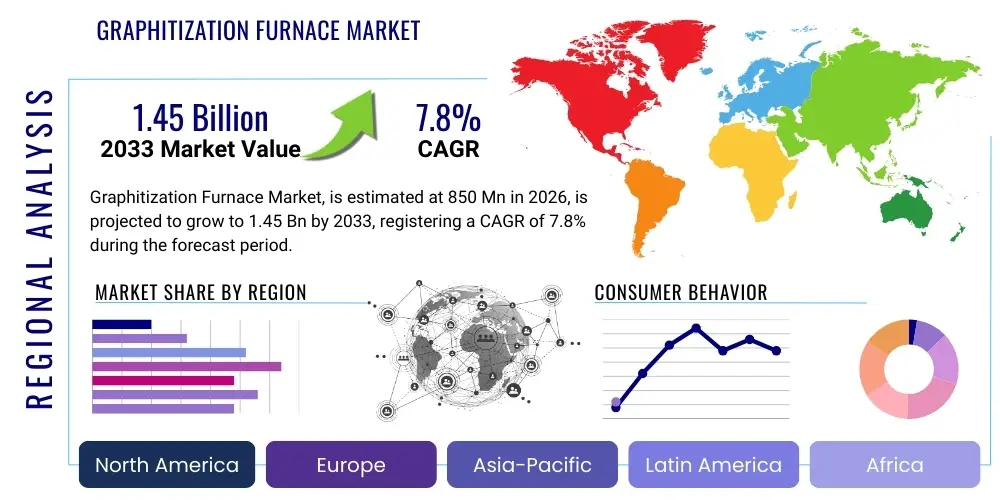

Graphitization Furnace Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439903 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Graphitization Furnace Market Size

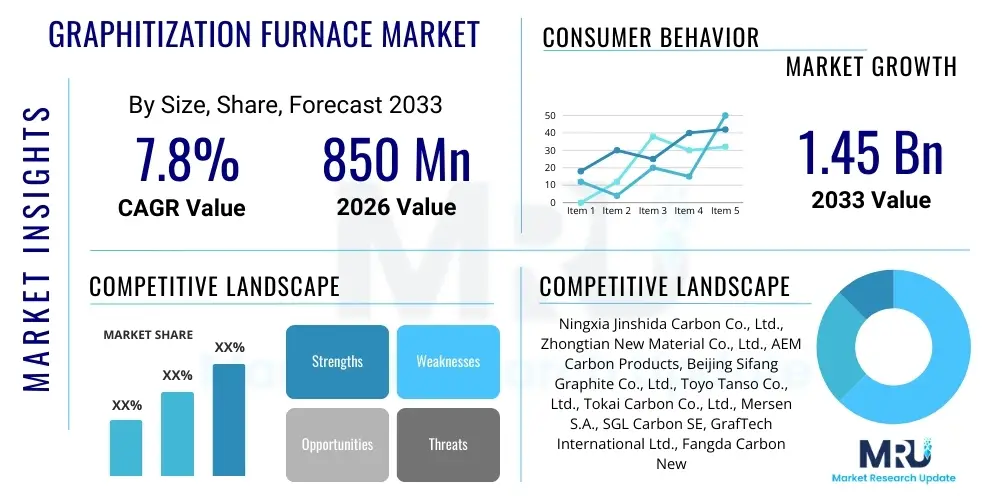

The Graphitization Furnace Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 850 million in 2026 and is projected to reach USD 1.45 billion by the end of the forecast period in 2033.

Graphitization Furnace Market introduction

The Graphitization Furnace Market is a pivotal industrial sector dedicated to the manufacturing and processing of advanced carbon materials through high-temperature thermal treatment. Graphitization furnaces are specialized thermal processing systems designed to convert amorphous carbon into highly crystalline graphite, or to improve the crystalline structure of existing graphite and carbon materials, by subjecting them to extremely high temperatures, often exceeding 2500°C, under precisely controlled atmospheric conditions. This process, known as graphitization, significantly enhances the material's electrical conductivity, thermal conductivity, mechanical strength, and chemical inertness, making it suitable for a multitude of demanding applications. The primary product description encompasses various types of furnaces, including batch and continuous systems, utilizing methods like resistance heating (Acheson process, L&P furnace) or induction heating, each tailored to specific production scales and material requirements. These furnaces are characterized by robust construction capable of withstanding extreme temperatures, advanced insulation materials, and sophisticated power and control systems to ensure uniformity and efficiency.

Major applications for graphitized materials, and consequently for graphitization furnaces, span across critical industrial sectors. A predominant application is in the production of graphite electrodes for electric arc furnaces (EAFs) in the steel industry, where their high electrical conductivity and resistance to thermal shock are indispensable. Another significant area is the graphitization of carbon fibers, transforming precursor fibers into high-performance carbon fibers used in aerospace, automotive, and sporting goods industries due to their exceptional strength-to-weight ratio. Furthermore, special graphite materials for semiconductor manufacturing, nuclear reactors, chemical processing equipment, and advanced battery components (e.g., anodes for lithium-ion batteries) heavily rely on graphitization processes to achieve the required purity and structural integrity. The benefits derived from these furnaces are numerous, including the ability to produce materials with superior electrical and thermal conductivity, enhanced mechanical properties, improved corrosion resistance, and high purity levels essential for sensitive applications. These attributes directly translate into higher performance and longer lifespan for end-products.

Driving factors propelling the expansion of the Graphitization Furnace Market are deeply intertwined with global industrial growth and technological advancements. The burgeoning demand for high-performance carbon materials in next-generation technologies, particularly in the electric vehicle (EV) battery sector and the semiconductor industry, is a primary catalyst. As the world transitions towards sustainable energy and advanced electronics, the need for materials with enhanced properties escalates, driving investment in graphitization capacities. Additionally, the increasing adoption of electric arc furnaces in steelmaking, due to environmental considerations and efficiency benefits over traditional blast furnaces, fuels the demand for high-quality graphite electrodes. Continuous innovation in materials science, coupled with stringent quality requirements across various end-use industries, further necessitates sophisticated graphitization processes, thus underpinning the steady growth and technological evolution within the graphitization furnace market. The push for greater energy efficiency and reduced emissions in manufacturing processes also encourages the development and adoption of advanced, more efficient graphitization furnace designs.

Graphitization Furnace Market Executive Summary

The Graphitization Furnace Market is currently experiencing dynamic shifts driven by a confluence of evolving business trends, regional growth patterns, and distinct segment-specific developments. From a business perspective, the market is witnessing a trend towards consolidation among manufacturers, aiming for economies of scale and enhanced research and development capabilities to offer more integrated and technologically advanced solutions. Customization and modularity are becoming increasingly important, as end-users demand furnaces tailored to specific material properties, production volumes, and energy efficiency targets. Furthermore, there is a growing emphasis on lifecycle management and after-sales services, including maintenance, upgrades, and operational support, reflecting a shift towards value-added offerings beyond just equipment sales. Manufacturers are also focusing on integrating automation and smart controls to improve process consistency, reduce operational costs, and enhance safety within graphitization facilities. Strategic partnerships and collaborations between furnace manufacturers and material producers are also on the rise, fostering innovation and accelerating market penetration of new technologies and applications. The global competitive landscape is intensifying, with both established players and emerging entrants striving for market share through technological differentiation and cost-effectiveness. The increasing scrutiny over environmental impact is also pushing manufacturers to develop more energy-efficient and environmentally compliant furnace designs, incorporating features such as waste heat recovery and optimized gas handling systems, further shaping business strategies and investment priorities across the industry.

Regional trends indicate a significant impetus from the Asia Pacific (APAC) region, particularly China and India, driven by rapid industrialization, expanding steel production, and burgeoning electric vehicle battery manufacturing capacities. These countries are not only major consumers of graphitized products but are also emerging as key manufacturing hubs for graphitization furnaces due to lower production costs and increasing technological expertise. North America and Europe, while mature markets, are experiencing growth propelled by stringent quality demands in aerospace, defense, and semiconductor industries, alongside a renewed focus on advanced materials research and development. Investments in renewable energy infrastructure and the growth of electric mobility are also significant drivers in these regions. Latin America and the Middle East & Africa (MEA) are projected to show nascent but steady growth, fueled by industrial expansion and the exploration of new manufacturing capabilities, albeit starting from a smaller base. The availability of raw materials and energy resources, coupled with government initiatives supporting manufacturing, will play a crucial role in shaping the trajectory of these emerging regional markets. Geopolitical stability and trade policies also significantly influence the supply chain dynamics and investment decisions across these regions.

Segment trends reveal a robust demand for high-temperature continuous graphitization furnaces, favored for their efficiency and throughput in large-scale production of materials like graphite electrodes and carbon fibers. Batch furnaces, while smaller in scale, remain crucial for specialized applications requiring extreme precision, custom runs, or R&D purposes, especially for new advanced materials with unique graphitization profiles. Application-wise, the graphite electrodes segment continues to dominate due to its established use in the steel industry, but the fastest growth is anticipated from applications in EV batteries and advanced carbon fibers, fueled by the global push for lightweight materials and sustainable energy solutions. The semiconductor industry's increasing demand for ultra-high purity graphite components is also a rapidly growing niche, driving innovation in precision graphitization technologies. Furthermore, material type segmentation highlights a growing interest in isotropic graphite and other specialty carbon materials requiring precise and uniform graphitization. End-user industry segmentation confirms the prominence of metals and mining, but significant diversification is occurring towards aerospace, automotive, electronics, and even medical sectors, each presenting unique demands for graphitized products. The evolution of these segments underscores a broader market trend towards diversification, specialization, and higher performance requirements for graphitized materials across a broader spectrum of advanced industrial applications.

AI Impact Analysis on Graphitization Furnace Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the traditionally energy-intensive and precise operations within the Graphitization Furnace Market. Common questions revolve around AI's ability to enhance efficiency, reduce operational costs, improve product quality, and mitigate environmental impact. There is considerable interest in how AI can optimize process parameters, predict equipment failures, and enable smarter decision-making in real-time. Users also express concerns regarding the complexity of integrating AI systems into existing infrastructure, the need for specialized data scientists, and the potential cybersecurity risks associated with networked industrial equipment. Expectations are high that AI will lead to more autonomous operations, consistent product output, and significant energy savings, thereby addressing some of the core challenges faced by the industry, such as high energy consumption and the difficulty of maintaining precise temperature profiles across large volumes of material. The overarching theme is a desire for greater operational intelligence, predictive capabilities, and a pathway to more sustainable and cost-effective graphitization processes, alongside an awareness of the implementation hurdles.

- Predictive Maintenance: AI algorithms can analyze real-time sensor data from graphitization furnaces, including temperature, power consumption, vibration, and atmospheric conditions, to predict potential equipment failures before they occur. This enables proactive maintenance scheduling, minimizing costly downtime, extending the lifespan of critical components like heating elements and insulation, and ensuring continuous production, thereby significantly improving operational reliability and reducing maintenance expenditures.

- Process Optimization and Control: AI-driven control systems can continuously monitor and adjust furnace parameters suchibilities as heating rates, holding temperatures, ramp-down cycles, and gas flow rates with unprecedented precision. By learning from vast datasets of past operations and material outcomes, AI can optimize the graphitization cycle for specific carbon materials, achieving desired crystalline structures and purity levels more efficiently, reducing energy consumption, and improving consistency in product quality across different batches or continuous runs.

- Enhanced Quality Control: AI-powered vision systems and data analytics can perform real-time inspection of graphitized products for defects, structural inconsistencies, or deviations from target specifications. This allows for immediate identification and correction of process anomalies, reducing waste, improving overall product yield, and ensuring that materials meet the stringent quality requirements of high-performance applications such as aerospace components, semiconductors, and EV batteries.

- Energy Management and Efficiency: Graphitization furnaces are highly energy-intensive. AI can analyze energy consumption patterns, identify inefficiencies, and recommend optimal operational schedules and parameter adjustments to reduce power usage without compromising product quality. This includes optimizing power profiles, integrating with renewable energy sources, and managing peak demand, leading to substantial reductions in energy costs and a smaller carbon footprint for manufacturers.

- Accelerated Research and Development: AI and machine learning can dramatically accelerate the development of new carbon materials and graphitization processes. By simulating various processing conditions and predicting material properties, AI can help researchers identify optimal parameters for novel precursors or discover new high-performance graphite compositions more rapidly than traditional trial-and-error methods, thereby fostering innovation and bringing new products to market faster.

- Automated Data Analysis and Reporting: AI can automate the collection, analysis, and reporting of vast amounts of operational data from graphitization furnaces. This reduces manual labor, eliminates human error, and provides deeper insights into process performance, material behavior, and equipment health. Such automated reporting facilitates compliance, improves decision-making, and supports continuous improvement initiatives within manufacturing facilities.

- Supply Chain Optimization: AI can optimize the procurement of raw materials and the scheduling of production based on market demand forecasts. By analyzing various factors such as raw material availability, pricing fluctuations, and transportation logistics, AI helps manufacturers make more informed decisions, reduce inventory costs, and ensure a smooth and efficient supply chain for the graphitization furnace ecosystem.

DRO & Impact Forces Of Graphitization Furnace Market

The Graphitization Furnace Market is significantly influenced by a complex interplay of drivers, restraints, opportunities, and broader impact forces that collectively shape its trajectory and competitive landscape. Key drivers include the escalating global demand for high-performance carbon materials, which are integral to numerous advanced industries such as electric vehicles (EVs), semiconductors, aerospace, and defense. The shift towards sustainable energy solutions, particularly the proliferation of lithium-ion batteries and fuel cells, directly translates into a higher demand for graphitized anode materials, fueling the need for more sophisticated and efficient graphitization furnaces. Furthermore, the increasing adoption of electric arc furnaces (EAFs) in the steel industry, driven by environmental regulations and efficiency benefits, sustains a robust demand for high-quality graphite electrodes, a primary product of graphitization. Continuous advancements in materials science and engineering, leading to new applications for graphitized products, also act as a strong market impetus. The ongoing research and development in carbon-based composites and their expanded use in lightweight structures and thermal management solutions further underpin the growth, requiring precise control over the graphitization process to achieve optimal material properties. The desire for enhanced material purity, critical for sensitive applications like nuclear reactors and high-end electronics, inherently relies on advanced graphitization technology.

However, the market also faces substantial restraints that can impede its growth. The high capital expenditure required for establishing or upgrading graphitization furnace facilities is a significant barrier to entry for new players and a major investment hurdle for existing ones. These furnaces are large-scale, technologically complex systems that demand considerable upfront investment in equipment, infrastructure, and specialized personnel. Moreover, the operational costs associated with graphitization, primarily due to the immense energy consumption required to reach extremely high temperatures, pose a continuous challenge for manufacturers, impacting profitability and product pricing. Fluctuations in energy prices, especially electricity, can significantly affect the economic viability of graphitization operations. Environmental concerns related to energy consumption and potential emissions, despite ongoing efforts towards cleaner technologies, lead to stringent regulatory frameworks that necessitate costly compliance measures and investment in emission control technologies. The availability and cost of high-quality raw materials, such as specific carbon precursors and refractory components, can also be volatile, affecting production costs and supply chain stability. The highly specialized nature of the technology and the scarcity of skilled personnel required to operate and maintain these complex furnaces present another operational restraint for the market.

Amidst these challenges, significant opportunities are emerging that could unlock new growth avenues for the Graphitization Furnace Market. The increasing focus on customization and modular furnace designs presents an opportunity for manufacturers to cater to diverse and niche applications, offering tailored solutions that optimize performance for specific material types and production volumes. The integration of Industry 4.0 technologies, including advanced sensors, automation, artificial intelligence, and predictive analytics, offers a substantial opportunity to enhance operational efficiency, reduce energy consumption, improve product consistency, and enable remote monitoring and control. This technological convergence can lead to "smart" graphitization facilities with higher throughput and lower operating costs. Furthermore, the retrofitting and upgrading of older furnaces with modern control systems and energy-efficient components represent a significant market opportunity, allowing existing facilities to improve performance without incurring the full cost of a new installation. The exploration of new and emerging applications for graphitized materials, such as in advanced medical devices, advanced energy storage systems beyond traditional batteries (e.g., supercapacitors), and lightweight structural components for urban mobility solutions, could open entirely new market segments. Lastly, the development of more sustainable and environmentally friendly graphitization processes, including waste heat recovery and novel heating methods, presents an opportunity for market differentiation and compliance with evolving global environmental standards, attracting environmentally conscious customers and investors.

The market is also shaped by several overarching impact forces. Technological advancements represent a primary impact force, continuously pushing the boundaries of what graphitization furnaces can achieve in terms of temperature uniformity, energy efficiency, and process control, directly influencing product quality and cost-effectiveness. The global economic conditions, including industrial output, investment cycles, and consumer demand for end-products relying on graphitized materials, significantly dictate market growth. Raw material availability and pricing dynamics, especially for crucial precursors and refractory materials, exert considerable influence on the supply chain and production costs. Geopolitical factors, such as trade policies, tariffs, and international relations, can disrupt supply chains, impact market access, and influence investment decisions, particularly for globally distributed manufacturing and consumption. Environmental regulations and sustainability mandates are increasingly powerful forces, compelling manufacturers to innovate towards greener processes and products, affecting design, operational practices, and market competitiveness. Finally, the competitive landscape itself, characterized by innovation, strategic alliances, and market consolidation, continuously reshapes market shares and technological leadership within the Graphitization Furnace Market, driving efficiency and pushing the envelope for performance.

Segmentation Analysis

Segmentation analysis of the Graphitization Furnace Market provides a granular view of its structure, dynamics, and growth potential across various dimensions. By dissecting the market into distinct categories based on product type, temperature capabilities, application areas, and end-user industries, stakeholders can gain profound insights into specific market trends, identify lucrative niches, and formulate targeted strategies. This detailed breakdown helps in understanding how different technologies and material processing needs contribute to the overall market landscape, enabling precise forecasting and strategic resource allocation. The diverse requirements of various industries, from the high-volume demands of steel production to the ultra-purity needs of semiconductors, necessitate a broad spectrum of furnace designs and operational parameters, making segmentation a critical tool for market assessment. Each segment exhibits unique growth drivers, competitive dynamics, and technological preferences, which are essential for market participants to comprehend for effective business planning and innovation efforts. The following sections delineate the key segmentation categories that collectively define the comprehensive structure of the graphitization furnace market.

- By Type:

- Batch Graphitization Furnaces: These furnaces process materials in discrete batches, allowing for precise control over individual processing cycles. They are typically preferred for smaller production volumes, specialized materials requiring unique thermal profiles, or research and development applications where flexibility and exact parameter adjustments are paramount. Batch furnaces offer high versatility for different material sizes and shapes, making them ideal for custom orders and high-value, low-volume production.

- Continuous Graphitization Furnaces: Designed for high-volume, continuous production, these furnaces move materials through different temperature zones in an uninterrupted flow. They are characterized by higher throughput and greater energy efficiency compared to batch systems, especially for standardized products. Sub-types include the Acheson furnace (resistance heating, materials packed around electrodes), L&P (Longitudinal & Peripheral) furnaces (also resistance heating, improved uniformity), and Resistance Rod furnaces (materials placed directly on resistance rods). These are predominantly used for large-scale manufacturing of graphite electrodes and carbon fibers.

- By Temperature:

- Medium Temperature Furnaces (up to 2000°C): These furnaces are used for initial graphitization stages or for materials that do not require ultra-high temperatures to achieve their desired properties. They are often employed in applications where a specific degree of carbon structure modification is sufficient, such as certain types of specialty carbon materials or precursor treatments. Their operating costs are generally lower than high-temperature counterparts.

- High Temperature Furnaces (above 2000°C, up to 3000°C): These represent the most advanced category, capable of achieving the highest levels of graphitization and purity. Essential for producing high-performance materials like ultra-high purity graphite electrodes, advanced carbon fibers, and nuclear graphite, these furnaces demand robust construction, specialized insulation, and sophisticated power delivery and control systems. They are critical for applications requiring superior electrical, thermal, and mechanical properties.

- By Application:

- Graphite Electrodes: A dominant application, graphitization furnaces are indispensable for producing high-quality graphite electrodes used in electric arc furnaces (EAFs) for steelmaking. The graphitization process enhances their electrical conductivity, thermal shock resistance, and mechanical strength, which are crucial for efficient and robust operation in high-temperature steel melting environments.

- Carbon Fibers: Graphitization is a critical step in the manufacturing of high-performance carbon fibers, transforming precursor fibers into highly crystalline structures. These fibers are vital for advanced composites used in aerospace, automotive, wind energy, and sporting goods industries due to their exceptional strength-to-weight ratio and stiffness.

- Special Graphite Materials: This segment includes the production of various specialized graphite products such as isotropic graphite, extruded graphite, and molded graphite. These materials find use in diverse applications including semiconductor manufacturing (e.g., susceptors, crucibles), chemical processing equipment, and high-temperature furnace components, where their unique properties are highly valued.

- Semiconductor Materials: The semiconductor industry requires ultra-high purity graphite components for processes like epitaxial growth, silicon wafer manufacturing, and chemical vapor deposition (CVD). Graphitization furnaces are used to purify and densify these graphite parts, ensuring minimal contamination and high performance in sensitive electronic fabrication environments.

- Nuclear Graphite: Highly specialized graphitization processes are required for nuclear-grade graphite, which serves as a neutron moderator and reflector in nuclear reactors. This application demands extremely high purity, consistent microstructure, and resistance to radiation damage, all of which are achieved through precise graphitization.

- Others: This category encompasses various niche applications, including graphitization for advanced battery anode materials (e.g., synthetic graphite for lithium-ion batteries), carbon felt for high-temperature insulation, and other emerging advanced carbon products in fields like medical devices and energy storage.

- By End-Use Industry:

- Metals and Mining: Primarily driven by the steel industry's demand for graphite electrodes in electric arc furnaces, this remains a cornerstone end-use sector. Graphitization furnaces play a direct role in the efficiency and sustainability of modern steel production.

- Aerospace and Defense: The need for lightweight, high-strength materials in aircraft, missiles, and defense systems fuels the demand for graphitized carbon fibers and specialty graphite components. These materials contribute to fuel efficiency and enhanced performance.

- Automotive: The automotive sector, particularly with the rise of electric vehicles, requires graphitized carbon fibers for lightweighting and synthetic graphite for battery anodes. Graphitization furnaces are crucial for producing these performance-enhancing materials.

- Semiconductor: With continuous miniaturization and increased performance demands, the semiconductor industry relies heavily on ultra-high purity graphitized components for various processing steps, including susceptors, heaters, and liners in vacuum furnaces.

- Chemical Processing: Graphitized materials exhibit excellent chemical inertness and corrosion resistance, making them suitable for use in heat exchangers, reactors, and linings in aggressive chemical environments. Furnaces supporting this sector produce specialized components.

- Renewable Energy (Solar, Fuel Cells): Graphitized materials are used in solar panel manufacturing (e.g., polysilicon production) and as bipolar plates or gas diffusion layers in fuel cells, contributing to the efficiency and durability of renewable energy technologies.

- Medical: Emerging applications in the medical field include specialized biocompatible carbon implants and components for medical devices, where the unique properties of graphitized materials are leveraged for their inertness and durability.

Value Chain Analysis For Graphitization Furnace Market

A comprehensive value chain analysis for the Graphitization Furnace Market reveals an intricate network of activities, from the sourcing of raw materials to the ultimate delivery of graphitized products to end-users, encompassing both upstream and downstream segments, along with various distribution channels. The upstream segment involves the critical supply of highly specialized raw materials and sophisticated components required for the construction and operation of these advanced furnaces. This includes manufacturers of high-purity refractory materials (such as graphite felt, carbon insulation, and ceramic fibers) that can withstand extreme temperatures and corrosive environments, as well as suppliers of heating elements (e.g., graphite electrodes, resistance rods, induction coils) which are at the heart of the thermal process. Additionally, the upstream chain incorporates providers of advanced power supply systems (transformers, rectifiers), precise temperature control units (PLCs, SCADA systems, sensors), inert gas supply systems (nitrogen, argon), and vacuum pumping equipment. These component manufacturers and raw material suppliers are crucial as the quality and performance of the graphitization furnace are directly dependent on the reliability and specifications of these foundational inputs. Innovation in these upstream segments, such as developing more energy-efficient heating elements or longer-lasting refractory materials, directly contributes to the overall efficiency and longevity of graphitization furnaces, impacting the entire value chain.

Graphitization Furnace Market Potential Customers

The Graphitization Furnace Market primarily serves a highly specialized and technologically advanced client base, comprising end-users and buyers who require superior quality graphitized carbon materials for their manufacturing processes. These potential customers are typically large industrial enterprises or specialized material producers operating in sectors that demand materials with exceptional electrical conductivity, thermal properties, mechanical strength, and chemical inertness. The most prominent group of customers includes graphite electrode manufacturers, who are integral to the steel industry's use of electric arc furnaces (EAFs). These manufacturers continuously require graphitization furnaces to produce the high-purity, high-density electrodes essential for efficient steelmaking. Their demand is directly linked to global steel production trends and the increasing adoption of EAF technology over traditional blast furnaces due to environmental benefits and flexibility.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 million |

| Market Forecast in 2033 | USD 1.45 billion |

| Growth Rate | CAGR 7.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ningxia Jinshida Carbon Co., Ltd., Zhongtian New Material Co., Ltd., AEM Carbon Products, Beijing Sifang Graphite Co., Ltd., Toyo Tanso Co., Ltd., Tokai Carbon Co., Ltd., Mersen S.A., SGL Carbon SE, GrafTech International Ltd., Fangda Carbon New Material Co., Ltd., IBIDEN Co., Ltd., Nippon Carbon Co., Ltd., SEC Carbon, Ltd., Caledonian Advanced Sintering, AVANCO GmbH, Liaoning Zizhu Group, Chengdu Jinsheng Carbon Co., Ltd., Shandong Sino-Carbon Graphite Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Graphitization Furnace Market Key Technology Landscape

The technological landscape of the Graphitization Furnace Market is characterized by a relentless pursuit of higher efficiency, greater precision, enhanced material quality, and reduced environmental impact. At its core, the primary technology involves specialized heating methods designed to achieve and sustain ultra-high temperatures required for carbon material transformation. Resistance heating, through methods like the Acheson process or longitudinal resistance furnaces (L&P furnaces), remains a dominant technology. This involves passing a high electric current directly through the carbon charge or through surrounding graphite heating elements, generating the immense heat necessary for graphitization. Another critical heating technology is induction heating, which utilizes electromagnetic fields to induce eddy currents within the material or a susceptor, generating heat internally. Induction furnaces offer advantages in terms of faster heating rates, more precise temperature control, and cleaner operation, making them increasingly popular for high-value specialty graphite production and research applications. The choice between resistance and induction heating often depends on the material type, desired production volume, and specific thermal profile requirements, with each method presenting unique benefits and operational considerations regarding energy consumption and scalability.

Regional Highlights

- North America: The North American Graphitization Furnace Market is characterized by a strong emphasis on advanced materials for high-tech industries such as aerospace, defense, and semiconductors. The region is a hub for research and development in carbon composites and specialty graphite, driving demand for high-precision, technologically advanced graphitization furnaces. Stringent quality requirements and a focus on domestic manufacturing capabilities, supported by government initiatives, contribute to market stability and growth. The growth of the electric vehicle industry and related battery material production also provides a significant impetus for demand. Manufacturers in this region often focus on offering highly customized solutions and integrated smart technologies to optimize production processes and meet specific customer needs.

- Europe: Europe represents a mature but technologically innovative market for graphitization furnaces, driven by strong industrial bases in Germany, France, and the UK. The region's automotive, aerospace, and renewable energy sectors are key consumers of graphitized materials, fostering continuous demand. There is a strong regional focus on sustainability, energy efficiency, and reducing carbon emissions, which encourages the adoption of advanced, greener furnace technologies and process optimization. European manufacturers are known for their engineering precision and adherence to high environmental and safety standards, driving innovation in waste heat recovery and cleaner graphitization methods. The region also benefits from robust R&D activities in new carbon materials and applications.

- Asia Pacific (APAC): The Asia Pacific region stands as the largest and fastest-growing market for graphitization furnaces globally, primarily propelled by rapid industrialization, burgeoning manufacturing capabilities, and significant investments in infrastructure across countries like China, India, Japan, and South Korea. China, in particular, dominates both the production and consumption of graphite electrodes and advanced carbon materials, leading to substantial demand for new furnace installations and capacity expansions. The booming electric vehicle market and associated battery production in the region further fuel the need for graphitized anode materials. India's expanding steel and automotive industries also contribute significantly to regional growth. Lower manufacturing costs and increasing technological expertise also position APAC as a key supplier of graphitization furnace equipment to other parts of the world.

- Latin America: The Latin American Graphitization Furnace Market is in its nascent stages but shows promising growth potential, driven by expanding industrial sectors and infrastructure development in countries like Brazil and Mexico. The steel industry in these nations is a primary driver, necessitating graphite electrodes for electric arc furnaces. While smaller in scale compared to APAC or North America, increasing foreign investment in manufacturing and a growing focus on industrial self-sufficiency are expected to spur demand for graphitization technologies. Challenges include economic volatility and the need for greater technological infrastructure development, but long-term prospects are positive as industrialization continues to advance across the region.

- Middle East and Africa (MEA): The Middle East and Africa region presents an emerging market for graphitization furnaces, with growth primarily linked to infrastructure projects, industrial diversification initiatives, and the development of local manufacturing capabilities, particularly in the metals and energy sectors. Countries like Saudi Arabia and the UAE are investing in steel production and other heavy industries, which will gradually increase the demand for graphitized products. While the market is currently small, strategic investments in industrialization and a push towards reducing reliance on oil revenues are expected to create new opportunities for graphitization furnace suppliers in the long term. Local content requirements and technology transfer initiatives may also influence market dynamics in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Graphitization Furnace Market.- Ningxia Jinshida Carbon Co., Ltd.

- Zhongtian New Material Co., Ltd.

- AEM Carbon Products

- Beijing Sifang Graphite Co., Ltd.

- Toyo Tanso Co., Ltd.

- Tokai Carbon Co., Ltd.

- Mersen S.A.

- SGL Carbon SE

- GrafTech International Ltd.

- Fangda Carbon New Material Co., Ltd.

- IBIDEN Co., Ltd.

- Nippon Carbon Co., Ltd.

- SEC Carbon, Ltd.

- Caledonian Advanced Sintering

- AVANCO GmbH

- Liaoning Zizhu Group

- Chengdu Jinsheng Carbon Co., Ltd.

- Shandong Sino-Carbon Graphite Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Graphitization Furnace market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a graphitization furnace?

A graphitization furnace is a specialized high-temperature thermal processing system designed to convert amorphous carbon materials into highly crystalline graphite or enhance the existing crystalline structure of carbon, typically by heating them to temperatures above 2500°C under controlled atmospheric conditions. This process significantly improves the material's electrical and thermal conductivity, mechanical strength, and chemical inertness, making it suitable for advanced industrial applications.

What are the primary applications of graphitization furnaces?

The primary applications include the production of graphite electrodes for electric arc furnaces in the steel industry, the graphitization of carbon fibers for aerospace and automotive composites, the manufacturing of special graphite materials for semiconductor fabrication and nuclear reactors, and the processing of synthetic graphite for lithium-ion battery anodes. These furnaces are critical for creating high-performance carbon products across diverse high-tech sectors.

What are the main types of graphitization furnaces?

Graphitization furnaces are primarily categorized into batch furnaces and continuous furnaces. Batch furnaces offer flexibility for smaller volumes and specialized applications, allowing precise control over each cycle. Continuous furnaces, such as Acheson or L&P types, are designed for high-volume, uninterrupted production, providing greater throughput and energy efficiency for standardized products like large graphite electrodes and carbon fibers.

What technological advancements are impacting the graphitization furnace market?

Key technological advancements include enhanced process control systems (PLCs, SCADA), integration of Industry 4.0 technologies like AI and machine learning for predictive maintenance and optimization, improved energy recovery systems, and the development of advanced insulation materials. These innovations aim to boost efficiency, reduce operational costs, enhance product quality, and improve environmental sustainability.

What are the key drivers and restraints for the graphitization furnace market?

Drivers include the surging demand for high-performance carbon materials in EV batteries, semiconductors, and aerospace, coupled with increased use of electric arc furnaces. Restraints involve high capital investment costs, significant energy consumption leading to high operational expenses, and stringent environmental regulations. Opportunities lie in customization, smart furnace integration, and emerging applications for advanced carbon products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager