Gun Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432580 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Gun Powder Market Size

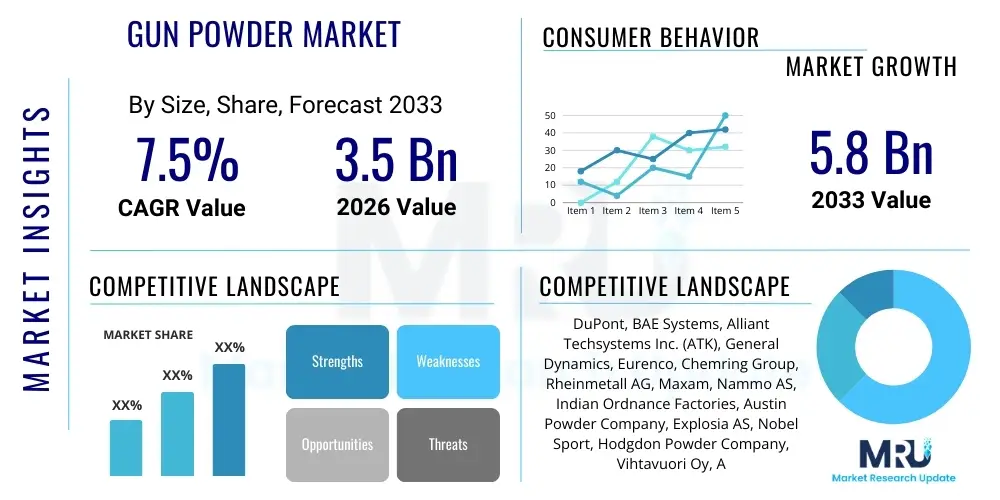

The Gun Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.8 Billion by the end of the forecast period in 2033. This robust expansion is primarily driven by escalating global defense expenditures, particularly in emerging economies modernizing their arsenals, alongside steady demand from the civilian sporting and hunting industries. The trajectory of growth is also influenced by continuous technological advancements aimed at producing cleaner-burning, more stable, and higher-performance propellant charges, which cater to specialized military and precision shooting applications, thereby expanding premium market segments.

Market valuation reflects the cumulative demand across core applications including ammunition manufacturing for both small and large caliber weapons, blasting agents utilized extensively in mining and infrastructure development, and pyrotechnics used in consumer and professional displays. While traditional black powder maintains a niche relevance, the overwhelming majority of market revenue is generated by smokeless powders, classified into single-base, double-base, and triple-base formulations, each optimized for specific energetic properties and operational environments. Geopolitical instability continues to act as a significant underlying accelerator for military procurement cycles, directly impacting the volume and financial size of the specialized military-grade gun powder sector globally.

Gun Powder Market introduction

The Gun Powder Market encompasses the production, distribution, and application of various energetic propellants and explosives utilized across multiple industrial and defense sectors. Historically rooted in black powder, the market has evolved significantly to be dominated by advanced smokeless powders, which offer superior performance characteristics, reduced residue, and greater stability. These products are crucial components in modern ammunition, providing the necessary energetic force to propel projectiles, and are essential in large-scale blasting operations across the construction and mining industries, serving as key facilitators of infrastructure development and resource extraction globally.

Major applications of gun powder span three primary domains: defense and military, where it is used extensively in small arms, artillery shells, and missile systems; mining and construction, providing necessary blasting power for quarrying, tunneling, and civil engineering projects; and sporting and hunting, supporting the vast consumer market for firearms and reloading components. The benefits derived from these products include high energy density, controlled combustion rates tailored to specific applications, and reliability under varying environmental conditions. Driving factors for market expansion include rising military budgets focused on preparedness, the proliferation of civilian firearm ownership in key regions, and sustained growth in the global infrastructure and mining sectors demanding efficient blasting solutions, all contributing to a consistently high-demand environment for these energetic materials.

Gun Powder Market Executive Summary

The Gun Powder Market is experiencing robust growth fueled by intertwined business, regional, and segment trends. Business trends highlight a strong focus on supply chain resilience and strategic vertical integration among leading manufacturers to manage volatility in raw material costs, particularly cellulose and nitrogen compounds. Furthermore, there is a distinct shift toward advanced material science, with companies investing heavily in R&D to develop environmentally benign, non-toxic primer and propellant formulations to comply with stringent environmental regulations, creating opportunities for specialized, high-margin products. Mergers and acquisitions remain prevalent, focusing on consolidating production capacity and gaining geographical strongholds, particularly in rapidly militarizing regions.

Regional trends indicate North America and Europe retaining dominant market shares due to established defense industrial complexes and large recreational shooting cultures; however, the Asia Pacific (APAC) region is projected to exhibit the highest growth rate. This APAC acceleration is attributed to significant military modernization programs in China, India, and South Korea, coupled with massive ongoing infrastructure projects demanding extensive commercial explosives. Segment trends reveal that the Smokeless Powder segment, particularly the double-base and triple-base types used in high-performance military applications, commands the largest market share. The defense and military application segment remains the primary revenue generator, yet the specialized market for reloading components and custom ammunition powders within the sporting segment is showing accelerating premiumization and sustained growth.

AI Impact Analysis on Gun Powder Market

User inquiries regarding the impact of AI on the Gun Powder Market primarily revolve around optimizing manufacturing efficiency, enhancing quality control and safety protocols, and predicting geopolitical demand fluctuations. Users are keenly interested in how AI and machine learning (ML) models can refine the highly sensitive chemical processes involved in propellant synthesis, seeking reduced batch variation and minimized waste. A major theme is the potential for predictive maintenance in explosive-handling equipment and the use of computer vision systems to detect microscopic flaws in powder granules or finished ammunition, thereby significantly improving reliability and mitigating risks associated with unstable products. Furthermore, strategic analysts inquire about utilizing AI-driven geopolitical modeling to forecast defense spending shifts and proactively adjust production capacity for specific propellant types, ensuring supply chain responsiveness in a volatile global environment, ultimately aiming for enhanced operational safety and superior product consistency through intelligent automation.

- AI-driven predictive maintenance optimizes machinery upkeep in sensitive explosive environments, minimizing downtime and catastrophic failures.

- Machine learning algorithms enhance quality control by analyzing chemical input parameters and predicting final propellant burn rates and stability with high precision.

- Computer vision systems, powered by AI, enable automated inspection of propellant grains for uniformity, particle size distribution, and defect detection, surpassing human inspection capabilities.

- AI modeling assists in supply chain optimization, predicting demand spikes related to global conflicts or legislative changes impacting civilian markets, ensuring inventory accuracy.

- Integration of AI in R&D accelerates the discovery and testing of novel, energetic material formulations, including environmentally friendly and non-toxic substitutes.

DRO & Impact Forces Of Gun Powder Market

The Gun Powder Market is governed by complex dynamics encompassing strong drivers, stringent restraints, and significant opportunities, which collectively exert considerable impact forces on its trajectory. Key drivers include continuously rising global defense expenditures, driven by geopolitical tensions and the necessity for national security preparedness, alongside sustained high demand from the vital mining and infrastructure development sectors globally, which rely heavily on commercial explosives. Concurrently, the increasing popularity and accessibility of recreational shooting and hunting sports in Western markets ensure a stable consumer base for civilian-grade propellants and reloading components. These drivers collectively push production volumes and necessitate continuous investment in manufacturing capacity and process optimization across the major players in the market.

Restraints, however, pose significant challenges to the market. Primary among these are the extremely strict regulatory frameworks and safety standards governing the storage, transportation, and handling of explosive materials, leading to high operational costs and barriers to entry for new competitors. Volatility in the price of key raw materials, such as cotton linters (for nitrocellulose) and natural gas derivatives, also impacts profitability and pricing stability. Furthermore, growing environmental scrutiny mandates the transition toward "green" propellants that are heavy-metal free and low-smoke, forcing expensive reformulation and technological pivots away from traditional chemistries. These restraints require companies to maintain substantial compliance departments and allocate significant capital toward safety infrastructure improvements.

Opportunities reside predominantly in technological innovation and market expansion. The development of specialized propellants for modern weapons systems, particularly insensitive munitions (IM) designed to resist accidental detonation from external stimuli, represents a major opportunity for high-value contracts with defense ministries. Geographic expansion into high-growth developing economies, especially in APAC and parts of MEA, where military modernization is accelerated, offers new demand pools. Additionally, integrating advanced manufacturing techniques, such as continuous manufacturing and additive manufacturing (3D printing) of energetic components, promises efficiency gains and customization capabilities, providing pathways for specialized product offerings and cementing market leadership for technologically advanced firms.

Segmentation Analysis

The Gun Powder Market is meticulously segmented based on composition (Type), intended final use (Application), and the immediate consumer (End-Use), providing a granular view of market dynamics and targeted opportunities. Understanding these segmentations is critical for market participants to tailor product offerings—ranging from military-specific triple-base propellants to consumer-grade reloading powders—and to align distribution strategies with the specific needs of end-user industries such as defense agencies, mining companies, and amateur shooting enthusiasts. The market complexity necessitates differentiating between traditional energetic materials and newer, high-performance formulations designed for optimized ballistics and improved safety profiles across various operational scenarios.

Segmentation by Type reveals a dominance of smokeless powders over traditional black powder, reflective of modern performance requirements. Smokeless powders are further refined into categories based on their chemical base, directly influencing their energy release rate and stability. Application segmentation clearly delineates between the highly regulated, high-volume defense segment and the steady, large-scale industrial segments like mining and construction, each requiring specific product specifications. Finally, End-Use segmentation helps distinguish between direct manufacturing inputs (like ammunition production) and direct consumer uses (like pyrotechnics or recreational reloading), guiding sales and marketing efforts toward specific buyer groups with distinct procurement requirements and regulatory compliance needs.

- By Type:

- Black Powder

- Smokeless Powder

- Single-Base Powder

- Double-Base Powder

- Triple-Base Powder

- By Application:

- Defense and Military

- Mining and Construction

- Sporting and Hunting

- Pyrotechnics and Fireworks

- By End-Use:

- Ammunition Manufacturing

- Reloading Components

- Blasting Agents

Value Chain Analysis For Gun Powder Market

The value chain for the Gun Powder Market is characterized by highly specialized processes, stringent quality control, and significant security requirements, beginning with the upstream sourcing of crucial chemical precursors. Upstream analysis focuses on securing stable supplies of raw materials such as refined cellulose (cotton linters or wood pulp), nitric acid, and sulfuric acid, which are essential for producing nitrocellulose, the primary energetic component. This stage is capital-intensive and subject to significant regulatory oversight due to the hazardous nature of inputs and intermediate chemicals. Key challenges upstream include managing commodity price volatility and ensuring purity standards, as even minor contaminants can drastically affect the stability and performance of the final propellant product. Effective supplier management and long-term contracts are crucial for mitigating supply risks and maintaining operational continuity.

The midstream segment involves the highly technical manufacturing processes, including nitration, purification, blending, extrusion, and surface treatment (graphitization) of the powder grains. This stage requires proprietary technology and specialized, geographically restricted facilities designed to meet demanding safety standards, such as those related to explosion isolation and controlled environment storage. Distribution channels for gun powder products are highly regulated and complex, involving specialized logistics providers certified to transport hazardous materials (Hazmat). Direct channels dominate the military and large industrial segments, where manufacturers deal directly with defense ministries or major mining conglomerates via secure, contracted routes, often involving specialized security protocols to prevent theft or diversion of explosive materials.

Downstream analysis focuses on the end-user market, including ammunition manufacturers, construction firms, and recreational users. Indirect distribution channels, such as specialized retailers and authorized dealers, handle the sporting and hunting segment, where products like reloading powders are sold in smaller, controlled quantities to licensed individuals. The high cost of compliance and the necessity for secure, traceable logistics systems characterize the entire distribution structure. The effectiveness of the value chain is measured not only by cost efficiency but primarily by the impeccable adherence to safety, security, and quality standards imposed by international defense and regulatory bodies, ensuring product integrity until the point of use.

Gun Powder Market Potential Customers

Potential customers for the Gun Powder Market are diverse, spanning governmental defense organizations, large industrial entities, and individual consumers, all requiring materials optimized for specific explosive or propellant applications. The largest and most strategically important customers are national defense ministries and government ordnance factories, which procure vast quantities of military-grade propellants for small-caliber ammunition, artillery shells, and rocketry applications. These institutional buyers prioritize insensitive munitions (IM) technology, consistent ballistic performance, extreme reliability under harsh conditions, and long-term storage stability. Procurement in this segment is characterized by long-term contracts, rigorous qualification processes, and strict confidentiality, representing the high-value core of the market.

The second major customer group comprises mining, quarrying, and construction companies that utilize commercial blasting agents to extract resources or facilitate infrastructure development (tunnels, roads). These end-users demand high-volume, cost-effective, and safe explosive solutions, often seeking formulations that minimize environmental impact and provide optimal fragmentation results for efficient material handling. Specialized distributors often serve this segment, requiring tailored logistics and on-site support. Furthermore, global ammunition manufacturers, who serve both military and civilian markets, are crucial intermediate customers, purchasing bulk powder to incorporate into finished cartridges, valuing consistency in burn rate and density for high-volume, automated production lines.

Finally, the consumer and recreational market segment, particularly prevalent in North America and Europe, represents a large base of individual potential customers. This group includes recreational shooters, competitive marksmen, and handloaders (individuals who assemble their own ammunition). These customers purchase smaller quantities of specialized smokeless powders through retail channels or online distributors, prioritizing specific performance characteristics such as low fouling, temperature stability, and accuracy for precision shooting. This segment is highly brand-loyal and sensitive to niche product availability, supported by a strong network of specialized gun powder retailers and component suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.8 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DuPont, BAE Systems, Alliant Techsystems Inc. (ATK), General Dynamics, Eurenco, Chemring Group, Rheinmetall AG, Maxam, Nammo AS, Indian Ordnance Factories, Austin Powder Company, Explosia AS, Nobel Sport, Hodgdon Powder Company, Vihtavuori Oy, Accurate Powder, Black Hills Ammunition, Olin Corporation, Nitrochemie AG, Poongsan Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gun Powder Market Key Technology Landscape

The technological landscape of the Gun Powder Market is dominated by continuous advancements focused on achieving superior energy output, enhanced stability, and compliance with modern safety standards, particularly the imperative for Insensitive Munitions (IM) technology. IM technology involves proprietary formulations and processes designed to make propellants resistant to unplanned stimuli such as heat, shock, or sympathetic detonation, drastically improving soldier safety and logistics security. This requires sophisticated chemical engineering to incorporate advanced binders, stabilizers, and surface coatings that modulate the propellant's combustion curve without sacrificing overall ballistic performance. Furthermore, manufacturers are increasingly leveraging advanced modeling and simulation tools to predict the performance of new formulations before costly physical testing, accelerating the R&D cycle for high-demand specialized propellants, such as those used in extended-range artillery systems and precision sniper ammunition.

Another critical area of innovation involves the shift towards environmentally cleaner propellant formulations. Traditional compositions often include heavy metals like lead, mercury, or barium in primers, leading to environmental contamination and health concerns, especially in enclosed shooting ranges. The industry is actively developing non-toxic, or "green," propellants and primer compositions utilizing less hazardous components like bismuth or copper compounds, which maintain or exceed the performance metrics of traditional chemistries. This technological pivot is crucial for maintaining market access in environmentally conscious jurisdictions and securing long-term government contracts that prioritize ecological sustainability in their defense procurement. The complexity lies in ensuring that these new green formulations maintain the required shelf life and ballistic consistency expected by military and professional users.

Manufacturing process technology is also rapidly evolving, moving away from traditional batch processing toward continuous flow manufacturing (CFM). CFM offers significant advantages in terms of safety, consistency, and cost efficiency by maintaining strict control over reaction parameters and minimizing the accumulation of large, hazardous chemical inventories. Furthermore, there is rising interest in utilizing additive manufacturing (3D printing) techniques for creating complex, customized energetic structures, such as precise geometric shapes for specialized rocket motors or propellant grains designed to deliver highly specific pressure curves within a weapon system. These technologies promise greater supply chain agility and the ability to produce highly specialized, low-volume products that meet bespoke customer requirements, marking a critical transition towards Industry 4.0 standards within the explosive materials sector.

Regional Highlights

Regional dynamics significantly shape the Gun Powder Market, reflecting differential levels of defense spending, industrial activity, and recreational culture across global territories. Each region presents a unique set of demands and regulatory challenges that manufacturers must navigate to maintain competitive advantage and secure market penetration. The interplay between geopolitical stability and economic development dictates the pace and nature of propellant procurement globally.

- North America: Dominates the market, primarily driven by the massive civilian market for sporting, hunting, and recreational shooting, supported by a strong domestic defense industrial base (DIB). The US is the largest consumer of both civilian and military propellants, requiring a constant supply of high-quality reloading powders and large-caliber military charges. Regulatory standards are stringent, but market access for specialized consumer products is relatively high.

- Europe: Characterized by established defense contractors and high regulatory hurdles focused on safety (ATEX directives) and environmental compliance (REACH). Demand is stable, driven by NATO obligations and modernization programs in countries like Germany, France, and the UK. The market shows a strong bias toward advanced, environmentally friendly, and Insensitive Munitions (IM) certified propellants.

- Asia Pacific (APAC): The fastest-growing region, fueled by escalating defense budgets in key nations such as China, India, and South Korea, primarily focused on large-scale military modernization and regional power projection. The massive scale of infrastructure and mining projects also drives immense demand for commercial explosives. Market expansion is opportunistic, but entry often requires navigating complex domestic manufacturing requirements and technology transfer agreements.

- Latin America: Characterized by moderate, localized defense spending and significant demand from the regional mining industry, particularly in Chile, Peru, and Brazil. The market is often served by international players supplying commercial-grade blasting agents, with defense procurement being highly centralized and subject to governmental budgetary cycles.

- Middle East and Africa (MEA): Growth is primarily driven by geopolitical instability and high military spending, especially in the Gulf Cooperation Council (GCC) states and Israel, focusing on acquiring advanced weapon systems and ammunition. The region is heavily reliant on imports of high-grade military propellants, making it a critical strategic export destination for Western manufacturers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gun Powder Market.- DuPont

- BAE Systems

- Alliant Techsystems Inc. (ATK)

- General Dynamics

- Eurenco

- Chemring Group

- Rheinmetall AG

- Maxam

- Nammo AS

- Indian Ordnance Factories

- Austin Powder Company

- Explosia AS

- Nobel Sport

- Hodgdon Powder Company

- Vihtavuori Oy

- Accurate Powder

- Black Hills Ammunition

- Olin Corporation

- Nitrochemie AG

- Poongsan Corporation

Frequently Asked Questions

Analyze common user questions about the Gun Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the current growth in the military segment of the Gun Powder Market?

Growth in the military segment is primarily driven by increasing global geopolitical tensions, resulting in elevated defense budgets worldwide, especially for ammunition stockpiling, military modernization programs, and the mandatory transition toward safer, high-performance Insensitive Munitions (IM) propellants.

How is the market addressing the environmental impact of traditional propellants?

The market is actively addressing environmental concerns by focusing on the research and development of "green" propellants and non-toxic primer compositions that eliminate heavy metals such as lead and barium, ensuring compliance with strict global environmental regulations like REACH and supporting sustainability initiatives.

Which type of gun powder holds the largest market share?

Smokeless powder, particularly double-base and triple-base formulations, holds the largest market share. This dominance is due to their superior energetic characteristics, stability, and clean-burning properties required for modern, high-performance military and sporting ammunition.

What is the primary challenge faced by manufacturers in the Gun Powder Value Chain?

The primary challenge is navigating the extremely complex and stringent global regulatory environment concerning the safe storage, transportation (Hazmat logistics), and secure handling of explosive materials, which significantly increases operational complexity and compliance costs across the entire value chain.

What role does technology play in modernizing the manufacturing process?

Technology plays a crucial role by enabling the shift toward safer, more consistent manufacturing through Continuous Flow Manufacturing (CFM), the use of AI for quality control and predictive maintenance, and the application of advanced modeling to design custom propellant compositions for enhanced ballistic performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager