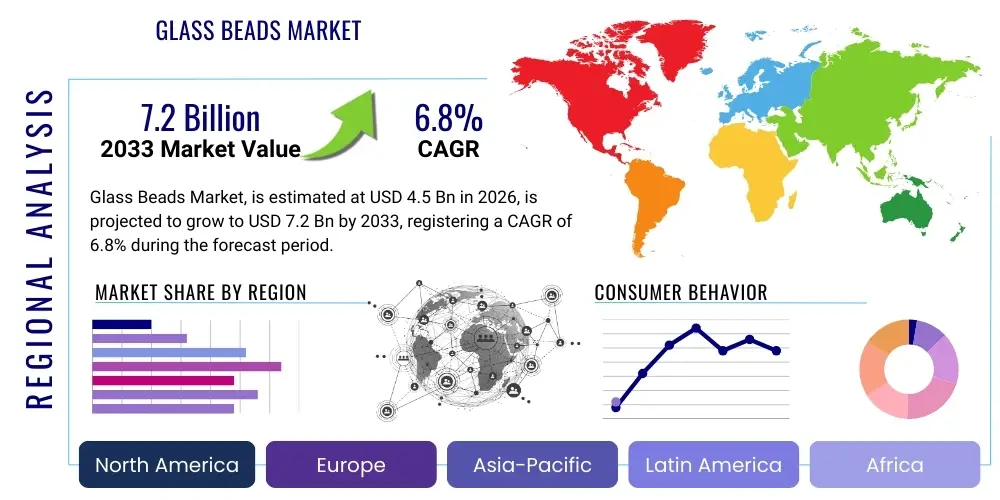

Glass Beads Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436882 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Glass Beads Market Size

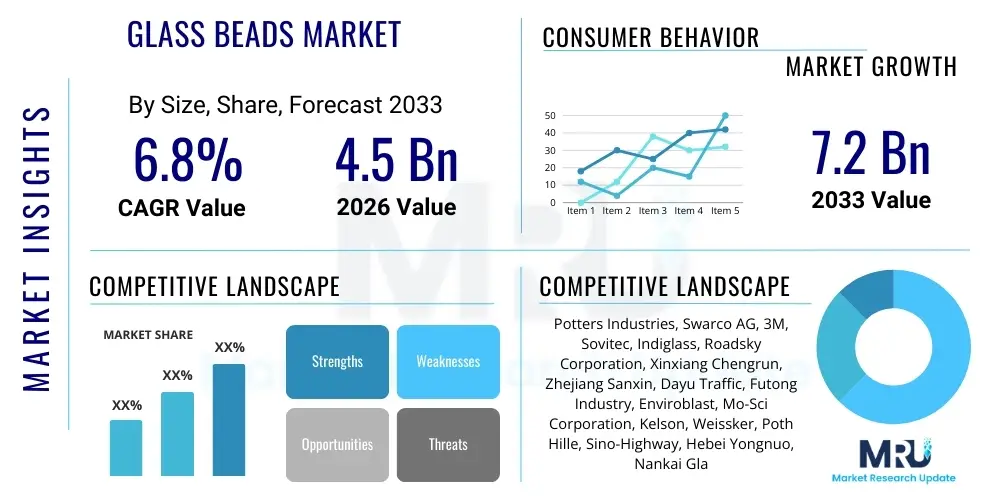

The Glass Beads Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.2 Billion by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by escalating global infrastructure development, particularly the rigorous implementation of road safety standards across emerging economies. Governments worldwide are prioritizing reflective road marking systems, which are the largest application segment for glass beads, ensuring visibility and reducing nighttime accidents. The consistent demand from the automotive sector for lightweight filler materials, alongside specialized applications in medical and aerospace fields, further solidifies this growth trajectory.

Glass Beads Market introduction

Glass beads, typically manufactured from soda-lime glass, borosilicate glass, or other specialized silicate compositions, are small, spherical particles renowned for their high durability, chemical inertness, and exceptional reflective properties. These characteristics position them as indispensable materials across a multitude of industrial applications, primarily categorized into solid beads used for blasting, fillers, and road marking, and hollow glass microspheres employed as lightweight additives in composites and plastics. The manufacturing process often involves melting high-quality glass cullet and forming the spherical structure through specialized spraying or high-temperature flame processing, ensuring precise size distribution and optimal sphericity for high-performance end-use requirements.

The major applications of glass beads are broadly distributed across public infrastructure and industrial manufacturing. In infrastructure, their primary role is in road marking paint and thermoplastic compounds, where they provide retro-reflectivity, significantly enhancing visibility for drivers during low-light conditions. Industrially, they are used extensively in abrasive blasting to clean and prepare surfaces without causing damage, a process known as peening. Furthermore, hollow glass beads serve as high-strength, low-density fillers and extenders in resins, coatings, and structural foam, offering weight reduction and improved material handling characteristics in sectors such as automotive and aerospace, where fuel efficiency and performance optimization are critical goals.

The fundamental benefits driving the adoption of glass beads include their superior chemical resistance, thermal stability, and low-cost profile compared to many synthetic alternatives. Their perfect spherical shape minimizes wear on application equipment and ensures uniform dispersion in mixtures. Key driving factors underpinning the market expansion include burgeoning global population growth necessitating increased investment in transportation networks, stringent governmental mandates concerning road safety protocols (especially in Asia Pacific and Latin America), and the increasing adoption of lightweight composite materials in advanced manufacturing sectors. The development of specialized coated beads, which offer better adhesion and durability in moist conditions, represents a critical technological advancement supporting long-term market growth.

Glass Beads Market Executive Summary

The global Glass Beads Market is experiencing robust expansion, fundamentally propelled by aggressive infrastructure spending and the modernization of transportation safety standards across emerging economies. Business trends indicate a shift towards higher-specification, functional beads, including those treated with specialized coatings like silane to enhance performance in demanding environments, resulting in premium pricing for specialized product categories. Manufacturers are focusing heavily on operational efficiency and sustainable sourcing, particularly utilizing recycled glass cullet, to mitigate raw material cost volatility and meet rising consumer and regulatory demands for environmentally responsible production processes. Strategic mergers and acquisitions among established players are common, aimed at consolidating production capabilities and expanding geographical reach into high-growth markets like India and Southeast Asia, where road development is accelerating rapidly.

Regional trends highlight the Asia Pacific (APAC) region as the dominant market, characterized by rapid urbanization, extensive highway construction projects, and substantial public sector investment in maintaining large road networks. North America and Europe, while mature, demonstrate stable demand driven primarily by maintenance, repair, and sophisticated industrial applications such as specialized filtration and aerospace components, rather than new infrastructure growth. The Middle East and Africa (MEA) are emerging as high-potential regions, fueled by large-scale oil and gas sector investments requiring specialized abrasive beads and ongoing smart city initiatives demanding high-performance road safety materials. These regional dynamics necessitate tailored market strategies focused either on volume and cost leadership in APAC or product innovation and high-specification supply in Western markets.

Segment trends reveal that the Road Marking application segment maintains the largest market share due to its direct link to government spending on transport infrastructure. However, the fastest-growing segment is anticipated to be Hollow Glass Microspheres, driven by their increasing integration into high-performance coatings, lightweight plastic compounds, and specialized cementitious materials, particularly in the automotive and construction sectors seeking energy efficiency and reduced weight. The Type segmentation shows a strong preference for standard Soda-Lime Glass Beads due to their cost-effectiveness and suitability for road applications, yet Borosilicate Glass Beads are gaining traction in niche, high-value applications requiring superior thermal and chemical resistance, such as medical diagnostics and chemical processing equipment, signaling a shift toward product diversification and performance optimization across the market landscape.

AI Impact Analysis on Glass Beads Market

The integration of Artificial Intelligence (AI) and Machine Learning (ML) within the Glass Beads market primarily addresses critical operational challenges such as manufacturing quality control, supply chain optimization, and predictive maintenance. Common user inquiries often revolve around how AI can minimize production defects related to sphericity and particle size distribution, which are paramount for performance in applications like retro-reflectivity and abrasive blasting. Users are particularly interested in AI's role in correlating raw material composition variability (e.g., glass cullet quality) with the final bead performance metrics, aiming to achieve 'first-pass yield' improvements and reduce waste. Furthermore, significant concerns exist regarding the implementation cost and the required technical skill uplift for adopting complex ML algorithms to manage high-speed, continuous-flow manufacturing processes typical in glass bead production.

AI's most profound influence is anticipated in enhancing production consistency and efficiency. By deploying computer vision systems integrated with ML algorithms, manufacturers can achieve real-time, high-precision inspection of glass bead output, instantaneously identifying and rejecting non-spherical or incorrectly sized particles before they proceed to packaging. This level of granular quality control far exceeds manual or traditional automated inspection methods. In the supply chain, AI-driven predictive analytics help forecast demand volatility from large government contracts and infrastructure projects, allowing manufacturers to optimize inventory levels of raw materials and finished products, thereby minimizing warehousing costs and mitigating risks associated with global logistics disruptions, ultimately leading to more stable pricing and delivery schedules for end-users like road marking contractors.

- AI-enhanced Quality Control: Utilizes machine vision and ML models for real-time inspection of bead sphericity, size, and coating integrity, significantly reducing defect rates in high-volume production.

- Predictive Maintenance: Implements AI algorithms to monitor furnace health, burner efficiency, and material handling systems, forecasting equipment failures and minimizing unplanned downtime in continuous manufacturing operations.

- Supply Chain Optimization: ML models predict fluctuating demand from public works sectors, optimizing raw material procurement (glass cullet) and finished goods inventory management for cost efficiency.

- Raw Material Composition Analysis: AI correlates subtle variations in raw glass composition with final product performance metrics (e.g., retro-reflectivity index), enabling dynamic adjustments to the melt process.

- Process Parameter Optimization: Machine learning identifies optimal temperature profiles and flow rates within the atomization or flame spheroidization process, maximizing yield and energy efficiency.

- Application Performance Modeling: AI simulations help predict the longevity and performance of different bead types (e.g., moisture-resistant coated beads) in specific geographical climates or traffic conditions, aiding targeted product development.

DRO & Impact Forces Of Glass Beads Market

The dynamics of the Glass Beads Market are governed by a complex interplay of positive and negative forces. The primary drivers include massive investments in global road infrastructure and the mandatory adoption of highly reflective road marking systems, especially across Asia and Africa, directly correlating market growth with government capital expenditure on transportation networks. However, the market faces significant restraints, chiefly the volatile cost and secure sourcing of raw materials, predominantly recycled glass cullet, which is susceptible to local collection efficiencies and global commodity price fluctuations. Furthermore, the specialized manufacturing equipment required for producing high-quality, uniform beads necessitates substantial capital investment, acting as a barrier to entry for new competitors. Opportunities are emerging through the development of specialized, high-performance product lines, such as anti-skid glass beads, lightweight hollow microspheres for advanced composites, and environmentally friendly, heavy metal-free alternatives, offering avenues for premium market penetration and technological differentiation.

Impact forces currently shaping the market trajectory include regulatory standards and technological substitution threats. Stringent government regulations, particularly concerning lead and heavy metal content in glass beads used for road marking and blasting, necessitate costly compliance measures but also elevate the quality bar, favoring established manufacturers with advanced production capabilities. Conversely, the potential rise of alternative retro-reflective materials or advanced LED-based lighting systems for road signage and vehicle guidance poses a long-term substitution threat, though glass beads currently maintain a dominant cost-to-performance ratio. Furthermore, the cyclical nature of infrastructure spending, often tied to political cycles and economic conditions, introduces inherent volatility in large-volume contracts, which necessitates sophisticated risk management strategies for market participants dependent on public sector procurement.

The confluence of these factors suggests a market that, while fundamentally robust due to essential infrastructure needs, requires constant innovation to manage cost pressures and regulatory shifts. Successful market players are those that diversify their product portfolios beyond standard road marking beads into industrial applications (blasting, filtration, fillers) and invest in advanced coating technologies to enhance product longevity and performance characteristics. The increasing focus on sustainability, specifically utilizing higher proportions of post-consumer recycled glass without compromising purity or sphericity, is transforming from a mere opportunity into a critical competitive requirement, influencing procurement decisions from governmental and corporate buyers committed to circular economy principles.

Segmentation Analysis

The Glass Beads Market is meticulously segmented based on Type, Application, and End-User, reflecting the diverse industrial needs served by these versatile materials. Segmentation by Type primarily distinguishes between Solid Glass Beads and Hollow Glass Microspheres, each possessing distinct density and mechanical properties suited for different applications, with solid beads dominating volume due to road safety applications. Segmentation by Application reveals Road Marking as the largest segment, followed by Abrasive Blasting (used for surface preparation and metal finishing), and specialized uses in Fillers & Additives for composite materials. This segmentation highlights the market's duality, catering to high-volume, low-margin infrastructure projects alongside high-value, performance-critical industrial manufacturing.

Analyzing the segmentation reveals key growth pockets. While road marking remains the backbone of the market, the fastest expansion is observed within the Fillers & Additives segment, particularly driven by the demand for lightweighting solutions in electric vehicles (EVs) and aerospace components, where hollow glass microspheres reduce density while maintaining structural integrity. Geographically, segmentation underscores the infrastructural disparities globally, with highly specified, premium-coated beads prevailing in regulated Western markets, whereas standard soda-lime beads prioritize cost efficiency and high volume in Asian emerging markets, necessitating segmented product offerings and pricing strategies based on regional performance expectations and procurement budgets.

- By Type:

- Solid Glass Beads (Standard, High-Refractive Index, Specialized Coated)

- Hollow Glass Microspheres (Low-Density Fillers, Buoyancy Applications)

- By Application:

- Road Marking and Traffic Safety (Paints, Thermoplastics, Tapes)

- Abrasive Blasting and Peening (Surface preparation, Cleaning, Stress Reduction)

- Fillers and Additives (Composites, Coatings, Plastics, Resins)

- Filtration and Chemical Processing (Media, Chromatographic separation)

- Others (Medical devices, Laboratory use, Retro-reflective signage)

- By Material:

- Soda-Lime Glass

- Borosilicate Glass

- Other Silicates (e.g., Lead-free glass)

- By End-User Industry:

- Construction and Infrastructure (Roads, Bridges, Tunnels)

- Automotive and Transportation (Lightweight components, Safety features)

- Aerospace and Defense (Specialized coatings, Composite parts)

- Marine (Buoyancy materials, Structural composites)

- General Industry (Paints & Coatings, Plastics manufacturing)

Value Chain Analysis For Glass Beads Market

The Glass Beads value chain commences with the upstream activities centered on raw material sourcing, primarily utilizing glass cullet (recycled glass) and virgin raw materials like silica, soda ash, and limestone. Quality control at this stage is crucial, as impurities in the cullet directly affect the sphericity, clarity, and performance of the final bead, necessitating rigorous sorting and preparation processes. Key upstream suppliers include glass recycling facilities and chemical providers. The core transformation stage involves the high-temperature melting and spheroidization process, where technological expertise and capital investment determine the final product quality, particularly the uniformity of size distribution and refractive index, which are critical for high-performance applications like Type III road markings.

The midstream phase involves specialized processing, including surface treatment and coating application. Many glass beads are treated with silane-based coatings to enhance adhesion to road marking materials, especially in wet conditions, adding substantial value. The downstream segment involves distribution and end-user deployment. Distribution channels are highly fragmented, ranging from direct sales to large government contractors or infrastructure authorities (common for high-volume road marking beads) to indirect sales through specialized chemical distributors and abrasive suppliers serving the industrial and automotive sectors. The shift toward digital procurement platforms and stringent adherence to specific national standards (e.g., AASHTO standards in the US) influences the distribution strategy and requires manufacturers to maintain extensive quality certifications.

Glass Beads Market Potential Customers

The potential customer base for the Glass Beads Market is diverse, spanning various industrial sectors that rely on the materials' unique physical and optical properties. The most significant customer demographic comprises governmental agencies and public works departments, or the contractors they employ, responsible for developing and maintaining road infrastructure. These entities purchase vast volumes of standard and high-index glass beads for mandatory retro-reflective road markings, prioritizing cost-efficiency and compliance with safety specifications (e.g., bead size, refractive index, and durability under traffic wear). Long-term governmental contracts often dictate market volumes and pricing stability within this segment.

Beyond public infrastructure, a rapidly expanding segment of high-value customers includes automotive component manufacturers and composite material suppliers, particularly those focused on lightweighting for electric vehicles and performance vehicles. These buyers seek high-performance, low-density hollow glass microspheres for use in structural composites, plastics, and specialized body fillers. Other key end-users include abrasive blasting contractors who require precision-grade glass beads for surface preparation (e.g., mold cleaning, metal peening) in the aerospace and marine industries, valuing the material’s non-contaminating and controlled abrasive characteristics, ensuring the structural integrity of the treated surface is maintained during preparation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.2 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Potters Industries, Swarco AG, 3M, Sovitec, Indiglass, Roadsky Corporation, Xinxiang Chengrun, Zhejiang Sanxin, Dayu Traffic, Futong Industry, Enviroblast, Mo-Sci Corporation, Kelson, Weissker, Poth Hille, Sino-Highway, Hebei Yongnuo, Nankai Glass, Shandong Fuhai, Glass Microbeads Pvt. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Glass Beads Market Key Technology Landscape

The technological landscape of the Glass Beads market is continuously evolving, driven primarily by the need for enhanced quality, superior performance characteristics (especially retro-reflectivity and durability), and manufacturing efficiency. A core technology remains the high-temperature flame spheroidization process, which utilizes specialized burners and atomization techniques to ensure near-perfect sphericity and tight particle size distribution—critical factors for maximum light reflection and uniform application. Advances in this area focus on optimizing fuel consumption and achieving higher yield rates for very fine, precision-sized beads. Furthermore, the increasing use of advanced particle analysis equipment, often utilizing laser diffraction and high-speed camera systems, allows manufacturers to maintain stringent quality control required by international road safety standards (e.g., EN 1423, AASHTO M247), thus ensuring product consistency across large batches.

A significant technological differentiator lies in surface modification and coating technologies. Specialized anti-clumping, moisture-resistant, and adhesion-promoting coatings, particularly silane compounds, are applied to the glass beads to ensure they remain free-flowing and adhere effectively to various road marking polymers (thermoplastics, epoxy, paint), thereby extending the service life of the road line. Another crucial area of technological advancement is the production of ultra-lightweight hollow glass microspheres. Manufacturing these requires highly controlled furnace environments and specific chemical additives to manage wall thickness and achieve very low densities (e.g., 0.12 g/cc to 0.60 g/cc) while maintaining high crush strength, making them suitable for demanding applications in automotive injection molding and deep-sea buoyancy components. Sustainable production methods, focusing on advanced sorting and cleaning processes for maximizing recycled glass utilization without compromising purity, also represent a key current technological focus area.

Regional Highlights

- Asia Pacific (APAC): APAC is the global market leader, dominating both consumption volume and growth rate, primarily driven by China, India, and Southeast Asian nations. The region's expansive infrastructure build-out, encompassing new highways, bridges, and expressways, necessitates massive quantities of standard and high-refractive glass beads for road safety compliance. Rapid urbanization, increasing vehicle ownership, and governmental focus on reducing traffic fatalities underpin sustained demand. The low-cost, high-volume manufacturing base in China further contributes significantly to the regional and global supply chain dynamics.

- North America: North America represents a mature, high-value market characterized by strict regulatory standards (such as federal mandates for high-visibility pavement markings) and a high demand for specialized products. While infrastructure growth is slower than in APAC, consistent maintenance and repair cycles drive steady consumption. Crucially, the US is a major consumer of hollow glass microspheres in the aerospace, defense, and oil & gas sectors for lightweight composite materials and drilling mud additives, prioritizing product performance and certification over cost minimization.

- Europe: The European market is defined by rigorous quality control and environmental regulations, leading to strong demand for premium, heavy metal-free, and coated glass beads compliant with standards like CE certification and REACH directives. Western European countries emphasize specialized applications, including precision abrasive blasting for historical preservation and high-end automotive manufacturing, while Eastern Europe contributes rising demand due to infrastructure modernization funded by the European Union. Sustainability initiatives promoting recycled content are highly influential here.

- Latin America (LATAM): LATAM is characterized by fragmented but increasing investment in regional connectivity and urban transportation safety improvements, particularly in Brazil and Mexico. The market growth is volatile, dependent heavily on governmental budgets and economic stability, but represents a significant emerging opportunity for standard road marking beads as road safety regulations are gradually enforced across major metropolitan areas. Price sensitivity is high, favoring cost-effective, durable product offerings.

- Middle East and Africa (MEA): The MEA region exhibits high potential, particularly within the GCC countries (Saudi Arabia, UAE) due to ambitious 'Vision' programs focused on major urban development and smart city construction, necessitating high-quality reflective materials for new highways and signage. Africa's market remains largely untapped but shows growth potential linked to Chinese-funded infrastructure projects and the expansion of the regional oil and gas sector, which utilizes specialized glass beads in drilling operations and high-performance coatings for pipelines.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Glass Beads Market.- Potters Industries (Part of PPK Group)

- Swarco AG

- 3M Company

- Sovitec

- Indiglass S.p.A.

- Roadsky Corporation

- Xinxiang Chengrun Glass Beads Co., Ltd.

- Zhejiang Sanxin Glass Co., Ltd.

- Dayu Traffic Facilities Co., Ltd.

- Futong Industry

- Enviroblast

- Mo-Sci Corporation

- Kelson

- Weissker Group

- Poth Hille & Co. Ltd.

- Sino-Highway Holding Group Co., Ltd.

- Hebei Yongnuo Reflektif Malzeme Co., Ltd.

- Nankai Glass Co., Ltd.

- Shandong Fuhai Glass Technology Co., Ltd.

- Glass Microbeads Pvt. Ltd.

Frequently Asked Questions

Analyze common user questions about the Glass Beads market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for glass beads in the global market?

The primary driver is the accelerating global investment in road infrastructure development and the mandatory implementation of rigorous road safety standards, which require highly retro-reflective road markings using standard and high-index glass beads to enhance nighttime visibility and reduce traffic accidents, particularly in rapidly urbanizing regions like Asia Pacific.

How do hollow glass microspheres differ from solid glass beads, and where are they mainly utilized?

Hollow glass microspheres are significantly lighter than solid beads, offering low density while maintaining high crush strength. They are primarily utilized as lightweight fillers and additives in composite materials, plastics, and coatings in sectors such as automotive (for vehicle lightweighting), aerospace, and deep-sea buoyancy applications, where weight reduction is critical for performance and fuel efficiency.

Which material type of glass bead dominates the market and why?

Soda-lime glass beads dominate the market by volume. This is due to their cost-effectiveness, widespread availability of raw materials (recycled glass cullet), and their adequate refractive index and durability properties for standard, high-volume applications in road marking paints and thermoplastics, catering to most government infrastructure projects globally.

What technological advancements are crucial for the future performance of glass beads?

Key technological advancements focus on specialized surface coatings, such as silane treatments, which improve adhesion to road marking materials and resistance to moisture and traffic wear, significantly extending the service life of the markings. Advancements in precision manufacturing techniques to ensure ultra-uniform size and perfect sphericity for high-index applications are also vital.

What role does the volatility of raw material prices play in the Glass Beads Market?

Volatility in the price and supply of high-purity recycled glass cullet, the main raw material, acts as a significant restraint. Manufacturers must strategically manage sourcing and processing costs, as raw material price fluctuations directly impact the profitability of high-volume, cost-sensitive segments like standard road marking beads supplied under fixed-price government contracts.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Apparel Reflective Tape Market Statistics 2025 Analysis By Application (Construction Overalls, Sportswear, Traffic Command Uniform), By Type (Glass Beads Materials, Microprismatic Materials), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Glass Beads Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Crackle Glass Beads, Furnace Glass Beads, Lead Crystal Beads, Molded Glass Beads, Dichroic Glass Beads, Drawn Glass Beads), By Application (Decorations, Consumer Goods, Industrial Applications), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager