Glycol Pumps Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435765 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Glycol Pumps Market Size

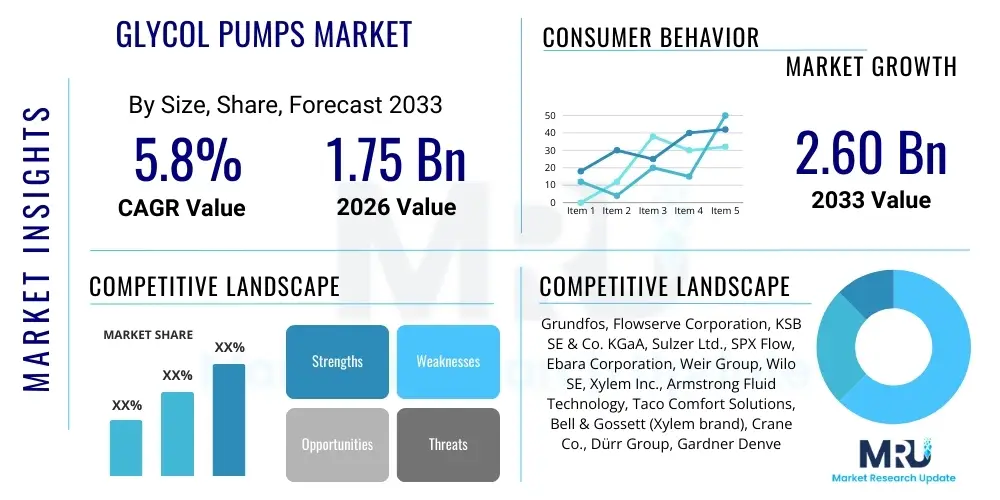

The Glycol Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.75 Billion in 2026 and is projected to reach USD 2.60 Billion by the end of the forecast period in 2033. This consistent expansion is primarily fueled by the increasing demand for energy-efficient HVAC (Heating, Ventilation, and Air Conditioning) systems globally, particularly in commercial and industrial infrastructure projects that rely on glycol solutions for optimal heat transfer and freeze protection.

Glycol Pumps Market introduction

Glycol pumps are essential fluid transfer devices designed specifically to circulate glycol-based solutions, such as ethylene glycol or propylene glycol, used primarily as coolants or anti-freeze agents in various industrial, commercial, and residential applications. These solutions are crucial for maintaining temperature stability, preventing corrosion, and protecting equipment from freezing, especially in closed-loop systems like chillers, solar heating units, and heat recovery ventilation systems. The primary product description centers on highly efficient centrifugal and positive displacement pumps engineered with specialized seals and materials compatible with viscous glycol mixtures. Major applications span industrial process cooling, commercial HVAC infrastructure, renewable energy systems (geothermal and solar), and automotive manufacturing. The market driving factors include stringent energy efficiency regulations compelling upgrades to modern pumping technology, rapid urbanization leading to increased construction activities globally, and the growing adoption of renewable energy technologies which frequently utilize glycol loops for thermal management. The inherent benefits of glycol solutions, such as superior heat transfer capabilities and freeze point depression, cement the necessity for reliable, high-performance glycol pumps across critical infrastructure sectors.

Glycol Pumps Market Executive Summary

The global Glycol Pumps Market is currently experiencing robust growth driven by significant business trends centered around sustainability and system optimization. Key business trends involve the shift towards smart pumping technologies equipped with Variable Frequency Drives (VFDs) and IoT connectivity, which enhance operational efficiency and reduce energy consumption in large-scale commercial applications. Segment trends highlight the dominance of the HVAC sector due to continuous infrastructure development, although the industrial process segment, particularly chemical and oil & gas, is showing accelerated demand for heavy-duty, high-flow rate positive displacement pumps suitable for challenging environments. Regionally, the Asia Pacific (APAC) market is exhibiting the fastest growth due to extensive industrialization and governmental investments in commercial real estate and district cooling projects in China, India, and Southeast Asian nations. Conversely, established markets like North America and Europe are focusing on replacement cycles and technological upgrades to comply with stringent environmental standards, driving demand for premium, energy-efficient centrifugal pump models.

AI Impact Analysis on Glycol Pumps Market

User queries regarding AI's influence on the Glycol Pumps Market frequently focus on predictive maintenance capabilities, energy optimization through adaptive control, and the potential for autonomous system management. Users are concerned about how AI algorithms can interpret pump performance data, identify anomalies before failure, and ultimately minimize downtime in critical cooling applications. There is high expectation that AI integration, particularly through embedded sensors and cloud-based analytics platforms, will transform traditional reactive maintenance strategies into proactive, condition-based monitoring programs. This technological shift is anticipated to significantly extend the operational lifespan of glycol pumps, optimize energy usage by adjusting pump speed based on real-time thermal load requirements, and revolutionize pump design through AI-driven simulation and optimization, leading to highly customized and efficient fluid transfer solutions tailored for specific glycol compositions and temperature profiles.

- AI enhances predictive maintenance protocols by analyzing vibration, temperature, and pressure data, forecasting potential mechanical failures in advance of catastrophic events.

- Generative AI models accelerate the design phase of high-efficiency impellers and casings, optimizing hydraulic performance specific to glycol viscosity characteristics.

- Machine learning algorithms embedded in VFD controls optimize pump speed in real-time based on fluctuating thermal loads, achieving significant energy savings (up to 30%) in HVAC systems.

- AI facilitates autonomous system operation and remote diagnostics, crucial for unmanned industrial facilities and complex district heating/cooling networks utilizing glycol loops.

- Improved supply chain forecasting and inventory management of specialized components (seals, motors) are achieved through AI-driven demand prediction models.

DRO & Impact Forces Of Glycol Pumps Market

The dynamics of the Glycol Pumps Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities, collectively defined as DRO & Impact Forces. Key drivers include the global mandate for enhancing energy efficiency in buildings and industrial processes, propelling the adoption of modernized, highly efficient pumps compliant with international standards like IE3/IE4 ratings. Furthermore, the expansion of commercial and residential infrastructure, particularly in developing economies, necessitates reliable heat transfer systems using glycol for climate control. Conversely, significant restraints include the high initial capital investment required for specialized, high-performance pumps and associated control systems, alongside the technical complexity involved in maintaining and servicing specialized glycol circuits which require precision balancing and fluid management. Opportunities are abundant in the aftermarket service sector, focusing on retrofitting older systems with smart, IoT-enabled pumps, and the burgeoning utilization of glycol-based solar and geothermal heating systems, which presents a green growth avenue. The overall impact force is moderately high, skewed positively by strong governmental support for energy conservation measures worldwide.

Segmentation Analysis

The Glycol Pumps Market is comprehensively segmented based on Type, Application, End-User, and Fluid Type, providing granular insights into varying market demands and technological preferences across sectors. The Type segment is critical, distinguishing between dynamic (centrifugal) and positive displacement technologies, with centrifugal pumps typically dominating high-flow, low-head HVAC applications, while positive displacement pumps are preferred for high-viscosity or metering tasks in industrial chemical processing. Application segmentation reveals the dominant role of commercial cooling systems, followed closely by robust demand from the oil & gas and chemical processing industries where specialized sealing and corrosion resistance are paramount. Analyzing these segments provides strategic clarity for manufacturers to align product development with specific end-user requirements, ensuring compliance with diverse operational standards and fluid characteristics.

- By Type:

- Centrifugal Pumps (Horizontal Split Case, Vertical Inline, End Suction)

- Positive Displacement Pumps (Gear Pumps, Lobe Pumps, Diaphragm Pumps)

- Submersible Pumps

- By Application:

- HVAC Systems (Chillers, Cooling Towers, Heat Pumps)

- Industrial Process Cooling (Chemical Processing, Pharmaceuticals, Food & Beverage)

- Oil & Gas (Heat Exchangers, Process Stabilization)

- Renewable Energy Systems (Geothermal, Solar Thermal)

- Automotive Manufacturing and Testing

- By End-User:

- Commercial Buildings (Hospitals, Data Centers, Office Complexes)

- Industrial Facilities (Manufacturing Plants, Refineries)

- Power Generation Plants

- Residential (Hydronic Heating/Cooling)

- By Fluid Type:

- Ethylene Glycol (EG) Solutions

- Propylene Glycol (PG) Solutions

- Blended Glycol Solutions (Inhibited and Non-Inhibited)

Value Chain Analysis For Glycol Pumps Market

The Value Chain for the Glycol Pumps Market begins with upstream activities involving raw material procurement, including specialized metals (stainless steel, cast iron, alloys), sealing materials (EPDM, Viton), and motor components. Manufacturers then focus on core activities: design, precision machining, assembly, and rigorous hydraulic testing to ensure efficiency and reliability under varying temperature and viscosity conditions inherent to glycol circulation. The downstream component of the chain primarily involves sophisticated distribution channels. Direct sales are common for large, customized industrial systems, providing technical support and tailored solutions directly to large EPC contractors and industrial end-users. Conversely, standardized pumps for commercial HVAC and smaller applications rely heavily on robust indirect channels, utilizing specialized distributors, wholesalers, and mechanical contractors who manage installation and immediate aftermarket support, crucial for market reach and timely project execution.

Glycol Pumps Market Potential Customers

The primary consumers and buyers of glycol pumps span critical sectors requiring reliable thermal management and freeze protection for sensitive equipment or extensive infrastructure. Potential customers include major Engineering, Procurement, and Construction (EPC) firms responsible for developing large-scale commercial real estate and industrial complexes, as these entities specify and integrate pumping solutions into comprehensive HVAC and process cooling blueprints. Furthermore, facility management companies operating data centers, hospitals, and large corporate campuses are continuous purchasers, driven by replacement cycles and upgrades aimed at improving energy efficiency and system redundancy. The fastest-growing customer segment includes original equipment manufacturers (OEMs) specializing in chillers, heat pumps, and specialized industrial refrigeration units, who integrate glycol pumps directly into their final product offerings, demanding high-volume, reliable components that meet stringent performance specifications and international certifications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.75 Billion |

| Market Forecast in 2033 | USD 2.60 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Grundfos, Flowserve Corporation, KSB SE & Co. KGaA, Sulzer Ltd., SPX Flow, Ebara Corporation, Weir Group, Wilo SE, Xylem Inc., Armstrong Fluid Technology, Taco Comfort Solutions, Bell & Gossett (Xylem brand), Crane Co., Dürr Group, Gardner Denver (Ingersoll Rand), Gorman-Rupp, Seepex, Sundyne, Teikoku Electric Mfg. Co., Ltd., IWAKI America. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Glycol Pumps Market Key Technology Landscape

The technological evolution within the Glycol Pumps Market is heavily influenced by the industry-wide focus on energy efficiency, connectivity, and material science innovation to handle corrosive glycol solutions effectively. Contemporary glycol pumps increasingly incorporate advanced motor technologies, specifically EC (Electronically Commutated) motors and high-efficiency induction motors paired with Variable Frequency Drives (VFDs). VFD integration is paramount as it allows the pump to modulate flow based on instantaneous system demand, significantly reducing power consumption and wear compared to fixed-speed operation. Furthermore, the development of specialized mechanical seals and materials, such as robust ceramic or silicon carbide components, ensures long-term compatibility with varying glycol concentrations and minimizes leakage, a common challenge when handling heat transfer fluids.

Digitalization forms the second critical pillar of the technological landscape. Modern glycol pump systems are often equipped with embedded sensors that monitor operational parameters such as flow rate, pressure, temperature, and vibration. This data is leveraged via IoT connectivity to cloud-based monitoring platforms, enabling real-time remote diagnostics and performance benchmarking. This shift towards smart pumping facilitates proactive maintenance scheduling and optimizes system performance dynamically, adhering to the principles of Industry 4.0. Furthermore, noise and vibration reduction technologies, including specialized baseplates and dampening systems, are becoming standard features, especially for glycol pumps installed in noise-sensitive environments like commercial offices and hospitals.

Material science continues to drive innovation, particularly in the selection of elastomers and metals for pump casings and impellers. Propylene glycol, while less toxic, often presents sealing challenges due to its viscosity profile, necessitating high-grade materials and precision engineering to prevent cavitation and ensure efficiency. Research is ongoing into novel protective coatings and specialized internal geometries designed to specifically handle the lower freezing points and higher viscosities of concentrated glycol solutions without compromising pump longevity or hydraulic performance. This focus on material optimization directly addresses operational longevity in harsh or fluctuating temperature environments.

Regional Highlights

The regional analysis of the Glycol Pumps Market reveals diverse growth trajectories influenced by local climate conditions, regulatory frameworks, and infrastructure development cycles. North America, characterized by its mature industrial base and severe weather variations requiring robust freeze protection, represents a substantial market share. Demand here is largely driven by the continuous modernization of commercial HVAC infrastructure, the proliferation of large data centers requiring precise process cooling management, and stringent energy efficiency mandates imposed by governmental bodies like the Department of Energy (DOE) and organizations such as ASHRAE. The U.S. and Canada prioritize high-efficiency, VFD-enabled centrifugal pumps suitable for large-scale closed-loop hydronic systems, emphasizing long service life and advanced monitoring capabilities. Replacement and retrofit cycles form a significant component of regional demand.

Europe stands as a leader in adopting sustainable and decentralized heating and cooling solutions, providing a strong environment for glycol pump adoption, especially in the renewable energy sector, including geothermal and solar thermal applications. Driven by ambitious climate targets set by the European Union, there is a high penetration rate of highly efficient circulator pumps and sophisticated control systems. Germany, the UK, and the Scandinavian countries show consistent demand, focusing on reliability and minimal environmental impact. Furthermore, the region’s established pharmaceutical and chemical industries require precise temperature control, mandating the use of specialized positive displacement pumps for chemical-grade propylene glycol circulation.

Asia Pacific (APAC) is forecast to be the fastest-growing region, powered by unprecedented rates of urbanization and massive investments in commercial and residential construction, particularly across China, India, and Southeast Asian nations. Rapid industrialization, coupled with the necessity for process cooling in manufacturing hubs (electronics, automotive), fuels substantial demand for glycol pumping equipment. While price sensitivity remains a factor, the shift toward higher quality, reliable pumps is accelerated by the development of sophisticated infrastructure projects, such as district cooling systems, which rely heavily on efficient glycol circulation to manage large thermal loads effectively across city centers.

Latin America and the Middle East & Africa (MEA) present emerging market opportunities. In the Middle East, the focus is heavily concentrated on extreme cooling demands for large commercial complexes, hospitality infrastructure, and data centers where chilled water loops often incorporate glycol to optimize heat rejection in high ambient temperatures. Similarly, Latin American countries show steady growth tied to industrial expansion and infrastructure projects, although regulatory standardization and the widespread adoption of advanced pumping technologies are still developing. In both regions, market penetration is often linked to the success of major international construction and engineering firms operating locally.

- North America: Market maturity, strong regulatory push for high-efficiency pumps, high demand from data centers and large commercial HVAC replacements.

- Europe: Focus on sustainability, high adoption rates in geothermal and solar thermal systems, stringent energy standards driving VFD integration.

- Asia Pacific (APAC): Highest growth trajectory driven by rapid urbanization, massive industrialization, and expansion of district cooling systems in major cities.

- Middle East & Africa (MEA): Significant demand for process cooling in extreme climates, driven by oil & gas infrastructure and large hospitality/commercial projects.

- Latin America: Steady growth fueled by industrial modernization and commercial infrastructure development, primarily focusing on cost-effective, reliable solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Glycol Pumps Market.- Grundfos

- Flowserve Corporation

- KSB SE & Co. KGaA

- Sulzer Ltd.

- SPX Flow

- Ebara Corporation

- Weir Group

- Wilo SE

- Xylem Inc.

- Armstrong Fluid Technology

- Taco Comfort Solutions

- Bell & Gossett (A Xylem brand)

- Crane Co.

- Dürr Group

- Gardner Denver (Ingersoll Rand)

- Gorman-Rupp

- Seepex

- Sundyne

- Teikoku Electric Mfg. Co., Ltd.

- IWAKI America

- Dover Corporation (Pump Solutions Group)

- Viking Pump, Inc.

- Netzsch Pumps & Systems

- Allweiler GmbH

- ClydeUnion Pumps (Celeros Flow Technology)

Frequently Asked Questions

Analyze common user questions about the Glycol Pumps market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a glycol pump in commercial HVAC systems?

The primary function of a glycol pump in commercial HVAC systems is to circulate a mixture of water and glycol (anti-freeze solution) through chillers, cooling towers, and heat exchangers. This prevents the system fluid from freezing in low-temperature environments and enhances heat transfer efficiency for optimal climate control and equipment protection.

Which type of glycol solution requires specialized consideration for pump material selection?

Ethylene Glycol (EG) solutions, especially when used in high-temperature or high-concentration applications, require careful selection of pump materials and seals. While Propylene Glycol (PG) is less toxic, its higher viscosity profile at low temperatures demands pumps with robust motors and precise hydraulic design to maintain flow efficiency and prevent cavitation.

How does the integration of Variable Frequency Drives (VFDs) impact the energy consumption of glycol pumps?

VFD integration significantly reduces energy consumption by enabling the pump speed to be dynamically adjusted based on the real-time thermal load demand of the system, rather than operating at a fixed maximum speed. This optimization results in substantial power savings (often governed by the cube law) and minimizes wear and tear on the pump components.

Which geographical region is expected to experience the fastest market growth for glycol pumps, and why?

The Asia Pacific (APAC) region is projected to register the fastest growth due to extensive infrastructure development, rapid industrialization, high investments in commercial real estate (data centers and large office complexes), and increasing adoption of district cooling technologies across key economies like China and India.

What is the significance of smart pumping technology in the Glycol Pumps Market?

Smart pumping technology, incorporating IoT connectivity and AI-driven monitoring, is crucial for implementing predictive maintenance strategies. It allows users to monitor operational health parameters remotely, anticipate component failures, optimize fluid circulation dynamically for energy efficiency, and ensure maximum uptime in critical industrial and commercial cooling applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager