Global Graphite Machining Center Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433527 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Global Graphite Machining Center Market Size

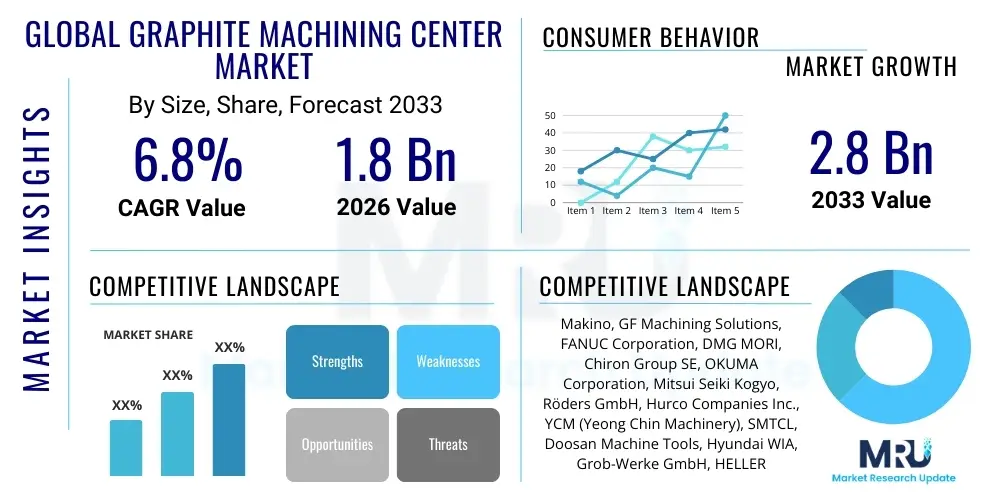

The Global Graphite Machining Center Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.8 Billion in 2026 and is projected to reach USD 2.8 Billion by the end of the forecast period in 2033.

Global Graphite Machining Center Market introduction

The Global Graphite Machining Center Market encompasses specialized Computer Numerical Control (CNC) machinery designed specifically for the high-precision machining of graphite electrodes, molds, and components. Graphite, known for its excellent electrical conductivity, thermal stability, and low density, is extensively used in complex die-sinking Electrical Discharge Machining (EDM) processes, requiring dedicated machining centers that can handle the abrasive dust and fine tolerances inherent in graphite processing. These centers are characterized by high-speed spindles, robust dust extraction systems, optimized kinematics, and advanced thermal management to maintain accuracy over long machining cycles. The primary product offering includes 3-axis, 5-axis, and multi-tasking graphite machining centers, differentiated by their complexity and operational capabilities.

Major applications for these high-performance machines are predominantly found in the mold and die industry, particularly for automotive stamping dies, plastic injection molds, and packaging tooling. Beyond traditional manufacturing, graphite machining centers are critical in emerging sectors such as aerospace for producing structural components, and in the electronics industry for fabricating heat sinks and specialized semiconductor tooling. The demand is intrinsically linked to the performance requirements of EDM electrodes, where superior surface finish and precise geometric accuracy directly translate into higher quality final parts and reduced post-processing time. This dependency underscores the strategic importance of reliable, high-speed graphite machining solutions.

The core benefits derived from utilizing specialized graphite machining centers include significantly higher material removal rates compared to conventional milling, achieving superior surface integrity, and extending the lifespan of cutting tools through optimized cutting strategies. Driving factors include the continuous push for lightweight materials in automotive and aerospace applications, the increasing complexity of mold designs demanding 5-axis simultaneous machining capabilities, and the global industrial shift towards fully automated, lights-out manufacturing environments. Furthermore, advancements in dust management and filtration technology are making graphite machining cleaner and safer, overcoming past industrial barriers related to airborne particulate matter.

Global Graphite Machining Center Market Executive Summary

The Global Graphite Machining Center Market is characterized by a robust integration of digital technologies, focusing heavily on enhancing automation and precision across various manufacturing sectors. Current business trends indicate a strong focus among leading manufacturers on developing hybrid machines that seamlessly integrate high-speed milling with in-situ measurement capabilities, reducing setup times and improving overall throughput. There is a palpable shift towards subscription-based service models and predictive maintenance solutions, leveraging IoT and machine connectivity to maximize uptime. Investment in advanced thermal compensation systems and anti-vibration technology is also peaking, driven by the requirement for micron-level accuracy in complex mold manufacturing, positioning technological differentiation as a primary competitive lever.

Regionally, the Asia Pacific (APAC) continues its dominance, fueled by the rapid expansion of the automotive and electronics manufacturing bases in China, South Korea, and Japan, which are primary consumers of high-precision molds and dies. North America and Europe, while growing at a slightly slower pace, focus intensely on adopting high-end 5-axis centers for specialized, low-volume, high-complexity production runs, particularly within the aerospace and medical device industries where regulatory standards necessitate rigorous precision. Emerging markets in Southeast Asia and Latin America are showing strong potential, driven by Foreign Direct Investment (FDI) into local mold making facilities, though their adoption remains largely focused on cost-effective, high-reliability 3-axis solutions.

Segment trends reveal that the 5-axis machining center category is experiencing the fastest growth rate, reflecting the industry’s need for simultaneous machining of intricate geometries required for complex electrodes. In terms of end-use, the automotive segment remains the largest consumer, primarily due to the continuous demand for large stamping dies and injection molds necessary for new vehicle models, including electric vehicles (EVs). Technological segments show increasing penetration of linear motor technology over traditional ball screw drives, due to linear motors’ capacity to deliver faster acceleration, reduced mechanical wear, and superior surface finish quality, making them ideal for high-speed graphite processing.

AI Impact Analysis on Global Graphite Machining Center Market

Common user questions regarding AI's influence in the Graphite Machining Center Market center around how AI can optimize toolpaths, predict machine failures, and enhance autonomous operation without human intervention, given the sensitivity and high cost of graphite workpieces. Users are keen to understand if AI can effectively manage the abrasive graphite dust environment to maintain sensor integrity and prediction accuracy. The key themes revolve around achieving 'zero-defect' manufacturing through adaptive machining parameters, minimizing electrode wear, and integrating AI for real-time quality control checks. Expectations are high regarding AI’s ability to move beyond basic monitoring toward truly generative manufacturing processes, where tool path generation is optimized dynamically based on material removal feedback and machine load.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is set to revolutionize the efficiency and accuracy of graphite machining operations. AI systems are being deployed for advanced process optimization, specifically in predicting optimal cutting conditions, adjusting spindle speeds based on material density variations within the graphite block, and minimizing thermal deformation effects. This capability allows machines to run closer to their physical limits safely, resulting in marked improvements in cycle time and reducing the overall energy consumption per part. Furthermore, AI facilitates the rapid analysis of sensor data (vibration, acoustic emission, power consumption) to detect minute anomalies indicative of tool breakage or premature wear, critical factors when machining expensive graphite blanks.

Predictive maintenance powered by AI is transitioning from a desirable feature to a standard requirement in advanced machining centers. ML models analyze historical operational data to forecast equipment breakdown with high accuracy, enabling manufacturers to schedule maintenance precisely when needed, thereby eliminating unscheduled downtime, which is particularly costly in high-volume production lines. Beyond machine maintenance, AI is also enhancing the complexity of human-machine interaction, making programming and setup easier for less experienced operators. By leveraging Natural Language Processing (NLP) and computer vision, future graphite machining centers could interpret complex design instructions and automatically suggest the most efficient machining strategy, democratizing access to high-precision capabilities.

- AI-Driven Toolpath Optimization: Reduces cutting time and enhances surface integrity through adaptive feed rate control.

- Predictive Maintenance: Uses ML models to forecast failures of high-speed spindles and dust extraction systems, maximizing uptime.

- Real-time Thermal Compensation: AI algorithms adjust axis positions instantaneously to counteract temperature-induced material expansion, crucial for micron-level accuracy.

- Autonomous Quality Control: Utilizes computer vision and sensor fusion to verify electrode geometry during machining, ensuring 'first-time-right' production.

- Generative Design Integration: Allows for automatic derivation of optimal electrode shapes and corresponding manufacturing parameters from final part geometry.

DRO & Impact Forces Of Global Graphite Machining Center Market

The dynamics of the Global Graphite Machining Center Market are shaped by powerful Drivers (D) such as the increasing demand for complex molds in high-growth industries like EV battery production and 5G electronics; Restraints (R) including the high initial capital expenditure associated with advanced 5-axis CNC equipment and the stringent requirements for effective dust mitigation; and Opportunities (O) arising from advancements in automation technologies, especially robotic integration for material handling and the adoption of hybrid manufacturing platforms. The Impact Forces (IF) of technology proliferation, coupled with intense competitive rivalry among key manufacturers focusing on speed and accuracy, dictate the market trajectory, compelling continuous innovation in spindle technology and control systems. Balancing these forces is crucial for sustainable market expansion and technological leadership.

The primary drivers propelling the market growth are centered on efficiency and precision requirements. The automotive sector's transition towards electric vehicles requires numerous specialized, large-format molds for battery casings and interior components, significantly boosting demand for large-capacity graphite machining centers. Furthermore, the global proliferation of sophisticated consumer electronics and medical devices necessitates highly accurate, microscopic electrodes that can only be reliably produced using ultra-precision graphite centers operating under tight environmental controls. The desire to shorten time-to-market across all major manufacturing sectors drives the adoption of faster, more reliable machining solutions capable of lights-out operation.

Conversely, significant restraints hinder market penetration, most notably the specialized nature and cost of the equipment. High-end graphite machining centers, especially those featuring linear drives and advanced thermal control, represent a substantial investment, limiting adoption by smaller job shops. Furthermore, handling graphite material requires specialized infrastructure—namely, sophisticated, explosion-proof dust extraction and collection systems—which adds complexity and cost to installation and maintenance. Opportunities lie prominently in the development of highly integrated software solutions that simplify complex programming and the increasing adoption of automated cell manufacturing, where graphite centers are integrated into comprehensive robotic workflows, thereby maximizing their utilization rates and justifying the high investment cost.

Segmentation Analysis

The Global Graphite Machining Center Market is strategically segmented based on factors such as machine type, application, axis type, and end-user industry, providing a granular view of market dynamics and adoption trends. Segmentation by machine type distinguishes between high-speed milling centers dedicated solely to graphite and hybrid machines capable of processing multiple materials. Analyzing these segments helps stakeholders understand which specialized tools are gaining traction versus versatile multi-purpose equipment. The complexity and demand for simultaneous machining capabilities further divide the market based on axis type, providing clear insight into the technological maturity and adoption rates across different geographical regions.

The market landscape is predominantly categorized by axis configuration, with 3-axis machines serving entry-level and less complex mold requirements, while 5-axis machines dominate high-precision, complex electrode manufacturing for aerospace and advanced automotive applications. Segmentation by application highlights the dependency of the market on the mold and die industry, which remains the bedrock of demand, followed by emerging consumption from sectors requiring specialized tooling like semiconductor manufacturing. Understanding these segmentation nuances is crucial for manufacturers to tailor their product development strategies, focusing either on high-volume, cost-effective segments or high-margin, ultra-precision niche markets requiring advanced technological specifications.

Geographic segmentation remains pivotal, reflecting regional manufacturing strengths and regulatory environments. For instance, APAC’s segmentation shows heavy reliance on automotive and electronics, demanding both 3-axis and high-speed 5-axis centers, whereas North America exhibits stronger demand within the aerospace and medical segments, favoring machines with superior traceability and reliability features. This multidimensional segmentation allows for precise market sizing and forecasting, identifying key areas for growth and technological investment based on the specific industrial requirements of each segment.

- By Machine Type:

- High-Speed Graphite Milling Centers

- Hybrid Machining Centers

- By Axis Type:

- 3-Axis Graphite Machining Centers

- 4-Axis Graphite Machining Centers

- 5-Axis Graphite Machining Centers (Simultaneous/Indexed)

- By Application:

- Mold and Die Manufacturing (Injection Molds, Stamping Dies)

- Electrode Production (EDM Electrodes)

- Aerospace Components

- Semiconductor Tooling

- Medical Devices

- By End-User Industry:

- Automotive

- Electronics and Consumer Goods

- Aerospace and Defense

- Medical

- Energy and Industrial Machinery

Value Chain Analysis For Global Graphite Machining Center Market

The value chain for the Global Graphite Machining Center Market commences with the upstream segment, dominated by highly specialized component suppliers. This includes manufacturers of ultra-high-speed spindles (often reaching 60,000 RPM or more), precision linear motors, advanced CNC controllers (Siemens, Fanuc, Heidenhain), and sophisticated thermal management systems. The quality and reliability of these upstream components directly dictate the performance and longevity of the final machining center. Component sourcing is often globally distributed, emphasizing strategic partnerships to secure high-quality, specialized technology that provides a competitive edge in machine performance metrics such as surface finish and volumetric accuracy.

In the midstream, machine tool builders procure these components and undertake the complex assembly, integration, and proprietary software development necessary for a specialized graphite machining center. This stage involves intense Research and Development (R&D) focused on kinematics, machine rigidity, and crucial dust extraction system integration—a non-negotiable requirement for graphite processing. Distribution channels are typically a combination of direct sales for major global manufacturers serving large OEMs, and indirect distribution through specialized local distributors and integrators who provide localized service, training, and application support to small and medium-sized enterprises (SMEs). Indirect channels are particularly vital in fragmented markets like APAC, where localized technical expertise is highly valued.

The downstream segment involves the end-users—the mold and die shops, aerospace suppliers, and automotive manufacturers—who consume the machines. Successful market penetration relies heavily on the quality of after-sales service, including rapid parts supply, advanced technical training, and continuous software updates. Direct channels offer manufacturers greater control over branding and customer relationships, particularly for customized, high-value 5-axis systems. Indirect channels, through regional agents, are crucial for reaching potential customers in geographically diverse areas and providing rapid deployment and maintenance services essential for maintaining high machine utilization rates in demanding production environments.

Global Graphite Machining Center Market Potential Customers

The primary purchasers and end-users of specialized graphite machining centers are organizations heavily engaged in tooling, mold making, and precision component fabrication across high-value industries. The most significant customer base resides within the captive tool rooms of large automotive Original Equipment Manufacturers (OEMs) and their Tier 1 suppliers, who require robust, high-throughput machines for stamping die and plastic injection mold production. These customers prioritize machine reliability, large working envelopes, and seamless integration into automated production cells, often demanding integrated automation features such as robotic loading and pallet changers to support high-volume, continuous manufacturing schedules. Their purchasing decisions are driven by total cost of ownership (TCO) and proven track records of maintaining high accuracy over extended periods.

A rapidly expanding segment of potential customers includes independent job shops and mold makers specializing in complex, high-precision tooling for consumer electronics (smartphones, wearables) and specialized medical devices (surgical tools, implants). These customers often require compact, ultra-precise 5-axis centers capable of achieving micron-level tolerances and superior surface finishes to minimize the subsequent EDM process time. For these buyers, technological features like advanced thermal compensation, superior vibration damping, and intuitive CNC interfaces are key differentiators, justifying the higher purchase price of specialized equipment over general-purpose CNC machines. Their demand is project-based and driven by technological evolution in their respective end-product markets.

Furthermore, aerospace and defense contractors represent a high-value, albeit lower volume, customer base. They utilize graphite machining centers not just for EDM electrode fabrication, but also increasingly for the direct machining of high-performance graphite components required for thermal management systems, rocket nozzles, and structural parts where material integrity and traceability are paramount. These customers demand machines certified for stringent regulatory standards, comprehensive data logging capabilities, and extensive service support contracts. The energy sector, particularly those involved in nuclear or specialized material processing, also represents niche buyers requiring high-reliability equipment for highly specific, critical applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.8 Billion |

| Market Forecast in 2033 | USD 2.8 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Makino, GF Machining Solutions, FANUC Corporation, DMG MORI, Chiron Group SE, OKUMA Corporation, Mitsui Seiki Kogyo, Röders GmbH, Hurco Companies Inc., YCM (Yeong Chin Machinery), SMTCL, Doosan Machine Tools, Hyundai WIA, Grob-Werke GmbH, HELLER GmbH, Mazak Corporation, United Grinding Group, Starrag Group, Yamazaki Mazak Corporation, FFG (Fair Friend Group) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Global Graphite Machining Center Market Key Technology Landscape

The technological landscape of the Global Graphite Machining Center Market is defined by the relentless pursuit of speed, precision, and automation, specifically optimized for the abrasive nature of graphite. Central to this evolution are ultra-high-speed spindle technologies, often utilizing ceramic bearings and reaching speeds up to 60,000 RPM, which are essential for achieving the mirror-like surface finishes required on EDM electrodes. Coupled with these high speeds is the mandatory implementation of robust, highly efficient dust extraction and filtration systems, often employing sophisticated cyclone and wet filtration techniques to safely manage graphite dust, ensuring both operator safety and protecting sensitive machine components like linear scales and drives. The machine design emphasizes extreme rigidity and superior damping characteristics, frequently relying on advanced materials such as polymer concrete or composite bases to absorb vibration generated during high-speed cutting.

A significant technological shift involves the widespread adoption of linear motor drives (LMDs) across the X, Y, and Z axes, replacing traditional ball screws, particularly in high-end 5-axis machines. LMDs offer several advantages critical for graphite machining: frictionless movement leads to zero backlash, ensuring high volumetric accuracy; superior acceleration/deceleration capabilities significantly reduce non-cutting time; and reduced mechanical components enhance reliability and minimize maintenance requirements. Furthermore, advanced CNC controllers are increasingly incorporating specialized software modules tailored for graphite processing, which includes adaptive feed control algorithms that automatically adjust cutting parameters based on spindle load fluctuations and tool wear estimates, crucial for maintaining consistent quality during long, unattended machining cycles.

The next generation of technological advancements focuses on enhancing autonomy and integration. This includes the development of sophisticated thermal compensation systems using multiple embedded sensors and predictive algorithms to automatically correct positioning errors caused by temperature variations, a major factor affecting precision during 24/7 operation. Moreover, integrated multi-sensor monitoring systems (acoustic emission sensors, power monitoring, thermal imaging) are becoming standard, feeding data directly into AI-powered diagnostics for real-time tool health assessment and predictive maintenance. This integration extends to automated workpiece and tool handling systems, utilizing robotic arms and standardized interfaces (e.g., EROWA) to facilitate seamless, lights-out operation, driving up the overall equipment effectiveness (OEE) for end-users.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market, primarily driven by the colossal manufacturing ecosystems in China, Japan, and South Korea. China's status as the global hub for electronics and automotive production dictates massive demand for molds and dies, fueling investments in both high-volume 3-axis centers and advanced 5-axis systems. Japan and South Korea, traditional leaders in machine tool technology, maintain high demand for ultra-precision graphite centers used in semiconductor tooling and advanced consumer goods manufacturing. The region benefits from lower manufacturing costs and rapid industrialization, leading to the highest growth rate globally.

- North America: This region exhibits a strong demand for high-end, specialized graphite machining centers, particularly within the aerospace, defense, and high-tech medical device sectors. Adoption is characterized by a preference for 5-axis and automation solutions that ensure superior precision, traceability, and minimized lead times. Investment decisions are heavily influenced by quality certifications and the integration capabilities with existing enterprise systems (ERP/MES). The focus here is less on volume and more on high-value, complex component production, supporting regional technological superiority.

- Europe: Europe represents a mature market, with steady, technology-driven growth, centered particularly in Germany, Italy, and Switzerland. These countries house global leaders in mold and die making, demanding continuous innovation in machining precision, energy efficiency, and automation. The European market leads in the adoption of sophisticated monitoring and Industry 4.0 integration, leveraging connectivity for remote diagnostics and optimizing production flows in compliance with strict EU environmental and safety regulations regarding dust management.

- Latin America: This region is an emerging market showing moderate growth, largely influenced by automotive manufacturing hubs in Mexico and Brazil. Demand is mainly for reliable, mid-range 3-axis and 4-axis centers. Market expansion is dependent on increased foreign direct investment into local tooling capabilities and the subsequent modernization of industrial infrastructure. Cost-efficiency and robust local support are key purchasing criteria for regional manufacturers.

- Middle East and Africa (MEA): MEA remains the smallest market but presents opportunities driven by infrastructure projects and diversification efforts, particularly in the UAE and Saudi Arabia. The demand profile is highly selective, focusing on specific applications in the energy sector (oil and gas tooling) and specialized maintenance repair operations (MRO). Growth here is sporadic and tied closely to large-scale government-backed industrialization initiatives.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Global Graphite Machining Center Market.- Makino

- GF Machining Solutions

- FANUC Corporation

- DMG MORI

- Chiron Group SE

- OKUMA Corporation

- Mitsui Seiki Kogyo

- Röders GmbH

- Hurco Companies Inc.

- YCM (Yeong Chin Machinery)

- SMTCL

- Doosan Machine Tools

- Hyundai WIA

- Grob-Werke GmbH

- HELLER GmbH

- Mazak Corporation

- United Grinding Group

- Starrag Group

- Yamazaki Mazak Corporation

- FFG (Fair Friend Group)

- Exeron GmbH

- Micron Machinery Co., Ltd.

- Haas Automation, Inc.

- Shenyang Machine Tool Co., Ltd.

- Komatsu Ltd.

- Kent Industrial Co., Ltd.

- Vision Wide Tech Co., Ltd.

- Takisawa Machine Tool Co., Ltd.

- Quaser Machine Tools, Inc.

Frequently Asked Questions

Analyze common user questions about the Global Graphite Machining Center market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using dedicated graphite machining centers over standard CNC machines?

Dedicated graphite centers offer ultra-high-speed spindles (up to 60,000 RPM) and specialized, robust dust extraction systems, enabling superior surface finish and higher material removal rates essential for producing precise EDM electrodes. Standard CNC machines lack the necessary containment and thermal stability for optimal graphite processing.

How does the high-speed capability of graphite machining centers impact the overall mold manufacturing process?

High-speed machining minimizes the need for manual polishing and reduces the cycle time for electrode creation. Crucially, high-precision graphite electrodes reduce the subsequent EDM burning time, improving overall efficiency and lead time in complex mold and die production.

What role do 5-axis graphite machining centers play in advanced manufacturing?

5-axis centers allow simultaneous machining of highly complex, contoured geometries required for aerospace components and intricate injection molds. They eliminate multiple setups, maintaining exceptional accuracy and surface integrity, which is vital for high-value, high-precision applications.

What are the major technological challenges faced in the graphite machining center market?

Key challenges include managing abrasive graphite dust effectively without compromising machine components, compensating for thermal expansion at ultra-high spindle speeds, and reducing the high initial capital investment required for linear motor-driven, high-precision equipment.

Which industry segment is the largest consumer of graphite machining centers globally?

The Mold and Die Manufacturing segment, particularly serving the Automotive industry for stamping dies and plastic injection molds (including those for EV components), is the largest and most consistently demanding consumer of high-speed graphite machining technology globally.

Is the integration of IoT and predictive maintenance standard in new graphite machining centers?

Yes, leading manufacturers are increasingly integrating IoT sensors and AI-powered predictive maintenance software to monitor critical components like spindles and linear guides. This shift is becoming standard to maximize OEE and prevent costly unscheduled downtime in automated production environments.

How significant is the Asia Pacific region in the global market growth?

APAC is the primary growth driver due to massive investments in electronics and automotive manufacturing, particularly in China and South Korea. The region drives demand for both volume production capacity (3-axis) and advanced precision technology (5-axis) fueling the fastest regional expansion.

What is the current trend concerning spindle technology in this market?

The dominant trend is the use of ceramic bearing spindles capable of 40,000 to 60,000 RPM, coupled with liquid cooling systems. This ensures the required speed for efficient graphite removal while managing the heat generated, thereby maintaining the necessary positional accuracy over extended operational cycles.

How do specialized linear drives benefit graphite machining operations?

Specialized linear motor drives offer non-contact, frictionless motion, providing superior dynamics, higher acceleration, and zero backlash compared to traditional ball screws. This results in ultra-smooth motion critical for achieving highly accurate, fine surface finishes necessary for final electrode quality.

Are hybrid machining centers gaining popularity in the graphite sector?

Yes, hybrid centers capable of handling both graphite and hardened steel are increasing in popularity, especially in job shops. They offer versatility, allowing manufacturers to maximize machine utilization by switching between high-speed graphite milling and hard material processing, streamlining workflow.

What are the specific environmental compliance considerations for graphite machining?

Environmental compliance centers on effective dust capture and safe disposal of ultra-fine graphite particles, which are conductive and abrasive. Manufacturers must install high-efficiency filtration systems (HEPA or specialized wet separators) to meet stringent workplace air quality and explosion prevention standards.

What influence does the aerospace industry have on technological development in this market?

The aerospace industry demands the highest levels of precision and material traceability. This drives technological development towards superior 5-axis simultaneous control, advanced thermal stability features, and rigorous quality assurance software, which subsequently benefits all other sectors utilizing graphite machining.

How does AI contribute to reducing defects in graphite electrode production?

AI algorithms analyze cutting forces and vibration data in real time, enabling adaptive control adjustments to prevent tool chatter or breakage. This dynamic process optimization ensures consistent material removal and surface quality, minimizing defects and improving the reliability of 'first-time-right' production.

What is the expected lifespan of a high-end graphite machining center?

With proper maintenance, a high-end center using durable components like linear motors and robust structures typically has an operational lifespan exceeding 15 to 20 years. However, technological obsolescence often prompts replacement or upgrading within 8 to 12 years to maintain competitive edge in speed and accuracy.

Are smaller job shops adopting 5-axis graphite machines, or are they reserved for large enterprises?

While historically dominated by large enterprises, smaller, specialized job shops are increasingly adopting compact, high-performance 5-axis centers. This shift is driven by the necessity to handle complex tooling outsourced from major OEMs and the falling relative cost of advanced CNC technology.

What is the current average lead time for acquiring a specialized graphite machining center?

Acquisition lead times vary significantly based on customization and global supply chain conditions, typically ranging from 6 to 12 months for standard high-speed models. Highly customized 5-axis solutions or those requiring specialized tooling integration can sometimes exceed a 15-month lead time.

How important are proprietary software interfaces for market competitiveness?

Proprietary software is extremely important as it simplifies complex 5-axis programming, integrates specialized dust management controls, and enables advanced features like automatic collision avoidance and remote diagnostics, offering a crucial competitive advantage in user experience and operational efficiency.

How does the shift toward electric vehicle (EV) production affect the demand for these machines?

The EV shift dramatically increases demand for large, complex plastic injection molds for battery housings, interior components, and specialized thermal management systems. This necessitates more large-format, high-speed graphite machining centers for electrode production.

Is there a trend towards consolidation among manufacturers in this market?

Yes, market consolidation is a recurring trend, with large, diversified machine tool groups acquiring specialized graphite machining center manufacturers (e.g., GF Machining Solutions). This allows the larger groups to integrate high-speed technology and offer comprehensive tooling solutions to global clients.

What is the expected impact of sustainability regulations on machine design?

Sustainability regulations drive demand for machines with higher energy efficiency (e.g., optimized linear motor performance), reduced coolant consumption, and enhanced filtration systems that minimize airborne emissions, pushing manufacturers towards greener manufacturing technology.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager