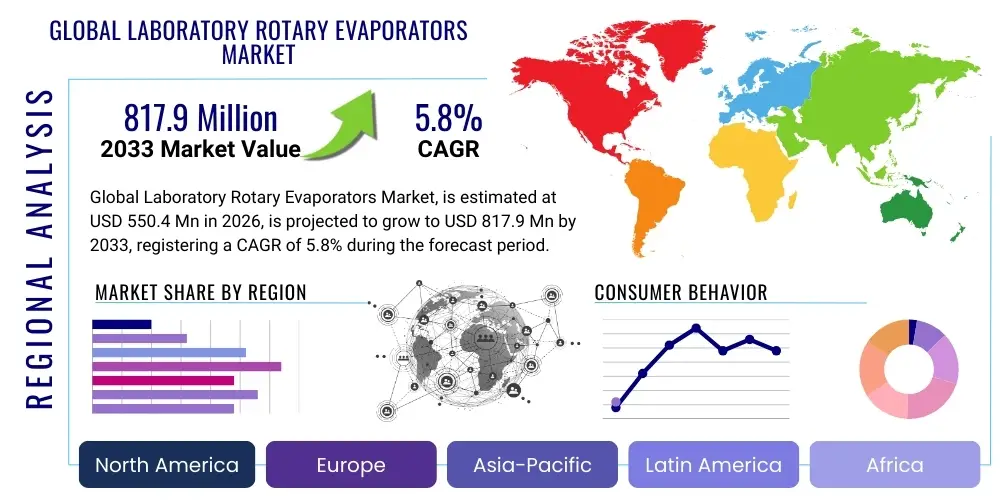

Global Laboratory Rotary Evaporators Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438632 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Global Laboratory Rotary Evaporators Market Size

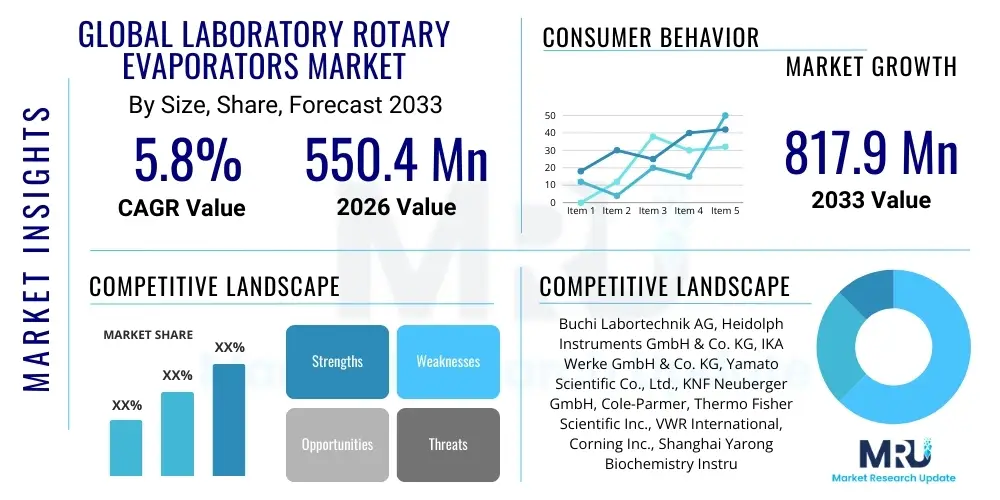

The Global Laboratory Rotary Evaporators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 550.4 million in 2026 and is projected to reach USD 817.9 million by the end of the forecast period in 2033.

Global Laboratory Rotary Evaporators Market introduction

Laboratory rotary evaporators are essential pieces of equipment used across various scientific disciplines, particularly in chemistry, biochemistry, and pharmaceutical research, for the efficient and gentle removal of solvents from samples by evaporation. The operational principle relies on reducing the pressure within the system, thereby lowering the solvent’s boiling point, while rotating the sample flask in a heated water or oil bath. This rotational motion maximizes the surface area of the liquid, accelerating the evaporation rate and ensuring homogeneous heat distribution, which is crucial for protecting temperature-sensitive compounds from degradation. The resulting solvent vapor is then condensed and collected, allowing for solvent recycling and the concentration of the non-volatile sample component.

The primary applications of rotary evaporators span sample concentration, solvent recycling, chemical synthesis, and standardized quality control procedures within both academic and industrial laboratories. In pharmaceutical development, these devices are indispensable for purifying intermediates and active pharmaceutical ingredients (APIs). Furthermore, in chemical synthesis, they are utilized for workup procedures following reactions, efficiently separating volatile reaction byproducts from desired products. The continued demand for high-purity chemical compounds and the expansion of research activities in drug discovery and materials science are fundamental driving factors sustaining the market’s growth trajectory.

Key benefits associated with modern rotary evaporators include high recovery rates, enhanced operational safety through integrated vacuum control and protective coating on glassware, and improved throughput via automated systems. The latest generation of evaporators often integrates intelligent features such as pre-programmed methods, automated distillation, and precise temperature regulation, minimizing user intervention and ensuring reproducible results. The market is currently witnessing a trend towards modular designs that offer flexibility in configuration, catering to diverse laboratory needs ranging from small-scale academic research to large-scale industrial quality control applications.

Global Laboratory Rotary Evaporators Market Executive Summary

The Global Laboratory Rotary Evaporators Market demonstrates robust expansion, largely catalyzed by increasing global R&D expenditures in the pharmaceutical and biotechnology sectors, coupled with rising stringent regulatory requirements necessitating high-purity substances. Business trends indicate a strong focus on the development of fully automated rotary evaporators that incorporate advanced vacuum and temperature management systems, which are critical for maximizing efficiency and reproducibility in high-throughput environments. Market leaders are strategically investing in modular designs and digital integration capabilities (e.g., remote monitoring and data logging) to enhance user experience and comply with modern laboratory informatics standards, thereby driving premium segment growth and solidifying competitive advantages.

Regional trends highlight North America and Europe as dominant markets due to the established presence of major pharmaceutical companies, sophisticated research infrastructure, and high adoption rates of advanced laboratory equipment. However, the Asia Pacific (APAC) region is projected to exhibit the highest growth rate, driven by significant government investments in scientific research, rapid expansion of contract research organizations (CROs), and increasing foreign direct investment in manufacturing facilities across countries like China and India. This regional shift is compelling manufacturers to localize production and distribution networks to cater to diverse regulatory landscapes and procurement preferences across developing economies.

In terms of segmentation trends, the automated rotary evaporators segment is expected to outpace the growth of manual systems, primarily due to the industry's shift towards high-precision and high-throughput analytical workflows. End-user analysis reveals that the pharmaceutical and biotechnology industries collectively represent the largest segment, demanding equipment capable of handling complex organic synthesis and API purification processes under controlled conditions. Furthermore, systems with larger flask capacities (e.g., 5-50 liters) are gaining traction in industrial scale-up applications, while smaller benchtop units (1-3 liters) remain foundational in academic and quality control laboratories, ensuring market diversification across varied operational scales.

AI Impact Analysis on Global Laboratory Rotary Evaporators Market

Common user inquiries regarding AI’s influence on rotary evaporation center on automating complex separation methods, optimizing energy consumption, and implementing predictive maintenance for high-value equipment. Users frequently question how AI can manage dynamic solvent mixtures and predict the optimal distillation parameters (temperature, pressure, rotation speed) in real-time to minimize sample degradation and maximize yield. The key themes revolve around achieving truly autonomous evaporation workflows, ensuring precise solvent profiling, and leveraging machine learning algorithms to analyze historical process data to improve overall laboratory efficiency and compliance with GxP guidelines, ultimately reducing experimental variability and operational cost overheads.

- AI-driven Predictive Parameter Optimization: Machine learning algorithms analyze solvent properties and sample volume to autonomously adjust vacuum pressure and bath temperature, ensuring optimal evaporation kinetics and preventing bumping or frothing.

- Automated Anomaly Detection: AI monitors real-time sensor data (pressure, temperature, rotation speed) to detect subtle operational drifts, signaling potential equipment failures or suboptimal process conditions before they impact the experiment.

- Predictive Maintenance Scheduling: Utilization of historical usage data and performance metrics to accurately predict when components, such as seals, gaskets, or pump diaphragms, require replacement, thereby minimizing unexpected downtime.

- Enhanced Data Logging and Compliance: AI systems automatically record and timestamp complex process variables, ensuring highly detailed and immutable data logs essential for pharmaceutical regulatory compliance and audit trails.

- Solvent Profiling and Management: Integration with spectral analysis tools (e.g., NIR spectroscopy) to verify solvent purity during distillation and optimize recycling programs based on real-time composition analysis.

- Autonomous Workflow Execution: AI orchestrates the entire evaporation process, from vacuum ramp-up to condensation collection and final shutdown, minimizing the need for constant human supervision in routine separations.

DRO & Impact Forces Of Global Laboratory Rotary Evaporators Market

The Global Laboratory Rotary Evaporators Market is primarily propelled by significant investment increases in pharmaceutical and biotechnology R&D activities globally, necessitating high-efficiency solvent removal techniques for drug discovery and quality control. Conversely, the market faces restraints such as the high initial capital expenditure associated with advanced, fully automated systems and the ongoing costs related to consumables and specialized vacuum pumps. Opportunities abound in emerging economies characterized by rapidly developing academic research sectors and the burgeoning establishment of local API manufacturing capabilities. These forces exert considerable impact on pricing strategies, technological innovation, and geographical market expansion within the laboratory equipment industry.

Driving factors include the constant need for compound purification across life sciences, the accelerating pace of academic research requiring specialized separation tools, and global initiatives aimed at solvent recycling for environmental sustainability. These drivers mandate the continuous evolution of evaporator technology towards higher solvent recovery rates and greater energy efficiency. However, the market’s growth is consistently challenged by the technical complexity of integrating high-end systems, which often requires specialized training, and competition from alternative, albeit less versatile, concentration methods such as lyophilization or speed vacuum concentration, particularly for specific types of samples.

The primary impact forces manifest through technological disruption, where manufacturers must continuously innovate to incorporate features like advanced non-contact temperature sensors, explosion-proof components, and seamless integration with lab management systems (LIMS). Market success hinges on addressing the dual demands of operational safety—particularly when handling volatile organic compounds—and throughput efficiency. Companies that successfully leverage modularity and digital connectivity to offer customizable solutions and superior after-sales service are best positioned to capture market share and mitigate the negative impact forces exerted by high equipment costs and perceived operational complexity.

Segmentation Analysis

The Global Laboratory Rotary Evaporators Market segmentation provides a detailed structure for analyzing market dynamics based on equipment characteristics, operational scale, and primary end-user applications. Key segments include categorization by Product Type (Manual/Basic Systems, Automated/Digital Systems), by Capacity (Small Scale: Below 3L, Medium Scale: 3L to 10L, Large Scale: Above 10L), and by End-User Industry (Pharmaceutical & Biotechnology, Academic & Research Institutions, Chemical & Petrochemical Industries, and Others). This granular breakdown helps stakeholders identify high-growth niches, tailor marketing efforts, and understand the differential adoption rates of technology across various laboratory environments.

The distinction between manual and automated systems is critical, reflecting the industry's shift towards precision and reproducibility. Automated systems, equipped with digital displays, programmable ramps, and automatic lift mechanisms, command a higher average selling price but deliver superior performance, especially in GxP compliant settings. Capacity segmentation is directly linked to application, with small-scale units dominating basic research and educational settings, while medium and large-scale evaporators are vital for pilot plants, scale-up synthesis, and high-volume industrial quality control testing, necessitating robust and continuously operable components.

- Product Type:

- Manual Rotary Evaporators

- Automated/Digital Rotary Evaporators

- Capacity:

- Small Scale (Below 3 Liters)

- Medium Scale (3 Liters to 10 Liters)

- Large Scale (Above 10 Liters)

- End-User:

- Pharmaceutical and Biotechnology Companies

- Academic and Research Institutions

- Chemical and Petrochemical Industries

- Food & Beverage and Environmental Testing Laboratories

- Component:

- Rotary Evaporator Unit

- Vacuum Pump

- Chiller/Recirculating Cooler

- Accessories (Glassware, Sensors, Heating Baths)

Value Chain Analysis For Global Laboratory Rotary Evaporators Market

The value chain for the Global Laboratory Rotary Evaporators Market begins with the upstream suppliers of critical raw materials and components, including specialized high-quality borosilicate glass for glassware (flasks, condensers), precision mechanical components for the rotation mechanism, and advanced electronic components for vacuum and temperature control systems. Manufacturers focus intensely on integrating high-efficiency components, ensuring durability, chemical resistance, and operational safety. Key upstream challenges involve maintaining a consistent supply of premium, crack-resistant glass and sophisticated vacuum pump technology, which often requires partnerships with specialized original equipment manufacturers (OEMs).

The manufacturing and assembly stage involves the integration of the heating bath, motor drive, condenser unit, and vacuum controller into a cohesive system. This stage emphasizes rigorous quality control, particularly for safety features such as protective coated glassware and over-temperature cut-offs. Downstream analysis reveals a reliance on a hybrid distribution channel structure, comprising both direct sales to major institutional clients (large pharma companies, government laboratories) and indirect channels through a network of specialized scientific equipment distributors and dealers who provide local support, installation, and maintenance services. The effectiveness of the distribution channel is highly dependent on technical expertise and the ability to offer comprehensive after-sales support.

The final stage involves the end-users and service providers. Direct channels allow manufacturers to maintain control over pricing and customer feedback, crucial for product development. Indirect channels, however, are essential for penetrating geographically diverse markets and servicing smaller academic or clinical laboratories. The overall efficiency of the value chain is determined by the speed of logistics, the quality of technical documentation, and the robustness of maintenance contracts offered post-sale. Optimization of the value chain is focused on reducing lead times for complex custom systems and improving the availability of consumable parts globally.

Global Laboratory Rotary Evaporators Market Potential Customers

The primary buyers and end-users of laboratory rotary evaporators are institutions and organizations heavily invested in chemical processing, analytical testing, and synthesis. The most significant customer base resides within the pharmaceutical and biotechnology sectors, where rotary evaporators are routinely employed for high-purity compound isolation during drug discovery, API development, and rigorous quality control testing required before product release. These customers prioritize equipment reliability, validation capability (IQ/OQ/PQ), adherence to GxP standards, and automation features that allow for documentation and reproducible solvent removal processes.

Academic and governmental research institutions constitute the second major customer segment. University chemistry departments, public research centers, and specialized environmental laboratories utilize these evaporators for educational purposes, fundamental research, and complex material synthesis. These customers often prioritize versatility, ease of use, and competitive pricing, often opting for medium-scale or manual/basic digital models suitable for varied, multi-user environments. Their purchasing decisions are often budget-constrained and dictated by grant cycles and government funding allocations.

Beyond life sciences and academia, potential customers include manufacturers in the specialty chemical, flavor and fragrance, and petrochemical industries. These sectors use evaporators for quality assurance, concentration of extracts, and solvent reclamation processes. Environmental testing laboratories also represent a growing segment, employing rotary evaporation for sample preparation (concentrating pollutants or contaminants) prior to advanced analytical testing, demanding robust, chemical-resistant systems that can handle aggressive solvents and complex matrices while maintaining minimal sample loss.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550.4 Million |

| Market Forecast in 2033 | USD 817.9 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Buchi Labortechnik AG, Heidolph Instruments GmbH & Co. KG, IKA Werke GmbH & Co. KG, Yamato Scientific Co., Ltd., KNF Neuberger GmbH, Cole-Parmer, Thermo Fisher Scientific Inc., VWR International, Corning Inc., Shanghai Yarong Biochemistry Instrument Co., Ltd., EYELA (Tokyo Rikakikai), J.P. Selecta S.A., Labconco Corporation, GPE Scientific Ltd., MRC Lab, Genser Scientific, SENCO Technology, Jiangsu Keyi Group, LAUDA Dr. R. Wobser GmbH & Co. KG, Julabo GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Global Laboratory Rotary Evaporators Market Key Technology Landscape

The technological landscape of the rotary evaporators market is defined by advancements aimed at improving vacuum control, enhancing safety, and maximizing solvent recovery efficiency. A significant innovation involves intelligent vacuum controllers, which utilize sophisticated pressure sensors to automatically adjust pump speed and gas ballast based on the solvent being processed. This adaptive control prevents sudden boiling (bumping), protects the vacuum pump from aggressive solvent vapors, and ensures a faster, more controlled distillation process. Furthermore, the shift towards chemically resistant, oil-free diaphragm pumps is gaining momentum, offering reduced maintenance and eliminating the risk of oil contamination in sensitive laboratory environments, which is highly valued in pharmaceutical and clinical settings.

Another crucial technological area is the integration of high-performance chilling and heating systems. Modern rotary evaporators are often paired with high-efficiency recirculating chillers (refrigerated circulators) that maintain precise cooling temperatures, maximizing the condensation rate of volatile solvents and thereby increasing solvent recovery. Heating baths have transitioned to using induction heating or highly uniform resistive heating elements, coupled with precise digital temperature control, ensuring that the sample is heated uniformly and accurately, preventing thermal degradation of labile compounds. The incorporation of safety features such as protective polymer coatings on glassware, automatic glassware detection, and remote monitoring capabilities through Wi-Fi or Ethernet connectivity also represent core technological advancements ensuring safe operation.

The future technology landscape is centered around digitalization and modularity. Advanced models feature touch-screen interfaces, internal solvent libraries, and the ability to link seamlessly with other laboratory instruments like mass spectrometers or chromatography systems for automated fraction collection. Modular designs allow users to easily switch condenser types (e.g., vertical, diagonal, cold trap) or bath sizes, offering unparalleled flexibility. The increasing adoption of sensors for detecting foam or liquid levels allows for autonomous operation, enabling researchers to set up runs and monitor progress remotely, which drastically increases laboratory throughput and operational flexibility across high-volume research and testing facilities.

Regional Highlights

- North America: This region holds a significant market share, primarily driven by substantial and continuous investments in pharmaceutical research, drug development, and a strong presence of leading biotechnology companies and major academic research centers. The high adoption rate of advanced, automated rotary evaporators, coupled with stringent regulatory standards (FDA) demanding high-precision equipment for validated processes, reinforces its market leadership. The United States remains the largest market within this region, fostering innovation and rapid technology uptake.

- Europe: The European market is mature and highly competitive, characterized by strong governmental funding for scientific research in Germany, Switzerland, and the UK, which are hubs for chemical and pharmaceutical manufacturing. Emphasis on sustainability drives demand for evaporators with high solvent recovery efficiency and low energy consumption. The market is also heavily influenced by ISO and other European standards related to laboratory safety and equipment quality, favoring established European manufacturers known for precision engineering and durability.

- Asia Pacific (APAC): APAC is anticipated to be the fastest-growing regional market due to accelerating economic development, rising healthcare expenditure, and increasing outsourcing of chemical synthesis and clinical trials to countries like China, India, and South Korea. Government initiatives to boost local R&D capacity and the proliferation of CROs and generic drug manufacturers are fueling the demand for both basic and advanced rotary evaporation systems. This market segment is highly price-sensitive but shows a rapidly increasing acceptance of automated technology.

- Latin America (LATAM): The LATAM market is growing steadily, primarily centered in Brazil and Mexico, driven by expanding local pharmaceutical production and agricultural research. While often characterized by slower technology adoption compared to North America, there is an increasing shift toward better quality laboratory equipment, supported by increasing foreign investment and improving access to specialized laboratory equipment distributors.

- Middle East and Africa (MEA): This region presents nascent opportunities, largely focused on oil and gas research (petrochemical analysis) and, increasingly, on developing local academic research capabilities. Growth is constrained by political instability and limited dedicated R&D budgets in several countries, but major investment in science cities and technology parks in nations like Saudi Arabia and the UAE provides pockets of high demand for sophisticated analytical and synthesis equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Global Laboratory Rotary Evaporators Market.- Buchi Labortechnik AG

- Heidolph Instruments GmbH & Co. KG

- IKA Werke GmbH & Co. KG

- Yamato Scientific Co., Ltd.

- KNF Neuberger GmbH

- Thermo Fisher Scientific Inc.

- Cole-Parmer

- Corning Inc.

- VWR International (Avantor)

- Shanghai Yarong Biochemistry Instrument Co., Ltd.

- EYELA (Tokyo Rikakikai)

- J.P. Selecta S.A.

- Labconco Corporation

- GPE Scientific Ltd.

- MRC Lab

- Genser Scientific

- SENCO Technology Co., Ltd.

- Jiangsu Keyi Group

- LAUDA Dr. R. Wobser GmbH & Co. KG

- Julabo GmbH

Frequently Asked Questions

Analyze common user questions about the Global Laboratory Rotary Evaporators market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the demand for automated rotary evaporators?

The demand for automated rotary evaporators is driven by the necessity for enhanced operational precision, reproducibility, and compliance with stringent pharmaceutical GxP regulations. Automation minimizes human error, optimizes distillation parameters in real-time, and supports high-throughput applications in modern R&D laboratories.

Which end-user segment dominates the Global Laboratory Rotary Evaporators Market?

The Pharmaceutical and Biotechnology segment currently dominates the market. These industries require rotary evaporators extensively for critical processes such as solvent removal, concentration of active pharmaceutical ingredients (APIs), purification of intermediates, and essential quality control testing.

How does the integration of AI affect rotary evaporator efficiency?

AI integration enhances efficiency by enabling predictive parameter optimization, where machine learning analyzes solvent data to autonomously control vacuum pressure and temperature, preventing product degradation and accelerating distillation time while reducing energy consumption.

What are the key geographical growth areas for rotary evaporators?

The Asia Pacific (APAC) region, specifically emerging economies like China and India, is projected to be the fastest-growing geographical market, fueled by increasing government investments in local R&D infrastructure and rapid expansion of contract research and manufacturing organizations.

What is the primary restraint impacting market growth?

The primary restraint is the high initial capital investment required for purchasing advanced, fully automated rotary evaporator systems, especially when combined with necessary auxiliary equipment such as high-efficiency vacuum pumps and recirculating chillers, posing a challenge for smaller research entities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager