ecosystem.

Key categories of potential customers include: Cement Manufacturers, who are a cornerstone of the GGBFS-GBFS market, utilizing it extensively as a partial replacement for clinker in Portland cement blends. This strategic substitution allows them to dramatically reduce their carbon emissions, lower energy consumption, and optimize production costs, aligning with both environmental regulations and economic objectives. Ready-Mix Concrete Producers form another critical customer segment, leveraging GGBFS-GBFS to produce high-quality, sustainable concrete mixes for a vast spectrum of residential, commercial, and industrial projects, meeting diverse client specifications for performance and eco-friendliness. Precast Concrete Manufacturers benefit from GGBFS-GBFS's contributions to enhanced early and long-term strength, superior surface finishes, and improved resistance to aggressive chemical environments, enabling the production of durable and aesthetically pleasing prefabricated elements.

Furthermore, Civil Engineering Contractors and Infrastructure Developers represent a substantial and growing customer base, as they are involved in executing large-scale public works projects such as bridges, highways, dams, ports, and high-speed rail lines, where long-term durability, minimal maintenance, and stringent environmental compliance are absolutely paramount. Road Construction Companies increasingly incorporate GGBFS-GBFS into pavement materials, enhancing their performance, longevity, and resistance to environmental stresses. Mining Companies are adopting GGBFS-GBFS for mine backfilling applications, benefiting from its strength development and solidification properties, which help stabilize excavated voids and improve operational safety. Finally, Waste Management and Remediation Firms constitute a specialized but growing customer segment, utilizing GGBFS for the solidification and stabilization of various hazardous and non-hazardous wastes, effectively reducing leachate potential and improving overall environmental safety, thereby showcasing the material's remarkable versatility and critical utility beyond traditional structural construction applications, contributing significantly to a cleaner and more sustainable environment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 18.5 Billion |

| Market Forecast in 2033 | USD 29.8 Billion |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Holcim Group, CEMEX S.A.B. de C.V., CRH Plc, Heidelberg Materials AG, Votorantim Cimentos S.A., ArcelorMittal S.A., JFE Steel Corporation, Tata Steel Limited, POSCO, Nucor Corporation, Baowu Steel Group Co., Ltd., Essar Steel (ArcelorMittal Nippon Steel India), Buzzi Unicem S.p.A., UltraTech Cement Ltd., Çimsa Çimento Sanayi ve Ticaret A.Ş., Nippon Steel Corporation, SCG Cement-Building Materials Co., Ltd., Semen Indonesia (Persero) Tbk, China National Building Material Group (CNBM), Steel Authority of India Ltd (SAIL) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

GGBFS-GBFS Market Key Technology Landscape

The GGBFS-GBFS market’s technological landscape is characterized by continuous innovation and advancements primarily focused on optimizing the production efficiency, enhancing the inherent quality, and expanding the application versatility of these critical sustainable materials. A foundational element of this landscape involves sophisticated grinding technologies, which are paramount for transforming raw Granulated Blast-furnace Slag (GBFS) into the highly reactive Ground Granulated Blast-furnace Slag (GGBFS). This primarily features high-efficiency vertical roller mills (VRMs) and advanced ball mills, both designed to achieve the ultra-fine particle size and high specific surface area that are indispensable for GGBFS to exhibit its superior pozzolanic and latent hydraulic properties. Modern grinding systems are often integrated with advanced classification technologies, such as dynamic air separators, to ensure a uniform particle size distribution, which is vital for achieving consistent concrete performance and optimal reactivity while simultaneously reducing overall energy consumption in the grinding process, a key operational challenge.

Beyond the core grinding technologies, the market extensively leverages advanced sensor-based quality control systems that employ real-time analytics and predictive modeling. These systems are crucial for continuously monitoring the chemical composition, fineness, reactivity index, and other critical physical properties of both raw GBFS and finished GGBFS. This meticulous monitoring ensures stringent adherence to international industry standards and specific client specifications, effectively minimizing product variations, enhancing overall reliability, and optimizing resource utilization. Automation and robotics are increasingly being deployed in material handling, precise blending, and efficient packaging operations, leading to significant improvements in operational efficiency, reductions in labor costs, and enhanced safety within GGBFS-GBFS production facilities. Furthermore, the development of sophisticated drying technologies for GBFS before grinding is crucial, as moisture content can significantly impact grinding efficiency and energy consumption, leading to innovations in rotary dryers and flash dryers.

Moreover, ongoing research and development efforts are dedicated to exploring novel activation techniques designed to further enhance the reactivity and performance of GGBFS-GBFS, thereby allowing for higher replacement levels of Ordinary Portland Cement or enabling its successful utilization in new, high-performance applications. These techniques include mechanical activation, which further refines particle size; chemical activation, employing alkaline activators; and thermal treatments that alter slag microstructure. Breakthroughs in blending technologies are also enabling the creation of multi-component cementitious systems that combine GGBFS with other supplementary cementitious materials like fly ash or silica fume to achieve tailored performance characteristics for highly specialized construction needs. The increasing integration of digital technologies, encompassing Artificial Intelligence (AI) and Machine Learning (ML) algorithms, is becoming central to predicting material properties based on raw material inputs, optimizing complex production parameters, and streamlining entire supply chain logistics, marking a significant and ongoing shift towards smart manufacturing and Industry 4.0 paradigms within the GGBFS-GBFS sector, promising further efficiencies and innovations in the coming years.

Regional Highlights

- Asia Pacific (APAC): Dominates the GGBFS-GBFS market due to unparalleled rates of urbanization, colossal government-backed infrastructure development initiatives (e.g., China's Belt and Road Initiative, India's Sagarmala Project), and extensive residential and commercial construction booms. Countries like China, India, Japan, and South Korea are major consumers, spurred by both robust demand and significant domestic steel production, making the region a powerhouse for GGBFS-GBFS adoption and manufacturing.

- Europe: A highly mature market characterized by stringent environmental regulations, advanced circular economy frameworks, and a strong, ingrained emphasis on green building and sustainable construction practices. Germany, France, the UK, and Italy are key contributors, demonstrating high adoption rates driven by supportive policy environments, a focus on CO2 reduction, and sophisticated construction technologies that value high-performance, durable materials.

- North America: Exhibits steady and consistent growth, propelled by increasing awareness and acceptance of the environmental benefits of GGBFS-GBFS, substantial government investments in upgrading aging infrastructure, and a growing trend towards LEED-certified and green building projects. The United States and Canada are leading the adoption, focusing on enhancing concrete durability, reducing life-cycle costs, and mitigating the carbon footprint of construction projects.

- Latin America: An emerging market with considerable untapped potential and significant growth trajectories, fueled by increasing government and private sector investments in infrastructure development, burgeoning housing projects, and industrial expansion. Brazil and Mexico are at the forefront of this regional growth, driven by rapid urbanization and the pressing need for cost-effective, durable, and sustainable construction solutions to support their expanding economies and populations.

- Middle East & Africa (MEA): Witnessing substantial market growth attributed to ambitious mega-projects (e.g., Neom in Saudi Arabia, extensive developments in UAE), rapid urban development, and economic diversification efforts aimed at reducing reliance on oil. Countries in the GCC region, alongside South Africa, are significant markets, actively seeking innovative and sustainable building materials for their large-scale construction ventures, which demand high performance and environmental compliance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the GGBFS-GBFS Market.- Holcim Group

- CEMEX S.A.B. de C.V.

- CRH Plc

- Heidelberg Materials AG

- Votorantim Cimentos S.A.

- ArcelorMittal S.A.

- JFE Steel Corporation

- Tata Steel Limited

- POSCO

- Nucor Corporation

- Baowu Steel Group Co., Ltd.

- Essar Steel (now ArcelorMittal Nippon Steel India)

- Buzzi Unicem S.p.A.

- UltraTech Cement Ltd.

- Çimsa Çimento Sanayi ve Ticaret A.Ş.

- Nippon Steel Corporation

- SCG Cement-Building Materials Co., Ltd.

- Semen Indonesia (Persero) Tbk

- China National Building Material Group (CNBM)

- Steel Authority of India Ltd (SAIL)

Frequently Asked Questions

Analyze common user questions about the GGBFS-GBFS market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is GGBFS and how is it fundamentally different from GBFS?

GGBFS (Ground Granulated Blast-furnace Slag) is the finely pulverized and activated form of GBFS (Granulated Blast-furnace Slag). GBFS itself is the glassy, granular material produced by rapidly quenching molten blast-furnace slag. The key difference lies in GGBFS's superior fineness and increased surface area, which enhances its pozzolanic and latent hydraulic reactivity, making it a highly effective supplementary cementitious material for direct use in concrete as a partial cement replacement.

What are the primary performance and sustainability benefits of incorporating GGBFS-GBFS into concrete mixtures?

Incorporating GGBFS-GBFS significantly enhances concrete performance by increasing long-term strength, improving durability, reducing permeability, and boosting resistance to aggressive chemical attacks (like sulfates and chlorides) and alkali-silica reaction. Environmentally, it contributes substantially to sustainability by repurposing an industrial by-product and drastically lowering the concrete's carbon footprint through reduced reliance on CO2-intensive Ordinary Portland Cement (OPC) production.

How does the use of GGBFS-GBFS directly contribute to global sustainable construction and circular economy principles?

The use of GGBFS-GBFS is a cornerstone of sustainable construction as it valorizes an industrial waste product (steel slag), diverting massive quantities from landfills. This directly supports circular economy principles by promoting resource efficiency. Furthermore, its substitution for traditional cement significantly reduces the embodied carbon of concrete, directly lowering greenhouse gas emissions and conserving natural resources, aligning with global climate action goals.

What are the main and emerging applications of GGBFS-GBFS across various segments of the construction industry?

The main applications include ready-mix concrete, precast concrete products, road and pavement construction, and large-scale infrastructure projects (bridges, dams, marine structures) due to enhanced durability. Emerging applications are in mine backfilling for stabilization, waste stabilization and solidification for environmental remediation, and as a key component in the production of geopolymer concrete, offering ultra-low carbon alternatives to traditional cement.

What is the future outlook for the GGBFS-GBFS market, considering current global trends?

The future outlook for the GGBFS-GBFS market is exceptionally positive. It is poised for sustained robust growth, driven by escalating global demand for high-performance, sustainable building materials, increasingly stringent environmental regulations promoting decarbonization and waste utilization, continuous large-scale infrastructure development across emerging economies, and ongoing technological advancements that further enhance its properties and expand its diverse range of applications worldwide.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager