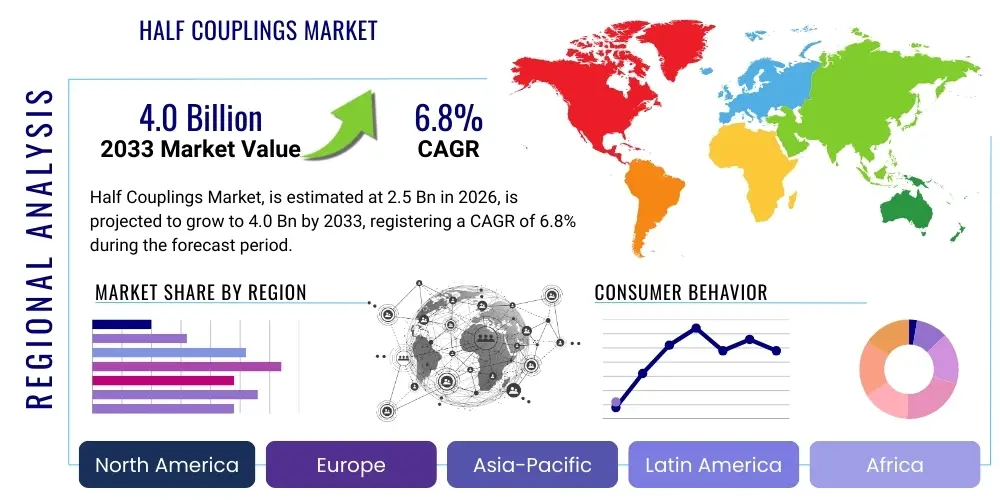

Half Couplings Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439977 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Half Couplings Market Size

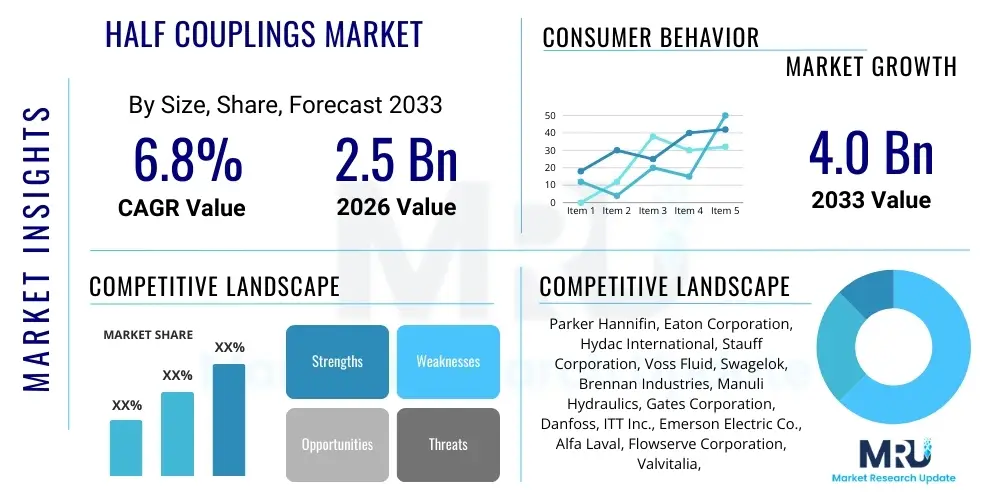

The Half Couplings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 2.5 Billion in 2026 and is projected to reach USD 4.0 Billion by the end of the forecast period in 2033.

Half Couplings Market introduction

The Half Couplings Market encompasses a specialized segment within industrial components, primarily featuring devices designed for securely connecting pipes, hoses, or shafts to equipment or other system elements. These components, often characterized by their robust construction and precision engineering, are crucial for maintaining system integrity and preventing leaks or disconnections in high-pressure or critical applications. The core product, a half coupling, is typically welded or threaded onto a vessel or pipe to create a reliable connection point for ancillary components like valves, instruments, or other pipe sections, acting as a crucial interface in complex fluid and power transmission systems.

Major applications for half couplings span across a diverse array of industrial sectors, including but not limited to oil and gas, chemical and petrochemical processing, power generation, water and wastewater treatment, marine engineering, and heavy manufacturing. Their versatility allows them to be utilized in various pressure and temperature conditions, ensuring stable and safe operations. Benefits derived from the adoption of half couplings include enhanced system reliability, simplified installation and maintenance procedures, and the ability to withstand harsh operating environments, which significantly reduces downtime and operational costs.

The market is predominantly driven by the ongoing industrialization and infrastructure development in emerging economies, coupled with the increasing demand for energy and processed materials globally. Expanding investments in critical sectors such as oil and gas exploration, refinery upgrades, and power plant construction directly fuel the demand for high-performance fluid transfer components. Furthermore, the imperative for operational safety and efficiency in industrial processes, alongside stringent regulatory standards, necessitates the use of robust and reliable coupling solutions, thereby bolstering market growth.

Half Couplings Market Executive Summary

The Half Couplings Market is experiencing dynamic shifts driven by global business trends, technological advancements, and evolving regional demands. Business trends indicate a strong emphasis on product customization, with manufacturers investing in advanced materials and precision engineering to meet specific industry requirements for corrosion resistance, high-pressure tolerance, and temperature stability. There is a discernible move towards integrating smart manufacturing processes, including automation and quality control systems, to enhance production efficiency and ensure consistent product quality, which is paramount in critical application areas like oil and gas, and chemical processing.

Regional trends reveal significant growth opportunities in the Asia Pacific region, primarily propelled by rapid industrial expansion, urbanization, and substantial investments in infrastructure projects, particularly in countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, continue to demonstrate stable demand, driven by stringent safety regulations, the modernization of existing industrial facilities, and a focus on advanced materials for high-performance applications. The Middle East and Africa (MEA) are also showing robust growth, fueled by extensive oil and gas projects and burgeoning industrial diversification initiatives.

Segmentation trends highlight a growing preference for specialized materials such as duplex stainless steel and exotic alloys due to their superior performance in corrosive and extreme environments, driving demand in critical sectors. In terms of application, the oil and gas industry remains the dominant segment, with substantial demand for both threaded and socket weld half couplings. However, significant growth is also observed in the power generation and chemical processing sectors, where the integrity of fluid transfer systems is non-negotiable. The market is also seeing differentiation based on pressure ratings, with high-pressure rated couplings gaining traction due to increasing operational demands in advanced industrial processes.

AI Impact Analysis on Half Couplings Market

The integration of Artificial Intelligence (AI) and Machine Learning (ML) technologies is poised to significantly transform the Half Couplings Market, particularly in areas concerning design optimization, manufacturing processes, and predictive maintenance. Users frequently inquire about how AI can enhance the durability and performance of these critical components, streamline production, and mitigate risks associated with their failure. Common themes revolve around AI's potential to improve material selection, predict wear and tear, automate quality inspection, and optimize supply chain logistics, thereby addressing concerns about product reliability, cost-efficiency, and faster market response.

- AI-driven generative design can optimize coupling geometries for superior strength-to-weight ratios and enhanced flow dynamics, reducing material usage and improving performance.

- Predictive analytics, powered by AI, can forecast material fatigue and potential failure points based on operational data, enabling proactive maintenance and extending product lifespan.

- AI-enabled quality control systems can conduct real-time, non-destructive inspections during manufacturing, identifying microscopic defects with greater accuracy than human inspection.

- Machine learning algorithms can optimize manufacturing parameters, such as welding temperatures and pressures, to achieve consistently high-quality half couplings, reducing waste and rework.

- AI in supply chain management can predict demand fluctuations, optimize inventory levels for raw materials and finished products, and enhance logistics, leading to reduced lead times and improved market responsiveness.

- Smart sensors integrated with half couplings can feed operational data into AI systems, allowing for continuous performance monitoring and early detection of anomalies, preventing catastrophic failures.

- AI can facilitate advanced simulation and digital twinning, enabling virtual testing of half couplings under various extreme conditions, accelerating product development and validation cycles.

DRO & Impact Forces Of Half Couplings Market

The Half Couplings Market is shaped by a complex interplay of drivers, restraints, opportunities, and various impact forces that influence its trajectory. Key drivers include the robust expansion of industrial sectors, particularly oil and gas, chemical, and power generation, which rely heavily on secure and leak-proof connections for fluid and gas transportation. The increasing stringency of safety regulations and quality standards across these industries further mandates the use of high-integrity components like half couplings, bolstering demand. Moreover, significant infrastructure development and modernization efforts in emerging economies contribute substantially to market growth, as new facilities and upgrades require a constant supply of these essential fittings.

However, the market also faces notable restraints. Fluctuations in raw material prices, particularly for metals like stainless steel and carbon steel, can impact manufacturing costs and product pricing, leading to market volatility. The intense competition from low-cost manufacturers, especially in Asian markets, puts pressure on profit margins for established players. Additionally, the relatively long product lifecycle of half couplings, coupled with the slow pace of technological innovation in this mature product category, can limit demand for new installations, with replacement cycles being the primary driver for a significant portion of the market.

Opportunities within the market largely stem from the development and adoption of advanced materials, such as specialized alloys designed for extreme temperatures, corrosive environments, or high-purity applications, opening new avenues in niche sectors. The growing emphasis on automation and smart infrastructure also presents opportunities for integrating sensors and advanced monitoring capabilities into coupling systems, enhancing their value proposition. Furthermore, the expansion of renewable energy infrastructure, including hydrogen transportation and carbon capture technologies, could create new demand streams for specialized half couplings capable of handling unique fluid properties. The overall impact forces include economic growth influencing industrial output, geopolitical stability affecting energy projects, and technological advancements dictating material science and manufacturing precision.

Segmentation Analysis

The Half Couplings Market is comprehensively segmented to provide a detailed understanding of its various facets, enabling targeted strategies for stakeholders. These segmentations typically categorize the market based on intrinsic product characteristics, the materials used in their manufacture, their specific applications across different industries, and the pressure ratings they are designed to accommodate. Such a granular breakdown allows for an in-depth analysis of market dynamics, identification of high-growth areas, and assessment of competitive landscapes within each sub-segment. Understanding these distinctions is crucial for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for end-users to select the most appropriate solutions for their operational needs.

- By Type

- Forged Half Couplings

- Cast Half Couplings

- Fabricated Half Couplings

- Threaded Half Couplings

- Socket Weld Half Couplings

- By Material

- Stainless Steel Half Couplings (304/304L, 316/316L, Duplex, Super Duplex)

- Carbon Steel Half Couplings (A105, A350 LF2)

- Alloy Steel Half Couplings (e.g., F11, F22)

- Non-Ferrous Alloy Half Couplings (e.g., Brass, Bronze, Nickel Alloys)

- By End-User Industry

- Oil & Gas (Upstream, Midstream, Downstream)

- Chemical & Petrochemical

- Power Generation (Thermal, Nuclear, Renewable)

- Water & Wastewater Treatment

- Marine

- HVAC

- Food & Beverage

- Pulp & Paper

- Pharmaceuticals

- By Pressure Rating

- Low Pressure

- Medium Pressure

- High Pressure

- Ultra-High Pressure

- By Standard

- ANSI/ASME

- DIN

- JIS

- BS

- Other International Standards

Value Chain Analysis For Half Couplings Market

The value chain for the Half Couplings Market is a multi-stage process encompassing raw material sourcing, manufacturing, distribution, and end-user application. Upstream analysis focuses on the procurement of primary metals such as stainless steel, carbon steel, and various alloys from steel mills and specialized foundries. The quality and cost of these raw materials significantly influence the final product characteristics and market competitiveness. Relationships with key material suppliers are crucial, as consistent quality and reliable supply chains are essential for uninterrupted production and meeting specific industry standards. Innovations in metallurgy and material science at this stage can offer significant competitive advantages in terms of product performance and durability.

The manufacturing stage involves processes such as forging, casting, machining, welding, and threading, followed by rigorous quality control and testing. Companies invest in advanced manufacturing technologies, including CNC machining and robotic welding, to achieve precision and efficiency. Downstream analysis then focuses on how these finished half couplings reach the end-users. The distribution channel is typically a mix of direct sales to large industrial clients and indirect sales through a network of distributors, wholesalers, and retailers. Direct sales are often preferred for highly specialized or customized orders, allowing manufacturers to maintain direct relationships and provide tailored support to critical customers in sectors like oil and gas.

Indirect distribution leverages regional and international networks to reach a broader customer base, including smaller enterprises and diverse industrial applications. These distributors play a vital role in inventory management, localized support, and providing immediate availability of standard products. The effectiveness of the distribution network is crucial for market penetration and timely delivery, directly impacting customer satisfaction and market share. Both direct and indirect channels require robust logistics and inventory management systems to ensure product availability and reduce lead times, catering to the urgent needs of industrial operations globally.

Half Couplings Market Potential Customers

The Half Couplings Market serves a broad spectrum of industrial end-users, where secure and robust fluid or gas connections are critical for operational safety and efficiency. The primary potential customers are industries involved in the extraction, processing, and transportation of fluids and gases, along with sectors requiring strong mechanical connections in high-stress environments. These end-users, or buyers, range from large multinational corporations managing complex oil refineries and power plants to smaller manufacturing facilities and municipal water treatment plants, each with specific requirements for material, pressure rating, and application standard. The diversity of applications necessitates a comprehensive understanding of each customer segment's unique needs and procurement processes.

Within the oil and gas sector, potential customers include exploration and production companies, pipeline operators, refinery owners, and petrochemical manufacturers. These entities require half couplings for drilling rigs, wellheads, pipelines, processing units, and storage tanks, demanding components that can withstand extreme pressures, corrosive media, and fluctuating temperatures. Similarly, in the chemical and pharmaceutical industries, buyers are typically process plant operators seeking chemically inert and high-purity half couplings for reactors, heat exchangers, and piping systems, where contamination prevention and material compatibility are paramount.

Beyond these heavy industries, other significant end-users include power generation companies (both conventional and renewable), water and wastewater treatment authorities, shipbuilding and marine engineering firms, and manufacturers of heavy machinery and HVAC systems. Each of these segments presents distinct purchasing criteria, driven by factors such as regulatory compliance, operational lifespan, ease of installation, and total cost of ownership. Understanding the specific technical requirements, procurement cycles, and decision-making structures within each of these diverse customer groups is essential for market penetration and sustained business growth.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.5 Billion |

| Market Forecast in 2033 | USD 4.0 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Parker Hannifin, Eaton Corporation, Hydac International, Stauff Corporation, Voss Fluid, Swagelok, Brennan Industries, Manuli Hydraulics, Gates Corporation, Danfoss, ITT Inc., Emerson Electric Co., Alfa Laval, Flowserve Corporation, Valvitalia, Hitachi Metals, Voestalpine, Bonney Forge, Forged Components Inc., M. B. Control & Systems |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Half Couplings Market Key Technology Landscape

The Half Couplings Market, while rooted in traditional manufacturing, is increasingly influenced by advanced technologies aimed at enhancing product performance, manufacturing efficiency, and overall system reliability. Material science plays a pivotal role, with ongoing research and development in new alloys such as super duplex stainless steels, nickel-based alloys, and specialized polymer composites. These advanced materials offer superior resistance to corrosion, extreme temperatures, and high pressures, enabling half couplings to perform reliably in increasingly harsh operating environments characteristic of modern industrial applications. The adoption of these materials extends the service life of components and reduces maintenance requirements, driving long-term cost savings for end-users.

Manufacturing technologies have also seen significant advancements. Precision machining techniques, including computer numerical control (CNC) machining and additive manufacturing (3D printing) for specialized or complex geometries, ensure high dimensional accuracy and surface finish, critical for leak-proof connections. Robotic welding and automated inspection systems are employed to improve consistency and quality during production, minimizing human error and accelerating output. These automated processes contribute to higher production volumes and consistent product quality, which are paramount in sectors where component failure can have catastrophic consequences, such as oil and gas or nuclear power.

Furthermore, the integration of digital technologies, such as advanced simulation software and digital twin concepts, is transforming the design and testing phases. These tools allow engineers to virtually model and test half couplings under various stress conditions, optimizing designs for specific applications and predicting performance long before physical prototypes are created. Non-destructive testing (NDT) methods, including ultrasonic testing, radiographic inspection, and magnetic particle inspection, are extensively used to ensure product integrity and compliance with rigorous industry standards. The ongoing development in these areas not only enhances the intrinsic quality of half couplings but also facilitates faster innovation cycles and greater customization capabilities, catering to the evolving demands of a diverse industrial landscape.

Regional Highlights

- North America: A mature market characterized by stringent safety regulations and a strong focus on high-performance materials. Significant demand originates from the revitalized oil and gas sector (shale gas and oil), chemical processing, and infrastructure modernization projects. The United States and Canada are key contributors, emphasizing durability and compliance.

- Europe: Driven by strict environmental regulations and an emphasis on industrial automation and efficiency. Western European countries like Germany, the UK, and France show stable demand from chemical, pharmaceutical, and power generation industries, including investments in renewable energy infrastructure. Focus on specialized alloys for advanced applications.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, extensive infrastructure development, and significant investments in manufacturing, oil and gas, and power generation, particularly in China, India, and Southeast Asian nations. This region represents immense potential due to large-scale projects and expanding industrial bases.

- Latin America: Experiencing growth from ongoing investments in its vast oil and gas reserves, mining operations, and developing industrial infrastructure. Countries like Brazil and Mexico are pivotal, with demand influenced by resource extraction and processing industries.

- Middle East and Africa (MEA): A high-growth region primarily driven by massive investments in the oil and gas industry, including upstream exploration, midstream transportation, and downstream refining and petrochemical projects. Saudi Arabia, UAE, and Qatar are central to this growth, alongside emerging industrialization in Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Half Couplings Market.- Parker Hannifin

- Eaton Corporation

- Hydac International

- Stauff Corporation

- Voss Fluid

- Swagelok

- Brennan Industries

- Manuli Hydraulics

- Gates Corporation

- Danfoss

- ITT Inc.

- Emerson Electric Co.

- Alfa Laval

- Flowserve Corporation

- Valvitalia

- Hitachi Metals

- Voestalpine

- Bonney Forge

- Forged Components Inc.

- M. B. Control & Systems

Frequently Asked Questions

What are the primary applications of half couplings?

Half couplings are predominantly used in industrial settings for securely connecting pipes, hoses, or shafts to vessels, tanks, or other piping systems. Key applications span across the oil and gas, chemical and petrochemical, power generation, water and wastewater treatment, and marine industries for fluid and gas transfer, instrumentation, and system access points.

What materials are commonly used for manufacturing half couplings?

Common materials include various grades of stainless steel (e.g., 304, 316, duplex), carbon steel (e.g., A105, A350 LF2), and alloy steel (e.g., F11, F22). Specialized applications may require non-ferrous alloys like brass, bronze, or nickel-based alloys for enhanced corrosion resistance or performance in extreme environments.

How do half couplings contribute to industrial safety and efficiency?

Half couplings ensure secure, leak-proof connections, which are critical for preventing hazardous leaks and maintaining system integrity, thereby enhancing safety. Their robust design and precise manufacturing contribute to operational reliability, reducing downtime, simplifying maintenance, and improving overall system efficiency in demanding industrial processes.

Which regions are driving the growth of the Half Couplings Market?

The Asia Pacific region, particularly countries like China and India, is a major growth driver due to rapid industrialization and infrastructure development. North America and Europe maintain stable demand through stringent regulations and industrial modernization, while the Middle East and Africa are witnessing significant growth from large-scale oil and gas projects.

What impact does AI have on the Half Couplings Market?

AI is increasingly impacting the market by optimizing coupling designs through generative AI, enabling predictive maintenance for extended component lifespan, and enhancing manufacturing quality control through AI-driven inspection. It also aids in optimizing supply chain logistics and facilitating advanced simulations for faster product development and validation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager