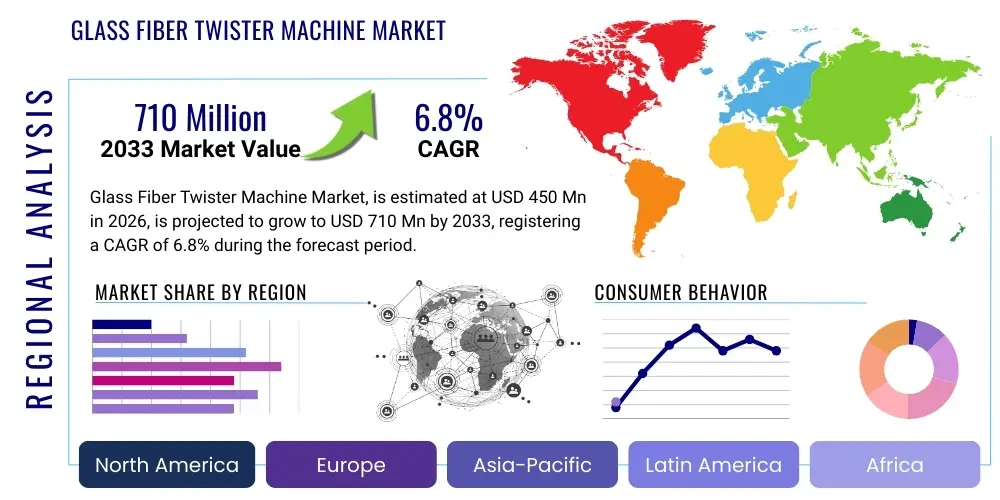

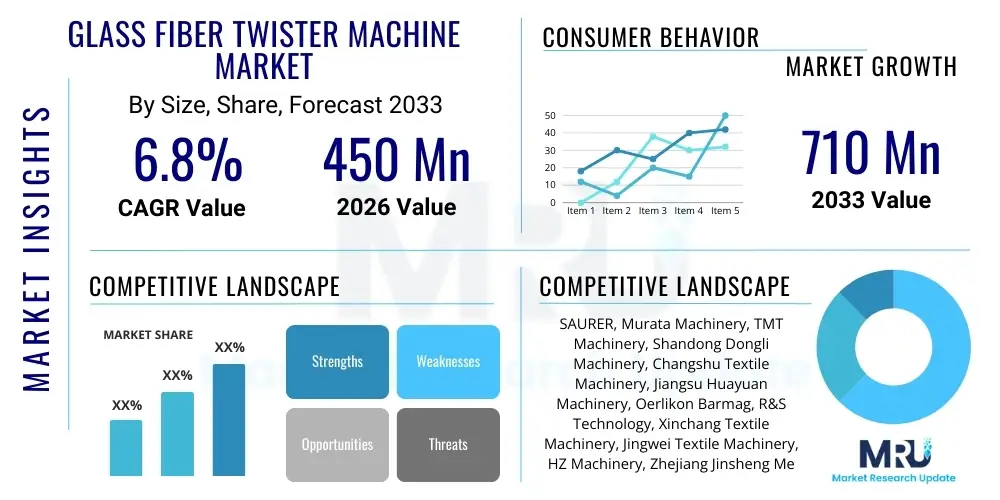

Glass Fiber Twister Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435337 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Glass Fiber Twister Machine Market Size

The Glass Fiber Twister Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 710 Million by the end of the forecast period in 2033.

Glass Fiber Twister Machine Market introduction

The Glass Fiber Twister Machine Market encompasses the manufacturing, sales, and servicing of specialized industrial machinery used to twist continuous glass filaments into stable, high-performance yarns or rovings. These machines are crucial in the initial processing stages of glass fiber manufacturing, ensuring the resulting product possesses the necessary mechanical properties, uniformity, and strength required for subsequent processes, such as weaving, knitting, or pultrusion. The core function involves applying controlled tension and rotation to bundle and twist multiple strands of glass fiber, preparing them for use in advanced composite materials.

Major applications of these highly engineered glass fiber yarns include reinforcement materials across various sectors, particularly construction, transportation (automotive, aerospace, marine), wind energy blade manufacturing, and electrical insulation. The intrinsic benefits derived from using glass fiber materials, such such as high tensile strength, resistance to heat and chemicals, and excellent dielectric properties, directly drive the demand for efficient and high-precision twister machines. These machines contribute significantly to material quality control, minimizing breakage and ensuring consistent linear density, which are paramount in end-use applications where structural integrity is critical.

The driving factors propelling market growth are fundamentally linked to global infrastructure development and the increasing adoption of lightweight, durable, and energy-efficient composite materials. Specifically, the rapid expansion of the wind energy sector, which relies heavily on glass fiber for turbine blade construction, alongside stringent fuel efficiency standards in the automotive industry necessitating lightweight components, fuel investments in modern, high-speed twisting technology. Furthermore, the push towards automated manufacturing processes and the demand for higher production throughput contribute to the consistent upgrade cycle of existing machine fleets globally.

Glass Fiber Twister Machine Market Executive Summary

The Glass Fiber Twister Machine Market is characterized by a strong shift toward automation and digitalization, enabling manufacturers to meet escalating demand for high-quality, high-denier glass yarns used primarily in structural composites. Business trends indicate aggressive research and development focused on optimizing energy consumption, reducing machine downtime through predictive maintenance, and enhancing flexibility to handle various fiber types and twists. Competitive intensity remains high, driven by technology differentiation, particularly concerning spindle speed and operational efficiency, leading to consolidation among technology providers specializing in two-for-one (TFO) twisting technology.

Regionally, the Asia Pacific (APAC) region maintains overwhelming dominance, largely fueled by colossal glass fiber production capacity in China and the burgeoning infrastructure and manufacturing sectors across Southeast Asia, necessitating continuous investment in new twisting lines. Europe and North America, while having mature markets, focus on specialty, high-performance fibers and advanced manufacturing techniques, prioritizing machines that offer superior precision and integration with Industry 4.0 standards. The shift in global manufacturing supply chains is leading to increased localization of production, prompting machine manufacturers to establish local service and support hubs.

Segment trends reveal that the Automatic/CNC operation mode segment is experiencing the fastest growth, as manufacturers prioritize labor efficiency and consistent output quality. By application, the Wind Energy and Transportation segments are the most significant consumers, reflecting the global commitment to renewable energy and the ongoing push for lightweight vehicle architectures. In terms of machine type, sophisticated Two-for-One (TFO) twisters are gaining traction over conventional direct cabling systems due to their superior productivity, higher twisting speeds, and reduced energy requirements per unit of yarn produced, driving the market toward efficiency-centric machine designs.

AI Impact Analysis on Glass Fiber Twister Machine Market

User queries regarding the integration of Artificial Intelligence (AI) in the Glass Fiber Twister Machine Market often center on themes of operational excellence, maintenance efficacy, and product quality consistency. Users frequently ask how AI can prevent sudden machine failures, whether machine learning models can optimize complex twisting parameters (like tension and speed) in real-time based on fiber input variability, and how automated visual inspection systems powered by AI can detect micro-defects or inconsistencies in the twisted yarn that human operators might miss. The consensus among these inquiries highlights the expectation that AI should drastically reduce waste material, maximize machine throughput, and facilitate true predictive maintenance beyond simple vibration analysis, translating raw sensor data into actionable insights about mechanical stress and component lifespan. Key concerns revolve around the high initial investment required for retrofitting existing machinery with requisite sensors and AI-driven control systems, and the need for a skilled workforce capable of managing and interpreting complex data outputs generated by these intelligent systems.

The integration of AI systems is fundamentally reshaping the operational landscape of glass fiber twisting facilities by shifting from reactive or preventive maintenance models to highly accurate predictive strategies. Machine learning algorithms analyze continuous sensor data—including temperature, vibration, spindle speed consistency, and yarn tension fluctuations—to forecast potential mechanical failures hours or days in advance, allowing for scheduled, minimal disruption interventions. Furthermore, AI is crucial for dynamic process optimization; models can instantly adjust machine settings in response to minor variations in ambient humidity, temperature, or the input quality of raw fiber strands, ensuring the output yarn consistently meets stringent quality specifications without manual operator intervention. This not only enhances product reliability but also significantly boosts overall equipment effectiveness (OEE).

- AI facilitates predictive maintenance, minimizing unplanned downtime and optimizing component lifespan.

- Machine learning algorithms enable real-time, dynamic optimization of twisting parameters (tension, speed, lay length).

- Computer vision and deep learning enhance quality control by automatically detecting microscopic yarn defects and inconsistencies.

- AI systems optimize energy consumption by modulating motor and heating elements based on load forecasting.

- Data analytics generated by AI provides actionable insights into overall production efficiency and bottlenecks.

DRO & Impact Forces Of Glass Fiber Twister Machine Market

The dynamics of the Glass Fiber Twister Machine Market are governed by a complex interplay of drivers, restraints, and opportunities, culminating in significant impact forces that shape investment and technological adoption strategies. The primary drivers are the surging global demand for composite materials, particularly in high-growth sectors like wind energy (turbine blade manufacturing) and lightweight automotive components, where glass fiber is a foundational reinforcement material. Coupled with this is the continuous pressure on glass fiber producers to increase operational throughput and improve yarn quality consistency to meet the exacting standards of advanced manufacturing processes. Technological advancements in twister design, leading to higher spindle speeds and greater energy efficiency, also act as a significant driver, encouraging manufacturers to replace older, less productive machinery.

Conversely, the market faces notable restraints, most prominently the substantial capital expenditure required for acquiring modern, high-precision glass fiber twister machines. This high barrier to entry can limit the expansion plans of smaller manufacturers and delay the adoption of new technology in developing regions. Furthermore, the inherent complexity and specialized nature of these machines necessitate a highly skilled technical workforce for operation and maintenance. Fluctuations in raw material costs (e.g., steel and precision components used in machine fabrication) and the cyclical nature of end-user industries, such as construction, can introduce market volatility, making long-term investment planning challenging for both machine vendors and fiber producers.

Opportunities for growth are concentrated in the rapid adoption of Industry 4.0 concepts, including the integration of IoT sensors, big data analytics, and automated material handling systems (e.g., automatic doffing and packaging). There is a significant market opportunity in developing highly flexible machines capable of efficiently processing specialty fibers (like high-modulus or basalt fibers) in addition to standard E-glass. The ongoing push for sustainability also presents an opportunity for manufacturers focusing on machines engineered for maximum energy efficiency and minimal material waste. These collective drivers, restraints, and opportunities exert powerful impact forces on market competition, pushing manufacturers towards continuous innovation, superior product reliability, and enhanced after-sales service capabilities to maintain competitive advantage and secure long-term client relationships.

Segmentation Analysis

The Glass Fiber Twister Machine Market is comprehensively segmented based on machine type, operation mode, and end-use application, providing a granular view of demand patterns and technological preferences across the global industry. Segmentation by type differentiates between established technologies such as direct cabling systems and the more modern, high-efficiency two-for-one (TFO) twisters, which dominate the high-volume production segment due to their superior productivity and efficiency gains. Operational segmentation highlights the accelerating shift from traditional manual and semi-automatic machines toward fully automatic and computer numerical control (CNC) systems, aligning with global trends favoring automation and precision manufacturing.

Analysis by end-use application is crucial for understanding demand elasticity and market potential, with key segments including the rapidly expanding wind energy sector, the high-volume transportation industry (automotive and aerospace), and the perpetually robust construction and infrastructure sector. This detailed segmentation allows manufacturers of twister machinery to tailor their product offerings—such as optimizing spindle counts or tension control mechanisms—to meet the specific requirements (e.g., low twist count for roving, high twist count for fine yarns) of different end-user industries, thereby maximizing market penetration and revenue streams in targeted segments.

- By Machine Type:

- Direct Cabling Twisters

- Two-for-One (TFO) Twisters

- Ring Twisters

- By Operation Mode:

- Manual

- Semi-Automatic

- Automatic/CNC

- By Application:

- Wind Energy

- Transportation (Automotive & Aerospace)

- Construction & Infrastructure

- Electrical & Electronics

- Marine & Others

Value Chain Analysis For Glass Fiber Twister Machine Market

The value chain for the Glass Fiber Twister Machine Market begins with the upstream segment, which involves the sourcing and processing of core raw materials and precision components essential for machine fabrication. This includes high-grade steel and alloys for structural components, advanced ceramic materials for yarn guides, specialized motors, high-speed spindles, and complex electronic control systems (PLCs, sensors, and software). Efficiency in this upstream segment is highly dependent on reliable supplier relationships and technological innovation in high-speed bearing and motor technology, as these components directly dictate the maximum operational speed and longevity of the twister machine.

The midstream segment is dominated by the original equipment manufacturers (OEMs) of the glass fiber twister machines. These manufacturers focus heavily on R&D to improve automation features, energy efficiency, and precision control systems. Key activities at this stage include machine design, precision assembly, rigorous testing, and the integration of control software tailored for complex twisting processes. The distribution channel, which spans both direct sales and specialized indirect distributors, is critical for market access. Direct channels are typically employed for major, high-value contracts with Tier 1 glass fiber producers, offering bespoke solutions and extensive after-sales service, while indirect channels utilize agents or regional distributors to penetrate smaller markets and manage installation logistics.

The downstream segment encompasses the end-users—primarily large-scale glass fiber manufacturers who use the machines to produce finished yarn and roving products. These yarns are then sold to composite material fabricators, pultrusion specialists, and weaving mills who create the final products utilized in wind turbine blades, circuit boards, and vehicle components. The performance and reliability of the twister machine directly impact the quality and cost-effectiveness of these downstream products. Strong linkages in the value chain, particularly robust after-sales support (spindle replacement, calibration services) from the machine OEMs, are crucial for maintaining the high utilization rates demanded by the continuous-operation nature of glass fiber production facilities.

Glass Fiber Twister Machine Market Potential Customers

Potential customers for Glass Fiber Twister Machines are concentrated among large, vertically integrated multinational corporations and specialized manufacturers engaged in the production of reinforcing glass fibers. These end-users are defined by their need for high-throughput machinery capable of operating reliably 24/7 while maintaining strict adherence to quality specifications regarding yarn denier, twist count, and uniformity. The primary buyers are the major global players in the glass fiber manufacturing industry, such as Jushi Group, Owens Corning, and Nippon Electric Glass, who require continuous investment in new equipment to expand capacity, replace aging fleets, and adopt state-of-the-art automation technologies to remain competitive on cost and quality.

Furthermore, regional glass fiber manufacturers focusing on specific niche markets, such as high-performance textiles, filtration media, or specialized composite reinforcement for aerospace, also constitute a significant customer base. These smaller, specialized buyers often seek twister machines that offer greater flexibility in handling different types of input materials (e.g., varying alkali content or specialized coatings) and demanding higher precision control for producing fine-count yarns. The purchasing decisions of all these buyers are heavily influenced by the machine's Total Cost of Ownership (TCO), which factors in energy efficiency, maintenance requirements, lifespan of high-wear components (like spindles), and overall operational stability and ease of integration into existing plant monitoring systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 710 Million |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SAURER, Murata Machinery, TMT Machinery, Shandong Dongli Machinery, Changshu Textile Machinery, Jiangsu Huayuan Machinery, Oerlikon Barmag, R&S Technology, Xinchang Textile Machinery, Jingwei Textile Machinery, HZ Machinery, Zhejiang Jinsheng Mechanical & Electrical, A.T.E. Enterprises, Lakshmi Machine Works (LMW), SSM Schärer Schweiter Mettler |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Glass Fiber Twister Machine Market Key Technology Landscape

The technology landscape of the Glass Fiber Twister Machine Market is defined by continuous evolution aimed at maximizing spindle speed, ensuring precise yarn tension control, and enhancing overall machine efficiency through sophisticated electronic and mechanical integration. A core technological advancement is the widespread adoption of Two-for-One (TFO) twisting technology. TFO machines effectively double the twist insertion rate per revolution compared to traditional methods, significantly boosting productivity while simultaneously minimizing energy consumption per unit of finished yarn. Modern TFO twisters utilize magnetic levitation or air bearings in their spindles, which allows for ultra-high rotational speeds (often exceeding 15,000 RPM) while reducing friction, noise, and maintenance requirements, making them the preferred choice for high-volume glass fiber producers.

Another crucial technological development revolves around the implementation of servo-motor driven systems and computerized numerical control (CNC) for precise parameter management. Unlike older mechanical systems, CNC twisters allow operators to digitally manage complex variables such as twist ratio, winding tension, and traverse speed with exceptional accuracy. This precision is vital for producing high-quality yarn required for demanding applications like aerospace prepregs or specialized construction textiles. Furthermore, the integration of automated handling systems, particularly automatic doffing (the process of removing full packages and placing empty ones), drastically reduces manual intervention and machine downtime, thereby directly improving overall equipment effectiveness (OEE).

In line with Industry 4.0 principles, modern twister machines are equipped with advanced sensor arrays for monitoring key performance indicators like vibration, temperature, energy usage, and yarn breakage in real-time. These IoT capabilities allow for remote monitoring, centralized data analysis, and seamless integration with Manufacturing Execution Systems (MES). The ongoing technological focus is also heavily weighted toward energy recovery systems and optimized motor controls to address the high power consumption inherent in high-speed twisting processes. Future innovation is expected to concentrate on material science advancements within the machine itself, utilizing lighter and stronger materials for rotating components to further push the boundaries of achievable spindle speeds and maintain low vibration profiles.

Regional Highlights

The global Glass Fiber Twister Machine Market exhibits distinct regional dynamics driven by local manufacturing capacity, technological maturity, and demand from key end-use industries. Asia Pacific (APAC) currently dominates the market, contributing the largest share of revenue and volume. This dominance is fundamentally attributable to China's position as the world's leading producer of glass fibers. Massive capacity expansion across China, fueled by robust demand from domestic infrastructure, automotive, and increasingly, the booming localized wind energy sector, necessitates continuous investment in new twisting machinery. Other developing economies in APAC, such as India and Southeast Asian nations, are also accelerating their industrial and construction activities, leading to strong secondary demand for both new installations and capacity upgrades.

North America represents a mature yet technologically advanced market. Demand here is characterized not by sheer volume expansion but by the replacement of older fleets with high-precision, automated systems. The primary drivers in this region are the stringent quality requirements from the aerospace industry and the high-performance material needs of the premium automotive sector, alongside the sustained growth of composite consumption in construction. Manufacturers in North America prioritize machines that offer superior digital integration, reliable predictive maintenance features, and the flexibility to handle specialized or high-modulus glass fibers, emphasizing quality over cost-efficiency in procurement decisions. The focus is increasingly on reducing labor costs through full automation.

Europe stands out for its high concentration of advanced R&D activities and a strong commitment to sustainable manufacturing processes. While production capacity growth may be slower compared to APAC, European demand for twister machines is highly focused on achieving maximum energy efficiency and minimizing environmental impact. Key market drivers include the mature wind energy market and the strict standards applied to insulation and composite materials within the European Union. Machine vendors operating in this region must comply with complex regulatory frameworks and often integrate sophisticated data management systems, catering to the regional preference for specialized, high-specification machines capable of processing complex industrial yarns.

The Latin America (LATAM) market for glass fiber twister machines is in a developmental phase, showing moderate growth potential tied directly to infrastructure projects and recovering automotive production levels in countries like Brazil and Mexico. Market penetration is often challenging due to high import costs and currency volatility, meaning capital expenditure is highly scrutinized. Demand typically leans towards cost-effective, reliable semi-automatic and TFO systems that offer a balance between productivity and investment cost. Local partnerships and strong distributor networks offering accessible service and spare parts are crucial for market success in this region.

The Middle East and Africa (MEA) region currently holds the smallest market share but is poised for steady growth, particularly in the Middle East due to ambitious economic diversification programs and large-scale construction projects (e.g., NEOM in Saudi Arabia). Demand is nascent and often project-specific, driven by the need for local glass fiber production capacity to supply insulation materials for large-scale construction and specialized industrial applications (e.g., oil and gas infrastructure). The adoption rate is dependent on foreign direct investment into manufacturing capabilities, prioritizing robust, climate-resilient machinery that can operate effectively in extreme temperatures and environments.

- Asia Pacific (APAC): Market leader driven by vast production capacity in China, strong demand from construction and wind energy, and rapid industrialization in Southeast Asia.

- North America: Focus on technological replacement, high-precision automation (CNC systems), and specialized yarn production for aerospace and premium automotive sectors.

- Europe: Emphasis on energy efficiency, adherence to strict environmental standards, and R&D for high-specification industrial and specialty composite fibers.

- Latin America (LATAM): Developing market growth linked to infrastructure spending and automotive recovery; preference for cost-effective, reliable TFO systems.

- Middle East and Africa (MEA): Nascent market primarily driven by large-scale infrastructure projects and the establishment of local industrial insulation material manufacturing capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Glass Fiber Twister Machine Market.- SAURER

- Murata Machinery

- TMT Machinery

- Shandong Dongli Machinery

- Changshu Textile Machinery

- Jiangsu Huayuan Machinery

- Oerlikon Barmag

- R&S Technology

- Xinchang Textile Machinery

- Jingwei Textile Machinery

- HZ Machinery

- Zhejiang Jinsheng Mechanical & Electrical

- A.T.E. Enterprises

- Lakshmi Machine Works (LMW)

- SSM Schärer Schweiter Mettler

- Teijin Seiki

- Rieter

- Cason

- RITM

- Galvanin Srl

Frequently Asked Questions

What is the primary technology driving efficiency in the Glass Fiber Twister Machine Market?

The primary technology driving efficiency is the Two-for-One (TFO) twisting system. TFO machines significantly increase production output and reduce energy consumption per unit of yarn compared to older direct cabling methods, making them the industry standard for high-volume glass fiber yarn production.

How does the integration of Industry 4.0 affect the operational costs of twister machines?

Industry 4.0 integration, specifically through IoT sensors and AI-driven predictive maintenance, significantly lowers operational costs by minimizing unplanned downtime, optimizing machine lifespan through timely interventions, and reducing energy expenditure via real-time process tuning and efficiency monitoring.

Which application segment is expected to exhibit the fastest growth for twister machine demand?

The Wind Energy application segment is expected to show the fastest growth. Global commitments to renewable energy necessitate continuous and massive production of high-strength glass fibers for constructing large turbine blades, directly translating into high demand for advanced twister machines.

What is the main challenge restraining market growth for new twister machine installations?

The main challenge restraining market growth is the high initial capital expenditure required for acquiring modern, high-speed, and automated twister machines, posing a significant financial barrier, particularly for smaller manufacturers or those in emerging economies.

Which region dominates the global Glass Fiber Twister Machine Market in terms of volume and production capacity?

The Asia Pacific (APAC) region, largely driven by the extensive glass fiber manufacturing capabilities in China, dominates the global market in both production capacity and overall market volume, fueled by strong domestic demand and export activities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager