Global Industrial Crane Collectors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438477 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Global Industrial Crane Collectors Market Size

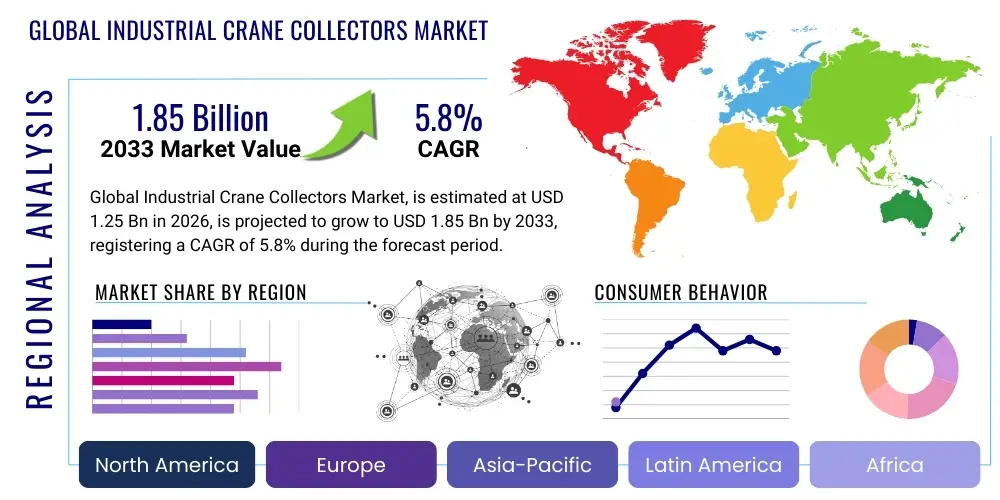

The Global Industrial Crane Collectors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.85 Billion by the end of the forecast period in 2033. This consistent expansion is primarily fueled by accelerated industrial automation globally, coupled with stringent safety standards requiring reliable power transfer systems for heavy-duty material handling equipment.

Global Industrial Crane Collectors Market introduction

The Global Industrial Crane Collectors Market encompasses highly specialized electrical devices essential for transferring electrical power from a stationary power source to the moving components of industrial cranes, typically bridge or overhead cranes. These collectors, often utilizing brushes made of carbon or specialized alloys, ensure continuous conductivity, enabling seamless operation across manufacturing facilities, ports, and heavy infrastructure projects. Products range from single-pole and multi-pole systems to highly secure enclosed conductor rail systems, designed for varying voltage requirements and environmental conditions. Major applications include material handling in steel mills, automotive assembly plants, shipyards, and large-scale warehousing and logistics hubs, where reliability and minimal downtime are paramount. The inherent benefits of these systems include enhanced operational safety by insulating live conductors, optimizing energy efficiency through stable current flow, and significantly reducing maintenance costs associated with outdated or unreliable power feeding methods, thereby acting as a critical component in modern, efficient industrial ecosystems. The market is primarily driven by the modernization of aging industrial infrastructure in developed economies and rapid industrialization and construction activities in emerging economies, alongside the global shift towards automated material handling solutions that demand high-performance, robust power transfer systems.

Global Industrial Crane Collectors Market Executive Summary

The Global Industrial Crane Collectors Market is characterized by a confluence of evolving business trends, significant regional shifts, and complex segment dynamics. Business trends emphasize the adoption of smart collector systems equipped with IoT sensors for predictive maintenance, moving away from reactive repairs towards proactive operational management. Customization based on specific environmental and load requirements is becoming a critical differentiator, especially in highly corrosive environments like coastal ports or high-heat operations such as steel production. Furthermore, sustainability is emerging as a key strategic focus, pushing manufacturers towards developing energy-efficient, low-wear materials, reducing carbon dust emissions, and extending product lifecycles. Companies are heavily investing in R&D to integrate advanced materials, such as specialized carbon composites and lightweight, durable conductor materials, ensuring high-speed operation and reduced mechanical strain on crane components.

Regionally, Asia Pacific continues its dominance driven by massive investments in infrastructure development, burgeoning manufacturing sectors, particularly in China and India, and the expansion of modern logistics facilities. North America and Europe, while mature markets, are experiencing growth through the replacement and modernization of existing crane infrastructure, focusing heavily on safety compliance and digital integration, adhering to rigorous standards set by bodies like OSHA and CE. Segments trend towards enclosed conductor systems, which offer superior safety and protection against harsh elements, gaining preference over open systems in new installations. The demand for heavy-duty collectors, particularly those rated for high amperage and continuous cycling, is escalating due to the increasing size and capacity of modern industrial lifting equipment, indicating a favorable outlook for suppliers catering to high-specification requirements in end-use sectors like metallurgy and container handling.

AI Impact Analysis on Global Industrial Crane Collectors Market

User queries regarding the impact of Artificial Intelligence on the Industrial Crane Collectors Market predominantly center around three core themes: predictive maintenance effectiveness, automation integration, and data security. Users frequently ask how AI can utilize sensor data from collectors (such as vibration, temperature, and current leakage) to anticipate failure before operational disruption occurs. They also inquire about AI's role in optimizing the alignment and contact pressure of collector shoes and brushes to maximize efficiency and minimize wear, especially in complex, high-speed environments. Furthermore, there is significant interest in how AI systems integrated with Crane Management Systems (CMS) can automate power transfer adjustments and ensure compliance with dynamic load conditions, thereby maximizing uptime. Concerns often revolve around the initial investment cost for implementing AI-driven monitoring and the reliability of machine learning algorithms in diagnosing nuanced mechanical or electrical faults specific to collector wear patterns across diverse industrial settings.

AI's primary influence is transforming crane collector maintenance from scheduled preventative measures to condition-based, predictive actions. By continuously analyzing terabytes of operational data—including current draw fluctuations, micro-vibrations, and thermal imaging captured by embedded sensors—AI algorithms can detect subtle anomalies indicative of brush wear, misalignment, or insulator degradation long before they lead to catastrophic failure. This capability minimizes unscheduled downtime, which is immensely valuable in time-sensitive operations like container ports. Secondly, AI facilitates automated diagnostics and self-correction in high-tech enclosed systems, optimizing the performance parameters of the collectors in real-time. This sophisticated level of operational intelligence ensures energy efficiency and significantly extends the lifespan of critical components, reducing the Total Cost of Ownership (TCO) for end-users and pushing the market towards higher specification, sensor-enabled collector assemblies.

- AI enables real-time monitoring and predictive failure analysis of collector components (brushes, insulators).

- Integration with IoT sensors facilitates Condition-Based Monitoring (CBM), drastically reducing maintenance intervals and optimizing brush replacement schedules.

- AI-driven optimization algorithms adjust collector pressure and alignment automatically, ensuring stable current transfer and minimizing arc damage.

- Enhanced data analytics derived from power quality monitoring assists manufacturers in designing more robust and efficient collector systems.

- Improved safety protocols through AI detecting abnormal electrical behavior or excessive heat generation near the conductor rails.

DRO & Impact Forces Of Global Industrial Crane Collectors Market

The dynamics of the Global Industrial Crane Collectors Market are profoundly shaped by a combination of powerful drivers, structural restraints, attractive opportunities, and compelling impact forces that influence strategic decision-making and market trajectory. Key drivers center on the global acceleration of industrial automation, particularly the expansion of automated storage and retrieval systems (AS/RS) and automated guided vehicles (AGVs) requiring continuous power. Furthermore, stringent global safety regulations mandate the use of enclosed and insulated collector systems, pushing legacy facilities towards modernizing their infrastructure. Restraints primarily involve the high complexity and customization required for large-scale projects, leading to longer sales cycles, alongside significant price sensitivity in emerging markets where procurement decisions often prioritize lower initial cost over long-term component durability. Opportunities are vast in leveraging smart factory initiatives, integrating collectors with Industrial IoT (IIoT) platforms for advanced diagnostics, and penetrating niche markets such as waste-to-energy plants and specialized foundries that demand highly robust, custom-engineered collector solutions. These forces collectively dictate the pace of technological innovation, supplier competition, and ultimately, market penetration across diverse industrial applications globally.

The primary driver sustaining market growth is the consistent global investment in infrastructure, including expansion of ports, large-scale warehousing, and heavy manufacturing facilities that rely on reliable overhead crane operation. Modern industrial settings demand continuous, high-amperage power transfer, making advanced collector systems—especially those utilizing multi-pole and enclosed structures—indispensable for maintaining high throughput and minimizing bottlenecks. Simultaneously, the focus on worker safety and minimizing fire hazards associated with poorly maintained or open conductor rails serves as a regulatory push, forcing industries worldwide to upgrade to modern, standardized collector designs. This regulatory compliance, particularly in Western markets, creates a non-negotiable demand floor for highly compliant, safety-rated products. The need for precise, continuous operation in environments ranging from clean room settings to highly corrosive chemical plants also mandates continuous technological evolution in material science for brushes and insulation, maintaining market vibrancy.

However, the market faces significant structural restraints. The lifecycle of industrial cranes is extensive, often spanning decades, leading to long replacement cycles for core components like collectors, which dampens continuous growth. Furthermore, the market faces challenges related to global supply chain volatility, particularly concerning the sourcing of high-purity copper, carbon composites, and specialized plastics used in collector assembly. These material price fluctuations directly impact manufacturing costs and product pricing stability. The specialized nature of installation and maintenance, requiring highly trained technicians familiar with specific rail systems and voltage requirements, also acts as a barrier, particularly for smaller facilities or in regions lacking specialized technical expertise. Overcoming these restraints requires manufacturers to focus on modular, easily serviceable designs and establishing strong, localized maintenance networks to support their installed base effectively.

Segmentation Analysis

The Global Industrial Crane Collectors Market is comprehensively segmented based on Type, Current Rating, Application, and End-Use Industry, providing a granular view of demand dynamics and specialization within the market landscape. Segmentation by Type distinguishes between single-pole systems, suitable for low-power, simple runs; multi-pole systems, offering compact installation for multiple phases; and enclosed conductor systems, which prioritize safety and protection from environmental factors, increasingly dominant in new industrial facilities. Current Rating segmentation highlights the critical difference between low-amperage (used in light duty warehousing) and high-amperage collectors (essential for steel mill ladle cranes or heavy port operations). Analysis by Application reveals demand pockets across key sectors, including infrastructure, manufacturing, and logistics, each requiring specific design considerations regarding speed and duty cycle, guiding product development and marketing strategies towards tailored solutions for maximizing performance in specialized environments.

- Type: Single-Pole Systems, Multi-Pole Systems, Enclosed Conductor Systems (Insulated and Covered), C-Track Festoon Systems.

- Current Rating: Low Amperage (50A to 150A), Medium Amperage (151A to 400A), High Amperage (401A and above).

- Application: Overhead Bridge Cranes, Gantry Cranes, Monorails, Stacker Cranes (AS/RS).

- End-Use Industry: Steel and Metallurgy, Ports and Shipbuilding, Automotive Manufacturing, Logistics and Warehousing, Mining and Construction, Aerospace.

- Material Type: Carbon Brushes, Metallic Brushes (Copper Alloy), Composite Brushes.

Value Chain Analysis For Global Industrial Crane Collectors Market

The value chain for the Global Industrial Crane Collectors Market commences with upstream analysis, focusing heavily on raw material sourcing. Key materials include high-purity copper for conductors and busbars, specialized carbon and graphite compounds for brushes and collector shoes, engineered plastics for housing and insulation, and high-strength steel or aluminum for mounting hardware. Material suppliers must ensure consistent quality and purity, as defects in components like carbon brushes can drastically affect conductivity and wear rates. Manufacturers often engage in vertical integration or long-term supply agreements to mitigate price volatility and ensure material specifications meet rigorous industrial standards, particularly for safety and high-temperature performance. R&D and design are crucial upstream activities, where product innovation focuses on enhancing current carrying capacity, improving wear resistance, and integrating smart sensor technology into the collector design, often adhering to global standards like DIN or NEMA to ensure universal compatibility and performance reliability. The cost structure is significantly impacted by fluctuating global copper prices and the specialized manufacturing processes required for composite materials.

Midstream activities involve core manufacturing, assembly, and quality assurance. Fabrication processes include extrusion of conductor rails, injection molding of insulator components, precision machining of contact shoes, and final assembly of the collector head. Quality control is paramount, involving rigorous testing for insulation integrity, current rating capacity under load, and mechanical robustness against vibration and environmental stressors. Distribution channels are varied but highly specialized. Direct sales and technical consultation are common for large, complex projects, where manufacturers work directly with major crane builders (OEMs) or large industrial end-users (e.g., steel mills). Indirect distribution relies heavily on specialized industrial distributors and maintenance service providers who possess the technical knowledge to correctly size, install, and maintain these systems. These channel partners play a critical role in reaching smaller and medium-sized industrial clients, offering localized inventory and immediate technical support, which is often a key differentiator in purchasing decisions. Effective inventory management at the distributor level is vital to minimize downtime for replacement components.

Downstream analysis focuses on installation, maintenance, and the relationship with the end-user. Installation often requires specialized engineering due to precise alignment requirements between the conductor rail and the collector shoe to prevent arcing and premature wear. Aftermarket services, including the supply of replacement brushes and shoes, constitute a significant portion of the market's revenue, driven by the consumables nature of these components. Customer relationship management centers on providing reliable technical support, training for maintenance personnel, and offering predictive maintenance contracts, often leveraging IIoT data collected by the collectors themselves. End-users, who include major industrial operators and port authorities, prioritize longevity, low maintenance requirements, and high operational safety, influencing demand toward high-performance, durable, and enclosed systems that minimize operational risk and maximize Mean Time Between Failures (MTBF).

Global Industrial Crane Collectors Market Potential Customers

Potential customers for industrial crane collectors are concentrated in sectors characterized by heavy material handling, continuous production cycles, and the utilization of extensive overhead or gantry crane networks. The primary end-users fall into three broad categories: heavy industrial manufacturers, logistics and port operators, and infrastructure development projects. Heavy industrial entities, such as steel mills, primary aluminum smelters, and large automotive stamping plants, require high-amperage, robust collectors capable of handling continuous, high-duty cycles in harsh, often high-temperature environments. These buyers demand custom-engineered solutions with exceptional thermal tolerance and wear resistance. Logistics and port operators, including marine terminals and large distribution centers, prioritize speed, safety (requiring enclosed systems), and reliability for 24/7 container and cargo movement, favoring systems that integrate easily with modern automated stacking cranes (ASCs) and rail-mounted gantry cranes (RMGs). Infrastructure clients, typically involved in large-scale construction or specialized facilities like power generation or waste management plants, seek specialized, durable solutions built to withstand unique environmental stresses, valuing system longevity and compliance with stringent safety standards above all else, ensuring a diverse and complex buyer base requiring highly tailored product offerings.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.85 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Conductix-Wampfler, Stemmann-Technik (A Wabtec Company), Vahle, Mersen, Eaton Corporation, Siemens AG, ABB Ltd., Delachaux Group (Barix), Metreel (UK) Ltd., Norelco Systems Inc., B&R Industrial Automation, Insul-8 Corporation, Schunk Group, Demag Cranes & Components, Power Rail Ltd., Elektromotoren und Geratebau GmbH (EGG), Pintsch Bamag, Wampfler AG, LJM Group, Tele Radio AB |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Global Industrial Crane Collectors Market Key Technology Landscape

The technological landscape of the Global Industrial Crane Collectors Market is experiencing rapid evolution, moving beyond basic electrical transfer towards highly sophisticated, integrated systems designed for extreme reliability and data acquisition. A key focus is on material science, specifically in the development of advanced carbon composite brushes and collector shoes. Manufacturers are leveraging nanotechnology and specialized binding agents to create brushes that exhibit significantly lower friction, reduced wear rates, and enhanced electrical conductivity, particularly crucial in high-speed, high-amperage applications. This material innovation directly translates into longer Mean Time Between Maintenance (MTBM) and reduced operational costs for end-users. Furthermore, the push towards enclosed conductor rail systems necessitates advancements in insulation technology, utilizing high-performance, flame-retardant polymers that maintain mechanical integrity and electrical isolation even under demanding thermal cycling and chemical exposure, ensuring compliance with rigorous international safety certifications.

A second major technological trend is the seamless integration of sensor technology and Industrial Internet of Things (IIoT) capabilities into the collector assemblies themselves, birthing the concept of "Smart Collectors." These collectors are embedded with sensors to monitor critical operational parameters such as brush temperature, vibration levels, contact pressure, and instantaneous current draw. Data collected is transmitted wirelessly to a centralized Crane Management System (CMS) or cloud-based analytical platforms. This capability enables true predictive maintenance, allowing facility managers to schedule brush replacements based on actual condition rather than fixed time intervals, thereby maximizing the utilization of consumable parts while avoiding costly unscheduled outages. The adoption of these smart systems aligns perfectly with the broader industry trend of Smart Factory and Industry 4.0 implementation, positioning the collector system not just as a power conduit, but as a data source vital for operational intelligence.

Further innovation is observed in the design of modular and quick-change collector heads, simplifying installation and maintenance procedures. Manufacturers are employing CAD/CAM technologies to optimize collector geometry for better tracking and reduced mechanical stress on the conductor rail, particularly important in long-travel applications such as gantry cranes at ports. Electrification infrastructure, including the design of highly efficient and durable conductor rails (often aluminum with stainless steel contact surfaces), is also critical. The convergence of robust mechanical design with advanced electrical engineering and embedded digital intelligence defines the cutting-edge technology in this market, ensuring that modern collector systems can handle the increasing speed, load, and operational complexity demanded by highly automated industrial environments globally, securing reliable power transfer under the most challenging circumstances and providing crucial operational data for system optimization and maintenance planning.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market, propelled by unprecedented levels of urbanization, massive infrastructure projects (e.g., ports, railways), and robust manufacturing sector expansion, particularly in China, India, and Southeast Asian nations. High demand for basic and medium-duty collectors characterizes the region, although sophisticated high-amperage enclosed systems are gaining traction with the adoption of automated port handling technologies and modern steel plants. Government investments in logistics hubs further solidify this region's market dominance, emphasizing rapid installation and cost-effectiveness.

- North America: This region is characterized by steady growth driven primarily by the modernization and replacement of aging industrial infrastructure. North American facilities, driven by stringent safety regulations (OSHA), show a strong preference for high-safety, enclosed, and highly durable collector systems. The automotive and aerospace sectors are key drivers, demanding highly precise, low-maintenance systems integrated with advanced monitoring technologies (IIoT) to minimize expensive production line downtime and ensure optimal operational performance.

- Europe: Europe is a mature market focusing heavily on technological innovation, energy efficiency, and regulatory compliance (CE marking). Growth is moderate, largely stemming from Industry 4.0 initiatives that mandate the integration of smart components. Scandinavian and German industries, known for high engineering standards, prioritize long-life cycle products and advanced materials, driving demand for specialized, high-performance carbon composites and sophisticated multi-pole systems that comply with strict environmental and operational efficiency mandates.

- Latin America (LATAM): Market growth in LATAM is closely linked to commodity markets, particularly mining, oil and gas, and shipbuilding in Brazil and Mexico. Demand is cyclical but consistent, requiring rugged, reliable collectors capable of operating in challenging outdoor and often remote environments. Price sensitivity remains a factor, balancing the need for durable systems with budget constraints, leading to a mixed adoption rate of both basic open and more secure enclosed systems depending on the capital investment cycle of key industries.

- Middle East and Africa (MEA): Growth in the MEA region is high, fueled by massive government investments in port development (e.g., UAE, Saudi Arabia) and expansion of logistics and industrial zones. The extreme climatic conditions (high heat, sand, dust) necessitate highly sealed, robust, and weather-resistant collector systems. Port infrastructure and construction projects are the predominant end-users, requiring reliable power transfer for high-capacity gantry and jib cranes, driving localized demand for specialized, durable products engineered to withstand the harsh desert and coastal environments effectively.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Global Industrial Crane Collectors Market.- Conductix-Wampfler

- Stemmann-Technik (A Wabtec Company)

- Vahle GmbH

- Mersen S.A.

- Eaton Corporation plc

- Siemens AG

- ABB Ltd.

- Delachaux Group (Barix)

- Schunk Group

- Insul-8 Corporation

- Metreel (UK) Ltd.

- Norelco Systems Inc.

- DEMAG Cranes & Components GmbH

- Power Rail Ltd.

- Akapp-Stemmann B.V.

- Gantrex (Specialized in rail solutions)

- Tele Radio AB (Focusing on control integration)

- Pintsch Bamag GmbH

- Elektromotoren und Geratebau GmbH (EGG)

- LJM Group

Frequently Asked Questions

Analyze common user questions about the Global Industrial Crane Collectors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Enclosed Conductor Systems over Open Systems?

Enclosed Conductor Systems offer significantly enhanced safety by preventing accidental contact with live conductors, minimizing dust/moisture intrusion, and reducing fire risk. They are mandatory in highly regulated environments like ports and automotive facilities due to superior reliability and reduced maintenance needs.

How does predictive maintenance technology impact the lifespan of crane collector brushes?

Predictive maintenance systems, utilizing IIoT sensors, monitor wear, temperature, and vibration in real-time. This allows for Condition-Based Monitoring (CBM), ensuring brushes are replaced optimally before failure, maximizing brush lifespan, and eliminating unscheduled downtime caused by premature wear.

Which end-use industry drives the highest demand for High Amperage Industrial Crane Collectors?

The Steel and Metallurgy industry, specifically processes involving large ladle cranes and continuous casting equipment, drives the highest demand for High Amperage (400A and above) collectors due to the necessity of continuous, reliable power transfer for heavy lifting and high-heat operations.

What key factors influence the choice between carbon and metallic collector brushes?

Carbon brushes are preferred for high speed and light/medium duty applications due to lower wear on the conductor rail, while metallic brushes (copper alloys) are typically chosen for extremely high current ratings (heavy duty) or in environments demanding maximal mechanical robustness and conductivity.

What regulatory standards primarily govern the design and installation of Industrial Crane Collectors?

Key governing standards include those related to electrical safety and machine operation, such as OSHA (North America), CE directives (Europe), and various ISO standards (e.g., ISO 12100) concerning machine safety, requiring insulation integrity, physical protection, and secure mounting procedures.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager