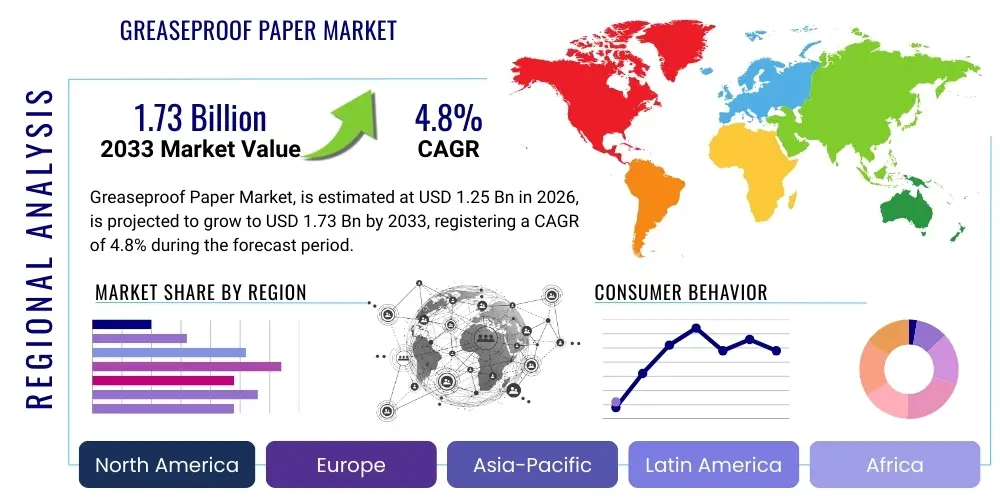

Greaseproof Paper Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438937 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Greaseproof Paper Market Size

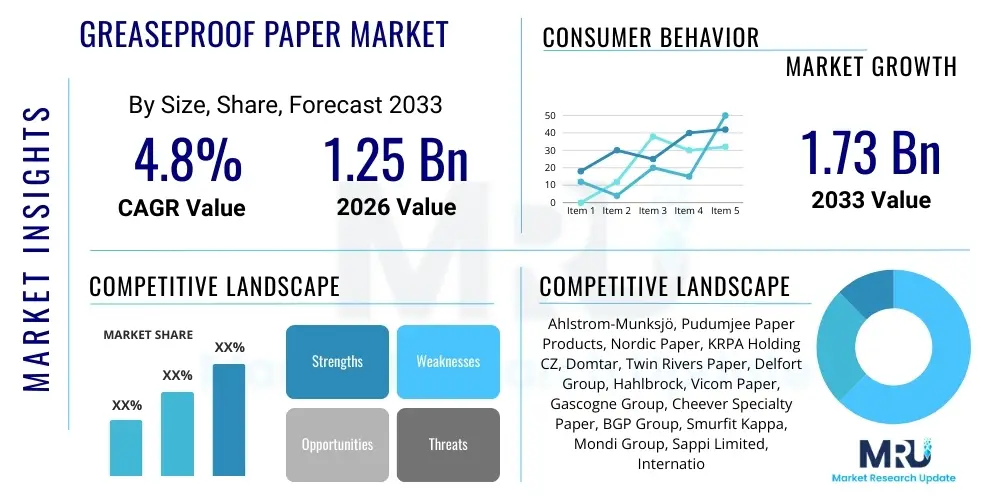

The Greaseproof Paper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.73 Billion by the end of the forecast period in 2033.

Greaseproof Paper Market introduction

The Greaseproof Paper Market encompasses the production and distribution of specialty paper designed to resist penetration by oils, fats, and grease. This resistance is typically achieved through specialized treatment during the pulping or finishing process, resulting in a dense paper structure without requiring additional chemical coatings in many traditional variants. The inherent barrier properties make it indispensable across various sectors, primarily food service and packaging, where maintaining food quality and preventing package staining are paramount. The market is witnessing robust growth driven by increasing consumer preference for sustainable and fiber-based packaging solutions over traditional plastic alternatives, particularly in developed economies emphasizing eco-friendly practices. Furthermore, stringent regulations concerning food safety and packaging hygiene contribute significantly to the sustained demand for high-quality greaseproof paper.

Greaseproof paper is a highly versatile product, finding major applications in baking, cooking, wrapping, and lining. In the food service industry, it is widely utilized for wrapping fast food items like burgers, sandwiches, and fries, ensuring oil absorption while maintaining the integrity of the packaging. Its natural composition and potential for biodegradability are significant benefits, aligning with global sustainability goals. Key driving factors include the expansion of the quick-service restaurant (QSR) sector, the boom in online food delivery services requiring functional and aesthetic packaging, and technological advancements leading to enhanced heat resistance and barrier properties in paper products. The shift away from single-use plastics provides a major structural tailwind for market expansion.

Product descriptions often highlight variations such as baking parchment (siliconized for non-stick properties) and traditional, uncoated greaseproof paper. The core functionality, however, remains its barrier capability against lipids. Major applications span retail packaging for baked goods, specialized industrial liners, and household cooking aids. Benefits include environmental sustainability, effective grease control, enhanced food presentation, and compliance with various food contact material standards globally. These factors collectively solidify the position of greaseproof paper as a foundational component in modern, responsible packaging strategies, positioning the market for steady, resilient growth throughout the forecast period.

Greaseproof Paper Market Executive Summary

The Greaseproof Paper Market is characterized by accelerating demand stemming from the global push for sustainable packaging and the rapid expansion of the food delivery ecosystem. Key business trends include increased investment in sustainable raw material sourcing, particularly certified pulp, and the development of high-performance, heat-resistant variants suitable for microwave and oven use. Manufacturers are also focusing on optimizing production processes to reduce water and energy consumption, catering to the growing scrutiny regarding the environmental footprint of paper production. Strategic mergers and acquisitions among specialty paper manufacturers and packaging converters are prevalent, aimed at achieving economies of scale and expanding geographical reach, particularly in high-growth Asia Pacific regions.

Regionally, Asia Pacific (APAC) is anticipated to emerge as the fastest-growing market, driven by rapid urbanization, increasing disposable income, and the modernization of the food retail and food service industries in countries like China and India. North America and Europe, while mature, maintain significant market share, primarily due to robust regulatory frameworks promoting sustainable packaging and a high concentration of sophisticated quick-service restaurant chains and large supermarket retailers. These regions are the primary adopters of innovative, premium greaseproof solutions, often focusing on aesthetic appeal and superior functionality.

Segmentation trends highlight the increasing preference for unbleached (natural brown) greaseproof paper variants due to their perception as being more environmentally friendly and minimally processed. Application-wise, the food packaging segment continues to dominate, although the baking and cooking segment is witnessing substantial growth fueled by the global popularity of home baking and gourmet cooking. Industry consolidation is mild to moderate, with several large international specialty paper manufacturers dominating the production capacity, while smaller regional players focus on specialized, niche applications or sustainable, localized sourcing models. These dynamic trends suggest a market poised for stable, value-driven growth predicated on sustainability and functional performance.

AI Impact Analysis on Greaseproof Paper Market

Analysis of common user questions regarding AI's impact on the Greaseproof Paper Market reveals key themes centered around manufacturing efficiency, supply chain predictability, and customer-facing innovation. Users frequently ask if AI can optimize pulp usage, minimize waste during coating or calendering processes, and improve defect detection in high-speed production lines. Another significant area of concern involves how AI-driven demand forecasting can stabilize volatile raw material costs (pulp prices) and enhance inventory management for both manufacturers and end-users (QSRs). Furthermore, there is curiosity about AI's role in developing novel, bio-based barrier materials that surpass current greaseproof performance standards through advanced material simulation and predictive chemistry.

The key consensus emerging from these inquiries is that while AI will not directly change the physical product itself—the fundamental need for a grease barrier remains—it will drastically transform the operational landscape. Manufacturers are expected to leverage machine learning algorithms to fine-tune machinery settings (like calendering pressure and temperature) for optimal paper density and consistency, thereby reducing off-spec production. Predictive maintenance, powered by sensor data and AI, will minimize costly downtime in capital-intensive paper mills. In the supply chain, AI is crucial for dynamic logistics routing and inventory optimization, which is vital given the perishable nature of the end products often wrapped in greaseproof paper.

Ultimately, the expectations are focused on achieving higher cost-efficiency and supply chain resilience. AI's ability to process vast datasets related to quality control, external market variables (like vegetable oil prices, which influence food service demand), and internal production metrics will drive competitive advantage. Companies integrating AI into their core operations will be better positioned to offer competitive pricing and maintain consistent product quality, especially important in a commodity-like market segment such as basic greaseproof paper, where marginal efficiencies translate directly into substantial profit gains.

- AI-driven optimization of pulp fiber utilization and refining processes, leading to reduced raw material consumption.

- Implementation of predictive maintenance in paper mills, increasing operational uptime and reducing repair costs.

- Enhanced quality control systems utilizing computer vision and machine learning for real-time defect detection during production.

- Improved supply chain planning and logistics through AI-powered demand forecasting and dynamic inventory management for volatile markets.

- Simulation and accelerated R&D of advanced bio-based coatings or treatments to enhance grease resistance sustainably.

- Optimization of energy consumption in drying and calendering sections using deep learning models based on environmental conditions.

DRO & Impact Forces Of Greaseproof Paper Market

The dynamics of the Greaseproof Paper Market are heavily influenced by a confluence of driving factors related to sustainability, regulatory pressure, and consumer lifestyle changes, counterbalanced by restraints stemming from raw material volatility and technological limitations, all while presenting significant opportunities in bio-based material innovation. The primary driver is the accelerating shift towards fiber-based packaging solutions globally, replacing traditional plastic films and wrappers in food service, directly benefiting greaseproof paper manufacturers. Furthermore, strict food safety regulations mandating non-toxic, contaminant-free packaging materials, especially those resistant to fat migration, reinforce market stability. The expansion of quick-service restaurants (QSRs) and cloud kitchens, particularly in developing economies, further amplifies demand for functional, single-use wraps.

Restraints include the significant volatility in the price of wood pulp, which is the core raw material, impacting production costs and profit margins, making price stabilization challenging for manufacturers. Environmental scrutiny of the paper manufacturing process itself, particularly regarding high water and energy consumption and effluent discharge, poses regulatory hurdles and necessitates substantial investment in sustainable mill operations. Moreover, challenges in achieving highly specialized barriers against oxygen and moisture typically require additional coatings (like silicone or minimal polymer layers), which can sometimes compromise the paper's claimed biodegradability or recyclability, creating a technological restraint in high-barrier applications.

Opportunities are abundant in the development and commercialization of next-generation greaseproof papers that utilize innovative, non-fluorochemical treatments (PFC-free) to achieve superior oil resistance, responding directly to consumer safety concerns. There is also a major opportunity in expanding penetration into untapped emerging markets in Africa and Latin America, where the organized food service sector is just beginning to mature. Impact forces, driven predominantly by regulatory shifts and strong consumer demand for eco-friendly products, compel continuous innovation in both product composition and manufacturing processes, ensuring that only certified, sustainably sourced, and highly functional products gain substantial market traction. These forces dictate that operational efficiency and environmental compliance are non-negotiable aspects of long-term market success.

Segmentation Analysis

The Greaseproof Paper Market is comprehensively segmented based on Type, Application, and End-Use Industry, providing a granular view of demand patterns and strategic focus areas for market participants. The segmentation by Type primarily differentiates products based on the pulp treatment and finishing, leading to variations in barrier performance and visual characteristics. Application segmentation identifies the primary functions the paper serves, ranging from direct food contact wrapping to industrial liners, while End-Use Industry segmentation highlights the key sectors that consume these specialized papers, with the food service industry being the most critical consumer.

The Type segment is crucial as it reflects manufacturer investment in sustainability and barrier technology. Bleached paper often appeals to markets requiring high aesthetic purity (e.g., confectionery wrapping), whereas unbleached paper caters to the strong demand for natural and minimal-processing appearance, especially favored by eco-conscious brands. The performance of these papers varies significantly depending on the density (achieved through high-pressure calendering) and the presence of specialized treatments, which dictate their suitability for high-fat or high-moisture applications. The Application segment analysis reveals that packaging applications hold the largest share, driven by single-use requirements in the massive global fast-food industry, but the demand for baking and cooking paper (parchment) is growing rapidly alongside the trends of home gourmet cooking and commercial bakeries.

Analyzing the End-Use Industry segmentation provides insights into B2B sales cycles and regional consumption intensity. The Food Service industry segment, including QSRs and catering, represents the backbone of the market due to the sheer volume of daily consumption. Conversely, the Household segment, driven by retail sales of baking sheets and sandwich wraps, is highly sensitive to consumer marketing and retail shelf presence. Strategic market players must tailor their product offerings, whether focusing on high-volume, cost-effective solutions for institutional food service or premium, aesthetically pleasing, and functionally superior products for the retail and confectionery sectors. This multi-dimensional segmentation approach allows for targeted business development and resource allocation.

- Type:

- Bleached Greaseproof Paper

- Unbleached Greaseproof Paper

- Parchment Paper (Siliconized/Non-stick)

- Application:

- Food Packaging (Wraps, Liners, Separators)

- Baking and Cooking (Sheets, Rolls, Muffin Cups)

- Industrial Use (Textile Separators, Technical Applications)

- Decorative and Specialty Use (Gift wrapping, Craft applications)

- End-Use Industry:

- Food Service (QSRs, Restaurants, Cafes, Catering)

- Retail (Supermarkets, Grocery Stores)

- Household (Consumer Use)

- Confectionery and Bakeries (Specialized wrapping)

Value Chain Analysis For Greaseproof Paper Market

The Value Chain for the Greaseproof Paper Market begins significantly upstream with the sourcing of raw materials, primarily virgin or recycled wood pulp, followed by complex manufacturing processes and culminating in diverse downstream distribution channels reaching end-users. Upstream activities involve sustainable forestry management, pulp production (often focusing on chemical pulping for high-strength fibers), and procuring specialized chemicals or bio-based additives necessary for achieving grease resistance. The quality and sustainability certification (e.g., FSC or PEFC) of the pulp profoundly influence the final product's marketability and premium pricing potential, making ethical sourcing a critical bottleneck and competitive factor.

Midstream processing involves highly technical paper manufacturing steps, including refining, high-pressure calendering (supercalendering to achieve density and barrier), and specialized chemical treatments (though increasingly PFC-free) to enhance grease resistance without relying on surface coatings. Manufacturers often convert large parent reels into consumer-friendly formats like sheets, rolls, or die-cut wraps. Downstream activities focus on the efficient distribution of these converted products. Direct channels are prevalent for large volume institutional buyers, such as major international food service chains or industrial users, offering customized specifications and bulk pricing. This direct interaction allows manufacturers to maintain higher control over specifications and delivery schedules.

The indirect distribution channel utilizes packaging distributors, wholesalers, and retail intermediaries. Wholesalers play a critical role in aggregating products from multiple manufacturers and supplying smaller independent restaurants, bakeries, and regional food processing units. Retail channels (supermarkets and e-commerce platforms) cater directly to the household segment, requiring robust brand marketing and shelf-appeal packaging. Efficient logistics and warehousing are vital, especially for delivering bulk orders on tight schedules to the demanding food service sector, making strong partnerships with third-party logistics (3PL) providers essential for market penetration and timely delivery across varied geographical regions.

Greaseproof Paper Market Potential Customers

Potential customers and end-users of greaseproof paper are highly diversified across commercial and household sectors, primarily unified by the need for hygienic, grease-resistant, and often sustainable food contact materials. The largest volume consumers are institutional users within the food service industry, including global quick-service restaurant (QSR) chains that require immense quantities of customized wraps for their signature menu items, demanding consistency, cost-effectiveness, and certification adherence. Beyond QSRs, independent restaurants, specialized bakeries, and large-scale catering operations are core customers, utilizing the paper for food wrapping, basket liners, and baking applications to enhance presentation and maintain hygiene.

A rapidly expanding segment of potential customers includes the e-commerce and food delivery platforms, where the need for reliable, leak-proof, and temperature-tolerant packaging for transport has surged exponentially. These customers require paper solutions that perform reliably in transport conditions, preventing grease bleed-through which can compromise external packaging integrity. Furthermore, industrial food processors, particularly those manufacturing greasy or oil-based products like butter, cheese, or processed meats, utilize greaseproof paper as interleavers or inner packaging to prevent product adhesion and maintain freshness during storage and distribution. This industrial application segment often demands specific wet strength and higher barrier properties.

The retail sector, encompassing supermarkets and grocery stores, serves the household end-user segment, where demand is focused on consumer-friendly products such as pre-cut baking sheets, small rolls for sandwich wrapping, and specialty wax paper substitutes. These consumers prioritize ease of use, non-stick properties (parchment paper), and clear labeling regarding food safety and environmental claims (e.g., compostability or PFC-free status). Targeting potential customers requires understanding their specific barrier performance needs, volume requirements, and regional regulatory compliance obligations, dictating whether a standard or highly customized solution is most appropriate.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.73 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ahlstrom-Munksjö, Pudumjee Paper Products, Nordic Paper, KRPA Holding CZ, Domtar, Twin Rivers Paper, Delfort Group, Hahlbrock, Vicom Paper, Gascogne Group, Cheever Specialty Paper, BGP Group, Smurfit Kappa, Mondi Group, Sappi Limited, International Paper, Resolute Forest Products, Dunn Paper, P&G Paper Products, Glatfelter Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Greaseproof Paper Market Key Technology Landscape

The technology landscape in the Greaseproof Paper Market is centered around fiber treatment, densification, and innovative barrier application methods aimed at achieving high oil resistance without compromising recyclability or sustainability. Traditional greaseproof paper relies heavily on supercalendering—a process involving intense pressure and heat—to create an ultra-dense, non-porous paper structure that physically resists grease penetration. This mechanical treatment remains foundational, and advancements focus on optimizing caliper uniformity and minimizing fiber damage during the densification process to maximize physical barrier efficacy while preserving paper strength. Modern research also focuses on utilizing specialty pulp fibers, such as highly refined microfibrillated cellulose (MFC) or nanofibrillated cellulose (NFC), which can significantly enhance barrier properties at a lower basis weight, offering material savings and improved environmental profiles.

A critical shift is the transition away from Per- and Poly-fluoroalkyl Substances (PFAS/PFCs), traditionally highly effective grease repellents, due to mounting environmental and health concerns. The key technology challenge now is the commercialization of sustainable, PFC-free barrier technologies. This involves applying bio-based coatings, such as specialized waxes, starch derivatives, biopolymers, or mineral coatings (like clay or talc), which offer competitive grease resistance without the environmental persistence associated with fluorochemicals. Manufacturers are investing heavily in customized coating machinery (e.g., curtain coaters or size presses) and formulation chemistry to ensure these bio-based barriers adhere effectively, are cost-competitive, and meet stringent food contact regulations globally, particularly in Europe and North America.

Furthermore, technology related to digital printing and customization is gaining prominence. Paper converters are adopting advanced digital printing capabilities to offer tailored branding and decorative features on greaseproof wraps, enabling QSRs and retailers to enhance their visual identity directly on the packaging material. Automation and sensor technology in paper mills, integrated with AI, are crucial for maintaining consistent quality in high-speed, high-volume production lines. The synergy between advanced fiber science, sustainable coating chemistry, and high-precision manufacturing equipment defines the current competitive technology landscape, emphasizing performance and environmental compliance as inseparable technological goals for long-term market sustainability.

Regional Highlights

The Greaseproof Paper Market exhibits distinct growth patterns and maturity levels across different global regions, driven by varying regulatory environments, consumer behaviors, and the maturity of the food service and retail sectors. North America (comprising the United States and Canada) represents a significant, mature market characterized by high consumer awareness regarding sustainable packaging and rigorous regulatory standards. The dominance of large fast-food chains and the high adoption rate of food delivery services drive substantial, consistent demand for specialized, certified greaseproof and parchment papers. Demand in North America is highly sensitive to innovations in PFC-free packaging, leading to rapid commercial adoption of new bio-based barrier technologies by leading market players aiming for brand differentiation and regulatory compliance.

Europe stands out due to the European Union’s strong environmental directives and strict emphasis on circular economy principles, making it a critical hub for sustainable innovation. Countries like Germany, the UK, and France show exceptionally high demand for unbleached, compostable, and certified paper products. European regulations, particularly concerning food contact materials and the phasing out of persistent chemicals, mandate continuous product reformulation, positioning Europe at the forefront of specialty paper R&D. The mature bakery and confectionery sectors in the region also contribute significantly, requiring high-quality, aesthetic greaseproof papers for wrapping and presentation. Pricing competition remains intense, demanding high operational efficiency from manufacturers catering to this sophisticated market.

Asia Pacific (APAC) is projected to be the fastest-growing region, fueled by demographic shifts, rapid economic growth, and the expansion of the organized food processing and quick-service restaurant sectors, particularly in China, India, and Southeast Asian nations. Urbanization and increased Westernization of dietary habits are leading to a surge in demand for packaged convenience foods that utilize greaseproof liners and wrappers. While pricing sensitivity remains a factor, the escalating regulatory focus on environmental protection and the growing middle class's disposable income are driving a gradual shift towards premium, high-quality sustainable papers. This region presents vast opportunities for global manufacturers seeking to expand capacity and establish local production facilities to serve the burgeoning domestic demand.

- North America: High penetration in QSR sector; strong regulatory push for PFC-free papers; high demand for silicone-coated parchment paper for household use; established manufacturing base focusing on high-volume production.

- Europe: Leading region for sustainability and circular economy mandates; focus on compostable and bio-based barriers; significant consumption in baking, confectionery, and high-end food service applications; stringent food contact material compliance requirements.

- Asia Pacific (APAC): Highest expected growth rate driven by urbanization and fast-food market expansion; large potential for unbleached paper adoption; increasing investment in localized manufacturing capacity to meet rapid domestic demand growth.

- Latin America (LATAM): Emerging market characterized by growing retail and food service modernization; localized demand often driven by cost-effectiveness; gradual adoption of sustainable standards aligning with global trends; focus on basic, functional greaseproof wraps.

- Middle East & Africa (MEA): Market growth linked to expanding tourism, hospitality infrastructure, and organized catering services; slower adoption of premium sustainable products compared to Europe, but consistent demand for standard food packaging applications is evident.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Greaseproof Paper Market.- Ahlstrom-Munksjö

- Pudumjee Paper Products

- Nordic Paper

- KRPA Holding CZ

- Domtar

- Twin Rivers Paper

- Delfort Group

- Hahlbrock

- Vicom Paper

- Gascogne Group

- Cheever Specialty Paper

- BGP Group

- Smurfit Kappa

- Mondi Group

- Sappi Limited

- International Paper

- Resolute Forest Products

- Dunn Paper

- P&G Paper Products

- Glatfelter Corporation

Frequently Asked Questions

Analyze common user questions about the Greaseproof Paper market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the shift towards sustainable greaseproof paper in the food industry?

The primary driver is stringent global regulatory pressure, particularly in Europe and North America, aimed at banning single-use plastics and harmful chemicals like PFCs (Per- and Poly-fluoroalkyl Substances). Additionally, strong consumer preference for eco-friendly, biodegradable, and compostable packaging solutions compels food service providers and retailers to adopt certified fiber-based alternatives, positioning sustainable greaseproof paper as a compliant and marketable option. This shift is deeply rooted in corporate sustainability commitments.

How does the production process for traditional greaseproof paper differ from parchment paper?

Traditional greaseproof paper achieves its oil barrier primarily through mechanical densification—supercalendering the pulp fibers under high pressure to reduce porosity. Parchment paper (baking paper), conversely, is typically treated with a sulfuric acid bath (or similar chemical treatment) followed by washing, which gelatinizes the surface fibers to create a highly dense, semi-transparent material, often subsequently coated with silicone to achieve non-stick properties crucial for baking applications, distinguishing its performance and composition.

What are the key challenges facing manufacturers regarding raw material supply?

Manufacturers face significant challenges primarily related to the volatility and secure sourcing of high-quality wood pulp, especially certified virgin pulp required for food contact applications. Fluctuations in global pulp commodity prices directly impact production costs and profit margins. Furthermore, maintaining a secure and ethically certified supply chain (e.g., FSC certification) requires careful long-term contract management and investment in sustainable forestry practices, adding complexity to the upstream procurement process.

Which regional market shows the greatest growth potential for greaseproof paper?

The Asia Pacific (APAC) region demonstrates the greatest growth potential, projected to experience the fastest CAGR through 2033. This growth is underpinned by rapid urbanization, substantial increases in disposable income, and the exponential expansion of the organized food service sector, including international QSR chains and domestic food delivery networks in populous countries like China and India, driving up the volume demand for functional food wraps and liners.

How are companies replacing harmful fluorochemicals (PFCs) in high-performance greaseproof products?

Leading companies are focused on developing and implementing advanced PFC-free barrier technologies. These replacements include sophisticated bio-based coatings derived from natural polymers, starch derivatives, specialized waxes, and mineral compounds (like clay or talc). Research emphasizes formulations that provide equivalent or superior grease resistance and heat stability while ensuring the final product remains fully recyclable, compostable, and compliant with stringent global food safety standards, representing the cutting edge of material science in this industry.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Greaseproof Paper Market Size Report By Type (Bleached, Unbleached), By Application (Residential, Commercial, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Natural Greaseproof Paper Market Statistics 2025 Analysis By Application (Residential Use, Commercial Use), By Type (Packaging Paper, Baking Paper), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Greaseproof Paper Market Statistics 2025 Analysis By Application (Residential, Commercial), By Type (Packaging Paper, Baking Paper), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager