Glossmeter Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440361 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Glossmeter Market Size

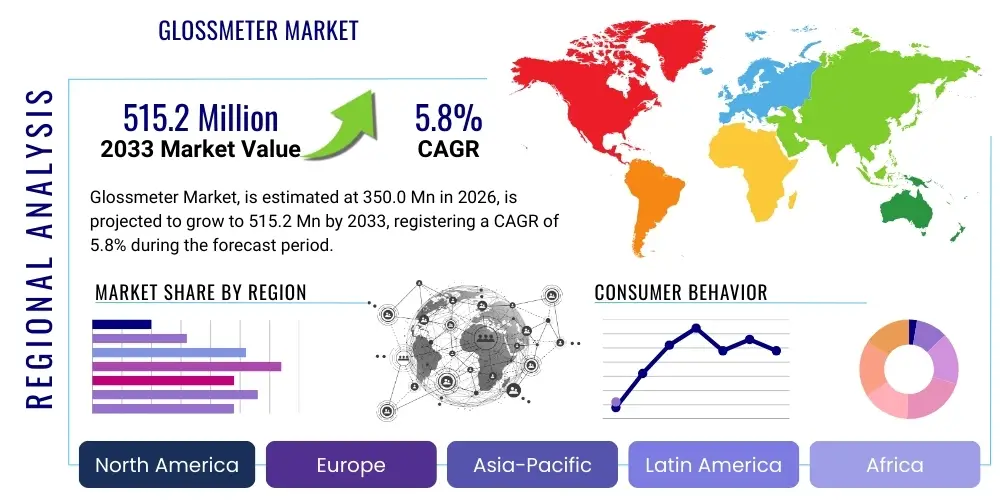

The Glossmeter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 350.0 Million in 2026 and is projected to reach USD 515.2 Million by the end of the forecast period in 2033.

Glossmeter Market introduction

The Glossmeter Market encompasses the global trade and utilization of instruments designed to measure the specular reflection (gloss) of a surface. These precision tools are crucial for evaluating the aesthetic quality and performance of a wide array of materials across various industries. A glossmeter typically operates by projecting a beam of light onto a surface at a specific angle and then measuring the amount of light reflected at an equal but opposite angle. The measurement results are expressed in Gloss Units (GU), providing a standardized and objective metric for surface sheen. This technology is foundational for quality control processes, ensuring product consistency and adherence to established visual specifications in manufacturing and R&D. The demand for glossmeters is continually driven by the increasing emphasis on high-quality finishes and the visual appeal of products, which directly impacts consumer perception and brand value.

Glossmeters are instrumental in maintaining brand image and product consistency across diverse applications. Their primary function revolves around quantifying the reflective properties of surfaces, ensuring that products meet specific aesthetic and performance benchmarks. This includes detecting surface imperfections, monitoring the curing process of coatings, and verifying the uniformity of finishes over large areas. The benefits of employing glossmeters extend beyond mere visual inspection; they enable manufacturers to reduce waste by identifying defects early, optimize production processes, and ensure compliance with international quality standards. Furthermore, these instruments provide objective data that mitigates subjective human judgment, leading to more reliable and repeatable quality assurance outcomes. The diverse range of available glossmeters, from single-angle to multi-angle and portable to benchtop units, allows industries to select instruments tailored to their specific measurement needs, whether for high-gloss paints or matte finishes.

Several significant factors are driving the expansion of the glossmeter market. Foremost among these is the escalating global focus on product quality and aesthetic excellence, particularly in competitive sectors such as automotive, consumer electronics, and decorative coatings. Manufacturers are under constant pressure to deliver visually superior products, making precise gloss measurement an indispensable part of their quality control protocols. Additionally, the rapid advancements in material science and surface engineering techniques necessitate sophisticated measurement tools to accurately characterize new finishes and textures. The ongoing trend towards industrial automation and Industry 4.0 integration further propels market growth, as glossmeters are increasingly incorporated into automated inspection systems for enhanced efficiency and data management. Moreover, stringent regulatory standards and the need for international standardization in manufacturing processes also contribute significantly to the adoption of glossmeter technology across various industrial landscapes.

Glossmeter Market Executive Summary

The Glossmeter Market is experiencing dynamic shifts driven by evolving business paradigms, regional economic developments, and specialized segment demands. Key business trends include the integration of glossmeters into smart manufacturing ecosystems, leveraging data analytics and connectivity for enhanced quality control and process optimization. There is a growing emphasis on portable and handheld devices that offer convenience and flexibility for on-site measurements, addressing the needs of diverse field applications. Furthermore, market players are focusing on developing user-friendly interfaces and robust software solutions that streamline data capture, analysis, and reporting, thereby adding significant value to the core measurement function. The push for greater automation within quality assurance departments is also compelling manufacturers to integrate glossmeters with robotic systems and automated production lines, reducing human error and increasing throughput. Innovation in sensor technology and light sources is leading to more accurate and reliable measurements, even on challenging surfaces with complex optical properties.

Regionally, the market exhibits varied growth trajectories and demand patterns. Asia Pacific stands out as a high-growth region, primarily fueled by rapid industrialization, expansion of manufacturing capabilities, and increasing foreign direct investment in countries like China, India, and Southeast Asian nations. This region's burgeoning automotive, electronics, and construction sectors are significant drivers of glossmeter adoption. North America and Europe, while mature markets, continue to represent substantial revenue bases, characterized by a demand for high-precision, technologically advanced instruments for specialized applications in aerospace, medical devices, and high-end consumer goods. These regions also lead in research and development, fostering innovation in glossmeter technology. Latin America and the Middle East & Africa are emerging markets, showing consistent growth as their industrial infrastructures develop and quality standards become more stringent, creating new opportunities for market penetration and expansion for leading glossmeter manufacturers.

From a segmentation perspective, the market is witnessing notable trends across product types and end-user industries. Multi-angle glossmeters are gaining traction due to their ability to provide a more comprehensive characterization of surface gloss, which is critical for complex finishes and effect pigments. The demand for highly specialized glossmeters tailored for specific applications, such as those designed for high-haze or distinct texture measurements, is also on the rise. In terms of end-users, the automotive industry remains a dominant consumer, continuously seeking advanced solutions for paint quality, interior component finishes, and overall vehicle aesthetics. The paints and coatings sector also demonstrates robust demand, driven by the need to ensure consistent product formulations and application quality. The plastics, paper & pulp, and packaging industries are increasingly investing in gloss measurement technology to meet escalating consumer expectations for product appearance and packaging integrity. This intricate interplay of technological advancements, regional dynamics, and segment-specific demands collectively shapes the trajectory of the global glossmeter market, highlighting opportunities for strategic growth and innovation.

AI Impact Analysis on Glossmeter Market

The integration of Artificial Intelligence (AI) into the glossmeter market promises to revolutionize surface quality measurement and analysis by introducing advanced capabilities for data interpretation, predictive insights, and process optimization. Common user questions often revolve around how AI can move beyond simple gloss unit readings to provide deeper, actionable intelligence, whether it can automate decision-making in quality control, and if it can enhance the accuracy and consistency of measurements in challenging industrial environments. Users are keen to understand how AI algorithms can detect subtle anomalies not easily discernible by human eyes or traditional methods, and how these systems can learn from vast datasets to improve performance over time. There's also significant interest in AI's role in integrating gloss data with other manufacturing parameters to create a holistic view of product quality, leading to more intelligent and proactive quality management systems.

AI's influence is primarily expected in transforming raw gloss data into meaningful operational insights. By analyzing large volumes of measurement data, AI can identify trends, predict potential quality issues before they escalate, and suggest optimal adjustments to manufacturing parameters. This predictive capability moves quality control from a reactive to a proactive paradigm, significantly reducing waste and rework costs. Furthermore, AI can enhance the objectivity of gloss measurement by reducing variability introduced by environmental factors or operator inconsistencies, ensuring a higher standard of data reliability. The ability of AI to process and correlate gloss data with other material properties, such as texture, color, and film thickness, provides a more comprehensive understanding of surface characteristics, which is invaluable for complex material development and quality assurance. This synergistic approach enables manufacturers to achieve unprecedented levels of precision and consistency in their product finishes, directly impacting customer satisfaction and brand reputation.

The impact of AI will extend to automating routine tasks, facilitating smarter calibration, and enabling seamless integration into broader smart factory frameworks. AI-powered glossmeter systems can autonomously monitor their performance, flag calibration needs, and even suggest maintenance schedules, thereby minimizing downtime and ensuring continuous operational accuracy. Moreover, by integrating gloss data with machine vision systems and robotic arms, AI can enable fully automated quality inspection lines where products are measured, analyzed, and sorted without human intervention, significantly increasing throughput and consistency. This level of automation is critical for high-volume manufacturing environments. Ultimately, AI will empower quality control professionals with more sophisticated tools for decision-making, allowing them to focus on strategic improvements rather than manual data analysis. The future of gloss measurement will increasingly rely on intelligent systems that not only provide data but also interpret it, learn from it, and act upon it to drive continuous improvement in product quality and manufacturing efficiency.

- Enhanced Data Analytics: AI algorithms can analyze vast datasets from glossmeters, identifying subtle patterns, trends, and anomalies that human operators might miss, leading to more proactive quality control.

- Predictive Quality Control: AI enables the prediction of potential gloss-related defects or deviations in advance, allowing for timely process adjustments and reducing material waste and rework.

- Automated Anomaly Detection: Machine learning models can be trained to recognize deviations from desired gloss profiles, automating the identification of surface imperfections or inconsistencies with high accuracy.

- Smart Calibration and Maintenance: AI can monitor the performance of glossmeters, predict when calibration or maintenance is needed, and even suggest optimal service schedules, ensuring instrument reliability.

- Integration with Smart Manufacturing: AI facilitates the seamless integration of gloss measurement data into broader Industry 4.0 ecosystems, enabling real-time feedback loops, centralized data management, and automated decision-making across production lines.

DRO & Impact Forces Of Glossmeter Market

The Glossmeter Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, collectively shaping its growth trajectory and competitive landscape. A primary driver is the pervasive and ever-increasing demand for superior product quality and aesthetic perfection across diverse industries, ranging from automotive and electronics to paints, coatings, and consumer goods. Manufacturers are under immense pressure to deliver products with consistent visual attributes, necessitating the use of precise gloss measurement instruments for quality assurance. This trend is further amplified by stringent regulatory frameworks and industry standards that mandate specific surface finish parameters, compelling companies to adopt advanced glossmeter technologies to ensure compliance and market competitiveness. The global expansion of manufacturing capabilities, particularly in emerging economies, also fuels demand as new production lines are established with integrated quality control systems. Furthermore, the continuous innovation in material science and surface treatment technologies, introducing novel textures and finishes, creates a perpetual need for sophisticated glossmeters capable of accurately characterizing these new properties.

Despite these robust drivers, the market faces several significant restraints that could impede its growth. The relatively high initial investment cost associated with advanced, multi-angle, or specialized glossmeters can be a barrier for small and medium-sized enterprises (SMEs) with limited capital budgets. This often leads to a reliance on less accurate, traditional methods or outsourcing, which may not always meet stringent quality requirements. Another restraint is the technical complexity involved in operating and maintaining some high-precision glossmeters, requiring specialized training and expertise. Challenges related to proper calibration, inter-instrument agreement, and environmental factors (such as temperature and humidity) affecting measurement accuracy can also deter adoption or lead to inconsistent results. Economic downturns or slowdowns in key manufacturing sectors like automotive or construction can temporarily suppress demand for capital equipment, including glossmeters. Moreover, a lack of widespread awareness regarding the long-term benefits of precise gloss measurement and its direct impact on brand perception and product durability might limit adoption in certain less industrialized regions or sectors.

The market is also ripe with opportunities that could unlock significant growth potential. The ongoing trend towards industrial automation and the adoption of Industry 4.0 principles present a substantial opportunity for integrating glossmeters into fully automated quality inspection lines, thereby enhancing efficiency and reducing labor costs. The development of portable and wireless glossmeters, offering greater flexibility and ease of use, is expanding market penetration into field applications and smaller workshops. Emerging markets, particularly in Asia Pacific, Latin America, and Africa, with their rapidly expanding industrial bases and increasing emphasis on quality standards, represent untapped potential for market expansion. Moreover, the evolution of glossmeter technology to incorporate advanced features such as enhanced optics, improved data processing algorithms, and seamless connectivity with enterprise resource planning (ERP) and manufacturing execution systems (MES) can create new value propositions for end-users. The increasing focus on sustainability and material efficiency also presents an opportunity for glossmeters to play a role in optimizing coating processes and reducing material waste, further positioning them as essential tools in modern manufacturing.

The impact forces influencing the Glossmeter Market are multifaceted, encompassing technological advancements, globalization of manufacturing, and increasing consumer expectations. Rapid innovation in sensor technology, LED light sources, and sophisticated optical systems continues to improve the accuracy, repeatability, and versatility of glossmeters, making them indispensable for high-precision applications. The globalization of supply chains and manufacturing operations necessitates standardized quality control measures across different geographic locations, driving the adoption of internationally recognized gloss measurement protocols. Simultaneously, rising consumer awareness and demand for aesthetically pleasing and high-quality products compel manufacturers to implement robust quality checks at every stage of production. These forces interact to create a dynamic environment where continuous innovation and strategic market expansion are crucial for success, influencing product development, market entry strategies, and competitive positioning within the glossmeter industry.

Segmentation Analysis

The Glossmeter Market is meticulously segmented across various dimensions to provide a comprehensive understanding of its structure, dynamics, and growth opportunities. These segmentation criteria typically include product type, application, end-user industry, and geographical region, each offering unique insights into market trends and demand patterns. By dissecting the market along these lines, stakeholders can identify specific niches, assess competitive landscapes, and formulate targeted strategies for product development and market penetration. This detailed breakdown highlights the diverse needs of different industries and users, from manufacturers requiring high-precision laboratory-grade instruments to field technicians needing robust portable devices, ensuring that the market caters to a broad spectrum of measurement requirements and operational environments. Understanding these segments is critical for both market entrants and established players to tailor their offerings effectively and capitalize on specific growth areas within the global glossmeter ecosystem.

The segmentation by product type typically differentiates between single-angle, dual-angle, triple-angle, and multi-angle glossmeters, reflecting the varying levels of measurement complexity and detail required by different applications. Single-angle meters are usually sufficient for basic quality control, while multi-angle devices provide a more comprehensive characterization of surface appearance, crucial for materials with complex optical properties or visual effects. Application-based segmentation covers the specific uses of glossmeters, such as for paints and coatings, automotive finishes, plastic components, paper and pulp, and various other industrial surfaces. This segment highlights where gloss measurement is most critical and prevalent. The end-user segmentation categorizes demand based on the primary industry utilizing the glossmeters, including manufacturing, research and development, and dedicated quality control laboratories, each with distinct purchasing criteria and operational needs. Furthermore, segmentation by portability, such as portable handheld devices versus benchtop laboratory instruments, addresses the operational flexibility and precision requirements of different working environments.

- By Type:

- Single-Angle Glossmeters (e.g., 60-degree, for general gloss measurement)

- Dual-Angle Glossmeters (e.g., 20/60-degree, for high and medium gloss surfaces)

- Triple-Angle Glossmeters (e.g., 20/60/85-degree, for high, medium, and low gloss/matte surfaces)

- Multi-Angle Glossmeters (offering more than three angles, for complex surfaces and special effects)

- By Application:

- Paints & Coatings (automotive, industrial, decorative)

- Automotive (interior, exterior components, paint finish)

- Plastics & Rubber (molded parts, films, sheets)

- Paper & Pulp (magazines, packaging, printing)

- Packaging (food, consumer goods, pharmaceuticals)

- Metal & Anodized Surfaces

- Wood & Furniture

- Ceramics & Stone

- Textiles & Fabrics

- Others (e.g., printing inks, leather, films)

- By End-User Industry:

- Manufacturing (various industries)

- Quality Control & Assurance Laboratories

- Research & Development Institutions

- Academic & Educational Institutions

- Retail & Consumer Goods Inspection

- By Portability:

- Portable/Handheld Glossmeters

- Benchtop/Laboratory Glossmeters

Value Chain Analysis For Glossmeter Market

The value chain for the Glossmeter Market is a sequential framework encompassing all stages from raw material sourcing to the final delivery and aftermarket support of the product, highlighting the various entities and processes that add value along the way. At the upstream stage, the market relies heavily on specialized suppliers providing critical components such as optical sensors, light sources (LEDs, lamps), precision lenses, electronic circuit boards, microprocessors, and high-quality casings. These suppliers are crucial for the performance, accuracy, and durability of the glossmeters, making robust supply chain management and quality control at this initial phase paramount. Manufacturers often maintain strong relationships with a limited number of specialized component providers to ensure consistency and reliability, as the quality of these core components directly impacts the instrument's overall functionality and compliance with measurement standards. Innovation in material science and electronic miniaturization at this stage can significantly enhance product capabilities and reduce manufacturing costs, driving value throughout the chain.

Moving downstream, the value chain progresses through the manufacturing, assembly, and testing phases, where raw components are transformed into finished glossmeter products. This stage involves precision engineering, software integration for data processing and user interfaces, and rigorous quality assurance protocols to ensure each instrument meets specified accuracy and repeatability standards. Following manufacturing, the distribution channel plays a pivotal role in reaching the end-users. This typically involves a combination of direct sales from manufacturers, particularly for large industrial clients or customized solutions, and indirect channels through a network of specialized distributors, resellers, and regional agents. These indirect partners often provide local support, technical expertise, and service, which are crucial for market penetration and customer satisfaction, especially in diverse geographical regions with varying technical requirements. The choice between direct and indirect distribution often depends on the manufacturer's market strategy, product complexity, and the geographic spread of its customer base.

Post-sales services, including technical support, calibration services, maintenance contracts, and spare parts supply, constitute a significant part of the downstream value chain. These services are vital for ensuring the longevity and continued accuracy of glossmeters, enhancing customer loyalty, and generating recurring revenue streams for manufacturers. Effective customer support and accessible calibration facilities are key differentiators in a competitive market, as the precision of these instruments deteriorates over time without proper care. The direct channel allows manufacturers to maintain tight control over customer relationships and feedback, facilitating product improvements and personalized support. In contrast, indirect channels, while offering broader market reach, require careful management to ensure consistent service quality from third-party partners. The overall efficiency and responsiveness of the distribution and service network are critical for sustaining market presence and growth, enabling the glossmeter market to effectively deliver and support its high-precision measurement solutions to a global clientele.

Glossmeter Market Potential Customers

The Glossmeter Market caters to a diverse range of potential customers, primarily comprised of end-users and buyers who require precise surface gloss measurement for quality control, research, and product development purposes. These customers span across numerous industrial sectors, each with unique applications and specific demands for glossmeter technology. The automotive industry, for instance, represents a significant customer base, requiring glossmeters for ensuring the consistent finish of vehicle paintwork, interior components, and trim. Similarly, manufacturers in the paints and coatings industry are crucial buyers, utilizing these instruments to verify the quality and uniformity of their products, from industrial coatings to decorative paints. The stringent aesthetic and functional requirements in these sectors make glossmeters an indispensable tool for achieving high standards of visual quality and product performance. The need for objective and repeatable measurements is a common thread that connects these varied customer segments, driving their investment in advanced glossmeter solutions.

Beyond these core sectors, potential customers for glossmeters include companies operating in the plastics and rubber industries, where these instruments are used to assess the gloss of molded parts, films, and sheets, ensuring product consistency and appealing aesthetics. The paper and pulp industry, particularly in the production of high-quality printing paper, packaging materials, and magazines, relies on glossmeters to control the sheen and printability of their products. The furniture industry, manufacturers of consumer electronics, and packaging companies also form substantial customer segments, as the visual appeal of their products and packaging directly impacts consumer perception and brand image. These industries often require both portable and benchtop glossmeters, depending on whether measurements are taken on the production line or in a dedicated laboratory environment, showcasing the diverse operational needs of the customer base.

Furthermore, academic institutions and dedicated research & development laboratories constitute another vital segment of potential customers. These entities utilize glossmeters for material science research, development of new surface treatments, and educational purposes, often requiring highly accurate and versatile instruments that can handle experimental materials and complex measurement protocols. Quality control and assurance departments within manufacturing facilities across almost all industrial sectors are primary buyers, as glossmeters are fundamental tools in their daily operations to maintain product specifications and comply with industry standards. The growing emphasis on standardization and quality certification globally further expands the potential customer base, as more companies recognize the critical role of objective surface gloss measurement in achieving and maintaining competitive advantage and customer satisfaction. The continuous expansion of manufacturing sectors in emerging economies also continually introduces new potential customers seeking reliable quality control solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.0 Million |

| Market Forecast in 2033 | USD 515.2 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Konica Minolta Sensing, Inc., BYK-Gardner GmbH (Altana AG), Elcometer Ltd., Rhopoint Instruments Ltd., TQC Sheen (Part of Industrial Physics), HORIBA, Ltd., Novo-Gloss (Part of Industrial Physics), Defelsko Corporation, Sheen Instruments (Part of Industrial Physics), X-Rite, Incorporated (Danaher Corporation), PCE Instruments, Datacolor, Nippon Denshoku Industries Co., Ltd., Zehntner GmbH Testing Instruments, ElektroPhysik Dr. Steingroever GmbH & Co. KG, Qualitest International Inc., Test Rite Products Corporation, Beijing Time High Technology Ltd., Erichsen GmbH & Co. KG, ZGM Instruments Co., Limited |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Glossmeter Market Key Technology Landscape

The Glossmeter Market's technological landscape is characterized by continuous innovation aimed at enhancing measurement accuracy, improving user experience, and facilitating seamless integration into modern industrial processes. At the core, advancements in optical technology are paramount, involving the development of highly stable LED light sources that ensure consistent illumination and sophisticated photodetectors capable of precisely capturing reflected light with minimal noise. These improvements contribute significantly to the repeatability and reproducibility of measurements, which are critical for high-stakes quality control applications. Furthermore, the integration of advanced signal processing algorithms within the instrument's firmware allows for more robust data analysis, compensating for minor environmental variations and improving the overall precision of gloss unit readings. The evolution of multi-angle measurement capabilities, enabled by sophisticated optical configurations, allows glossmeters to provide a more comprehensive characterization of surface appearance, moving beyond simple specular gloss to include haze and distinctness-of-image metrics.

Another crucial aspect of the technological landscape is the significant progress in connectivity and data management. Modern glossmeters are increasingly equipped with wireless communication capabilities such as Bluetooth and Wi-Fi, enabling effortless data transfer to computers, mobile devices, and cloud-based platforms. This connectivity facilitates real-time data logging, remote monitoring, and integration with quality management systems (QMS) and enterprise resource planning (ERP) software, streamlining data flow across the manufacturing ecosystem. The development of intuitive touch-screen interfaces and robust, user-friendly software for data analysis and reporting has also greatly enhanced the usability of these instruments, making complex measurements more accessible to a broader range of operators. These software solutions often include features for trend analysis, statistical process control, and customizable reporting templates, adding substantial value to the raw measurement data and empowering users to make informed decisions about product quality and process optimization.

Beyond core measurement and data handling, the technological evolution in the glossmeter market also extends to the physical design and ergonomic considerations of the devices. There is a growing trend towards miniaturization and the development of highly portable, handheld glossmeters that offer convenience and flexibility for on-site measurements without compromising accuracy. These compact designs often incorporate durable materials and enhanced environmental resistance, making them suitable for use in demanding industrial settings. Additionally, the increasing focus on the Internet of Things (IoT) and Industry 4.0 paradigms is driving the development of "smart" glossmeters that can autonomously communicate with other machines and systems on the production line. This allows for automated quality inspection, predictive maintenance, and closed-loop process control, representing a significant leap towards fully integrated and intelligent manufacturing environments. These technological advancements collectively define a dynamic and forward-looking market, continuously striving for higher precision, greater efficiency, and seamless operational integration.

Regional Highlights

- North America: A mature market characterized by stringent quality standards and a strong emphasis on R&D. Demand is driven by the automotive, aerospace, and high-tech manufacturing sectors, with a focus on high-precision and automated gloss measurement solutions. The region also sees significant adoption in sophisticated material science research and advanced coating applications.

- Europe: Similar to North America, Europe is a well-established market with robust demand from the automotive, paints & coatings, and packaging industries. Strict environmental regulations and quality mandates, particularly from the EU, propel the adoption of advanced glossmeter technologies. Germany, the UK, and France are key contributors, focusing on innovation and high-quality finishes.

- Asia Pacific (APAC): The fastest-growing region, driven by rapid industrialization, expanding manufacturing bases, and increasing foreign investments in countries like China, India, Japan, and South Korea. The automotive, consumer electronics, and construction sectors are booming, leading to a significant uptake of glossmeters for quality control and aesthetic consistency. Cost-effectiveness and production efficiency are key drivers here.

- Latin America: An emerging market experiencing steady growth dueably due to industrial development, particularly in Brazil and Mexico. Increasing foreign direct investment in manufacturing and infrastructure projects is boosting the demand for quality control instruments, including glossmeters, to meet international standards. The paints, automotive, and construction sectors are key growth areas.

- Middle East & Africa (MEA): This region is also an emerging market, driven by significant infrastructure development, expansion in construction, oil & gas, and automotive industries. Growing awareness of quality control and the need for standardized finishes in burgeoning industries are fostering the adoption of glossmeters, with key demand centers in the UAE, Saudi Arabia, and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Glossmeter Market.- Konica Minolta Sensing, Inc.

- BYK-Gardner GmbH (Altana AG)

- Elcometer Ltd.

- Rhopoint Instruments Ltd.

- TQC Sheen (Part of Industrial Physics)

- HORIBA, Ltd.

- Novo-Gloss (Part of Industrial Physics)

- Defelsko Corporation

- Sheen Instruments (Part of Industrial Physics)

- X-Rite, Incorporated (Danaher Corporation)

- PCE Instruments

- Datacolor

- Nippon Denshoku Industries Co., Ltd.

- Zehntner GmbH Testing Instruments

- ElektroPhysik Dr. Steingroever GmbH & Co. KG

- Qualitest International Inc.

- Test Rite Products Corporation

- Beijing Time High Technology Ltd.

- Erichsen GmbH & Co. KG

- ZGM Instruments Co., Limited

Frequently Asked Questions

What is a glossmeter used for?

A glossmeter is an optical instrument primarily used to measure the specular reflectance of a surface, quantifying its "gloss" or "sheen." It is indispensable in industries like automotive, paints and coatings, plastics, and paper, where surface appearance and finish quality are critical. The instrument helps ensure product consistency, detect surface imperfections, and maintain adherence to specific aesthetic and quality standards, playing a vital role in quality control and research and development processes by providing objective and repeatable measurements of surface reflectivity.

How do glossmeters work?

Glossmeters operate by projecting a precisely controlled beam of light onto a test surface at a specific angle (typically 20°, 60°, or 85°) and then measuring the amount of light reflected at an equal but opposite angle. The intensity of the reflected light is detected by a photodetector and converted into a numerical value called Gloss Units (GU). A highly reflective, smooth surface will reflect more light directly, resulting in a higher GU reading, while a matte or rough surface will scatter more light, yielding a lower GU value. The measurement process is governed by specific international standards like ASTM D523 and ISO 2813 to ensure consistency and comparability.

What are the main types of glossmeters available in the market?

The glossmeter market offers several types categorized by the measurement angle and portability. Common types include single-angle glossmeters (e.g., 60° for general purpose), dual-angle glossmeters (e.g., 20°/60° for high and medium gloss), and triple-angle glossmeters (e.g., 20°/60°/85° for high, medium, and low gloss/matte finishes). Multi-angle glossmeters provide even more comprehensive surface characterization, particularly for complex materials. Additionally, glossmeters are available as portable/handheld devices for on-site flexibility and benchtop/laboratory instruments for higher precision and controlled environments, catering to diverse industrial and research needs.

Which industries heavily rely on glossmeters for quality control?

Numerous industries heavily rely on glossmeters to maintain stringent quality control standards and ensure product aesthetics. Key sectors include the automotive industry for paintwork and interior finishes, the paints and coatings industry for product formulation and application quality, and the plastics and rubber industries for molded parts and films. The paper and pulp sector uses them for print quality and packaging appearance, while the consumer electronics and furniture industries utilize them to ensure the visual appeal and consistency of their products. Glossmeters are essential tools for any industry where surface finish and visual appeal directly impact product perception and market value.

What impact does AI have on glossmeter technology and market trends?

Artificial Intelligence (AI) is significantly impacting glossmeter technology by enhancing data analysis, enabling predictive quality control, and facilitating integration into smart manufacturing. AI algorithms can interpret vast amounts of gloss data to identify subtle trends and anomalies, moving beyond simple readings to provide deeper, actionable insights. This allows for predictive maintenance of glossmeters, automated anomaly detection on surfaces, and proactive adjustments to production processes, reducing waste and improving efficiency. AI also supports seamless integration with broader Industry 4.0 systems, fostering automated quality inspection and data-driven decision-making, thereby revolutionizing surface quality management and driving smarter, more efficient manufacturing operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager