Greenhouse Heaters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432959 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Greenhouse Heaters Market Size

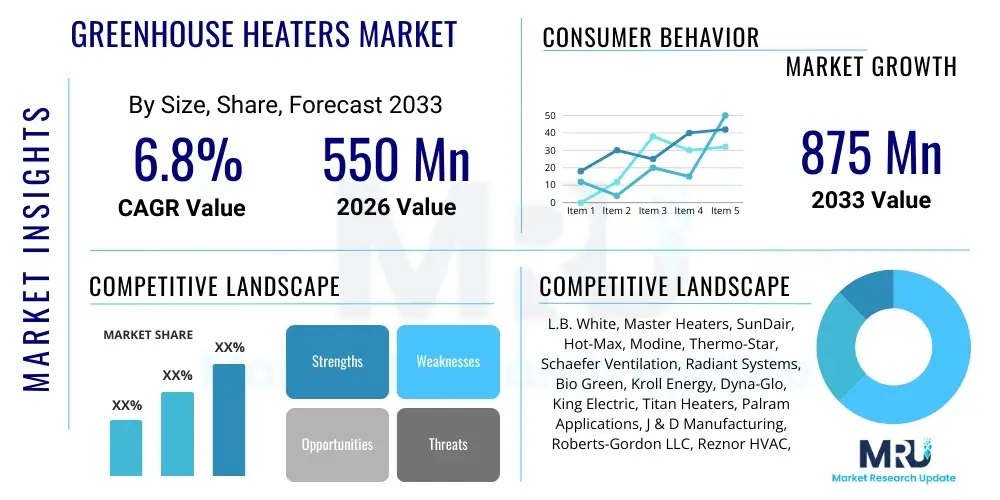

The Greenhouse Heaters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $550 Million USD in 2026 and is projected to reach $875 Million USD by the end of the forecast period in 2033.

Greenhouse Heaters Market introduction

The Greenhouse Heaters Market encompasses specialized heating solutions designed to maintain optimal temperature and humidity levels within controlled agricultural environments, crucial for ensuring year-round crop vitality and maximizing yields, particularly in temperate and cold climates. These systems are essential tools for Controlled Environment Agriculture (CEA), addressing the physiological needs of various crops by preventing chilling damage, promoting necessary metabolic processes, and regulating flowering and fruiting cycles regardless of external weather conditions. Product offerings range widely, including electric, gas, propane, and radiant heating systems, catering to diverse greenhouse sizes, operational budgets, and energy availability.

Major applications of greenhouse heaters span commercial horticulture, research and development institutions, and small-scale hobbyist operations. Commercially, they are indispensable for high-value crops such as ornamental flowers, exotic fruits, and year-round vegetable production, allowing farmers to access premium off-season markets. The primary benefits derived from the implementation of effective greenhouse heating include predictable crop scheduling, enhanced crop quality uniformity, significant reduction in crop losses due to frost, and expansion of agricultural feasibility into previously unsuitable geographical zones. The consistent provision of optimal thermal conditions ensures better nutrient absorption and reduced susceptibility to cold-related diseases.

Driving factors propelling market expansion are primarily centered on the increasing global demand for fresh, locally-sourced produce, the necessity of securing food supply chains against volatile climatic conditions, and the continuous technological advancements leading to more energy-efficient and smarter heating systems. The shift towards intensive farming techniques, driven by limited arable land and population growth, further necessitates the adoption of reliable greenhouse climate control equipment. Moreover, government subsidies and incentives promoting CEA infrastructure, particularly in developed economies focusing on indoor farming, contribute significantly to market acceleration.

Greenhouse Heaters Market Executive Summary

The Greenhouse Heaters Market is experiencing robust growth driven by structural shifts in global agriculture towards controlled environments and the integration of precision agriculture technologies. Current business trends indicate a strong move away from traditional, inefficient fuel sources toward advanced, eco-friendly heating solutions such as biomass boilers, solar thermal systems, and high-efficiency electric heat pumps. Manufacturers are focusing heavily on developing smart heating systems that utilize IoT sensors and predictive analytics to optimize energy consumption based on real-time environmental data, thereby addressing the high operational cost concerns traditionally associated with greenhouse heating. Consolidation among smaller regional players by larger international corporations is also a key feature, aiming to capture specialized technological expertise and expand geographic reach, particularly in emerging Asian markets.

Regionally, North America and Europe remain the dominant markets, characterized by established CEA infrastructure, sophisticated governmental support for sustainable farming, and high adoption rates of advanced climate control technologies. However, the Asia Pacific (APAC) region is projected to register the fastest growth, largely fueled by rapid urbanization, increasing middle-class demand for high-quality fresh produce, and substantial governmental investments in agricultural modernization, particularly in China and India. The Middle East and Africa (MEA) are also showing promising potential, driven by the acute necessity to overcome harsh desert climates for localized food security initiatives, requiring robust and specialized heating and cooling solutions.

Segmentation trends highlight the increasing dominance of Gas/Propane heaters in large-scale commercial operations due to their high caloric output and scalability, although Electric heaters are rapidly gaining traction in smaller, often automated, high-tech indoor farms where precise temperature control and integration with renewable energy sources are prioritized. By capacity, the medium to high-capacity segment is witnessing the most significant investment, reflecting the expansion of commercial-scale greenhouse operations. Furthermore, the push for energy sustainability is driving the segment of specialized radiant heating systems, which offer superior distribution efficiency compared to conventional forced-air methods, minimizing heat loss and improving overall plant environment quality.

AI Impact Analysis on Greenhouse Heaters Market

User inquiries frequently revolve around how Artificial Intelligence (AI) can minimize the substantial energy costs associated with heating, improve temperature stability across large greenhouse structures, and integrate seamlessly with existing environmental control systems. Key concerns often include the complexity of implementing machine learning models for predictive maintenance of heating units and the reliability of AI-driven temperature forecasting based on microclimatic variables. Users are keenly interested in determining the return on investment (ROI) from systems that use AI to dynamically adjust heating output in response to forecasted weather changes or real-time plant physiological needs. The consensus expectation is that AI will transform greenhouse heating from a reactive process to a highly proactive, predictive, and resource-efficient operation.

The integration of AI directly impacts the operational efficiency and strategic planning within the greenhouse heating domain. Machine learning algorithms analyze vast datasets, including external weather patterns, internal temperature gradients, humidity levels, insulation effectiveness, and historical energy consumption profiles, to create highly accurate predictive models. These models enable heating systems to anticipate thermal demands hours or even days in advance, allowing for optimized pre-heating or gradual energy adjustments, which smooths energy demand peaks and significantly reduces overall utility expenditure. This capability moves beyond simple thermostat settings to a complex, multivariate approach to climate management.

Moreover, AI contributes significantly to preventive maintenance and diagnostics of heating equipment. By continuously monitoring the operational parameters of burners, fans, heat exchangers, and distribution networks, AI can detect subtle anomalies that signal impending component failure or reduced efficiency long before they lead to critical system downtime. This predictive capability minimizes unexpected repair costs and ensures uninterrupted climate control, which is vital for protecting high-value crops. The future trajectory involves AI systems not just controlling the temperature but optimizing the entire ecosystem, determining the most energy-efficient distribution method (e.g., floor heating vs. air circulation) based on current crop stage and canopy density.

- AI-driven Predictive Heating Control: Optimizes energy usage by forecasting thermal load based on external weather data and internal sensor readings.

- Real-Time Gradient Mapping: Uses deep learning to analyze spatial temperature variations, enabling precision heating adjustments in specific zones.

- Energy Consumption Optimization: Machine learning algorithms dynamically adjust fuel burn rate or electrical input to match the minimum required thermal energy.

- Predictive Maintenance: Monitors heater component health to anticipate failures, reducing downtime and maintenance costs.

- Integration with Crop Models: Adjusts temperature setpoints based on the optimal growth parameters required for specific crop species and life cycle stages.

DRO & Impact Forces Of Greenhouse Heaters Market

The Greenhouse Heaters Market is shaped by a critical balance between the increasing global necessity for controlled agriculture (Driver) and the persistent high energy costs associated with climate control (Restraint), presenting significant opportunities for innovative solutions focused on sustainability and efficiency. The primary driving force remains the imperative for year-round production of fresh produce, essential for bolstering food security and meeting escalating consumer demand for specific, high-quality, and locally-sourced items. This requirement mandates dependable heating infrastructure, particularly in regions prone to extreme seasonal temperature fluctuations. Alongside this, rapid technological improvements in boiler efficiency, heat pump technology, and smart climate controls have made modern heating systems more economically viable and environmentally sound, further stimulating market adoption.

Key restraints, however, significantly impact the market's trajectory, most notably the substantial initial capital investment required for installing high-efficiency heating systems and the inherent volatility and rising costs of traditional energy sources like natural gas and electricity. While operational efficiency has improved, heating remains the single largest operational expense for most commercial greenhouse operators, creating financial barriers, especially for small and medium-sized farms. Furthermore, the complexity involved in retrofitting old, existing greenhouses with advanced heating infrastructure often presents logistical and structural challenges that deter immediate modernization, requiring specialized planning and significant downtime.

Opportunities for market growth are strongly linked to the global pivot toward renewable and sustainable energy sources. The development and deployment of greenhouse-specific geothermal heating systems, biomass boilers utilizing agricultural waste, and solar-assisted heat pumps offer pathways to drastically reduce reliance on fossil fuels, mitigating both cost volatility and environmental impact. The integration of advanced sensor networks, IoT, and AI enables precision climate management, maximizing the efficiency of every unit of energy consumed. The regulatory environment, especially in Europe and North America, increasingly favors technologies that reduce carbon footprint, opening up new avenues for manufacturers specializing in eco-friendly heating solutions. The interplay of these forces dictates that market success will increasingly belong to providers offering integrated, sustainable, and highly intelligent heating packages.

- Drivers (D): Expansion of Controlled Environment Agriculture (CEA), increasing consumer demand for year-round specialty crops, technological advancements in energy efficiency (e.g., heat pumps, radiant floor heating), and government support/subsidies for modernizing agricultural infrastructure.

- Restraints (R): High initial capital expenditure for advanced heating systems, significant operational costs due to fluctuating energy prices (gas/electricity), and complex regulatory hurdles related to fuel emissions and boiler standards.

- Opportunities (O): Development of sustainable heating solutions (geothermal, biomass, solar thermal), integration of IoT and AI for precision climate control and energy optimization, and market expansion in emerging economies focused on food security (APAC and MEA).

- Impact Forces: The high impact of regulatory pressures driving energy efficiency and the medium-high impact of technological innovation in minimizing the cost restraints associated with operation.

Segmentation Analysis

The Greenhouse Heaters Market is comprehensively segmented based on the type of fuel or heating mechanism, the thermal capacity designed for different operational scales, and the specific application sector where the equipment is deployed. This segmentation allows manufacturers to tailor solutions precisely to the varying needs of commercial, research, and hobbyist growers. Analysis of these segments is crucial for understanding market dynamics, guiding product development, and targeting marketing efforts towards high-growth areas. The increasing demand for precise temperature control and energy efficiency drives innovation across all segmentation categories, particularly favoring advanced electric and radiant systems capable of integrating with smart controls.

Segmentation by Type reveals a continuous competition between conventional gas/propane heaters, favored for their robustness and high heat output in large spaces, and modern electric heaters, which offer precise control and zero localized emissions, making them ideal for urban farms and smaller high-tech setups. Radiant heaters, utilizing hot water or infrared technology, are gaining prominence due to their superior efficiency in directly warming plants and surfaces rather than just the air. The Capacity segmentation directly reflects the scale of operations; while low capacity units serve the hobbyist and research sectors, the high-capacity segment is the financial core of the market, driven by large commercial vegetable and flower producers requiring continuous, reliable, high-volume thermal energy.

Application analysis highlights that Commercial Greenhouses remain the largest revenue-generating segment, encompassing sophisticated operations that demand reliable, scalable, and often custom-engineered heating solutions to protect substantial crop investments. Research Greenhouses, although smaller in volume, represent a critical segment requiring the highest degree of precision and variability in temperature control to facilitate controlled experimentation. Home Greenhouses, while individually small, collectively represent a growing segment driven by gardening enthusiasm and the desire for self-sufficiency, often preferring ease-of-use and portability found in smaller electric or paraffin units.

- By Type:

- Electric Heaters (Fan Heaters, Heat Pumps)

- Gas/Propane Heaters (Vented and Unvented)

- Oil/Paraffin Heaters

- Radiant Heaters (Infrared, Hot Water Systems)

- Biomass/Geothermal Systems

- By Capacity:

- Low Capacity (Under 50,000 BTU/hr)

- Medium Capacity (50,000 – 200,000 BTU/hr)

- High Capacity (Over 200,000 BTU/hr)

- By Application:

- Commercial Greenhouses

- Research Greenhouses

- Home/Hobby Greenhouses

Value Chain Analysis For Greenhouse Heaters Market

The value chain for the Greenhouse Heaters Market begins with the Upstream suppliers responsible for providing raw materials such as specialized metals (steel, copper, aluminum) for heat exchangers, advanced combustion components, electrical wiring, and high-efficiency insulation materials. Also crucial are the suppliers of complex electronic components, including thermostats, sensors, microprocessors, and smart control interfaces necessary for modern climate management systems. Ensuring a stable supply of high-quality, corrosion-resistant materials is critical, as heating units operate in challenging, humid greenhouse environments, demanding longevity and reliability.

The core of the value chain involves the Manufacturers, who specialize in designing, assembling, and testing the diverse range of heating products—from simple electric heaters to complex, integrated boiler systems and heat pumps. Differentiation is achieved through innovation in energy efficiency (BTU output per unit of fuel/electricity), durability, and the integration of connectivity features (IoT compatibility). Manufacturers often conduct rigorous testing to meet stringent safety and emission standards (e.g., ETL, CE certifications). Post-manufacturing, the products move through the Distribution Channel, which is multifaceted, involving direct sales teams for large commercial projects, specialized agricultural equipment distributors, HVAC wholesalers, and increasingly, e-commerce platforms targeting the hobbyist and small-scale commercial segment.

Downstream analysis focuses on the Installation, Maintenance, and End-Users. Installation typically requires specialized technicians, especially for large, integrated hot water or geothermal systems. Maintenance services, including routine checks, cleaning, and preventative repairs, represent a crucial recurring revenue stream, particularly for complex gas and biomass units. The Indirect distribution channel involves consultants and agricultural engineers who specify particular heating solutions during the design phase of a new greenhouse project, influencing purchasing decisions significantly. The direct channel often involves large commercial growers purchasing directly from manufacturers for volume orders, demanding bespoke service and long-term maintenance contracts, completing the lifecycle from raw material extraction to optimized operation in the controlled environment.

Greenhouse Heaters Market Potential Customers

Potential customers, or End-Users/Buyers, of greenhouse heaters span across a wide spectrum of agricultural and research sectors, unified by the common need to precisely manage internal climate conditions for biological consistency and economic viability. The largest segment of potential customers comprises large Commercial Greenhouse Operators involved in intensive horticulture, including the cultivation of cut flowers, ornamental plants, vegetables (such as tomatoes, cucumbers, peppers), and specialty crops (herbs, microgreens). These commercial enterprises rely on high-capacity, highly reliable heating systems to ensure consistent supply chains and protect millions of dollars in crop value against sudden temperature drops. Their procurement decisions are heavily influenced by energy efficiency, scalability, and integration with comprehensive environmental control software.

Another significant group consists of Agricultural Research Institutions and University Botanical Gardens. These buyers typically require smaller, but highly accurate and flexible heating solutions that allow for precise manipulation of temperature regimes for experimental purposes. In this segment, the emphasis is placed less on sheer capacity and more on the system's ability to maintain tight tolerances and log detailed data, often favoring electric resistance heaters or small heat pump systems for their exactitude. The need for specialized heating is paramount in genetic research or phytopathology labs where conditions must be strictly reproducible.

Finally, the growing demographic of home gardeners and small-scale farm operations constitutes a rapidly expanding potential customer base. Often referred to as 'Hobbyists' or 'Urban Farmers,' these customers seek user-friendly, affordable, and often portable heating solutions, such as small electric fan heaters or portable propane/paraffin units. This segment is highly responsive to digital marketing and relies heavily on reviews and ease of installation. Their purchasing behavior drives the market for low-to-medium capacity heaters designed for simplicity and safety, reflecting the broader trend of localized food production and gardening enthusiasm.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550 Million USD |

| Market Forecast in 2033 | $875 Million USD |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | L.B. White, Master Heaters, SunDair, Hot-Max, Modine, Thermo-Star, Schaefer Ventilation, Radiant Systems, Bio Green, Kroll Energy, Dyna-Glo, King Electric, Titan Heaters, Palram Applications, J & D Manufacturing, Roberts-Gordon LLC, Reznor HVAC, Sierra Manufacturing, Wadsworth Control Systems, Argus Controls. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Greenhouse Heaters Market Key Technology Landscape

The technology landscape of the Greenhouse Heaters Market is rapidly evolving, moving away from simple combustion units towards integrated, highly sophisticated climate management systems focused on energy conservation and precision. A key technological shift involves the development of high-efficiency modulating gas heaters and condensing boilers, which adjust their heat output based on precise demand, minimizing energy wastage compared to traditional on/off systems. Furthermore, the increasing adoption of electric heat pump technology, which can provide both heating and cooling functions with superior energy efficiency by moving heat rather than generating it, is reshaping the market, especially in regions transitioning to renewable energy grids. These advancements demand specialized materials science for durable heat exchangers capable of handling corrosive greenhouse atmospheres.

The second major technological trend involves digitalization and connectivity. Modern greenhouse heaters are increasingly equipped with IoT sensors that feed real-time atmospheric data (temperature, humidity, CO2 levels) back to centralized Environmental Control Systems (ECS). These systems utilize cloud-based computing and predictive algorithms, often incorporating AI, to manage heating schedules dynamically. This level of connectivity allows growers to monitor and adjust heating parameters remotely, optimizing energy input based on specific crop requirements and forecasted microclimatic changes. The rise of wireless sensor networks simplifies installation and expands the range of data collected, leading to smarter, more granular climate control across vast commercial operations.

Finally, sustainability-focused technologies, such as advanced biomass boiler systems designed to burn renewable fuel sources like wood chips or agricultural residue efficiently, are gaining significant traction, particularly in Europe where carbon taxes and sustainability mandates are strict. Similarly, geothermal systems, utilizing the stable subterranean temperature to heat greenhouse water loops, represent a crucial high-CAPEX, low-OPEX solution for large, permanent installations. Infrared and radiant heating systems, which focus energy directly onto the plants and soil, bypassing the inefficient heating of large volumes of air, also represent a mature yet continually improving technology, capitalizing on precise thermal delivery to enhance plant growth rates while lowering overall energy consumption.

Regional Highlights

- North America: This region is characterized by extensive investment in high-tech, large-scale commercial greenhouses, particularly in the US (California, Arizona, Florida) and Canada (Ontario, British Columbia). The market here is driven by the strong consumer preference for domestically grown food and stringent requirements for high-quality produce. High adoption rates of gas and high-efficiency electric heating systems, coupled with significant R&D in AI-integrated climate control, position North America as a leader in innovative heating solutions. The increasing legalization and expansion of the cannabis cultivation industry also heavily contribute to the demand for precise, high-capacity climate control systems.

- Europe: Europe is a mature market heavily influenced by ambitious governmental sustainability targets and high energy costs. This drives demand primarily towards highly efficient and renewable energy-based solutions, such as biomass boilers, advanced heat pumps, and geothermal installations, especially in countries like the Netherlands (a global leader in greenhouse technology) and Scandinavian nations. Regulatory frameworks like the European Green Deal push manufacturers to prioritize low-emission and carbon-neutral heating technologies. The region's focus is on retrofitting existing infrastructure with smart, energy-saving systems.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market due to rapid industrialization of agriculture, significant governmental support for modern farming techniques, and increasing population size necessitating reliable food supply. Countries like China, Japan, and South Korea are heavily investing in plastic tunnel and high-tech glass greenhouses, fueling demand for reliable, often imported, heating equipment. While initial adoption favors affordable electric or oil-based heaters, there is a swift transition occurring towards smart, medium-capacity solutions to boost yields and manage operational costs efficiently.

- Latin America (LATAM): The LATAM market, while smaller, is growing steadily, particularly in temperate zones like Mexico and Chile, which focus on export-oriented horticulture. The demand is often for robust, moderate-cost heating solutions, frequently utilizing propane or natural gas, suitable for large-area coverage. Market growth is closely tied to investment in commercial flower and vegetable exports to North American and European markets, requiring compliance with international quality standards enforced by climate control.

- Middle East and Africa (MEA): This region faces extreme climatic challenges, necessitating robust heating in winter months (especially at night) and integrated cooling solutions. The market is primarily driven by massive, government-backed food security initiatives, particularly in Gulf Cooperation Council (GCC) countries. Demand focuses on highly specialized, durable equipment capable of handling harsh, often arid conditions, with an emphasis on integrated thermal management and efficient water-based heating systems powered by solar or waste heat recovery.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Greenhouse Heaters Market.- L.B. White

- Master Heaters

- SunDair

- Hot-Max

- Modine

- Thermo-Star

- Schaefer Ventilation

- Radiant Systems

- Bio Green

- Kroll Energy

- Dyna-Glo

- King Electric

- Titan Heaters

- Palram Applications

- J & D Manufacturing

- Roberts-Gordon LLC

- Reznor HVAC

- Sierra Manufacturing

- Wadsworth Control Systems

- Argus Controls

Frequently Asked Questions

Analyze common user questions about the Greenhouse Heaters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the most energy-efficient types of greenhouse heaters currently available?

The most energy-efficient heaters include electric heat pumps, which transfer heat rather than generate it, and advanced geothermal or biomass boiler systems. Radiant (infrared) heaters are also highly efficient as they directly heat plants and objects, minimizing wasted energy used to heat the air.

How does the integration of smart controls affect the operational cost of greenhouse heating?

Smart controls and IoT integration drastically reduce operational costs by using sensors and predictive AI to modulate heat output precisely, preventing overheating and minimizing energy consumption during peak periods. This typically leads to energy savings ranging from 15% to 30% annually.

Which fuel type is preferred for large commercial greenhouse operations?

Natural gas and propane heaters (both vented and unvented) are often preferred for large commercial operations due to their high caloric output, scalability, and rapid heating capability. However, there is a growing trend towards using high-efficiency condensing boilers powered by biomass or sustainable energy for long-term cost stability.

What factors should be considered when sizing a greenhouse heater?

Sizing is critical and depends on the greenhouse volume, insulation quality (double poly, glass), the minimum outdoor design temperature, and the desired internal temperature (temperature rise required). Calculations involve determining the total BTU loss (thermal load) to ensure the heater can maintain the set point under the worst-case external conditions.

What is the primary driver for market growth in the Asia Pacific region?

The primary driver in APAC is increased investment in food security and agricultural modernization by governments, coupled with rising middle-class demand for high-quality, year-round fresh produce. This necessitates the rapid deployment of reliable climate-controlled agricultural infrastructure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager