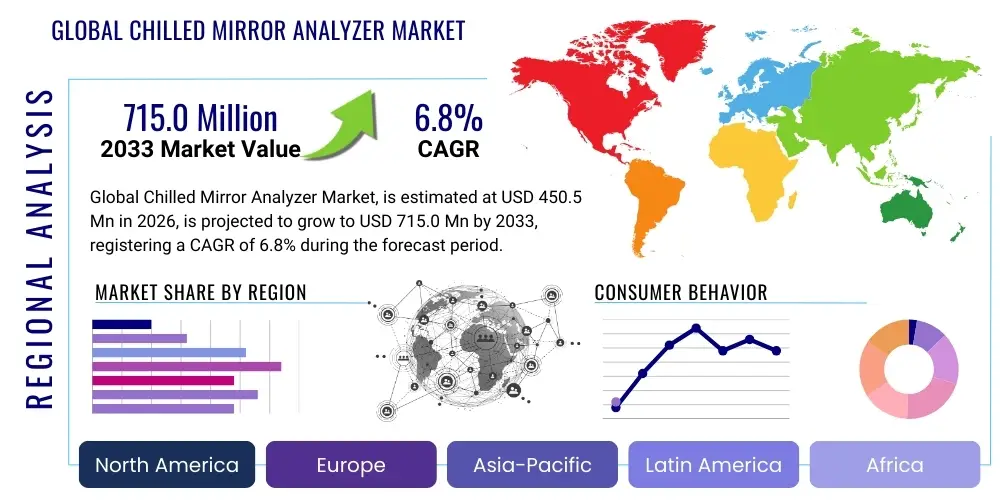

Global Chilled Mirror Analyzer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438144 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Global Chilled Mirror Analyzer Market Size

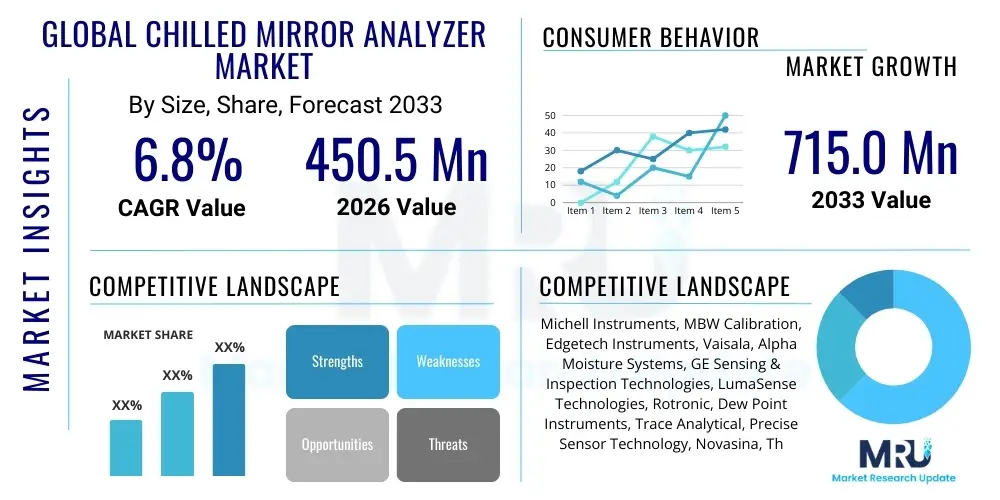

The Global Chilled Mirror Analyzer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 715.0 Million by the end of the forecast period in 2033.

Global Chilled Mirror Analyzer Market introduction

The Global Chilled Mirror Analyzer Market centers on precision instrumentation utilized for highly accurate measurement of dew point, frost point, and relative humidity. These analyzers operate based on the fundamental principle of thermoelectric cooling of a polished metallic mirror until condensation forms, determining the exact temperature at which the saturation point is reached. This methodology provides a direct and fundamental measurement, often serving as the benchmark standard (primary reference) against which other humidity sensors are calibrated, distinguishing it from technologies that rely on inferential or calculated measurements.

Chilled mirror technology is paramount in industrial sectors where moisture content is a critical parameter influencing product quality, process efficiency, or safety. Key applications include the manufacturing of semiconductors, where ultra-low moisture levels in process gases are crucial to prevent device failure; environmental test chambers used for product durability assessments; and custody transfer of natural gas, where precise water vapor measurement prevents pipeline corrosion and hydrate formation. The primary benefits derived from using chilled mirror analyzers include their high accuracy, exceptional stability over extended periods, and wide measurement range, making them indispensable in metrology laboratories and high-stakes industrial environments requiring NIST traceability.

The market growth is fundamentally driven by increasingly stringent regulatory requirements across industries such as pharmaceuticals and specialty chemicals, necessitating highly reliable and verifiable moisture data. Furthermore, the expansion of high-tech manufacturing, particularly in complex processes like lithium-ion battery production and advanced materials research, significantly boosts demand. As these industries expand globally, the need for international consistency in humidity measurement standards reinforces the adoption of chilled mirror technology, despite the higher initial investment compared to conventional humidity probes.

- Primary measurement technology offering unmatched accuracy and stability.

- Used for dew point, frost point, and relative humidity measurement.

- Key applications in semiconductor manufacturing, natural gas processing, and calibration laboratories.

- Driving factors include regulatory compliance and expansion of high-precision manufacturing sectors.

Global Chilled Mirror Analyzer Market Executive Summary

The global market for Chilled Mirror Analyzers is undergoing transformation driven by technological advancements focused on miniaturization, enhanced automation, and integration capabilities. Business trends highlight a strong shift toward portable and battery-operated units, satisfying the demand for on-site calibration and monitoring in diverse field applications, which previously required bulkier laboratory equipment. Furthermore, key market players are focusing on developing analyzers capable of handling extreme conditions, such as high pressure or corrosive gases, thereby expanding the potential application scope beyond traditional cleanroom environments. Strategic partnerships between analyzer manufacturers and metrology service providers are also observed, aimed at offering comprehensive calibration and maintenance contracts, thereby stabilizing recurring revenue streams.

Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market segment due to massive investments in semiconductor fabrication plants (fabs), pharmaceutical manufacturing hubs, and the burgeoning electric vehicle (EV) battery production ecosystem, all of which mandate ultra-precise moisture control. North America and Europe, while representing mature markets, maintain high demand for advanced, high-end analyzers, primarily fueled by strict adherence to international measurement standards (e.g., ISO 17025) and consistent demand from national metrology institutes and specialized research facilities. Emerging regions, including Latin America and the Middle East, are seeing moderate adoption, primarily centered around oil and gas processing facilities where moisture measurement is crucial for infrastructure integrity and compliance.

Segmentation trends indicate that stationary/benchtop models continue to dominate the revenue share due to their use as primary reference standards in laboratories, but portable units are gaining rapid traction in volume terms due to their convenience and reduced cost of ownership in field applications. In terms of technology, analyzers utilizing automatic balance control systems (ABC) for enhanced long-term drift stability and those incorporating advanced optics for precise condensation detection are commanding premium pricing. The demand remains robust across the entire range of dew point detection, from trace moisture analysis (parts per million range) in industrial gases to high humidity measurement (ambient air conditions).

AI Impact Analysis on Global Chilled Mirror Analyzer Market

User inquiries regarding the integration of Artificial Intelligence (AI) and Machine Learning (ML) in the Chilled Mirror Analyzer market frequently revolve around how these technologies can mitigate the inherent labor intensity and high maintenance requirements associated with these high-precision instruments. Users are primarily concerned with the implementation of predictive maintenance schedules, the automation of complex calibration procedures (especially drift correction), and the integration of large, distributed data sets from multiple analyzers for holistic process optimization. Key expectations focus on AI enhancing measurement reliability, reducing operational downtime, and ultimately lowering the overall cost of ownership through smarter data interpretation and autonomous system management, moving beyond simple data logging to true intelligent monitoring.

- Predictive Maintenance: AI algorithms analyze real-time performance data (e.g., cooling rate stability, mirror temperature fluctuations) to predict potential component failures (e.g., thermoelectric coolers, optics), enabling timely intervention before measurement accuracy is compromised.

- Automated Calibration and Balancing: Machine learning models can optimize the automatic balancing control (ABC) mechanisms used in chilled mirror systems, ensuring faster equilibrium achievement and minimizing operator influence during critical measurement cycles, improving inter-instrument consistency.

- Enhanced Data Interpretation: AI processes vast historical and environmental data alongside measurement results to flag anomalies that might indicate external contamination or sample gas flow irregularities, providing superior quality assurance compared to traditional statistical process control (SPC).

- Optimization of Sample Conditioning: ML helps optimize the complex sample conditioning process (flow rates, pressure reduction) required for accurate trace moisture analysis, ensuring the sample gas accurately reflects the source condition without introducing measurement uncertainty.

- Remote Diagnostics: AI-driven systems facilitate sophisticated remote troubleshooting and diagnostics, allowing manufacturers to analyze error codes and performance metrics globally, significantly reducing the need for costly and time-consuming physical technician visits.

DRO & Impact Forces Of Global Chilled Mirror Analyzer Market

The Global Chilled Mirror Analyzer Market is significantly influenced by a confluence of strong drivers related to quality assurance and critical restraints concerning operational costs and complexity. The primary driver stems from the non-negotiable requirement for high-accuracy humidity standards across regulated industries, particularly metrology, where the chilled mirror device functions as the gold standard for traceability. Opportunities lie primarily in extending the technology's application scope through integrating IoT and digital communication protocols, enabling seamless data exchange and remote calibration checks, especially in geographically dispersed industrial sites. These forces collectively shape the competitive landscape and technological investment decisions made by market participants.

The robust market drivers include the accelerating globalization of manufacturing supply chains, which mandates universal and verifiable measurement traceability, favoring the use of internationally recognized primary standards like the chilled mirror principle. Furthermore, the rapid growth in high-purity gas applications—used extensively in the production of flat panel displays, specialized aerospace components, and advanced microprocessors—requires ultra-low dew point measurement capabilities that standard electronic sensors cannot reliably deliver. Technological enhancements, such as improved Peltier cooling elements and advanced optical detection systems (e.g., fiber optics or laser-based detection), are constantly improving the analyzers' response time and lower detection limits, further reinforcing their value proposition in demanding applications.

Conversely, the high initial capital investment required for these precision instruments, coupled with the need for specialized training for operation and maintenance, acts as a significant restraint, particularly for small and medium-sized enterprises (SMEs). The operational complexity, including the meticulous sample handling required to prevent contamination and the regular calibration needed to maintain traceability, also poses an adoption barrier. Impact forces are also driven by competition from advanced secondary technologies, such as Tunable Diode Laser Absorption Spectroscopy (TDLAS), which offers faster response times in some gaseous applications, putting pressure on chilled mirror manufacturers to continuously demonstrate superior long-term stability and reference-grade accuracy.

- Drivers: Mandatory use as primary reference standard; increasing demand for ultra-high purity gas analysis in semiconductors; stringent international regulatory standards (ISO, NIST traceability).

- Restraints: High initial purchase cost; complex maintenance and specialized calibration requirements; vulnerability to mirror contamination in harsh industrial environments; competition from alternative laser-based spectroscopic technologies.

- Opportunities: Integration with Industrial IoT (IIoT) frameworks; development of field-deployable, automated calibration services; penetration into new high-growth areas like specialized lithium-ion battery manufacturing dry rooms.

- Impact Forces: Technological advancements in cooling and detection pushing accuracy limits; regulatory mandates enforcing verifiable humidity control; cost-benefit analysis driving adoption only in critical applications.

Segmentation Analysis

The Global Chilled Mirror Analyzer Market is primarily segmented based on product type (Benchtop/Stationary and Portable/Handheld), the cooling technology employed (Peltier Cooling and Cryogenic Cooling), and the primary application or end-user industry (Metrology/Calibration, Process Control, and Environmental Testing). Analyzing these segments provides crucial insights into demand patterns, technological preferences, and the varying levels of market maturity across different industrial sectors. Benchtop models dominate the high-end metrology space, while portable units are rapidly capturing the field validation and routine quality control market, driven by the need for mobility and ease of use.

- By Type:

- Benchtop/Stationary Analyzers

- Portable/Handheld Analyzers

- By Cooling Method:

- Single-Stage Peltier Cooling

- Multi-Stage Peltier Cooling

- Cryogenic Cooling (for Ultra-low Dew Points)

- By End-Use Industry:

- Metrology and Calibration Laboratories (National and Private)

- Semiconductor and Electronics Manufacturing

- Natural Gas and Petrochemical Processing

- Pharmaceutical and Biotechnology

- Environmental and Climatic Test Chambers

- By Measurement Range:

- Trace Moisture Analyzers (PPM range)

- High Humidity Analyzers (RH range)

Value Chain Analysis For Global Chilled Mirror Analyzer Market

The value chain for the Global Chilled Mirror Analyzer Market begins with the sourcing of highly specialized raw materials, including high-quality optical components (polished mirrors, detection sensors) and advanced thermoelectric (Peltier) cooling modules, which are essential for achieving the required precision and stability. Upstream activities are characterized by rigorous material selection and qualification, focusing on components that offer long-term stability and resistance to corrosive environments. Manufacturing is a highly specialized process involving precision machining, cleanroom assembly, and meticulous sensor integration, primarily concentrated among a few global experts who possess the proprietary knowledge for balancing cooling, detection, and purging systems.

Downstream activities involve specialized distribution channels, which are typically divided into direct sales and indirect channels utilizing highly technical distributors or representatives. Direct sales are often preferred for high-volume, critical national metrology laboratory contracts or large industrial projects where custom integration is required. Indirect channels are crucial for reaching smaller end-users and providing localized technical support and calibration services, particularly in diverse regional markets like Asia Pacific. The post-sales phase is exceptionally important, as chilled mirror analyzers require ongoing, traceable calibration and maintenance, often forming a lucrative service revenue stream for manufacturers and certified third-party labs.

The distribution channel strategy is heavily influenced by the product type; benchtop reference standards are frequently sold directly or through highly specialized scientific equipment dealers, ensuring the integrity of the setup and initial calibration. Conversely, portable analyzers may be distributed through broader industrial instrument suppliers who can offer rapid deployment and field support. The core strategic focus within the value chain is maintaining stringent quality control, especially during the final factory calibration phase, which ensures the analyzer meets internationally accepted standards (NIST, NPL, PTB traceability), cementing its role as a trusted primary measurement standard for the end-user.

Global Chilled Mirror Analyzer Market Potential Customers

Potential customers for Chilled Mirror Analyzers are concentrated in industries that prioritize measurement accuracy and require verifiable, traceable data for regulatory compliance or critical process control. These customers typically operate within highly controlled environments where variations in moisture content can lead to significant financial loss, catastrophic product failure, or regulatory penalties. The primary end-users are not only direct consumers of the instrument but also third-party service providers who utilize these instruments to certify the humidity environment for their own clients, acting as key market multipliers.

The highest demand originates from Metrology and Calibration Laboratories, including National Metrology Institutes (NMIs), where these devices serve as the foundation for disseminating the humidity scale. Similarly, the Semiconductor and Electronics sector represents a vital customer segment, utilizing chilled mirror analyzers to monitor ultra-high purity (UHP) gases and ensure humidity control within dry rooms and cleanrooms during sensitive fabrication steps like photolithography and deposition. The strict demands of the semiconductor industry for parts-per-million (PPM) trace moisture detection drive investment in the most advanced, often cryogenically-assisted, chilled mirror models.

Other substantial customer bases include the Natural Gas and Petrochemical industries, which use these analyzers to measure water vapor content in pipelines to prevent corrosion and hydrate formation, and the Pharmaceutical and Biotechnology sectors, where precise humidity control is essential for validating climatic test chambers, storage environments, and manufacturing processes like lyophilization. These diverse applications necessitate rugged designs for industrial settings (gas processing) and highly specialized, contaminant-resistant designs for clean environments (pharma/semiconductors), driving segmentation in the analyzer offerings tailored to specific customer needs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 715.0 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Michell Instruments, MBW Calibration, Edgetech Instruments, Vaisala, Alpha Moisture Systems, GE Sensing & Inspection Technologies, LumaSense Technologies, Rotronic, Dew Point Instruments, Trace Analytical, Precise Sensor Technology, Novasina, Thunder Scientific, General Eastern, Sensirion, Testo SE & Co. KGaA, Drägerwerk AG & Co. KGaA, Ametek Process Instruments, Panametrics (Baker Hughes), OptiSense. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Global Chilled Mirror Analyzer Market Key Technology Landscape

The core technology of Chilled Mirror Analyzers relies on the detection of condensation (dew or frost) on a cooled mirror surface. The technological landscape is primarily defined by the precision of the cooling mechanism and the sophistication of the detection system used to identify the exact point of condensation formation. Historically, cooling relied on mechanical refrigeration, but modern analyzers almost exclusively utilize solid-state thermoelectric (Peltier) coolers, allowing for precise, rapid temperature control necessary to accurately track the dew point. Advances in multi-stage Peltier cooling now enable much deeper cooling, pushing the measurable dew point down to -90°C or lower, essential for ultra-trace moisture applications.

A crucial technological differentiator is the method of detecting the condensation layer. Early models relied on visual or rudimentary optical detection. Contemporary high-end analyzers employ advanced optical systems, often utilizing back-scattered or front-scattered light principles, sometimes incorporating fiber optics or dedicated lasers, to detect minute changes in the mirror reflectivity caused by the formation of a fractional monolayer of moisture. This high-resolution detection ensures maximum accuracy and repeatability. Furthermore, sophisticated microprocessor control systems are integrated to manage the automatic balancing of the cooling rate and optical detection—known as Automatic Balance Control (ABC)—which compensates for environmental fluctuations and subtle mirror contamination, ensuring long-term stability without frequent operator intervention.

The convergence of chilled mirror technology with digital interfaces and remote connectivity is another major trend. Modern analyzers are increasingly equipped with Ethernet, Wi-Fi, and sophisticated proprietary communication protocols (e.g., Modbus, OPC UA) to facilitate seamless integration into distributed control systems (DCS) and SCADA networks. This enables centralized data logging, remote diagnostics, and automated calibration routines, reducing reliance on physical interaction. Research is also ongoing into developing novel mirror materials and surface treatments that minimize the effects of contamination and prolong measurement integrity in aggressive gas matrices, further enhancing the robustness and applicability of the technology across demanding industrial settings.

Regional Highlights

The geographical analysis of the Global Chilled Mirror Analyzer Market reveals distinct growth patterns and market maturities driven by localized industrial activity and adherence to metrological standards. North America, particularly the United States, represents a highly mature market characterized by robust demand from federally regulated sectors, including aerospace, defense, and high-level national metrology laboratories (e.g., NIST). Demand here is focused on purchasing high-end, traceable reference standards and sophisticated instruments for R&D in advanced materials and climate simulation. Europe mirrors this trend, with strong demand emanating from Germany, the UK, and France, driven by strict EU directives regarding industrial quality control, supporting a large installed base in automotive testing, pharmaceutical validation, and energy sector monitoring.

Asia Pacific (APAC) is currently the epicenter of market expansion and growth, primarily due to large-scale infrastructure investments in advanced manufacturing. Countries like China, South Korea, Taiwan, and Japan are rapidly expanding their semiconductor fabrication capacities, which necessitates massive deployment of trace moisture analyzers for monitoring ultra-high purity process gases. Furthermore, the region’s dominant role in global lithium-ion battery production requires highly controlled dry rooms monitored by precise humidity instruments to prevent chemical degradation during manufacturing. This rapid industrialization, combined with improving regulatory enforcement across key economies, positions APAC as the dominant growth region throughout the forecast period.

The Middle East and Africa (MEA) and Latin America (LATAM) markets demonstrate nascent but focused growth, largely tied to the oil, gas, and petrochemical sectors. In the MEA region, the need to comply with international standards for natural gas custody transfer and processing efficiency drives the adoption of robust, industrial-grade chilled mirror analyzers designed for continuous operation in harsh climates. LATAM, particularly Brazil and Mexico, shows increasing demand tied to domestic industrial expansion in automotive, food processing, and pharmaceuticals, though market penetration remains lower than in the established regions. Manufacturers must tailor their sales strategies in these regions to emphasize instrument ruggedness, ease of maintenance, and localized technical support.

- North America: Mature market, strong demand for traceable primary standards; dominant use in aerospace, defense, and NIST-compliant metrology.

- Europe: High adoption driven by strict EU quality standards (e.g., pharmaceutical QA/QC, automotive testing); focus on high-accuracy stationary models.

- Asia Pacific (APAC): Fastest-growing region; massive investment in semiconductor manufacturing, EV battery production (dry rooms), and expansion of calibration service centers (e.g., China, South Korea).

- Middle East & Africa (MEA): Growth centered on oil and gas processing for corrosion prevention and custody transfer; requires rugged, reliable instrumentation.

- Latin America (LATAM): Moderate growth driven by localized industrial expansion in Brazil and Mexico; increasing regulatory awareness fostering demand for accurate instrumentation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Global Chilled Mirror Analyzer Market.- Michell Instruments

- MBW Calibration

- Edgetech Instruments

- Vaisala

- Alpha Moisture Systems

- GE Sensing & Inspection Technologies

- LumaSense Technologies

- Rotronic

- Dew Point Instruments

- Trace Analytical

- Precise Sensor Technology

- Novasina

- Thunder Scientific

- General Eastern

- Sensirion

- Testo SE & Co. KGaA

- Drägerwerk AG & Co. KGaA

- Ametek Process Instruments

- Panametrics (Baker Hughes)

- OptiSense

Frequently Asked Questions

Analyze common user questions about the Global Chilled Mirror Analyzer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of a Chilled Mirror Analyzer over conventional humidity sensors?

Chilled Mirror Analyzers provide a fundamental, direct measurement of dew point (or frost point) based on the physical condensation principle, serving as a primary standard. This method offers significantly higher accuracy, stability, and traceability compared to secondary sensors (like capacitive or impedance sensors) which rely on empirical calibration curves.

In which industries is the high cost of Chilled Mirror Analyzers justified?

The high initial investment is justified in industries where moisture control is absolutely critical and failure is costly, such as metrology and calibration laboratories, semiconductor fabrication (monitoring UHP gases), pharmaceutical manufacturing (dry room validation), and custody transfer of high-value natural gas products.

How are Chilled Mirror Analyzers integrated into modern Industrial IoT (IIoT) systems?

Modern analyzers integrate via digital communication protocols (e.g., Modbus TCP/IP, Ethernet, OPC UA) that allow for remote data logging, centralized monitoring, predictive maintenance notifications, and automated, real-time comparison of humidity data across large, dispersed process control networks.

What are the key challenges associated with operating chilled mirror instruments?

Key operational challenges include the necessity for careful sample conditioning (to prevent gas contamination), the need for specialized calibration maintenance to ensure traceability, and the susceptibility of the mirror surface to contamination from particulates or oil vapor, which can severely impact measurement accuracy.

What technological advancements are driving the miniaturization of Chilled Mirror Analyzers?

Miniaturization is driven by advancements in solid-state multi-stage Peltier cooling modules, highly efficient LED/optical detection systems that require less space, and the integration of smaller, dedicated microprocessors for Automatic Balance Control (ABC), leading to the development of highly accurate portable units suitable for field use.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager